Stainless Steel - BOC World of Welding

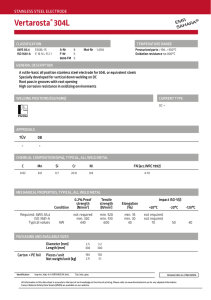

advertisement