low-cost houses from `small-diameter trees, plantation

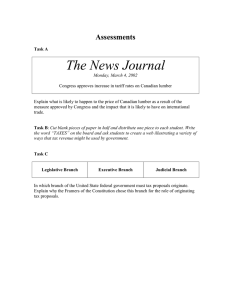

advertisement

LOW-COST HOUSES FROM

'SMALL-DIAMETER TREES,

PLANTATION THINNINGS, AND

TREE TOPS AND BRANCHES

Published by tIN

FOIEST PRODUCTS IESEAl.CH AND DEVELOPMENT INS1'ITU1E

DEPARTMENT OF SCIENCE AND TECHNOLOGY

~ft

nmaNAn01lAL TltOPlCAL TIMIU OItGAIIIZA-':::

LOW-COST HOUSES FROM

SMALL-DIAMETER TREES,

PLANTATION THINNINGS, AND

TREE TOPS AND BRANCHES

l'uhUshed hy the

FOREST PRODUCTS RESEARCH AND DEVELOPMENT INSTITUTE

DEPARTMENT OF SCIENCE AND TECHN OLOGY

College, Laglma 4031

Philippines

alld the

INTERNATIONAL TROPICAL TIMBER ORGANIZATION

International Organizations Center

5th Floor Pacifico-Yokohama, I-I,

Minato-Mirai, Nishi-Ku

Yokohama 220, Japan

THE FOREST PRODUCTS RESEARCH

AND DEVELOPMENT INSTITUTE

The Forest Products Research and Development

Institute (FPRDI) is the research and development arm

on forest products utilization of the Department of

Science and Technologv (DOST), the body that

coordinates and manages the Philippines' national

science and technologv system.

Its functions include: 1. the conduct of basic and

applied research and development on forest products

based on the needs of the wood-using arid related

industries and the general public; 2. the transfer of

completed Rand D results to end-users via linkages,

and 3. the provision of technical services and trainings

to various clientele.

THE INTERNATIONAL TROPICAL

TIMBER ORGANIZATION

The International Tropical Timber Organization (ITTO) is

a consortium of timber-producing and timber-using

countries worldwide. It encourages and supports the

efficient and improved management of tropical forests

and wood utilization including the utilization of lesserknown and plantation-grown timber species; sustainable

utilization and conservation of tropical forests and their

genetic resources, and maintenance of an ecological

balance in the areas concerned.

CONTENTS

Introduction

1

Technology Generation

3

I. Lumber Processing Technologies

5

• Sawmilling Systems for SDLs

(Saw-Dry-Rip Process)

• Lumber Dryer Heated by NonConventional Sources

• Treatability of Lumber from SDLs

• Stress-Grading Machine for Structural Lumber

• Housing Components from SDLs, Plantation

Thinnings and Tree Tops and Branches

5

S

10

12

14

11. Veneer and Plywood from SDLs, Thinnings

and Tree Tops and Branches

17

Ill. Woodwool Cement Boards from SDLs,

Thinnings and Tree Tops and Branches

19

IV. Design and Construction of Low-cost Houses

from SDLs, Thinnings and Tree Tops and Branches

21

INTRODUCTION

Providing adequate shelter to are rapidly vanishing. Most of

which ·, once

the millions of underprivileged these forests

and homeless continues to be a catered to foreign needs are

major goal of the Philippine now exploited for domestic

national

government today. consumption.

The

country's

burgeoning

population estimated to reach Cognizant of this scenario's

70 million by the year 2000 repercussion on the wood and

industries

puts pressure on this task. "' wood-based

Add

to

that the natural especially the housing and

industry,

the

calamities that cause untold construction

damage to lives and property, . Forest Products Research and

Institute

and the escalating prices of Development

non-wood

construction Department of Science and

materials like cement, hollow Technology (FPRDI-DOST) in

blocks,

steel

and

related College, Laguna, Philippines

products. Over the next five and the International Tropical

Organization

(lTTO)

years, at least 1.2 million Timber

housing

units

are

being based in Yokohama, Japan

targetted to be built as partial collaborated in the search for

alternative yet cheaper woodanswer to this need.

based · sources of building

Because of its properties, materials.

wood remains the most popular

material in the construction The

FPRDI

proposed

business.

It is suitable for project on "Low-cost Houses

structures like walls, external from Small Diameter Trees,

claddings, floors, joinery and Plantation Thinnings, Tree Tops

interior furnishings. Wood also and Branches", which

lends itself to modular and subsequently

approved

for

prefabrication systems, thus implementation

with

funds

hastening construction time. from the ITTO.

Traditional sources of wood for

construction are the premium Among

the

non-traditional

wood species or those with wood-based materials identified

diameters of

above 60 cm. as substitutes for conventional

But the country's forests, once wood

and

wood-based

a treasure trove of resources,

construction

materials

logging wastes, milling wastes

and plantation thinnings.

All

these

materials

can

be

converted

into

building

components

provided

appropriate technologies are

developed to process these

resources into cheap but of

acceptable quality products.

Despite the impending log ban

in the country, some forms of

logging still continue.

The

operations generate wastes and

residues in the form of tops and

branches,

culled

and

abandoned ~ogs, stumps and

damaged res.iduals. The FPRDI

found that for every ' cubic

meter of log extracted from the

forest, about 0.8 cubic meter

of logging

wastes is left

behind.

other

hand;

the

the

processing efficiency of local

sawmill

and

veneer

and

plywood plants is estimated to

be 50%. This means that for

every cubic meter of log

into

lumber

or

processed

veneer and plywood, one half

becomes mill waste in the form

of slabs, sawdust, trimmings,

edgings, rounding-up waste and

As of 1992, the country's

residual or sec'ondary forests

stand at about 3.13 million

hectares. An ongoing program

on Timber Stand Improvement

(TSI) by the Department of

Environment and

Natural

Resources

(DENR)

involves

thinning of second growth

forests to remove defective

trees, reduce the number of

secondary species and free the

primary

species

from

competition to ensure better

growth

conditions

for

the

selected trees that will form

the final crop. This operation

can yield at least 300,000 to

400,000 m 3 of raw materials

per year with diameters ranging

from 10 to 40 cm.

The DENR is actively pursuing

the development of plantations

both thru the private sector in

terms

of

industrial

tree

plantation (ITP) scheme and its

own reforestation program. As

of 1992, the Philippines has

about 0.48 million hectares of

ITPs.

A number of these

plantations are more than 30

years old and promising as

potential

sources

of

raw

materials

for

the

housing .

industry.

Plantations are subjected to

thinning operations similar to

the thinning of residual stands.

Thinning is a periodic activity

during the rotation of the

plantation.

The

materials

removed during the thinning

oper"ation yield raw materials.

Plantation-grown timbers and

thinnings

share

the same

characteristics of being small in

diameter, of lower specific

gravity, younger and therefore

a higher proportion of juvenile

wood.

TECHNOLOGIES GENERATED

The 12 studies comprising the

FPRDI-ITTO project on cheap

housing from non-traditional

wood materials were grouped

into four categories: 1. raw

material

preparation;

2.

of

housing

development

components, house designs

and construction; 3. socioeconomics of producing raw

materials from non-traditional

sources including construction,

and

4.

promotion

and

dissemination of the developed

technologies.

The project

generated

a

package

of

environment

friendly

technologies to extract the

potential of the small-diameter

logs, plantation thinnings and

tree tops and branches (see

schematic diagram).

Logs from small-diameter trees

and thinnings are processed

into lumber which are dried and

treated with preservatives to

prolong service life.

Lumber

intended as structural members

for trusses, columns and beams

are subjected to stress grading.

Low-stress grade non-structural

members

include

panelling

materials, doors, jalousies, door

and

window

jambs

and

battens.

Veneer and

plywood

wood wool cement boards can

also be harnessed from SOLs,

thinnings

and

tops

and

branches.

These

panel

products are ideal as partition;

ceiling and kitchen cabinet

materials.

The collaboration between the

FPRDI and the ITTO resulted in

the design and development of

a low-cost house which even

an ordinary wage earner can

afford.

It is hoped that the

majority of the Filipinos will

benefit from this undertaking.

~

SCHEMATIC DIAGRAM OF THE PROJECT

'LOV-COST HOUSES FROM SMALL DIAMETER TREE~ PLANTATION

THINNING~ TREE TOPS & BRANCHES'

I

VD£ER PRDllUCTlIl'l

--_._,

I

GUJING &.

CtlNSTRUCTIDN Of"

RA.. MAT£RIA!..CSIV

LD'w'-COST HIlDEL

HOLIS£S

1. ITPS

2. PlNITATlIIN

TH!h!rum

3. l1JPS AND

BRANCI£S

CHIP PRODUCTlIIN

BOI\RD PRIlDUCTIDN

- ~ StftJlllING

-MIXINti.IIAT F1lRKING.

CILlJ PRESSING

AND F1.AIC!NG

- SrwaHG. DRYING

RA 'vi

MATERIAL

AND CUWING

-ct.R!Ni AND CONDITIONING

- TJUIIoIINGS

PROCESSES

NOTE, ECIlNCKlC CDHPIlNENTS CUTS ACROSS THE. VHCL£ PROJECT.

- EXTERIllR \{AU.

PART~

I

I

PRODUCTS

LO'vl-COST HOUSES

5

I. Lumber Processing Technologies

Sawmilling Systems for SOLs (Saw-Ory-Rip Process)

Technology Description

The technology provides an economical and efficient method in

converting small-diameter logs into lumber.

This involves

appropriate machinery and log breakdown pattern to optimize

lumber recovery and at the same time minimize or prevent a major

problem associated with the conversion of small hardwood logs

into lumber - the tendency to warp excessively during the drying

process.

Technical and Economic Advantages

. Lumber yield. The average lumber recovery in big band mills is

about 60% for large-diameter logs. Lumber recovery for the small

band mills used in the st.udy for milling logs as small as 1 2 cm in

diameter averaged 57%, 60%, 64% and 56% for the table-type

bandmill, wood mizer (horizontal mobile bandmill), ARAKAWA and

PTPI band mill, respectively.

Efficiency. The adaptability of small band mills for milling small

logs leads to a more efficient and economical processing operation

compared with bandmills designed for large-diameter logs. This

may '· be attributed to less problems in handling the logs, lesser

power requirements and smaller saw k~re (blade is thinner, i.e.,

gauge 19 or 20). Depending on the species and size.s of logs,

small band mills can process up to 3 m 3 of logs per hour. ·

Labor and Materials.

Small bandmills require less steps in

operations than big band mills. Small band mills particularly the

wood mizer (mobile horizontal band mill) can be operated by at

least three persons.

6

Logs smaller than 30 cm in diameter are difficult to handle in big

band mills. In small bandmills, specifically the wood mizer, logs at

least 1 m long and 20 cm in diameter can be efficiently processed

into lumber.

Lumber Quality. With the application of the SDR process, warp

The

development in lumber may be minimized or prevented.

traditional practice of sawing the lumber to required dimensions

prior to the drying operation results in excessive warping

particularly in speci~s with high growth stresses (e.g., fastgrowing trees).

Based on the study on bagras (Eucalyptus

deglupta) , warped lumber was reduced to nil in the SDR versus

28% in the traditional sawing system.

Sawmilling System. -Any of the four types of mills studied offers

an efficient and profitable method of processing small logs into

lumber in the countryside. Depending on the log supply, these are

suitable for small to medium-scale saw milling operations.

However, in terms of processing cost per board foot, the wood

mizer (mobile horizontal band mill) is the most economical system.

It is also adaptable to a wide range of conditions. Sawmilling is

possible in any accessible site near or within the forest.

Processing cost per board foot may be as low as P 0.42

depending on the lumber production per hour.

Financial Feasibilities

[For mobile horizontal sawmill operation (wood-mizer)]

Initial Investment Cost

I.

Fixed Investment

• Land

• Buildings

• Auxilliary and service

facilities

• Plant machinery and

equipment

Total Fixed Investment

Amount (P)

180,000

750,000

1,035,000

2,200,000

P 4.165.000

7

11.

Pre-operating Capital

Ill.

Working Capital Requirement

44,000

TOTAL INITIAL INVESTMENT

1,281,185

P 5.490,185

Financial Indicators

Net Present Value

Internal Rate of Return

Return on Investment

Payback Period

=

=

=

=

P 889,184

22.84%

25.96%

4 years

8

.Lumber Dryer Heated by Non-conventional Sources

Technology Description

This is a 2.35-m 3 (1,000 bd ft)-capacity solar lumber dryer with a

back-up heater. It can accomm,odate a load m~asuring 10 x 4 x 5

ft on 3/4~inch stickers. The roof, two sides and the rear end are

covered with plastic sheets (double-wall mylar) for trapping the

UV rays of the sun. Two propeller-type fans (61 cm diameter),

run by 1 hp electric motor, provide air circulation. The back-up

heater, made of empty drums welded "end to end and attached to

a wood waste-fired furnace, provides energy at nighttime. To

increase humidification, a spray line is installed above the empty

drums to produce mist. A butterfly damper attached to the base

of the chimney controls the combustion rate. The dry bulb and

the wet bulb thermometers control the drying conditions based on

a predetermined drying schedule. The kiln operator controls the

feed rate of fuel and the drying condition based on the set point of

the drying condition.

The south side is made of marine plywood (double-walled) where

the main door and the four vents are installed. The vents likewise

control the drying condition inside the kiln.

Technical and Economic Advantages

Heat source. Source of heat during daytime is the sun. This

saves at least 30 to 35 % of the cost for generating heat energy.

In kiln drying, 60% of the total production cost goes to energy

generation.

Additional heat source.

A back-up heater can be used at

nighttime. The back-up heater is a furnace fueled by biomass or

agricultural wastes. The design is simplified and the materials

used for construction are locally available.

The quantity of

materials that can be dried in the solar dryer is comparable with

that in the conventional type lumber dryer although drying time

takes 2 to 3 days longer.

9

Availa bility of Materi als. The kiln design is suited to rural

areas,

and the kiln compo nents are locally available excep t

for the

glazing mater ials which are of plastic film.

Drying condit ions. The required workin g tempe rature of 150°F

is

attaina ble in the system . Based on the workin g tempe rature

, an 8

to 1.0% MC is attaina ble in a period of 10 - 14 days for

25-mm thick lumbe r mater ials which are accep table in the expor t marke

t.

Note: Althou gh the results of initial .tests are promis

ing, the

lumbe r dryer needs furthe r testing for verific ation purposes.

10

Treatability of Lumber from SDLs

Technology Description

By following established preservative treatment schedules, wood

considered to be inferior, perishable or of low durability can be

protected against attacks of wood-destroying organisms. Building

components like trusses, outer walls, framings and other portions

of the house must be properly treated to prolong their service life.

Preservative treatment of wood is done by applying either

pressure or non-pressure methods.

Pressure-treated wood,

however, is not easily available. Moreover, pressure treatment is

not always economical, desirable or feasible.

Thus, non-pressure treatment becomes an alternative. Two of the

commonly used non-pressure treatments are soaking for air-dried

In

and kiln-dried lumber and dip-diffusion for green wood.

soaking, wood is submerged in a tank of water-borne or oil-borne

preservative and allowed to soak for several days or even weeks.

Dip-diffusion, on the other hand, is done by momentarily dipping

the green wood in highly concentrated solution, and allowing the

preservatives to diffuse for several days or weeks in tightly sealed

polyethylene bags.

Technical and Economic Advantages

Soaking Method. The optimum treatment schedule established for

small-diameter logs is 5-day soaking in 6% or 8% concentration of

borax-boric acid or chromated-copper-arsenate (CCA).

This

schedule yields retention and penetration values required in wood

for indoor use and for exposure to weather.

Preservative absorption is most rapid in the first 2 or 3 days but

continues indefinitely at a decreasing rate.

This method does not require preDip-diffusion Method.

conditioning of sawn timber. It can be applied to every timber

11

considered difficult to treat can be penetrated by preservative.

The best treatment combination for this method is 30%

concentration of borax-boric acid and 1 5-day diffusion period.

Other Advantages. Non-pressure preservative treatment, either

the soaking or dip-diffusion method, can be done even outside

the wood treatment plant. It is also more practical in rural areas

and in housing construction where it is applied on some housing

components and mill work, in the control of sapstain in freshly cut

lumber and remedial treatment of partially decayed utility poles.

Although the degree of protection using non-pressure method is

less compqred with pressure treatment, it can be improved by

observing proper treating schedules .

..

12

Stress-grading Machine for Structural Lumber

Technology Description

Stress-grading of lumber is the sorting of sawn lumber into

specified stress grades to ensure quality control and confident use

of graded timber for structural purposes.

The FPRDI-developed stress grading machine employs a timber

frame to which are attached a cable, pulleys and a lever for easy

loading and unloading of a specified weight for flexing the timber

to be graded. A dial gauge with a sensitivity of 1/10 mm (1/1000

inch). placed underneath the center span of the timber measures

deflection upon loading.

The stress grading machine is so simple that it can be fabricated

locally. It can predict the basic stresses of wood with acceptable

precision by using the deflection criteria established for each

grade (Tables 1 and 2).

Technical and Economic Advantages

Accuracy. It can stress-grade lumber with reasonable degree of

accuracy regardless of specific gravity, moisture content and

presence of defects which can affect strength.

Lumber Quality. The lumber quality is assured because the design

stresses can be predicted through stress grading ~

Marketing. Newly discovered lumber is easier to sell since stress

grading is done in terms of strength instead of specifying the

species, thus simplifying the design and specification procedures.

Cost of Stress Grading Machine

P 10,000

Table 1. Maximu m deflecti on limits (mm) for gra~ing timber

.at EMC or 16.±. 2% MC

SECTION

TxW

(mm)

45

45

45

45

45

x 45

X. 70

x 95

x 120

x 145

SPAN

m

APPLIED

WEIGHT

(kg)

1-F36

2-F29

3-F23

4-F18

5-F15

6-F12

F9

F7

1.354

1.569

1.737

1.878

2

96.3

96.3

96.3

96.3

96.3

7.4

7.4

7.4

7.4

7.4

8.9

8.9

B.9

8.9

8.9

10.7

10.7

10.7

10.7

10.7

13

13

13

13

13

15.6

15.6

15.6

15.6

15.6

18.9

18.9

18.9

18.9

18.9

22.8

22.8

22.8

22.8

22.8

27 .4

27.4

27.4

27.4

27.4

STRENGTH GROUP OR STRESS GRADE DESIGNATION

Table 2. Basic stress for the differen t properties at EMC or 1 6 .±. 2

% MC

STRENGTH GROUP OR STRESS GRADE DESIGNATION

PROPERTY

1-F36

2-F29

3-F23

4-F18

5-F15

6-F12

MOR (MPa) ·

36.50

14.40

26.00

10.50

4.'00

695

0.484

· 29 .40

. 12.10

20.40

7.25

3.15 .

525

0.355

23.40

10.20

15.50

5.04

2.55

395

0 .269

18.80

8.50

12.40

3.50

2 .05

300

0.188

15.00

7.20

9.60

2.42

1.65

. 225

o 155

12.00

6. 10

7.50

1.'56

1.30

170

0.096

MO~(GPa)

MCS (MPa)

GP (MPa)

SH (MPa)

JS (NI

S slip ,(mm)

F9

9.60

5.10

5.80

1.17

1.05

170

0.096

F7

7.70

4.30

5.80

1..17

1.05

170

0.096

14

Housing Components from SDLs, Thinnings,

and Tree Tops and Branches

Technology Description

This technology involves the utilization of small-diameter trees,

plantation thinnings and tree tops and branches to augment the

supply of commercial timber for housing components such as

trusses, columns, beams, doors, windows, door and window

jambs. A set of working stresses for each strength group was

established and related to this, a systematic way of sorting the

timber was developed through the use of a simple stress grading

machine.

The use of stress-graded timber is very effective when designing

structural members like trussed rafters, columns and beams. The

FPRDI-developed truss system, for instance, shows a balanced

design of the structural members aimed at efficient timber

utilization. The trusses are engineered to use minimum section of

timber, just sufficient to withstand imposed dead load, live load

and wind forces prevailing in the three typhoon zones of the

Philippines.

Technical and Economic Advantages

Strength Grouping. Classifying a timber species to a particular

strength group based on its specific gravity is convenient for

design information purposes.

This facilitates marketing of

especially the non-commercial 1umber products since grouping is

done in terms of strength rather than specifying the species. Each

member species within a group can substitute for another so that

newly discovered timber, when grouped with the more common

species, can easily enter the market.

Grading System. This employs a simple stress grading machine

that is easily constructed yet can predict with acceptable

15

precIsion . the wood's basic design stresses using the deflection

criteria derived for each grade.

Investment. Minimal investment is needed since the processing of

raw materials into housing components requires no sophisticated

processes, rollers and other expensive equipment for assembly.

An ordinary hammer, hand or table saw and flat surface or

flatform jig will suffice. Greater return of investment can be

expected with the use of alternative materials from SDLs,

plantation thinnings, tops and branches.

Fabrication. The components can be fabricated either in the

construction site or in the factory for mass production. It is

economical when undertaking construction in remote areas or

where factory-made commponents using imported technoJogy are

either not available or the transport cost is prohibitive.

Installation. Since the components are prefabricated, construction

time is faster.

Financial Feasibility

(Based on 14 trusses, 1 set door/jamb, 2 sets window/jamb,15

beams and 1 5 columns fabricated)

Initial Investment Cost

I.

Fixed Investment

o Land

o Buildings

o Auxilliary and service

facilities

o Plant machinery and

equipment

Total Fixed Investment

11.

Pre-operating Capital

Ill.

Working Capital Requirement

TOTAL INITIAL INVESTMENT

Amount (Pl

240,000

750,000

1,020,000

1,492,550

P 3.502.550

29,851

1,652,253

-P 5,184,654

16

Financial Indicators

Net Present Value

Internal .Rate of Return

Return on Investment

Payback Period

=

=

=

=

P 1,261,134

25.51 %

18.41 %

3 years and

6 months

Finger-jointed and Nail Laminated

Columns and Beams from Plantation

Thinnings, Tree Tops and Branches

Technology Description

Wooden structures like columns and beams from small-diameter

trees, plantation thinnings and branches do. not meet the length

and cross-section r-equirements, hence they are finger-jointed and

glue-nail laminated 'respectively. The low-grade spedes is used in

portions not subjected to high stress, while the high strength

species is put in portions of greater stress.

In beams, for

instance, the low-grade species is placed at the center,

sandwiched by the higher-grade species. This eliminates strengthreducing defects such as knots, checks/splits and wane, thereby

upgrading otherwise poor quality materials.

.

Finger-jointed and glue-nail laminated structural members and solid

wood possess comparable strength.

17

11. VENEER AND PLYWOOD FROM

SDLs, THINNINGS AND TREE

TOPS AND BRANCHES

Technology Description

The technology is a very low-investment business addressed to

community forest-based enterprise. It involves the I use of nonconventional 60 cm rotary veneer lathe, a furnace-type veneer

dryer and a cold press system in the production of small-size

plywood from small-diameter logs. It further applies glue/glue mix

suitable for veneers with 1 8 % moisture content.

Economic and Technical Advantages

Veneer Yield. Green veneer recovery is found to be high (48% to

73%) compared with that of the traditional system of cutting

veneer (55 %). A 60-cm rotary veneer lathe is used to process the

SDLs into veneers.

Drvino. Energy consumption is reduced since the furnace-type

veneer dryer uses very low temperatures of 60 - 70°C versus the

more than 100°C temperature required in conventional dryer.

Moreover, the dryer is fueled by woodwastes. The system of

gluing accepts veneers with 1 8 % moisture content in contrast to

the 8 - 12% MC in conventional gluing, thus making for savings in

drying of veneers.

Of the various glue mixes

Gluing and Pressing System.

formulated for veneers, the one with 100 pbw urea-formaldehyde

powder, 75 pbw water, 20 pbw filler and 3.25 pbw catalyst is the

best for indoor plywood. It is applied using the cold press system

which, unlike the hot press system, does not need a boiler for

steam generation. Only 4 hours is needed for the glue mix to set

compared with the 8 hours for commercial glue.

The bond

18

strength passed the requirement in accordance with the PNS

standard.

Plywood Size. Smaller-sized plywood (2 ft x 2 ft, 2 ft x 4 ft) can

be produced which are deemed more versatile than commercial

plywood (4 ft x 8 ft) as partition, ceiling and kitchen cabinet

materials.

Financial Feasibilities

(Based on 396 and 198 pieces of 2 ft x 2 ft and 2 ft x 4 ft

plywood, respectively, per 8-hour operation)

Initial Investment Cost

I.

Amount (P)

Fixed Investment

o Land

o Buildings

o Auxilliary and service

facilities

o Plant machinery and

equipment

240,000

750,000

1,035,000

1,317,019

Total Fixed Investment

P 3,342,019

11.

Pre-operating Capital

Ill.

Working Capital Requirement

26,340

TOTAL INITIAL INVESTMENT

524,590

-P 3,892,949

Financial Indicators

Net Present Value

Internal Rate of Return

Return on Investment

Payback Period

=

=

=

=

P 955,582

24.77%

16.17%

3 years and 1 0 months

19

Ill. WOO DWO OL CEMENT BOARDS

FROM SDLs, THIN NING S AND

TREE TOPS AND BRANCHES

Technology Description

Wood wool cemen t board (WWCB) is a panel produ ct

made of

shredd ed wood, bonded with ordina ry portlan d cemen t, with

some

additiv es and cold-p ressed under low pressu re and

ambie nt

tempe rature . It is an energy -savin g materi al that is suitab

le for

the Philipp ines' climat e and socio- econo mic condit ions.

Like

plywo od, it finds applic ation as wall panels, kitche n cabine

ts and

ceiling s.

Model house s to demon strate the WWC B's versat ility and

variou s

applic ations were constr ucted at the Nation al Housing Autho

rity

Comp ound, the Forest Produ cts Research and Devel

opmen t

Institu te (FPRDI), the Depar tment of Scienc e and Techn

ology

(DOST) in Bicuta n, Taguig , Metro Manila and in Florida

blanca ,

Pampa nga Reset tlemen t Site for the Mt. Pinatubo

victim s.

Severa l housin g contra ctors are explor ing the possib ility of

puttin g

up big comm ercial plants to produc e this type of building

materi al.

Technical and Economic Advantages

Waste Utiliza tion. WWC B manuf acture is an enviro nment

-friend ly

proces s since agrofo rest waste s are the main ingred ients

of the

boards .

Manuf acturi ng is enhan ced by the availa bility of

indige nous raw materi als.

Worka bility. Light in weigh t by nature , WWC B is easy

to glue,

nail, paint and plaste r. Only simple equipm ent, the minim

um of

energy , and not too highly skilled manpo wer are neede

d in its

manuf acture .

20

Size. The board's dimension (2 ft x a ft x 3 /B -inch) makes it easy

to handle and transport, thus facilitating its use in modular or

prefabricated structures to hasten construction time.

Other Characteristics. WWCB can withstand the adverse effects

of earthquakes, typhoons and high humidity. It is water-, fire-,

termite-, vermin-, fungus- and rot-resistant. It also possesses

excellent insulation and acoustical properties.

Financial Feasibilities

(Based on 200 boards per a-hour operation)

Initial Investment Cost

I.

Amount (P)

Fixed Investment

o Land

o Buildings

o Auxilliary and service

facilities

o Plant machinery and

equipment

240,000

1,420,000

535,000

1,096,000

Total Fixed Investment

P 3.291.000

11.

Pre-operating Capital

Ill.

Working Capital Requirement

21,920

TOTAL INITIAL INVESTMENT

666,401

-P 3.979.321

Financial Indicators

Net Present Value

Internal Rate of Return

Return on Investment

Payback Period

=

=

=

=

P 2,842,861

34.55%

30.0%

4 years and

4 months

21

IV. DESIGN AND CON STR UCT ION OF LOW COS T HOUSES FROM SDLs, THIN NING S

AND TREE TOPS AND BRANCHES

Technology Description

The FPRDI-DOST-ITTO house is designed for and built from

nonconve ntiona l wood-based source s of building materials, i.e.,

smalldiame ter logs, planta tion thinnin gs and tree tops and branch

es.

These previo usly untapp ed materi als are processed into

sawn

timber , housing compo nents, and panel produ cts like plywo

od and

wood wool cemen t boards.

Design. It can be a one- or a two-be droom unit (see Figure

s 1 and

2). It is designed for simpli city, utility and durab ility to satisfy

the

basic requir ement s of a family of five. The open "all-in

-one"

space can be flexibl y used as a living room, dining room,

kitche n

and even as an extra bedroom. This space can also be conve

rted

into the family 's social functio n room which is not possib

le in

partiti oned quarte rs.

Install ation. Faster erectio n of the unit to save on labor

cost is

possible since some of the housing compo nents such as

doors,

windo ws, their jambs , exterio r and interio r wall framin gs

and the

truss system s are prefab ricated .

Truss Syste m. The FPRDI developed a truss system using

graded

timbe r mater ials to attain a balanced design of the struct

ure as

well as efficie nt utiliza tion of timber . The trusse s are engine

erea

to use minim um sectio n of timber just enough to withst

and the

impos ed dead load, live load and win forces prevailing

in the

install ation site. The conne ctors used for the truss joints

are

splice plates made of 13-mm thick, 5-ply pieces of plywo

od

fasten ed by flat-he ad 32 mm long nails with 3.5 mm

shank

diame ter.

/

22

A one-bedroom model house with a floor area of 26.5 m 2 was

erected within the DOST Bicutan Compound in Taguig, Metro

Manil a. The two-bedroom unit with a floor area of 32 m 2 can be

found at the Floridablanca Resettlement Site in Floridablanca,

Pampanga. A replica of the Floridablanca model house can be

seen at the University of the Philippines-College of Forestry (UPLBCF) Compound in · College, Laguna. These houses are equipped

with plumbing and electrical fixtures and a septic vault.

Construction Cost

{For a 2-bedroom house as of Sept. r993f

•

•

•

•

•

•

Concreting work

Masonry

Carpentry

Tinsmithry

Plumbing

Electrical

TOTAL DIRECT COST

(excluding labor)

P 4,080

5,708

49,723

7,700

2,345

2,149

P71,705

23

t -_ _ ___4.05 M

'~

@

BEbROOM.

~I

@

F

L

0

0

R

P

~I

SALA

@

L

A

N

SCALE'I:~

M

r;l

r~r

·l--:-:--. :- ----------I

1 ' ~-

I

o

~\

1 :

1 1

L _ ___ _

; i--~

-'

--,

I1 II g

_,

I fr--- - - -- 1 :

: I

1 :

11

"',,;

1

I

1

1

\ 1

I

I

J

I

L

N

II

1 1

I I

1

A

o

I

I

N

D

T

I

t

l

I1

1

11

1

t<i

I1I

!I i'

1.1

1 11

1 1

_---J~- -J l ___________ J i

~

o

II

1

on

on

uS

o

U

i l l

1

l'JL

F

I

1 1

11

1 1

1

ii

___-~ ___ _=_~_JU-

Fig. 1. One-bedroom house

0

,,;on

P

L

A

N

SCALE' I: 50M

24

5.35 M

2.70

1.25

®

I

-.

.

-

@l

~±l:.... ~U

_

-.-.

0

I-N

!~

~:

•

.

~

@

~

..

\!

o

.

. ..

0

.

...:

<t

- . .

w

o

CD

-

KIT.

BEDROOM

@~

(@

0:

....!!!..

~

0

I--

°1

.

0 '

CD

t)

DINING

@

0

o·

t<'I

LIVING ROOM

BEDROOM

t<'I

n

1.40

L

,,;

@

@

I

r;

ENTRY

FLOOR PLAN

se

Fig. 2.

ALE =

I : 50 M

Two-bedroom house

'10---.

I