ABchimie 526UV DS55 M/ ABchimie 526UV DS140 M UV

advertisement

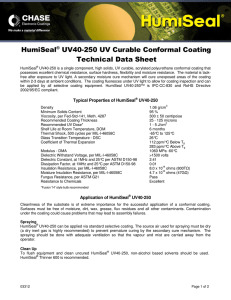

EF by ABchimie ABchimie 526UV DS55 M/ ABchimie 526UV DS140 M UV Dual Cure Conformal Coating FEATURES ABchimie 526UV M Conformal Coating is a transparent one-component coating for the protection of electronic PCBAs formulated to meet the highest resistance requirements. The dual cure technology (UV/moisture) allows cross-linking in shadowed areas. ABchimie 526UV M is suitable for selective coating machine which is the ideal way to apply. The low viscosity of our system permits to limit the thickness around 80 microns. PERFORMANCE & RELIABILITY COST ENVIRONMENT High accurate deposit Very fast curing for short process Excellent chemical and solvent resistance No cracking Excellent dielectric properties Complies with IPC-830CC UL94V0 and NF EN 61056 approved High speed process for increase of productivity Floor plan can be reduced compared to solvent base coatings Non-flammable Solvent Free No VOCs TYPICAL PROPERTIES Properties Liquid Nature Colour Non-volatile content % Flash Point Viscosity @ 25°C ABchimie 526UV M Conformal Coating Urethane/ Acrylate Slightly yellow liquid 100 > 100° C 55 – 140 cSt ABchimie526 UV DS55 M/ DS140 M Properties Cured ABchimie 526UV M Conformal Coating Colour Transparent Adhesion per ISO 2409 Class 0 – Excellent Electrical Resistivity 1 x 10 Ohms/ cm Insulation Resistance per MIL-I-46058C Temperature Range Touch Dry Time (min) Dielectric Strength Electric breakdown voltage per MIL-I-46058C Saline mist per NF EN 61086 (35°C, 5% salt, 2 ml/h) Flammability Rapid Temperature Variation test (-25° to 25° C, 100 cycles, 15 min plateau, 5°C/min) Thermal Shock (15 min @ -25°C to 15 min @ 50°C/ 50 cycles) SIR test (15 Hr/ 20° to 80°C / 90% RH) Moisture Resistance (10° to 80° C/ 95% RH/ 90 days) Removal of coating 14 12 1 x 10 ohms (NF EN 61086) -55° to 150°C NA 90 KV/ mm > 1750 V (NF EN 61086) Pass Self extinguishing, UL94V0 Pass Pass Pass Pass Mechanical by abrasive blasting CHARACTERISTICS Excellent adhesion under all climatic conditions. Fluorescent under UV light as an aid to inspection. Wide temperature range from -55°C to 150°C. Can be soldered through without fear of highly toxic gases being produced. Resistant to mould growth. Provides excellent Dielectric properties. Very fast curing under UV light and offers moisture curing for shadowed areas. Low viscosity for select coat machine. Used with SC200 head in Asymtek machinery. ABchimie526 UV DS55 M/ DS140 M Characteristics ABchimie 526UV M Conformal Coating Solder-through repairability Yes Solvent and chemical resistance Yes 6 months, when stored in the original, unopened container Shelf life Transparent after curing Yes Environmental No VOC Approvals CEI NF EN 61086 Approvals UL files QMJU2 – E308681 Application options Dipping, spray, brushing, or selective coating Recommended coating thickness 30 – 150 microns APPLICATION ABchimie 526UV M can be applied by brush, spray or selective coating machine: Spraying (two crossed layers): 60-80 microns Brushing: 40-60 microns Selective coating machine: 70-80 microns (380mm/s) Workshop temperatures of minimum 16°C and relative moisture of 50% minimum are suitable for the application of ABchimie 526UV M conformal coating. Relative moisture of 50% minimum is suitable for the second cure mechanism. All PCBs, being composite materials, absorb moisture. If this is not removed, the conformal coating may not protect to its fullest extent. Pre-drying of 4 hours at 80°C, or better still, vacuum desiccation, will remove most of the moisture. ABchimie 526UV M Conformal Coating contains a fluorescent tracer which allows inspection of the PCB after coating to ensure complete and even coverage. The stronger the fluorescence, the thicker the coating layer is. ABchimie 526UV DS55 M (55 cSt) is default set viscosity for standard coating process. ABchimie 526UV DS140 M version (140 cSt) can be used for double side coating with heat fluid circulating system and if environment at the dispensing machine is submitted at high temperature variations along the day Cleaning Boards should be thoroughly cleaned before coating. This is required to ensure that satisfactory adhesion of the coating to the substrate is achieved. Solder paste flux residues must also be removed as they may become corrosive when left on the PCBA. In past years there have been major improvements in flux residues reliability and their compatibility with conformal coating. This improvement in electrochemical corrosion has been achieved using the Bono test as key technique to assure the chemical residue of the flux is chemically inert after soldering providing a reliable adhesion. This is a key reliability advantage for no-clean processes using conformal coating. Inventec offer TM ECOREL solder pastes compliant with Bono test and all SIR industry standards. To clean equipments of ABchimie 526UV M conformal coating not cured, it is recommended to use cleaning solvent SND. ABchimie526 UV DS55 M/ DS140 M Spray application Spray in cross lapped coats in order to cover correctly all the components and the confined spaces and to ensure an optimal coating. The used air must be dry to avoid the premature gelling of conformal coating. Brushing application Gently apply the coating with a good quality brush (silk). Dry Times and Curing Conditions ABchimie 526UV M conformal coating polymerises with UV technology and moisture for the second cure mechanism. UV Curing: It is important to use the appropriate UV equipment, as well as the parameters recommended to obtain the optimal properties of the ABchimie 526UV M conformal coating. The following graph gives the optimal conditions to polymerize the ABchimie 526UV M conformal coating and obtain the best performances: Mercury arc lamp 120 W/cm 1 x 1m/min < cycle < 1 x 3m/min 0,7 J/cm² < UVA dose < 2,7 J/cm² UVA Dose and UVA irradiance vs speed belt => Determination of optimal cured conditions Characteristics of the UV equipment: Mercury arc lamp 120 W / cm 3,000 0,400 0,350 2,500 0,300 2,000 UVA dose must be included between 0,7 J/cm² and 2,7 J/cm² 0,250 1,500 0,200 belt speed must be included between 1 m/min and 3m/min (Can vary according to the height of the lamp, the reflector...) 0,150 1,000 0,100 0,500 0,050 0,000 0 UVA dose J/cm² 2 4 6 8 10 speed belt m/min 12 14 16 18 0,000 20 UVA irradiance W/cm² ABchimie526 UV DS55 M/ DS140 M Moisture cure: Ambient temperature 50% minimum relative moisture Curing mechanism: moisture UV acrylate monomer R R2 R R R2 R2 R2 urethane prepolymer R R R R R R acrylate prepolymer liquid conformal coating R R2 R2 UV then moisture cure R R R R2 R R R2 R R2 R R polymerized conformal coating R R2 PACKAGING ABchimie 526UV M conformal coating 5 litre Bulk 5 litres Bulk ABchimie 526UV DS55 M 05L ABchimie 526UV DS140 M 05 L STORAGE ABchimie 526UV M conformal coating must be stored in opaque and hermetic container, away from excessive heat, and at temperature below 40°C. ABchimie 526UV M conformal coating cures under UV, so it is important not to expose it to light sources. This conformal coating also cures with moisture, so be careful that there is no moisture in the select coat machine, in the used tanks, in the begun bulks. After opening of bulks, it is recommended to purge these bulks with a dry and inert gas (Nitrogen) to avoid the polymerisation of the conformal coating during the storage. ABchimie526 UV DS55 M/ DS140 M HSE Before using this product, please read the current product material safety data sheet (available through your sales or technical service representative) and the precautionary statement on the product package. Follow all applicable precautions and directions. No issues when used as recommended. INVENTEC Material Safety Data sheets can be found at www.quickfds.com Please refer to Material Safety Data Sheet before use This data is based on information that the manufacturer believe to be reliable and offered in good faith. In no event will INVENTEC be responsible for special, incidental and consequential damages. The user is responsible to the Administrative Authorities (regulations for the protection of the Environment) for the conformity of his installation. BRY-FP-409-v2-16/07/14