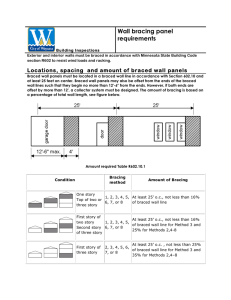

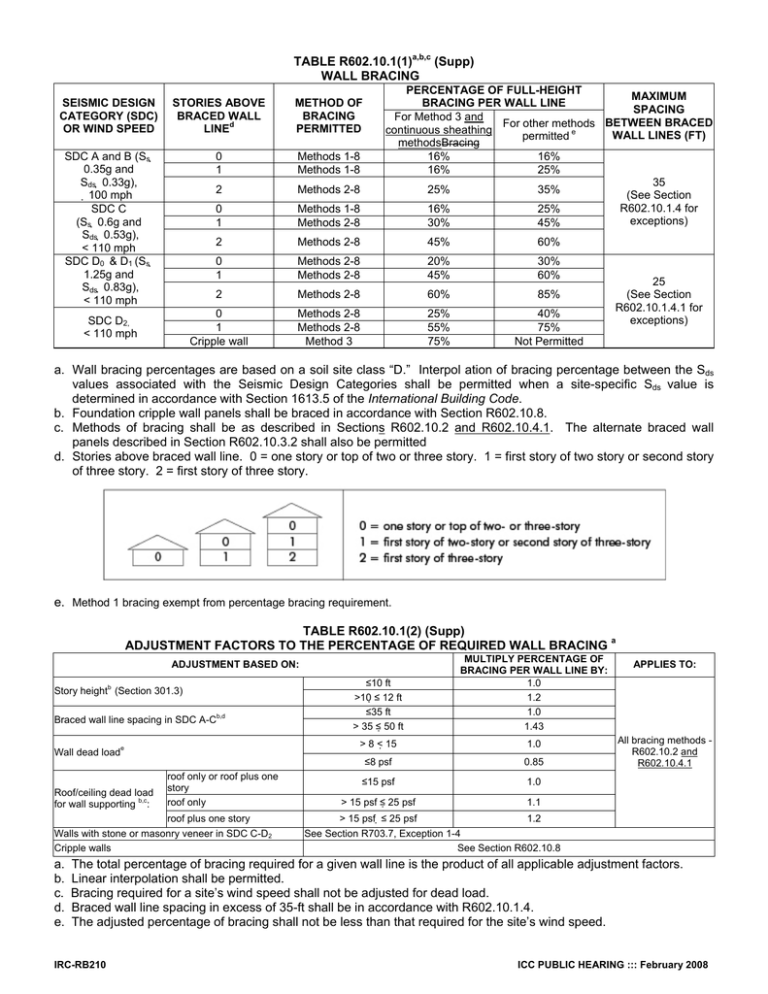

TABLE R602.10.1(1)

advertisement