Condensation Simulation

advertisement

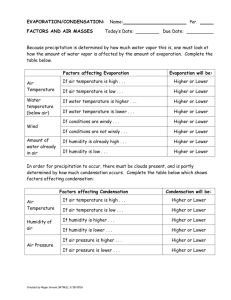

デンソーテクニカルレビュー Vol.10 No.2 2005 特集 Condensation Simulation for ECU Package* 青木孝司 岡本真一 伊 奈 治 杉浦昭夫 Takashi AOKI Shinichi OKAMOTO Osamu INA Akio SUGIURA 成田量一 Ryoichi NARITA Up to now, while automobile electric packages have demanded the high density for small and light products, electric leaks, which have occurred due to condensation, have been a major problem. To prevent any electric leaks, a conformal coating on the electric parts (ex. ECU : Electronic Control Unit ) has been needed, but in general the design rules of the conformal coating (ex. Application area) is vague. Therefore, DENSO demands to clarify the design rules of conformal coating electric package for higher reliability. To meet the demand, DENSO has developed a condensation simulation method using CAE that can show the occurrence condition of condensation fast and accurately. In the result, DENSO has been able to get the design rules where to need the conformal coating in the electric package for automobiles. Key words : Condensation simulation, Automobile electric package, Conformal coating, Electric leak 1.INTRODUCTION a drop of condensation forms between terminals, current In recent years, car electronic products are characterized leakage will result. If the drop grows, as shown in Fig. 2, by smaller gaps between terminal pins and high-density there will be a short-circuit. There are generally two packaging using CSP, as shown in Fig. 1. methods of preventing this, as depicted in Fig. 3. 1995 2000 2003 Condensed water Current leakage (specific residence: 1MΩcm) Terminal 2005 e [CSP] (Positive) [QFP] (Negative) Circuit board 0.4mm gap CSP Fig. 2 Leakage by condensation 0.8mm gap CSP [520P] 0.4mm gap QFP [256P] 1.0mm gap BGA 0.5mm gap QFP [208-256P] 0.65-0.8mm gap QFP [120-160P] <Moisture-proof coating> Moisture-proof material 1.2mm gap PLCC [68P] Condensation QFP: Quad Flat Package CSP: Chip Scale Package Fig. 1 Trend in electronic packaging Circuit board These trends lead to concerns that the increased strain on <Completely sealed structure> Condensation soldered points may result in shortened service life due to Casing thermal fatigue, and that moisture resistance may deteriorate, as is often observed in leakage due to Water vapor condensation. Conventional acrylic coating protection Circuit board against moisture only increases the thermal strain on soldered points; furthermore, the use of acrylic resin itself Fig. 3 Moisture-proof structure is being scrutinized under the stringency of environmental regulations. The objective of moisture-proof treatment is to (1) Moisture-proof coating (insulation) on the circuit board prevent current leakage and migration between terminals in (2) Complete sealing of the circuit board to prevent the the event of condensation on a printed circuit board. When ingress of moisture (without moisture-proof material) *Reprinted with permission from SAE paper 2004-01-1696 2004 SAE International −102− 特 集 Thus far, however, both methods have shortcomings. In Phase change Water vapor rises method (1), it is still unclear which portion of the board is Liquefaction and vaporization Latent heat transfer (due to difference in specific gravity with air) likely to experience condensation, and therefore, where the Water vapor coating must be applied. As for method (2), guaranteeing completeness of the seal may require higher manufacturing Air Temperature differential cost. To maintain product competitiveness, it is necessary Board wettability Condensed water Board surface to : ① Fig. 4 Condensation process model minimize amount of moisture-proof material by applying it only to necessary points, and minimize cost of casing by defining conditions for due to difference in the speed of the temperature rise, as preventing condensation (e.g. maximum gap allowed) shown in Fig. 6. When the dew point is within the range to guarantee insulation reliability equal to that of a between air temperature and board temperature, completely sealed structure even when the casing is not condensation occurs. When the temperature stabilizes after completely sealed. a certain time, the condensation disappears. Under the ② Given ① and ② above, it is essential to do the following to improve product competitiveness. transient condition in which the temperature falls, the circuit board temperature will be relatively higher than that 1) Quantitative analysis of condensation process of the air; therefore, condensation occurs on the inner walls 2) Establish structural design technique optimized to of the casing. Although condensation is a familiar practical environments in which products are used phenomenon, it can occur transiently within a minute space In the meantime, the solution cannot be found merely by with very little temperature difference. Considering evaluating actual products, due to the complexity of the limitations in the forms and accuracy of measuring condensation process and the difficulty of measurement in instruments, it is difficult to solve the problem by relying minute areas. With the aim of improving problem-solving (ºC) (%RH) 40 Temperature (T) was initiated by applying thermohydrodynamic analysis methods to quantitative analysis of the condensation process under transient temperature and humidity conditions in electronic products. 100 75 20 10 0 50 0 -10 25 -20 2.OBJECTIVES OF CONDENSATION 0 -30 SIMULATOR 2.1 P=1atm 30 40 90 40 90 0 0 390 900 (s) Time (t) Understanding condensation process 1200 Fig. 5 Condensation evaluation pattern Condensation occurs on a circuit board when, by convection or diffusion, warm air or moisture in the ambient air enters via an opening in the casing around a (ºC) 40 Dew point Temperature (T) circuit board and liquefies on the board surface, as shown in Fig. 4. The parameters involved in the process are temperature, relative humidity, and the latent heat transfer that takes place in phase change. In general, the condensation in car electronic products is Condensation range on the circuit board -30 evaluated by testing under different combinations of Air temperature within casing Board surface temperature temperature and humidity specified in Fig. 5. Under the Time (t) transient condition in which the temperature rises, a temperature differential arises between circuit board and air Fig. 6 Condensation range −103− (s) Relative humidity (RH) efficiency, the development of a condensation simulator デンソーテクニカルレビュー Vol.10 only on the evaluation of actual products. Therefore, our aim was to solve the problem rationally and effectively by Studying simulation method/ procedure combining parameters measured in theoretic product 2.2 1st step Verification (Conditions / Amount of condition) evaluation using CAE. No.2 2005 Defining elements of structural optimization Causes and effects of condensation Condensation is a phenomenon in which the water Calculating optimum structure vapors in moist air liquefy upon reaching the state of supersaturation. Condensation on a circuit board is Fig. 8 Research procedure governed by three factors, shown in Fig. 7: the product structure, atmosphere and mounting conditions. Thus, the humidity, and their transitions at respective positions. objective was to find the optimum structure efficiently by From this observation, the modeling involves, at least a standardizing each parameter. combination of structure and fluid (internal air). The ambient air may be included in the modeling, or represented by setting up a boundary that transfers heat at Atmosphere (Temperature / Humidity) Opening the outer surface of the casing. Judging from these, a multi- Air phase thermo hydrodynamic analysis is generally Condensed water considered the appropriate simulation method that covers all governing formula involved in the condensation process. Electronic device Circuit Board However, it is also extremely complex and, as shown in Mounting condition Table 1, is probably inapplicable in terms of calculation (Gravitational force) time and convergence. In addition, this method is of the structural mesh type and poses difficulty in modeling the Product structure Number of openings Thermal capacity Casing Opening structure Position Humidity subject faithfully. Self-heating Area Inner volume Condensation Single-phase thermohydrodynamics Multi-phase thermohydrodynamics + sub-program Position Profile Temperature Atmosphere Table 1 Comparison of simulation methods Direction Mounting condition Simulation model Fig. 7 Cause and effect diagram of condensation in car electronic products 2.3 Research procedure Figure 8 describes the research procedure adopted. This paper focuses on the first step from the study of simulation 3.STUDY OF SIMULATION Some limitations (Structural mesh) Convergence Yes No Calculation time Calculation precision Cost ratio Ease of use ca.10hours over 1000hours (Parallel operation) (Convergence program) Good NG 1 over 100 Evaluation procedure to defining elements of structural optimization. Greater freedom (Non-structural mesh) Good (Interactive) NG Good NG Therefore, it was decided to adopt a method in which METHOD/PROCEDURE moist air is regarded as a single-phase fluid whose three In electronic products to be simulated, condensation elements (dry air, water vapor, and condensed water) are occurs when the moisture in the internal air, or ambient air defined as scalars. The fraction of the masses of three that has entered the interior, liquefies on various elements elements is determined by a sub-program that calculates the of circuit boards depending on the ambient temperature and phase change from water vapor to condensed water by −104− 特 集 incrementing time; the results are integrated into an ordinary loop of flow field calculation. Dry air Relative humidity >100% Sub-program Creation Figure 9 shows the algorithm used in the calculation and Ingress by Water convection Passage Diffusion of time output of each process. This method creates the added task of developing a sub-program for simulating the process of Ingress by convection Water vapor Passage Diffusion of time phase change from water vapor (gas) to condensed water <Equation of condensation> (liquid). Calculations of enthalpy, radiation and form of condensed water wetting are excluded here. Single-phase Thermohydrodynamics simulation START Time increment Excluded All enthalpies Radiation Board wetting form Calculation of mixed gas physical property Applicable Equation of state fomula (Mixed gas) Outputs Density Thermal conductivity Specific heat Flow Calculation Navier-Stokes Applicable equation fomula Equation of continuity Equation of energy (Mixed gas) Outputs Flow Temperature Sub-program (Condensation simulation) Outputs Time increment Equation of mass transfer (Mixed gas) Fraction of each element Flow Circuit board w= -Relative humidity f = mvapor mair w P0 (0.622 + w)Ps -Water formation (Condensation) mH2O = -Disappearance of water vapor mvapor = m H2O (w- w ) P [kg sm ] t f =1 3 [kg sm 3 ] Fig. 10 Formulas for gas-liquid phase change simulation (condensation process simulation) PRECISION VERIFICATION Flow Water vapor -Absolute humidity 4.BASIC MODEL SIMULATION AND Dry air Pressure Mixed gas Ps = Ps (T) (T: temperature, t: time, P: density) Gas-liquid phase change simulation Applicable fomula -Saturation pressure of water vapor Circuit board 4.1 Conditions for simulation using the basic Condensed water model END Figure 11 shows the general concept of the test model. Fig. 9 Calculation algorithm Inputs are histories of temperature and relative humidity under the transient condition in which the temperature rises Next, Figure 10 shows the formulas used to simulate the (transient boundary conditions of ambient temperature and gas-liquid phase change for analyzing the condensation humidity), with transient analysis of 1,200 steps at 1 second process. Normally, condensation occurrence is represented intervals. In addition, these inputs are defined as the by the dew point, but here it is determined by defining the boundary conditions for the simulation model while water vapor saturation pressure (Ps) by an approximated temperature, relative humidity and pressure (1 atm, high degree function of temperature. Ps is defined by constant) are assigned for openings (end sections of internal formula (1). air) and temperature and thermal conductivity (33 w/m2k) are assigned for the boundaries with thermal transfer at the Ps=103(6E-7X 4+1E-5X 3+1.7E-3X 2+4.28E-2X+0.6119) respective outer walls of the casing and connectors. The fomula (1) transient behaviors of these parameters are defined by the X=T-273(T: Temperature (k)) sub-program. Here, the relative humidity of the atmosphere is defined by the fractions of the masses of three elements Using this method, it is possible to determine (dry air, water vapor and condensed water) of moist air. condensation occurrence by combining default outputs of the solver; this reduces the computational load and 4.2 Simulation results and precision verification enhances calculation efficiency. To verify the precision of simulation using the basic model, condensation occurrences were compared with measurements taken on actual products under transient −105− デンソーテクニカルレビュー Vol.10 < ECU (Basic model) > No.2 2005 determined by transient changes in electric current leakage Comb-shaped gage Casing as measured using a comb-shaped gauge (with 300 µm gap) that conforms to JIS Z 3197, placed on the surface of a circuit board in an open casing as shown in Fig. 12. The current leakage was measured by the method depicted in Circuit board the circuit diagram, while temperature and humidity of Section for simulation model atmosphere, internal air and circuit board were monitored using thermometers and relative humidity gauges. Boundaries at openings (Boundaries with pressure,temperature, humidity and mixed gas defined) Measurement points are also shown in the figure. Internal air - Determining condensation on actual products Circuit board Comb-shaped gage Constant temperature, humidity tank Condensation leakage (Comb-shaped gauge) Casing walls (Boundaries with thermal transfer defined) Temperature measurement (Temperature sensor on board / in air) - Conditions for simulation Item Conditions Inputs Histories of temperature and humidity (Fig. 5) Histories of temperature, humidity, and amount of condensation Transient analysis Outputs Calculation method Governing formulas • Equation of continuity • Navier-Stokes equation • Equation of energy • Equation of state • Equation of mass transfer Pre/Post FEMAP + PROSTAR Solver Circuit board Condensed water Relative humidity measurement (Humidity sensor) - Circuit diagram for condensational leakage measurement JIS-Z-3197 RG STAR/CD (v3100A) 4-node parallel operation) CPU 20V - Input boundary conditions Item Boundaries at openings Outer wall Comb-shaped gauge Conditions 100kV Standard pressure boundary (Pressure) Pressure : P=1atm (Constant) Temperature : T (Fig.5 equivalent) Relative humidity: RH (Fig. 5 equivalent) Mixed gas definition (Scalar) Water vapor Condensed water Dry air V Condensation leakage : Ia = Gage resistance Boundaries with thermal Temperature : T (Fig.5 equivalent) Thermal conductivity : 33 W/(m2.K) transfer (Wall) V/10000 : RG = KR (20/IL) Fig. 12 Determining condensation on actual products - Physical properties of mixed gas Properties Dry air Conditions Water vapor Condensed water Weight kg/kmol 28.9 18.0 18.0 Density kg/m3 1.21 0.88 998 Specific heat J/(kg.K) 1006 2090 4183 Viscosity Pas 1.85 E-5 1.05 E-5 1.00 E-3 0.026 0.0018 0.603 Thermal . conductivity W/(m K) Figure 13 shows an example of actual measurement and a simulation result. The two contors represent the temperature distribution at respective points and the distribution of condensed water fractions around the comb-shaped gauge after 1,000 seconds. It was observed on actual products that, as the ambient temperature and humidity rose, those of the internal air and components also rose, due to heat transfer from the outer walls of the casing and convection. After 750 Fig. 11 Conditions for simulation using basic model seconds, condensation commenced on the surface of the conditions in which the temperature and humidity change. comb-shaped gauge, due to the difference in response time First, condensation on actual products was observed and constants between circuit board and internal air, and peaked −106− 特 集 at around 900 seconds. Subsequently, the ambient 4.3 Application examples and verification temperature and humidity became constant, forcing As application examples, the effects of changing the area component and internal air temperatures to converge at the and direction of the opening were simulated. The focal points ambient temperature, reducing the amount of condensation. in these simulations were vent hole shape and direction. Two On the other hand, the simulation shows condensation standards were set for each factor: an open casing without a starting after about 700 seconds, peaking at around 900 lid and a waterproof casing with a 6mm diameter vent hole seconds, and diminishing thereafter. The results are for the former, and vent holes on top and bottom for the consistent with each other, with little discrepancy in starting latter. The models of these simulation examples and the vent time. Condensation occurrences and disappearances were holes (location of boundaries with atmosphere) are shown in thus successfully visualized and qualitative level precision Fig. 14. Note that boundary conditions were set following was achieved. the example of the basic model. Transient temperature distribution (1000s) 39.1ºC Simulation models 34.1ºC Distribution of condensed water around comb-shaped gauge (1000s) Top Output point Casing Circuit board Circuit board Bottom Opening casing Vent hole Vent hole - Actual measurement (µA) 3 (RH) 100 Temperature humidity 80 Relative humidity 60 2 40 20 Humidity setting 0 Leakage 1 current Board Temperature -20 Temperature setting -40 0 1200 700 900 0 Time Current leakage at gauge (ºC) Top Fig. 14 Simulation models Next, the condensation evaluation results are shown in gauge for actual measurement and maximum fractions of (s) condensed water for the simulation. Both measurement and (%) simulation show that the open casing has condensation 100 10 more than 104 times that of the waterproof casing. From this Relative humidity 60 40 Condensation amount Humidity setting 20 5 0 -20 -40 0 Board Temperature Temperature setting 700 900 Time 0 Fraction of condensed water (RH) 80 Temperature humidity Vent hole Table 2. Evaluated values were maximum leakage at the - Simulation result (ºC) Circuit board Circuit board Bottom Waterproof casing Vent hole 1200 (s) Fig. 13 Simulation results and precision verification it can be concluded that the area of openings is the major contributing factor to condensation. As for correlation between vent hole direction and condensation, more condensed water was observed with the bottom vent hole for both types of casing. This is because with the vent hole on top, water vapor in the moist air does not usually enter the casing due to its lightness compared to dry air and because the moisture in the internal air tends to liquefy on the ceiling. Therefore, it is more advantageous to have a −107− デンソーテクニカルレビュー Vol.10 vent hole on top and the circuit board at the bottom of the No.2 2005 Simulation models casing. Vent hole top under transient conditions in which the temperature rises. Figure 16 shows the contour outputs at the peak of condensation for each simulation standard. Given these Top examples, it can be said that quantitative analysis and here will apply effectively to the design of optimum moisture-proof structures and the development of moisture- 0.5% Top 0.003% 0.005% Circuit board Circuit board Bottom product development method and procedures established 34% Vent hole Waterproof casing been made possible. These examples also suggest that the 9% Vent hole visualization of the condensation/vaporization process, which is difficult to measure with actual products, have 1% Circuit board Circuit board Bottom (simulation output) for both the casing with a vent hole on Opening casing Figure 15 shows the fractions of condensed water 0.007% 0.001% Vent hole proof treatment with theoretical support. In the future, efforts will be made to propose appropriate moisture-proof Fig. 16 Contour outputs of condensed water fraction structures and conditions for coating, through planned 5.CORRELATION BETWEEN research into defining elements of structural optimization. CONDENSATION AMOUNT AND INSULATION RESITANCE Table 2 Condensation evaluation results As indicated in earlier sections, it has become generally Simulation outputs Gravitational (condensed force (leakage at gauge) water fraction) Actual measurement 2 ~ 200µA +1G Opening casing -1G +1G Waterproof casing possible to simulate the extent of condensation. This section reviews the correlation between amount of condensation 9% and insulation resistance. Condensation leakage current is 34% determined by the resistance of the condensed water that bridges two conductors on the circuit board, and the 0.005% ‹ 0.002µA difference in electrical potential between the two 0.007% -1G conductors. Condensation typically begins with a hemispheric drop of condensation 1 µm diameter or less at (%) the core, growing with expansion of the diameter and by Condensed water fraction 100 joining with adjacent droplets. The process is very complex Opening casting / top vent hole 10 and depends on the temperature, humidity, surface conditions of the board etc. Assuming that condensed water 1 is a film of constant thickness and that the specific 0.1 resistance of condensed water is ρΩ-cm, the correlation 0.01 between amount of condensed water and leakage current is Waterproof casting / bottom vent hole 0.001 expressed by formula (2) in Fig. 17. Figure 18 is a chart that depicts this correlation, based 0.0001 0 300 600 900 1200 Time on formula (2) (ρ=1 MΩ-cm), and the correspondence (s) between simulated condensation amount using the basic Fig. 15 History of condensed water fraction model and leakage measurements taken on actual products. Through comparison of these two relations, it can be said that the latter relation, based on measurement, tends to indicate smaller leakage. This is presumably due to various −108− 特 集 Condensed water [Factor1] Wetting form : Increased resistance V Condensed water Terminal IR Terminal t Circuit board Circuit board L t V ρ r IR W L [Factor2] Board temperature increased due to latent heat from condensation : Less difference in temperature : Length between terminals : thickness of condensed water : Voltage : Specific resistance of condensed water : Length of terminal : Leakage current : Condensation amount Heat radiation Assumption : condenses evenly on board surface IR = V / R = V tr Lρ =V [Factor3] Effects of specific resistance of condensed water W10-3 r Lρ Fig. 17 Formula for calculating leakage by condensation (µA) Condensed leakage IR ρ Large Large IR Small Fig. 19 Major factors affecting leakage by condensation 100 1 Small Theoretical line (ρ = 1MΩcm) tool has been developed, while achieving qualitative precision. The simulator makes it possible to understand V : 20V L : 0.318mm r : 160mm 0.01 and visualize the condensation process that takes place in a minute area, which is impossible to measure in actual Measured condensation leakage 0.0001 product evaluations. It will also be used in the future to solve problems in optimizing moisture-proof structures and 0.0001 0.01 1 100 Condensation amount W (µg / mm2) Fig. 18 Correlation between condensation and leakage developing new moisture-proof treatments for electronic products. REFERENCES 1) Nobuyuki Kato etc., The Society of Heating, Air- real-life factors, such as wetting forms of condensed water, Conditioning and Sanitary Engineering of Japan No.74 board temperature increase due to latent heat from (1999.7) condensation, and the specific resistance of condensed 2) You Matsuo, The Society of Heating, Air-Conditioning water as shown in Fig. 19. To improve the accuracy of simulation, it will be necessary to extract these factors, and Sanitary Engineering of Japan C39 (1999.10) 3) Nobuyuki Kato etc., The Society of Heating, AirConditioning and Sanitary Engineering of Japan No.72-1 quantify them and reflect them in the algorithm. (1998) 6.CONCLUSION 4) Hitoshi Takeda, The Society of Heating, Air-Conditioning and Sanitary Engineering of Japan C40 (1990.10) By combining the transient thermohydrodynamic calculation feature from a general purpose program written 5) Masanori Yadoya, Architectural Institute of Japan, (1987.10), p.921. for single-phase fluids and an optional feature of gas-liquid phase change simulation (condensation simulation), a condensation simulator that is easy-to-use as a development −109− デンソーテクニカルレビュー Vol.10 No.2 2005 666666666666666666666666666666666666 <著 者> 岡本 真一 青木 孝司 (おかもと しんいち) (あおき たかし) 材料技術部 材料技術部 絶縁・接着材料の研究・開発に 絶縁・接着材料の研究・開発に 従事 従事 伊奈 治 杉浦 昭夫 (すぎうら あきお) (いな おさむ) 材料技術部 材料技術部 CAE解析に従事 絶縁・接着材料の研究・開発に 従事 成田 量一 (なりた りょういち) 材料技術部 非金属材料の研究・開発に従事 −110−