26 43 00 Surge Protection Devices

advertisement

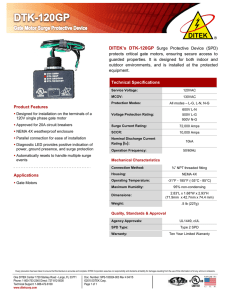

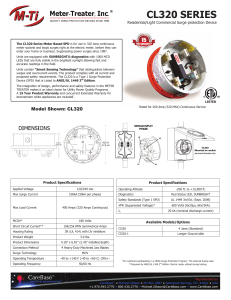

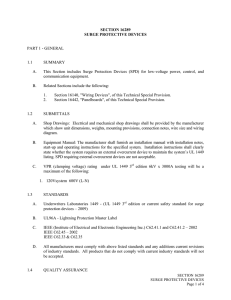

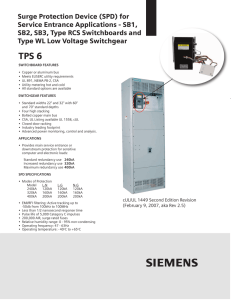

CPS Control Rev: 2_08/20/10 Project Rev: A_03/11/14 SECTION 26 43 00 SURGE PROTECTION DEVICES PART 1 - GENERAL 1.1 SUMMARY A. 1.2 Section includes Surge Protection Devices for low-voltage power, control, and communication equipment. DEFINITIONS A. ATS: Acceptance Testing Specifications. B. In: Nominal Discharge Current. C. NRTL: National Recognized Testing Lab. D. OCPD: Over Current Protective Device. E. RMS: Root Mean Square. F. SPD: Surge Protection Devices. G. VPR: Voltage Protection Rating. 1.3 SUBMITTALS A. Product Data: For each type of product indicated. Include rated capacities, operating weights, operating characteristics, furnished specialties, and accessories. B. Product Certificates: For SPD, signed by product manufacturer certifying compliance with the following standards: 1. C. UL 1449, 3rd Edition. Field quality-control test reports, including the following: 1. 2. 3. Test procedures used. Test results that comply with requirements. Failed test results and corrective action taken to achieve requirements. D. Operation and Maintenance Data: For SPD to include in operation, and maintenance manuals. E. Warranties: Special warranties specified in this Section. 1.4 QUALITY ASSURANCE A. Manufacturer’s Qualifications: HERZL CO-LOCATION 2015-23771-CSP 26 43 00 - 1 SURGE PROTECTION DEVICES CPS Control Rev: 2_08/20/10 Project Rev: A_03/11/14 1. 2. Manufacturer shall be certified ISO 9001 or 9002. The manufacturer of this equipment shall have produced similar electrical equipment for a minimum period of five (5) years. B. Source Limitations: manufacturer. C. Electrical Components, Devices, and Accessories: Listed and labeled as defined in City of Chicago Electrical Code, by a testing agency acceptable to authorities having jurisdiction, and marked for intended use. D. Comply with City of Chicago Electrical Code. E. Comply with IEEE C62.41, "IEEE Guide for Surge Voltages in Low Voltage AC Power Circuits," and test devices according to IEEE C62.45, "IEEE Guide on Surge Testing for Equipment Connected to Low-Voltage AC Power Circuits." F. Comply with UL 1449 3rd Edition, "Surge Protection Devices." G. Permanently affix surge ratings to the unit. H. IEEE Compliance: Comply with Standard 1100 (Emerald Book) 2006 Edition. 1.5 Obtain SPD and accessories through one source from a single DELIVERY, STORAGE AND HANDLING A. Deliver SPD in original factory shipping cartons, with manufacturer's labels intact. B. Store SPD indoors in clean, dry space, protected from weather, with uniform temperature and humidity to prevent condensation. Protect SPD from exposure to dirt, fumes, water, corrosive substances, and physical damage. C. Handle SPD in accordance with manufacturer's instructions and to avoid damage. 1.6 PROJECT CONDITIONS A. Existing Utilities: Do not interrupt utilities serving facilities occupied by Owner or others unless permitted under the following conditions and then only after arranging to provide temporary utility services according to requirements indicated: 1. 2. B. Notify Architect and Board’s Authorized Representative not less than seven days in advance of proposed utility interruptions. Do not proceed with utility interruptions without Architect's and Board’s Authorized Representative written permission. Service Conditions: Rate surge protection devices for continuous operation under the following conditions, unless otherwise indicated: 1. 2. 3. Maximum Continuous Operating Voltage: Not less than 115 percent of nominal system operating voltage. Operating Temperature: 30 to 120 deg F. Humidity: 0 to 85 percent, non-condensing. HERZL CO-LOCATION 2015-23771-CSP 26 43 00 - 2 SURGE PROTECTION DEVICES CPS Control Rev: 2_08/20/10 Project Rev: A_03/11/14 1.7 ENCLOSURES A. 1.8 NEMA 250, with type matching the enclosure of panel or device being protected. IDENTIFICATION A. 1.9 General: Refer to Division 26 Section “Identification for Electrical Systems” for labeling requirements. COORDINATION A. 1.10 Coordinate location of field-mounted SPD to allow adequate clearances for maintenance. WARRANTY A. Special Warranty: Manufacturer's standard form in which manufacturer agrees to repair or replace components of SPD which fail in materials or workmanship within ten (10) years from date of Preliminary Acceptance. B. Special Warranty for Cord-Connected, Plug-in Surge Suppressors: Manufacturer's standard form in which manufacturer agrees to repair or replace electronic equipment connected to circuits protected by surge suppressors. PART 2 - PRODUCTS 2.1 MANUFACTURERS A. Manufacturers: Subject to compliance with requirements, provide products by one of the following manufacturers: 1. 2. 3. 4. 5. 6. 7. 8. 2.2 Current Technology, Inc. Cutler-Hammer, Inc.; Eaton Corporation General Electric, Inc. LEA International Liebert Corporation; a division of Emerson. Siemens Square D; Schneider Electric Advanced Protection Technologies, Inc. GENERAL A. Maximum Continuous Operating Voltage (MCOV): Greater than or equal to 115% of the nominal system operating voltage to ensure the ability of the system to withstand temporary RMS overvoltage (swell) conditions. B. Operating Frequency: 47 to 63 Hertz. C. Integral OCPD for Suppression: The unit shall require the distribution panelboard assembly to have an integral OCPD as a means of disconnecting the suppression/filter system for maintenance and/or test purposes without interruption of power to the facility’s distribution system. The OCPD shall be 3-pole for three-phase applications and shall be padlockable. HERZL CO-LOCATION 2015-23771-CSP 26 43 00 - 3 SURGE PROTECTION DEVICES CPS Control Rev: 2_08/20/10 Project Rev: A_03/11/14 D. Accessories: 1. 2. 3. Accessories listed shall be included for all types of SPDs. Status Indicators. Integral status circuit to monitor the operational status of all modes of protection. No manual testing is required to confirm the integrity of the suppression and filter systems. If the unit does fail, the green LED will go out and the red LED will be lit. Dry Contacts for remote monitoring. a. b. 4. 2.3 Electrically isolated Form C dry contacts, rated at a minimum of 2A and 24 Vdc, one normally open and one normally closed set standard on all units for remote monitoring. Interface with building power monitoring and control system. Audible Alarm. Activated when any one or more of the surge current diversion components has failed. An alarm silence button shall be provided. The audible alarm and switch shall be located on the unit’s hinged front cover. SERVICE ENTRANCE SUPPRESSORS A. Surge Protection Device Description: Solid state metal oxide varistor suppression modules. No series connected suppression components are allowed. 1. 2. 3. 4. B. Type 1 as defined by UL 1449, 3rd Edition. Short Circuit current rating complying with UL 1449, 3rd Edition, and matching or exceeding short circuit current value available at the point of connection. Voltage Protection Rating shall be in compliance with test and evaluation procedures described in UL 1449, 3rd Edition. Nominal Discharge Current Rating: 20 kA minimum as determined by the actual Nominal Discharge Current test. Modular design with individually fused modules with the following features and additional accessories: 1. 2. 3. 4. 5. Fabrication using bolted compression lugs for internal wiring. Integral disconnect switch or circuit breaker. Redundant suppression circuits. Arrangement with copper bus bars and for bolted connections to phase buses, neutral bus, and ground bus. Surge-event operations counter. C. Peak Single-Impulse Surge Current Rating 100 kA per mode/200 kA per phase minimum. D. All primary transient path wiring shall be of copper minimum size as required by the manufacturer but not less than #2AWG, or via bus bar of equivalent capacity to provide equal impedance interconnection between phases. No plug-in modules, components or printed circuit boards shall be used in surge carrying path. E. Connection Means: Permanently wired, integral to the switchboard or externally mounted adjacent to the switchboard. F. VPR rating under UL 1449, 3rd edition, 6kV 3000A testing should fall within: HERZL CO-LOCATION 2015-23771-CSP 26 43 00 - 4 SURGE PROTECTION DEVICES CPS Control Rev: 2_08/20/10 Project Rev: A_03/11/14 1. 2. 3. 2.4 120V system 700-800V L-N,L-G, 600-800V N-G and 1000-1,200V L-L. 277V system 1,000-1,200V L-N, N-G, 1,200V L-G and 1,800-2,000V L-L. 480V Delta system 1,500-2,500V L-L, L-G PANELBOARD SUPPRESSORS A. Surge Protection Device Description: Modular or Non-modular design, sign-wave-tracking type with the following features and additional accessories: 1. 2. 3. 4. 5. 6. 7. 8. Type 1 or Type 2 as defined by UL 1449, 3rd Edition. Short Circuit current rating complying with UL, 1449 3rd Edition, and matching or exceeding short circuit current value available at the point of connection. Integral disconnect switch when required by contract documents. Voltage Protection Rating shall be in compliance with test and evaluation procedures described in UL 1449, 3rd Edition. Nominal Discharge Current Rating: 10 kA minimum as determined by the actual Nominal Discharge Current test. Fabrication using bolted compression lugs for internal wiring. Redundant suppression circuits. Arrangement with wire connections to phase buses, neutral bus, and ground bus. B. Peak Single-Impulse Surge Current Rating: 50kA per mode/100 kA per phase. C. Connection Means: Permanently wired, integral to the panelboard or externally mounted adjacent to the panelboard. D. VPR rating under UL 1449, 3rd edition, 6kV 3000A testing should fall within: 1. 2. 3. 120V system 500-800V L-N,N-G, 600-800V L-G and 900-1200V L-L. 277V system 1,000-1,200V L-N, N-G, 1200V L-G and 1,800-2,000V L-L. 480V Delta system 1,500-2,500V L-L, L-G E. Equipment shall be multi-stage parallel protector rated for noted VAC. capacity shall be 50kA per mode/100 kA per phase. F. The system protection modules shall contain an array of metal oxide varistors (MOV). The SPD shall be listed in accordance with UL 1449, 3rd Edition. G. All primary transient path wiring shall be of a #6 AWG copper minimum or via bus bar of equivalent capacity to provide equal impedance interconnection between phased. No plug-in modules, components, or printed circuit boards shall be in use in surge carrying paths. H. Provide visible status indicator mounted on the front of the panel or a glass window shall be installed on the enclosing cabinet to make indicators on the modules visible. 2.5 Minimum surge PLUG-IN SURGE SUPPRESSORS A. Description: Non-modular, plug-in suppressors with at least four 15-A, 120-V ac, NEMA WD 6, Configuration 15-15R receptacles, suitable to plug into a NEMA WD 6, Configuration 15-15R receptacle; with the following features and additional accessories: HERZL CO-LOCATION 2015-23771-CSP 26 43 00 - 5 SURGE PROTECTION DEVICES CPS Control Rev: 2_08/20/10 Project Rev: A_03/11/14 1. 2. 3. 4. 5. LED indicator lights for reverse polarity and open outlet ground. Circuit breaker and thermal fusing. When protection is lost, circuit opens and cannot be reset. Close-coupled direct plug-in. Rocker-type on-off switch, illuminated when in the on position. One RJ11/12C telephone line protector, suitable for modem connection. Maximum clamping voltage 220 peak on pins No. 3 and No. 4. B. Peak Single-Impulse Surge Current Rating: 33 kA per phase. C. Protection modes and UL 1449 VPR shall be as follows: 1. 2. 3. Line to Neutral: 475 V. Line to Ground: 475 V. Neutral to Ground: 475 V. PART 3 - EXECUTION 3.1 PREPARATION: A. 3.2 Examine conditions for compliance with requirements for installation tolerances, power characteristics and other conditions affecting performance of the SPD device. Do not proceed until unsatisfactory conditions have been corrected. INSTALLATION A. Install devices at service entrance on load side, with ground lead bonded to service entrance ground. B. Install devices for panelboard and auxiliary panels with conductors or buses between SPD and points of attachment as short and straight as possible. Do not exceed manufacturer's recommended lead length. Do not bond neutral and ground. 1. 2. 3. Comply with manufacturer's written recommendation for conductor and circuit-breaker size for connecting SPD to distribution system. Match circuit-breaker size to conductor size. Coordinate with Drawings. Provide multipole, 30A circuit breaker as a dedicated disconnect for SPD if mounted exterior to the switchboard or panelboard, unless otherwise indicated. Where SPD cannot be mounted within 18-inches of the panel, high performance, low impedance cable as recommended by the manufacturer may be provided to eliminate any potential degradation of voltage protection. C. Device shall be installed without extending manufacturer’s wire lengths. D. Externally mounted service entrance SPD shall be installed with less than 5’-0" of lead length from the panels. Installation of leads shall avoid sharp and unnecessary bends. Where SPD cannot be mounted within 5’-0" of the panel, an internal SPD mounting shall be utilized. Terminals shall be provided for all necessary power and ground connections. HERZL CO-LOCATION 2015-23771-CSP 26 43 00 - 6 SURGE PROTECTION DEVICES CPS Control Rev: 2_08/20/10 Project Rev: A_03/11/14 E. Externally mounted panelboard SPD shall be installed with less than 18-inches of lead length from the panels. Installation of leads shall avoid sharp and unnecessary bends. Where SPD cannot be mounted within 18-inches of the panel, an internal SPD mounting shall be utilized. Terminals shall be provided for all necessary power and ground connections. F. Installation shall be in accordance with the NEC 280 & 285 and City of Chicago Electrical Code. G. System shall not require removal and replacement for warranty and/or other repairs. All internal component replacements shall be capable of being completed by a licensed electrician. H. Ground each SPD enclosure. I. Tighten electrical connectors and terminals according to manufacturer’s published torquetightening values. Where manufacturer’s torque values are not indicated, use those specified in UL 486A and UL 486B. 3.3 CLEANING A. Remove paint splatters and other spots, dirt and debris. Touch up scratches and mars of finish to match original finish. B. Clean devices internally using methods and materials recommended by the manufacturer. C. Do not use compressed air for cleaning. 3.4 CONTRACTOR START UP AND REPORTING A. Verify that electrical wiring installation complies with manufacturer's written installation requirements. B. Do not energize or connect service entrance equipment, panelboards, control terminals or data terminals to their sources until surge protection devices are installed and connected. C. Testing: Perform the following field tests and inspections and prepare test reports: 1. 2. 3. D. After installing surge protection devices, but before electrical circuitry has been energized, test for compliance with manufacturer’s requirements. Complete startup checks according to manufacturer's written instructions. Perform each visual and mechanical inspection and electrical test stated in NETA ATS, "Surge Arresters, Low-Voltage Surge Protection Devices" Section. Certify compliance with test parameters. Remove and replace malfunctioning units and retest as specified above. END OF SECTION HERZL CO-LOCATION 2015-23771-CSP 26 43 00 - 7 SURGE PROTECTION DEVICES