Olivio Piccolo LED Technical Specifications

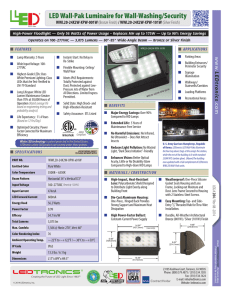

advertisement

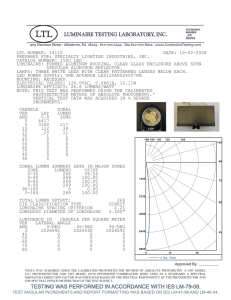

Olivio Piccolo LED DIVISION 26 00 00 SECTION 26 56 00 ELECTRICAL EXTERIOR LIGHTING Part 1 1.01 General Summary A. Section Includes: 1. Exterior LED Luminaire, LEDs, and drivers 1.02 References A. Tested to IESNA LM-79-08 and LM-80 Testing Standards at 25°C ambient temperature B. Union Made Affiliated with IBEW Local 363 C. NRTL Listed for Wet Location D. IP66 Rated E. IDA Compliant 1.03 Definitions A. CCT – Correlated Color Temperature B. CRI – Color Rendering Index C. UL – Underwriters Laboratory D. LED – Light Emitting Diode E. NRTL – Nationally Recognized Testing Laboratories F. RoHS – Restriction of Hazardous Substances Directive G. L70 – Reported Life of LED luminaire at 70% lumen maintenance H. IBEW – International Brotherhood of Electrical Workers I. PCI – Powder Coating Institute J. IESNA – Illuminating Engineering Society of North America K. LM-80 – IESNA approved method of measuring Lumen Depreciation of LED Light Sources L. LM-79-08 – Approved Method for the Electrical and Photometric Measurements of Solid-State Lighting Products or LEDs. M. PWM – Pulse Width Modulation N. hrs – Hours 1.04 Performance Requirements A. All lighting products as herein after specified shall be a standard product of the manufacturer, and shall consist of components that will be readily available for future replacement for a period of five (5) years. B. Provide all lighting fixtures as shown complete with all hardware necessary to install fixtures. C. All external fasteners shall be stainless steel. D. Fasteners shall be manufactured of non-magnetic stainless steel. E. Luminaire shall be free of light leaks. F. Luminaire and driver(s) suitable for use in ambient temperatures of -30ºC (-22ºF) to 35°C (95ºF). G. LED package shall be designed around the lumen maintenance of 82.69% at 60,000 hrs. reported, and L70 calculated to greater than 60,000 hrs. H. All wiring shall be adequate for LEDs, Driver and Voltage requirements. 1.05 Quality Assurance A. Manufacturer’s Qualifications: 1. Minimum 30 years’ experience in the manufacture of exterior luminaires. 2. Provide reference list of at least ten major transportation authorities, municipalities, universities, or other high-use public environments currently using site products fabricated by the manufacturer. Selux Corporation · 5 Lumen Lane · P.O. Box 1060 · Highland, NY 12528 · Tel.: (845) 834 1400 · Fax: (845) 834 1401 · Website: www.selux.us · Email: seluxus@selux.com Page 1 of 4 | Rev. 04 29 2015 Olivio Piccolo LED 3. 4. 5. Installer’s Qualifications: minimum 5 years’ experience assembling and installing luminaires. All fixtures and electrical components shall be new, of good quality, and be approved by and bear an NRTL Label (e.g. CSA, UL). All fixtures shall meet all required national codes and regulations 1.06 Delivery, Storage, and Handling A. Store products in manufacturer's unopened packaging until ready for installation. B. Store components off the ground in a dry covered area, protected from adverse weather conditions. 1.07 Warranty A. 5 Year Limited LED Luminaire Warranty - Selux offers a 5 Year Limited LED Warranty to the original purchaser that the Olivio LED assembly shall be free from defects in material and workmanship for up to five (5) years from date of shipment. This limited warranty covers the LED driver and LED light engine when installed and operated according to Selux instructions. For details and exclusions, see “Selux Terms and Condition of Sale.” Part 2 2.01 Products Manufacturer A. Manufacturer Contact: Selux Corporation 5 Lumen Lane, P.O. Box 1060 Highland, NY 12528 phone: (845) 834-1400 fax: (845) 834-1401 toll free: (800) 735-8927 email: seluxus@selux.com website: www.selux.us/en.html B. Substitutions: Not permitted. 2.02 Series: OLPL (Olivio Piccolo LED) A. Is a two-piece high pressure die-cast low-copper aluminum housing B. Single recessed captive screw creates easy access to the light engine and gear tray components. C. UV and Ozone Resistant Silicone gasket and screened tempered glass lens protects and seals the optical chamber providing the luminaire with an IP67. D. Luminaire will include an additional surge protection device to protect from indirect lighting strikes (up to 10kA). E. Luminaire is “Dark Sky Friendly” IDA-Approved with the 0° Mounting Option. 2.03 Optics A. Tempered clear glass lens 1. S09 (Spot, 11º) 2. F40 (Flood, 45º) 3. F80 (Flood, 74º) B. Reflectors made from high purity aluminum to ensure high efficiencies throughout lifetime. 2.04 Mounting A. Universal Mounting 1. Universal Surface Mounting (U) a) Wall Plate is mounted to surface structure over junction box (by others) B. Bollard 1. Cast aluminum 2. 3 foot nominal height 3. Pre-installed power cord at factory and fed hidden through the luminaire hinge and hinge arm Selux Corporation · 5 Lumen Lane · P.O. Box 1060 · Highland, NY 12528 · Tel.: (845) 834 1400 · Fax: (845) 834 1401 · Website: www.selux.us · Email: seluxus@selux.com Page 2 of 4 | Rev. 04 29 2015 Olivio Piccolo LED C. a) Specified to fit the length of the pole specified with the luminaire Sistema 2 Arm Mount 1. Cast aluminum mounting arms for flexible pole mounting. a. Fixture head join provides tilt-swivel range from 0º to 175º, and 360º rotation b. Locks down with set screws c. Two Rivnuts per fixture arm – installed by manufacturer 2. Mounting Options a. Single b. Double at 90º c. Double at 180º d. Quadruple Pole Arms stepped at 90º e. Sextuple Pole Arms stepped at 60º 2.04 Light Engine A. High Flux brand-name COB and vacuum metalized aluminum reflectors. B. For future upgrades, the LED light engine can be easily removed. C. Light Engines 1. L14 (14W) a. S09 – 1038 lumens (3000K); 1108 lumens (4000K) b. F40 – 1034 lumens (3000K); 1103 lumens (4000K) c. F80 – 1004 lumens (3000K); 1072 lumens (4000K) 2. L7 (7W) 2.05 CCT A. CCT packages shall be available in 3000K and 4000K. CCT tolerances are to be kept within a 3-step MacAdam ellipse and are to maintain a minimum CRI of 80. 1. 30 (3000K) 2. 40 (4000K) 2.06 Finish A. Exterior luminaire finishes shall utilize a high quality Polyester Powder Coating 1. WH (White) 2. BK (Black) 3. BZ (Bronze) 4. SV (Silver) 5. SP (Specify Premium Color) a. All luminaires are to be finished in a Tiger Drylac certified facility and undergo a 5 stage intensive pretreatment process where product is thoroughly cleaned, phosphate, and sealed. b. Powered coated products shall provide excellent salt and humidity resistances, as well as an ultraviolet resistance for color retention. c. All products shall be tested in accordance with test specification for coatings from ASTM and PCI. 2.07 Options A. DS (Dark Sky 0º Tilt Option) 1. Luminaire head tilt angle preset and fixed at the factory to comply with IDA Dark Sky and BUG U0 ratings. B. SLH (Spread Lens Horizontal) 1. Spread Lens for horizontal light distribution 2. Replaces clear lens and intended to be used with reflectors for S09, F40, or F80 distribution 3. Preset and fixed at the factory C. SLV (Spread Lens Vertical) Selux Corporation · 5 Lumen Lane · P.O. Box 1060 · Highland, NY 12528 · Tel.: (845) 834 1400 · Fax: (845) 834 1401 · Website: www.selux.us · Email: seluxus@selux.com Page 3 of 4 | Rev. 04 29 2015 Olivio Piccolo LED D. 1. Spread Lens for vertical light distribution 2. Replaces clear lens and intended to be used with reflectors for S09, F40, or F80 distribution 3. Preset and fixed at the factory PC (Photocell) 1. Consult factory END OF SECTION Selux Corporation · 5 Lumen Lane · P.O. Box 1060 · Highland, NY 12528 · Tel.: (845) 834 1400 · Fax: (845) 834 1401 · Website: www.selux.us · Email: seluxus@selux.com Page 4 of 4 | Rev. 04 29 2015