1940 March 08th

advertisement

MARCH

8, 1940

-

221

THE ENGINEER

-

A Seven-Day Journal

Machine Tool Trades Association

ON Thursdny, February 29th, the Machine Tool

TradE's Association h<.>ld a luncheon at G rosvenor

H ouse, L ondon. This function took the place of the

dinner that th<' Association usually holds at this time

of •year. Mr. H arold Butler, President of the Association, took the chair. After the loyal toasts of " The

King" and " The Pr·<'sident of tho French Republic"

had been honourE-d , Mr. But.l<'r proposed the t.oa.st of

" H is Maj('sty's <:ovE:>rnm<•nt and the success of t.h<'

AlliC's." A f<'w of his r<•marks werC' made in Fr·cnch

in acknowl<'dgm<'nt of tlw pr<>sc<>nee of n number· of

French gu<>sts. H e m<•ntionod that t he Association

had. during t h<> pr<•vious w<•ck. dis<·uss<>d with thE'

Prench matters <tfl'<>cting tlw ]JI'Ocluc·t ion of machinE'

tools in both countr·ics, and that the French were

experien cing the sam e conditions as it was. One of

the troubles was the " labour bottleneck." H e

a s ured Mr. Burgin, Minister of upply, ·wh o was the

principal guest of the Association, that the members

were determined to tackle their problems resolutely.

In reply, l\Ir. Burgin said that the war was one of

machines and material. There were 2000 different

types of machine tools and 35,000 persons employed

in the machine tool trade. Would that the number

could be multiplied ! T o that object their efforts

must be directed. H e had received a letter from his

opposite number in France, M. Dautry, expressing

appreciation of the visit of the president of the Association and his colleagues. After r eferring to the extent

of modernisation that was necessary to economise

labour, and to the dcvolopment of machine tools

simpler to operate, he thanked the industry for its

efforts in that direction. Many countries made

machine tools. In terms of cost those from the

United States wore between 1! and 2! times as

expensive as British machines.

H e assured the

Association that the expansion of the industry would

make its hold on the home market more secure.

ir

Alfred H erbert then prop osed the toast of " The

President," remarking that, at a meeting held before

the lunch, he had consented to retain that position for

an unspecified p eriod, probably the duration of the

war. H e also pointed out that productivity could

be greatly increased by working night shifts. It

was a sad fact that one half of our m achining capacity

was lying idle at the present time. Mr. Butler

replied in suitable terms.

The

Lar~est

Am erican Liners

particulars a re now available concerniug

the two liners for the Pacific service between San

Francisco and the Orient, for which the United States

Maritime Commission has recently invited t end ers,

which are to be opened on Tuesday, May 17th. The

ships, whi<'h will be the largest ever built in the United

States, it is Wlderstood. are to be constructed in s uch

a way that, in an emergen cy they can be quickly

converted into aircraft-carriers. The principal hull

dimensions and m achinery particulars a re as follows :

length 759ft., beam on water-line 98·2ft., with a

d esigned displacement of 35,500 tons, and speed of 24

knots. The s hips are to be d esigned for about 1000

passengers, with a p ersonnel of about 500. The

space available for cargo is to be about 535,000

bale cubic feet. The hulls a re to have a curved

raked stem , a cruiEer stern, and a long bridge h ouse.

There will be five complete steel d ecks in addition

to the promenade, boat, and s tm-decks. The sub division of the hull will include fourteen main watertight t ransverse bulkheads with additional nil and

watertight bulkhE-ad s. The pa senger quarters

arranged on the boat, promE-nadE', main, a nd '' A " to

" D " d ecks, will be in ac·cor·dance with thE' latest

practice, and will include ai r· conditioning for t.he

cabin and tour·ist ttccommodation and the diningrooms. An Pfficien t fire d etection ::;ystem

is to be

•

provided. The pr·opelling machinPry will comprisE>

a twin-screw ~:u·r·angem<'nt of t,riple-E'xpansion tm·bines

with double - rc>duction gear·ing, taking stc>am fr·om

modern water·tube boilers. The machinery is to be

arranged in two separate compartments, in such a

way that damage to ono compartment will not

necessari ly involve the flooding of the other.

FuRTR.ER

The Women 's

En~ineerin~

Society

THE twenty-first armiversary of the foundation of

the \Vomen's Engineering , ociety was celebrated on

Monday, March 4th, by a luncheon at the Park Lane

H otel, London, with Mi.J s Caroline H aslett, President

of the society, in the chair. In prop osin g the toast to

the society, the Right Hon. Ernest Brown, Minister

of Labour and National ervice, spoke of the place

that women could fill in industry to a.c;sist in achieving

the coWltry's maximum effort. In t h e last twenty

years, he said, there has b een a growing acceptance

of women's place in industry, and the demand for their

services in various directions was bound to continue.

A matter of importance at present was the expansion

of the engineering industry to meet war demands and

to maintain and increase our export trade, and

conversations were proceeding on both sides of the

industry on matters of labour and national service.

I t wa..:; not possible at the present stage t o anticipate

the outcome of those conversations, but the Minis ter

expressed his gratitude for the manner in which both

sides of the engineering ind ustry were showing their

readiness to tackle the problems of expansion. The

Oovcmmont's progr·amme was a v ery big one, and

it was eonfidently ox pccted that men a.nd women

suit.able and avai la ble for employment would bP.

r<'quir<•d in numbc>r's far in excess of those of th ~

present unPmpl oycd. Jn responding to the toast.

Miss H a!-!lett r·<'viPwed t.l1<' g r·owth o f the sociE-t y, a nd

s poke of its <'rHlPavours to nssist the <>ngineering

indlLStric>s. Other spNtkers WfWO thr- Dowager Lady

, 'wayth ling, president of th<' E lectrical A<> ociation

for womc>n, Miss Paulin<' <:ower, and Miss Monica

Mauricc.

Railway

Workin~

in War Time

IN the course of his address at the annual general

m eeting of the Great W estern Railway Company,

held on February 28th, the Right Hon. Viscount

H orne, chairman of the company, who presided, reviewed the activities of the Great W estern system

under war time conditions. H e suggested that in

playing their part in the m echanism of war the stockholders already deserved well of the nation. If the

stockholders had insisted upon dividend s rather than

a high standard of maintenance and ren ewals, the

Gover·nment would now have been faced with the

necessity of large expenditure- for without efficient

railways, the war could not be fought. Happily, it

s tands, he said , to the credit of the British railways

that they compare in efficiency with any other

railways in the world, for they had been maintained

in a condition which render them adequate to the

needs of the nation in war. Referring to the effects

of war conditions on the s taff, he said that he could

not speak too highly of the magnificent efforts made

by all grades. , ince the war began over 3500 special

t rains had been run over the system for the conveyance of troops and munitions and in addition

t here had been large increases in goods traffic. The

lighting restrictions seriously reduced the working

efficiency at s tations, goods s heds, and marshalling

yards, in some cases by as much a 30 per cent. Mter

overcoming those initial difficulties consid erable

improvement in passenger· services had been made.

H e went on to say that in this time of anxiety and

uncertainty it would be imprudent to predict anything with regard to the future. But it was p ossible

to mention one factor which- unless the world was

entirely changed after the war-would gi~ hope for

increased activity on the Great W estern Railway.

During the last three years there had been 239 n ew

industria l and commercial undertakings establish ed

on the system , embraci ng a large variety of businesses.

But nothing would ever be s uccessful or prosperous

in this country unless we seized victory from the

grim struggle upon which we had entered.

Institution of Structural

En~ineers

four hundred m embers and guests were

present at the annual dinner of the Institution of

tructural Engineers which was held in L ondon at

the Dorchester Hotel on Friday, March 1s t. The

toast of the Institution and its president, Mr. Percy J.

Black, was pr·oposed by the Parliamentary ecretary

to the Minis tr·y of , upply, Colonel J. J. Llewellin,

who dc>alt mainly with the work of his d epartment

as concemed with structural engineering. H e

pointed out tha t the two principal sid es of the

Ministry's wor·k were to erect and equip ordnance

factori es, and to see t.hat the raw materials of indus try

were adequately provided. In his remarks r·egarding

the second of thesE'. C.:olonel Llewellin said that an

econ omy committee> had been set up to inves tigate

the possibility of any savings which might be made

on the various d epartmental specifications particuarly

with regard to timber and steel. Factories for the

Ministry which h ad hitherto been built through the

Office of Works were now being constructed by private

contractors, and the speaker said that the cooperation which existed between the ar chitects and

constructional cngineerR in this work was particularly

encouraging. He> concluded b y saying that, although

the present trend of events was more towards

destruction than con truction, h e hoped that the

great constructive effort of the Institution would

steadily progress. In replying to the toast, l\fr. Black

said that the dinner, held at s uch a time, was symbolic

of the optimism of the structural engineer, and

although the Institution was comparatively young

it was very virile. He reminded his listeners that

b efore the war building was one of the most beneficial

industries to this cowttry, and it had reached a high

level of efficiency owing to the co-operation of all

branches. lt was on e of the few industries which

had had but little State subsidy or assistance. In his

N EARLY

opinion it wM in the public interest that the Governm ent s hould make an effort to set to work the

number of branches at present halted owing to their

work not being of immediate national importance ,

because if the co-operative s pirit that had been built

up was allowed to break down it would be to the

d etriment of the country when p eace was declared.

The health of the gues ts was proposed by Mr. M. B.

Buxton, vicP- prN;ident of the Ins titution , and

respondod to by Sir· Clement D. M. Hindley, thf>

pr·c>siclc>nt of t.lw f nstit,ution of Civil Engineers.

The Unemployment Returns

•

'l'tH~

tot,ttl uumlwr of unemployed on the registers

on Ft>bnra ry 12th, 1940, was 1,504, 100, made up of

1,1 41 ,5:38 wholly unemployed, 315,072 temporarily

stopped, and 4 7,670 normally in casual employment.

There was a drop, relative to the previous month, of

80, 145 in the number wholly Wlemployed and

normally in casual employment. But this decrease

was largely offset by an increase of 65,349 in the

number of those temporarily s topped, being a n et

reduction of only 14,796. As compared with the

previous month there were increases in the number

of unemployed in agriculture, coal-mining, building,

iron and steel, public works contracting, tinplate

manufacture, s hipbuilding and repairing. Among

the engineering trades, only motor-v ehicles, cycles,

and aircraft r ecorded a d ecrease. When the comparison is made with February 1939, however, it is found

t hat heavy decreases in unemployment are recorded

in practically a ll trades, with the notable exception of

building. The increases in the numbers unemployed

relative to the previous month can be traced, it is con sidered almost wholly to the weather conditions at the

time when tho count was taken. The effect of long

continued fros t and s now had, of course, a marked

effect on outdoor employment and employment in

other trades was influenced by the partial dislocation

of t ransport and the consequent difficulty of ensur·ing

d eliveries of essential materials. During the fortnight following the date of the count, the continuance

of better weather enabled much of the dislocation to

be remedied. There was certainly a large drop in

the number of lmemployed, and the reduction is

<'Sti matcd to amount to about 200,000.

The Financial Basis of

Shippin~

ON Thu1-sday, F ebruary 29th, Sir Philip Halclin,

in his presidential address to the annual meeting of

the Chamber of Shipping of the United K ingdom,

emphasised the n eed to put British shipping on a

sound financial basis now, so that it can accumulate

adequate reserves t o r eplace losses and to p repare

for intensified competition after the war. H e

pointed out that a day lost in waiting or in loading

or dischal'ge of cargo was a clay given to the enemy.

The s uccess of the requ isition policy, he said, would

d ep end in great measure upon the Government

relying on the incentive of the shipowners and

on their experience. Satisfactory charter conditions

had b een secured in the prolonged negotiations with

the Government, and he hoped that the industry

would secure rates of hire which would be adequate

for expenses, a fair return on capital, and something

towards re erves. If at the end of the war the

industry was left with depleted resources to meet

increased foreign competition, there would be no

alternative to subsidising it on a scale far in excess

of the a.<>sistance recently offered. Otherwise our

mercantile ma1·inC' would sink to the level of a thirdrate powe1·. The Government'::; proposed scheme

to provide ins urance for vessels lost by war casualty

was being t'Onsidered by the industry. The replacement problem , however, was not confined to war

losses, which might prove to be the s m allest part of it.

Tht> essence of the problem was to find means of

building MW ships for· old, of replacing ships lost by

mar·ino accident, and of obtaining fresh capital.

1n s upport, Lord E ssendon stated that the Britis h

~hipping Assistan ce Bill never became law b ecause

of the war. The proposal for grants was suspended,

but h e felt s ure that the Government ·would implement

their p romise, because it was an undoubted fact that

had it not been for those proposals about 1,000,000

gross tons of orders placed last spring would never

have been contracted for. That tonnage was now

rapidly approaching completion, and would b e of the

greatest possible value to the country. The cost of

building had already increased by 50 p er cent. in

the last few months, and at the higher cost of replacement the existing d epreciation reserves would be

hopelessly inadeq uate. The meeting took place for

the first time in the new h ome of the Chamber, at

Bury Court, ,'t. Mary Axe, L ondon, E.C.3. Amongst

the r<'solutions passed was one placing on record the

appreciation and thanks of the Chamber to ir

Vern.on Thomson for tho service he had rendered

to the indus try in ins tigating and bringing to a

s uccessful completion the building of the Chamber's

n<'w homo.

E

-

222

THE ENG£NEER

Heavy Passenger Engines, South

African RailW"ay s

By K C. POULTNgY, M. Inst. Loco. E.

ro

pla te. At the fire-box end they a re set in thin

copper sleeves, and t hen expanded a nd prossQrcd,

a nd fina lly beaded over and electrically welded.

The ratio of tubo bore to leng th is 1 to 119. The

net gas area through the boiler measured a t the

fu ll internal diameters of both tubes a nd flu es is

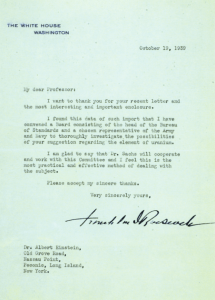

General DimeMio1111, 1feight~. attd Proportiorts of th e S. A .R .

8- 2 'l'ype Lowmotive, ClaiJB " 23."

.. ...

No. I

meet a demand for locomotives of g reat er

pow<w, required especially t o work t he im portant through passenger services over the

main line between Uapo 'T'own a.nd J ohannesburg,

l:lome largo 4- 8- 2 t y pe cngi nos have recently been

placed in traffic, built to the designs of Mr.

W . A . J . Day, Chief Mecha ni cal Engineer of the

outh African R ailways Administration . Thoug h

officially designated as heavy pa enger locomotives, they a re intended to be <' qually suitable

for handling both passenger and freight trains,

a nd in many respects con::;t itute a n outst anding

design, both as regards size a nd pot ential power

output, especially so when tho rail gauge of 3ft. 6in.

is t aken into consideration.

The object of t his arti cle* i ~; t o d escribe t hese

remarkable locomotives. B efore doing so, however,

a brief reference will be mad e t o others of tho same

general type, introduced during the last few years

as part of a programme having fo r its purpose the

provision of powerful locomotives of modern design

required t o handle the traffic economically, and t o

t ake t he place of older and smaller engines. F or

some few years past the ' .A. R ailway Administration has been g iving considerable attention to

the improvement of the main lines, a nd to this end

realignment of t he track t o reduce curvature a nd

a lso a certain amount of gradient elimina tion has

been undertaken, while a t the same time a departmenta lly designed 96 lb . rail has been adopted a s

::;tandard in place of t he B .•'X 80 lb . rails formerly

employed. This cha nge in conjunction with st eel

:;leepers a nd adequate a nd well -ma intained ballast

has g reatly improved the road . With these improvements, heavier a nd more powerfu l locomotives have been made po:;siblo, resu lting in the

construction in 1935 of sorne la rge 4-8- 2 and

4-6- 2 ma in line engines, the former by R. 'tephenson and Co., Ltd., Da rling ton (now Stephenson

a nd H awthorns, L td.), and H enschel und , 'ohn,

Cassel, Germa ny. Both types represented a con:;iderable advance in size a nd power over those in

genera l service at that time, and in severa l features

wrre alike. The cylinders, 24in. by 28in., were

common t o both, and generally the boilers were the

same, except that in the case of the " P acifi c "

type the length of the barrel section was somewhat shorter . F or th o eig ht -coupled design t he

driving wheels had a diameter of 5ft., while for

t he 4-6- 2 engines the coupled wheel:; had a diameter of 6ft., the largest ever used on the 'outh

African R ailways. Those locomotive:; are classified

" 15 E " and " 16 E ," a nd twenty of t he former

were built a nd six of t he la tter. No more of

tho " P acifi es " were ordered , but a further Jot

of the class " 15 E " were construct ed by

Henschels, a nd a ls:> by t he Berliner Maschinenbau

A.G. Vormals L . Schwartzkopft, B erlin. Both of

t hese firm s between t hem recently furnished

a further twenty-one locomotives of the same

design a nd t y pe, in certain respects slightly

modi fied , principally by having Wa lschaorts

motion in place of poppet valve gear. They

are known as class " J5 Ji'." I n addition , fortyfour of these engines were built by t he North

Britil;h L ocomotive Company, Ltd., during 1938

and 1939. Except for slight differences in det ail ,

the boiler a dopted for th e 4-8- 2 ty pe engines is of

a standard pattern , and is, in fact, applicable t o a ll

t he new 4-8- 2 locomotives, including the latest

desig n, class " 23," formin g the main subject of

t his a rticle. Furt her, in the sta nda rdi ation of

other parts, including the cylinder castings, as

well as other of the principa l d etails of construction, the newest locomotive:; follow closely those

previously mentioned.

These new engines were dc::;igned in 1936, a nd

subsequently orders wore placed with H enschel

und 'ohn and the Berliner Maschinenbau A.G. fo r

t hirt een and seven respecti vely, both these contracts being la ter extended by a total of one hundred

und sixteen engines, eighty-five t o be built by Hen:;choh; and thirty-one by the Berliner l\1a schinenbau

A.G. All are a like, though slig ht d eta il cha nges

have been made, a nd the following description

applies more particularly to those built by the

•1)ro11ont.ed by permissio n o f Mr. T . 11. Wate rmoyer, <.:enon\1

Mn.nagor , and Mr. W . A. J . Day, AKMis tant. General ~lantlgor,

T .,chnical, South Afri can Railways and H arbours.

Berliner Maschinenba u, being those with which

the writer is moHt intimately conversant. While,

as a lready menti oned, th e new locomoti ve:; follow

in genera l desig u the prov iow; 4-8- 2 classes, and

more parti cula rly the " I !) F " series, th ey aro

distinguished from t.lw form er by having larger

coupled wheels of 5ft. 3in. dia meter t o fit t hem for

higher s peeds, a nd t o c·ombin(' as far aR possible

the running characteristic·:; of t he six-coupled a nd

<·ight-eoupled ty pes, a nd thus provide a locomotive which would be equally :;uita ble for all scctionl-.1

of t he main line. Furth <'r, to render the design

generally more suitable, both from an opera ting

standpoint and the d evelopment of a higher susta.incd power output, large-capacity t enders have

boon ad opted a nd mecha nical stokers provided.

The class " 2:1 " is th o la rgest non-articula ted ty pe

of locomotive •vet bui lt for the 'outh African R ai lways, the weight in working order of the engine only

bei ng no less than 111 t ons, whilst t he t ender is

the largest so far placed in service ; the water

capacity is 9500 gallons, and there is s p~tce for

18 t ons of coal. When loaded, the waight is 107 tons,

giving a t otal locomotive weight of 218 long t ons.

Tho use of these high-capacity t enders will in

certain circumstances ena ble stopping for water t o

be avoided , a nd , furth er, provide the required fu el

and water supplies necessary when working at the

high rates of power output mad e possible by the

mecha nical st oker. The cylinders a re of the same

size as t hose previously employed , namely, 24in.

by 2 in., a nd in order t o maintain the same

maxi mu m rat ed tracti ve effort with the la rger

wheelH the boiler working pressure has been

in creased t o 225 lb. per :;qu<tre inch , as agai nst th e

210 lb. previously used. It may here be mentioned th at 24in. cylinders a rc t he largest permissible with the exil:lting load gauge. However,

it is con:;idered that t he provision of the mecha.ni cn.l st oker will ena ble higher powers t o be obtained

while maintaining the standa rd boiler and the

24-in. by 2 in. cylindet·s.

A photograph and drawings reproduced in the

accompanying engravings illustrate the new locomotives, and their p rincipa l dimensions a re given

in the table below.

'l'HE B OILE R

Coming now t :> a more det a iled d escription of

t hese engines, t he boi ler first claims attention. It

i:; of t he rou nd-top radia lly st ayed ty pe, and t he

barrel section, whi ch is of t he usual t elescopic

de:;cl'iption, is made up of three courses, t he front

end hav ing an outside diameter of 6ft. 3~in .,

ta pered to 6ft. 4!in. a t the first circumferential

joint. The plates a re Vn. t hick, a nd inner and

outer butt st raps ,\in. a nd i in. thick are used for

t he longitudina l joints, which a re a lso welded for

a dista nce of a bout l 4in. from each end to ensure

tightness at the junction with t he circumferential

joints. The fire-box wrapper is in one -&in . pla t e,

a nd the back a nd throat plates a re -&in. a nd {~ i n .

t hick. The smoke- box tube pla te of 26; 30-ton

carbon :;teel is ~ in . t hick, and a fter being dished

iH tu rned outside round t he circumference, and

single-rivet ed into the front barrel course. The

circumferential la p joints are double riveted, and

for t he longitudinal butt joints the inner cover

straps are quadruple ri veted , a nd the outer straps

double rivet ed. The out:;ide fire-box wrapper

plat e is double riveted to the t hroat and back

plat el-.1. No longitudina l stay~ are used , but th e

l:lmoke- box tube pla te a nd the fire- box back plate

a rc well supported by g usset type staying. l 'fhe

boiler shell plates a nd the inner a nd outer b utt

straps a re of Thyssen 0 · 2 to 0 · 5 per cont . nickel

steel, having a tensile strength of from 29 t o 36

tons per squa re inch . A st eam dome is not provided, but a manhole is fitted on the rear barrel

course. Between t he tube pla t es the length is

22ft. 6in. There a re 136 tubes, st eel, solid

drawn , of outside diameter 2!.. in . and t hickne:;s

11 '. W.G. , and thirty-six flue t ubes, 5lin . outside

by f 6 in. thick . The tubes are swelled to 23in.

at the smoke-box end, and reduced to 2~in. where

t hey fit the fire- box t u be plate, and the flu es are

increased to 5-}tin . a t the front tube pla t e and

redu ced to 4 ijin. a t the fire-box end . The tubofi

and Hues are expanded into the smoke-box tube

8, 1940

MARCH

...

...

.•.

.. .

'l'ypo of locomotivo .. .

Rai l guuge... .. . .. .

Mini mum curvl:' radiu11

R oad class . .

. ..

Date built .

... ...

Ser vice

. .

...

...

•.

...

.. .

...

l:hul de rs

•

•

•

•

..•

0

.. .

South Africa n R oil.

ways

H enschol und Sohn

an d Berline r

Maschinonbau ,

German y

4 !! 2

.. .

...

•

.. .

:lft. 6111.

276ft.

.. 23 ..

1938- 1939

F ast. passenger and

fre ight

Hated tra ctlve <•fforl ('ngmes, 75 per

4 3,200 lb.

t't'OI.

Ih

r

111 1111iomt.

J l eigh t lo lop ol' chimney

H eight to cent re of boiler

Width overa ll .. . .. . .. . .. . .. .

Cylinder cent res

... ... ... .. .

T otal length over ongin o und t ender

buffo1· bottms .. . .. . .. . .. . .. .

;,~

ll'c.iglttiJ

•

4 .!

84

•

ll'orking Order.

Ou coupled wheels

On loading bogie

.. .

O n trailing bissel

Total eng ine

'render

. . . . . . . ..

•

Ft. Ill .

12 l i t

g 0

9 11

6 11

...

...

•

•

0

T. cwt.

.. .

.. .

•

72 I 2

21 0

17 16

111 8

107 6

ll'lleel BastJ/.

... .. .

Coupled wheels ... ... ...

T otal engine

T ender bogie .. . ... ..

T end er. total ...

Bng ine and tend er·, Lotal

. .. .

... ... .. . .. .

... ...

Wheel , Diameter

Cou pled wh eels .. .

Leading bogie .. .

Trailing bissel .. .

Tender bogie

.. .

.. .

• ••

•••

Oil

Tread.

F t. in .

5 3

...

•••

Ft. in.

16 6

37 0!

8 8

30 8

78 2t

• ••

2 10

2 10

2 10

Engi1te.

Cylinde rs, number , d iamott•r a nd

s t•·oke . . . . . . . . . . . . . ..

Vttlve gear, type

.. . ... .. .

VttlveR, piston typl', tlmrnottw.. .

Maximum t.mvol

.. . .. . ... .. .

l:lteam lap .. . . ..

Exhuust lap

Lea(l . . . . . . . . . . . . . . . . ..

Two, 24in. by 28w.

\\'alsc haorL

I 2in.

7!iu .

B oiler.

~loam pressure . . .

. . . . . . . . . . ..

l:lmallest inside diumet <>r ... .. .

La rgest outside diame te r ... .. .

F ire. box length at foundation ring ...

F ire· box width at foundati on ring ...

He ight, foundation ring to crown :

Bo.cl<

. . . . . . . . . . . . . . . . ..

225

6ft.

6ft.

7ft.

8ft.

0 •

}""'r ont

. ..

.. .

. ..

•

. ..

•

••

.. .

. ..

Arch tubes, numbor u.n<l di a motor ...

Boiler tubos, number untl dium et.er·

sug:~:~~~~. ~u~. ~~~b.~~· ~~.~·.mb.~~ u.r~.~

D istance between t.ubo plutc11

lt"uel . . . . . . . . . . . . . . . . . .

Stoker ... ...

.. . ...

Grate type

G rut o a ro11 ...

... ... ...

. ..

...

1 ~in .

Ni l

13/ o•in .

lb. per sq. inch

2tm .

7lin.

9 ft in.

5ft. ll kin.

7ft. l tin.

Five, 3in.

I :!6, 2A in.

36, 5!in .

22ft. 6in.

Coal

H T.! t y po. Stnntlnrd

Stoker Co.

Pinhole

62 · 5 sq. foot

lltal ill(l Surjac:e11.

Sq. foot .

...

Firo. box

... ...

Arch tubes

.. . .. . .. . .. .

Boi lo•· tubes

.. . .. . .. . .. .

S uperheater flue tubo11 ... .. .

l>uporh oa.t or olornont11

.. .

Combin ed evu.p . and su porht•at.

209 · 3

26·2

20 14

11 65

66 1

...

'l'endu.

\\'utor capacity

... . . ...

Fuel capacity .. . ... ... .. .

ll ogics

. . . . . . . . . . . . . ..

Length over tendur buffer beum11 ...

\\' rdth of tender tank

... ... ...

4075 ·5

9500 gallOIII!

18 t ons

• ix.who<'l

:!1:1ft. 1:1,6, i 11 .

9ft. l l in.

11"tight ProportiolliJ.

\Vorght on coupled wheels weight.

ertgine

. ..

.. .

.. .

...

. ..

. ..

65 · 0 per ce nt.

\"{eight on co upled whools · 1rnct.ive

Ofl·ort

:l · 76 p er con t..

\-Voigh t. of eng ine .,. twn.po r·uLi,•o heat..

ing s urface ... . .. . .. . ..

7:1· 2 lb . per s q . ft.

Weight of C~ngine t·mu lmwd lwut iui{

Hlarforu . . . . . .

0.

• • •

• • •

• ••

Ill · 2 lb. per i!(J. ft.

•

•

•

•• 0

0 •

•

•

•

0

•

0 0

0 •

•

o

J:Joilu ProportiiJIUJ.

F1re. box and a rch tul)tl hc11ti ng surface . combined heat1n!( su rface ...

Flue an d tube ht:allng surllwo com.

bined heati ng twrftlt'~' . . .. . .. .

Superheater ~lom<•nt lwnting I!UI'fuco+comblnod hoM mg 11urface ...

Fire. box h eating sur·fuco 7 grato uron

Flue tubes h eati ng surface . grato

areo.

...

. ..

. ..

. ..

.. .

. ..

5 · 78 pe r c(lnl.

71! per Cl'fll.

I 6· 2 por con t .

3 · 35 per cont.

60 · 86 por cont.

10· 576 p or cont.

Superheat su rface ~ p;rMo urea

E vupo rative heati ng surface : grate

areu.

.. . .. . ... .

54 · 63 per cont..

Tractive effort grato...:.. a rea ... ... 691 · 21b. por HCJ. ft.

Tractive effort. 7 ovnporat•vo lwati ng

Rl!rfaco . . . . . . . . . . . . . . . . .. 12 · 65 1b. p ers11. ft .

Tractive efTo r·t - combrnl'tl <'vnporn·

tivo and superheat surfuco .. . .. . 10·6lb. pl• rsq. ft.

0 •

•

•

•

•

••

1039 squa re inches, of which 4 · 19 square in ches,

or 47 per cent ., is through the flue tubes. The ratio

of t ota l gas area to grate a rea is 11 · 6 per cont.

The superheat er oornpri~o::~ thirty-six sets of

elements, l !in. outside diameter and 10 S.W .G.

•

MARCH

223

TH E EN G INEER

8, 1940

thick. They a re of the short loop type, having

integr ally forged return bendAand 11pherical 1Seatings

forged integra lly with t he pipes to make the jointH

with the header casting. The heating sur face of

the superheat er is 661 square feet, or 16 · 4 p er cE'nt.

ofthecombinedheatingMurfaceof4075Rquarefeet.

The inside fire- box is of steel supplied by Lukens

1 't eel Compa ny, Coat svil1e, P a., U.1 '.A.

A single

plate 3in . thi ck com prises the ''Ta pper , which is

single-rivet ed t o t he inner back and throat pl ate~;,

It may be here Rtatcd t hat for t he first forty ongines

the rocking grates were collectively shaken by

steam power, whereas the grat es for t he rema ining

ninety-six engines a rc Heparatcly operated in

six sections by hand. The a r ch iH carried on fi ve

a rch tubes of stC'cl, :~ i n. outside d ia meter. As in

the case of the boiler t ubes they a rc set in h oles

lined with copper s lcevNL T hey arc t hen expanded

a nd beaded over a t both r ndH.

'uitablc t aprred

p lugs a rc fitted in t hr t hr·oat a nd back plate~;

1

SOU TH

which a rc la-in . a nd 3in . thick resp ectively. Th e

ma t eria l complies with the A .S.'J'.M. s pecification .

There a re three fu sibl e plugs in the fire-box roof,

one at the front a nd two a t the back . The firehole in the oute r door pla te is flanged inwa rds

and in th e inner door pl a t e it is fla ngcd outwards,

thus bring ing the two plates togeth er and forming

a butt joint tha t can bo unitC'd by welding. The

foundation ring i ~; a ~;tcel forg ing m ~tchin ed a ll

ove r, exc-C'pt on the Hurface nex t to th (' water f- l pac·C'.

AFRI CAN

R A ILWAYS'

C LASS

2l

PA SSE N GER

It is not att ached t o the founda tion ring. Air inlet

i ~; provided for in th e hopper portion a nd round the

top next t ho founda tion ring. As the a shpa n is

necessarily s hallow whore it p asses over the framing

a nd under the fire- box dren ching pipes are fitted ,

one a long each !iido; th ey arc of iron and a rc

~; u ppJi ed with wa t er from the inj ector delivery

connC'ctions. T hey cma ble all ash a ccumula tions

to be cffcctivC'ly washed off the s ha llow p art of

the a!-ihpa n , a nd into tho hopper, which is fitted

L O CO MOTIVE

opposite each t ube for fitting a nd cleaning purpose~;.

Tir o inner a nd oute r fire- boxes a rc stayed

together by Hl 2 rigid a nd 586 fl exible ~;tays, a nd

t he cro wn of the inne r b ox is supported by 254

rigid roof stay~; a nd twenty-four sli ng ~;tayl'>,

whi ch comprise th o first t wo ro ws at the tube pl a t e

end . The rig id st ay:-; in the wat c·r space a r<} ~ in .

diameter·, and th e flex ible HtayH h<LVC' a, dia me ter

of ~ in . st"rcwccl 4in . dia m<'k r in t lw inner fire- box

plates. T he roof st <tys have a di<~ uw te r of I ?1, in .

with <~ s liding bottom operated f rom the footplate. T he boiler a nd fire-box a re complet ely

cloth ccl with R oberts' Blue Asb est os Ma ttras,

covered with pla niHhed st eel pla te, which is

supported on a crinoline a nd bound by stainless

st eel bands.

The smok e-box i ~; bolted to t he half saddles

ca~; t with each of the cylinde rs, a nd th e boi le r·

ba rrC' I .is supported a t four p oints by diaphragm

phttt'H Hccured t o fra me H trc tcher~; a nd t o t ee

IYurlun9 Prc.,surc 22.5 lb per square tncl>

--Water Capacitv 9500 gallons

PRI N C I PA L

The ~;ectio n if> 4in. by 4in . At the foundation

r ing the length of the fire-box inside the throat

a nd back plates i~; 8ft. 6ll / 64 in . a nd th e widt h over

the wr a pper pla t e is 8ft . 9i in. 'J'h e g rate ha~; a n

inclina tion of 1 in 8 · 5 a nd a n a rea of 62 · 5 ~;quare

feet . I t iR of th e round -hole t a ble pattern, a nd

iH a rra nged with Hha king gr a r , ha nd oper a ted .

There is a lso a, clrop sec:tion to facilitate c·loaning.

t

J~

r.l •

'Of •;) .•

t

8"5'

- 'z.

4-

DIMENSI ON S

OF

L OCOMOTI VE

scre wed Ijin . in t he fire-box crown , a nd 1 ,'t in.

in the nut. All have eleven t hreadH pe r inch .

Al l thr Htay~ a rc of Brown Baylry's" Longst ra nd "

or 1 'teel 1 'ymbol 1 't . C. J0 · 6 J, s u ppli cd by 1 'ta h !werke Bruningha us A .G . The same mate rial~;

a rc used for the eight een palm stays. 'T'he ash pan

is of steel plate, <'l ectrically welded , and is of th e

hoppe r t y pe, a ncl iH c:arriod on t he mn,in fntmos.

-

i

81

1

I

.!:!

•<::>

•<o

<o•

1. '

\

-

0/a

SECTION ON A· 8

llw••• 'k

T HC [ H QIH(. t ~··

A RRANGEM ENT

OF

BOI LER

AND

STEAM

COLLECTOR,

sections ri veted to the underside of t h e barr el,

which is reinforced by liner pla t es on the inside

where the t ees a re fitted . At the fr ont corners

the fire- box is carried by slides formed to fit

footings machined in t ho founda tion r ing. They

a r e 9Fn. wide a nd Sin. long, and bear on liner

p la tes of s teel fixed in cast steel brackets bolt ed to

th o main frameH. The s lides a rc each fitted with

two g rease nipples for lu bri cation . At tho hind

e nd the fir<'- box is furthC'r carried h •y <t vertical

plato bolted t o th o hind drag box <·asting a nd t o

<L projection machined in tho founda tion ri ng.

Boile r feed is s upplied by two GrrHham anrl

( 'r<tvrn No. I :3 se lf-acting, non -lift ing injectors

<U' r<tnged unde r th o footpla t r. t They a.rC' s pecified

t o h<we a capacity of about :31{,000 I b. of wat(:'r

per hour a t full boilPr p ressure, and d elivery is

mad e throug h t wo t op-feed check val ves mounted

on the front end of t he ba rrel, the wa t er being

fed through nozzles into t rays carried in the

top of th e ba rrel, a nd d esigned to a llow a ny air

t o escape a nd thus minimise corrosion .

Firing i!> by m eans of a mech a nical st oker

su pplied by the 1 'tanda rd 1 'toker Uompa ny,

Eric, Pa., U .~ '.A . It consist s of t wo scre w con voyorH, ono a rranged in the bottom of the coal

bunkC'r on t he t ender c·cntre line, and a nothe r

a rti cula t<.-d from it, a nd Rloping upward a t a n

t F orty

t·n~i tWH

h1wc. l> tWII'H und ~INN1l ft• t• xh tttiHt 11tram

injN·tortt on t lw lt·lt-hn nd Hld CI tlncl 11 Gr«'flh um a ncl ('r!Wt'n

Xo. l :l Hf"lf.u.c·tmg mjN·Ior on lht• r1~h t hnnd tndr·.

224

a ngle to the fire door. The conveyor is driven

through gearing by a two-cylinder, t ota lly enclosed ,

reversible engine mounted on the tender in a space

on the left-ha nd front corner . The coal is carried

by the screw through a crusher, and from t hence

is elevated to the fire door, where it falls on a

tray inside the fire-box, from which it is blown

off by jet s of steam , the intensity of which can be

controlled by the fireman. In this manner it is

possible to distri bute the fuel as required on the

grate surface. Steam to the stoker engine is

t aken from one of the turrets t hrough a control

valve, a nd by a ball-ann .socket universal connection between the engine and tender, and the

exhaust is taken by a metallic flexible pipe back

to the engine, and is discharged into the base of

the chimney in the smoke-box. The stoker is

capable of delivering 15,000 lb. of coal per hour,

equal to about 240 lb. per square foot of grat e

per hour. On test at the makers' works the

capacity was 10,500 lb. per hour at an engine speed

of 550 r .p.m.

The boiler fittings consist of two t urrets of cast

steel mounted on the fire-box. They are fitted with

all the valves required for the various auxiliary

purposes, and take steam t hrough internal pipes

of 3in. diameter , connecting with the main steam

collector in the boiler . All the turret valves are

fitted with extension spindles passing t hrough the

....

..

~

<>

0

.

----

11 Thds. per inch

Steam Tight

11 Thds. per inch

Thread Taper

'lt in T2

Square Head to

be Cut-off after

Screwing in

,'~~~;t"--.1...

SWAIN

FIRE - BOX

ROOF

AND

FLEXIBLE

Se.

STAYS

front of the cab with hand wheels within reach of

the engine men. There are two blow-off valves,

one on each front corner of the throat plate. They

are of the Gestra make, and may be steam-operated

from the cab. They arc fitted with silencers. This

type of blow-down valve is fitted to 121 engines,

and the remaining fifteen, comprising part of the

first twenty, have H opkinson valves operated by

connections to the cab. A Diamond soot blower is

a lso fitted . The water gauges are of Dewrance

make . Two Ross pop safety valves are fitted on

the rear ba rrel course. The smoke-box, which is

8ft. 4!in. long and 6ft. S!in. diameter outside, is

fitted with a spark arrestor, the arrangement being

genera lly similar to that found in American practice. The blast pipe has a gun-metal cap, comprising the nozzle fitted with Goodfellow proj ecting

pieces, and having a diameter of 6fi-in., combined

with t he blower ring a nd an additional outer ring

which connects with the eject or exh aust. The

chimney extends into the smoke-box t o a point

5!in. from the boiler centre, a nd has a diameter

at t he choke of lft. 8!in. and at the top lft. lOfi-in.

Behind the chimney a detache..blc cover gives access

to the regulator valves.

STEAM SUPPLY TO THE CYUNDERS

•

MARcH 8, 1940

THE ENGINEER

The. main steam supply t o the cylinders is by

m eans of t wo internal steam collectors, made up of

lengths of 5in. bore steel piping running parallel

inside the top of the boiler. At about half way in

their length they join a cast iron junction casting

having five flanges, two on each side, to take the

front and rear collector pipes, and at the front

facing the smoke-box an additional connection

which receives the main steam pipe, passing forward

along the boiler centre a nd between the t wo front

lengths of the collector pipes to the superheater

header. The main steam pipe, also of steel, has a

bore of 7in. The collecting pipes are fitted with a

number of small diameter pipes with trumpetshaped ends, which proj ect upwards in the steam

space t o points close to the inside of the barrel

plating. In this manner the steam is taken from

the highest point possible from the surface of the

water. The regulator is of the multiple valve type

supplied by the Superheater Company, and incorporated in the superheater header casting. The

valves are, however , on the saturated stea m side,

and not on the superheater steam side, between the

header and the steam chests. From the superheater to the cylinders the steam is conveyed by

two seamless st eel branch pipes, of 6in. bore. An

expansion joint on the steam chests ta kes the form

of a gland fitted with packing rings, the ends of the

branch pipes being machined so that they may slide

in the rings. The pipes pass t o the steam chests

through a suitable asbestos-packed gland in the

steel castings fixed to the smoke-box.

(To be continued)

Son1e 0 bservations on Metallic

Arc Fluxes

By W . ANDREWS, B.Met.

H E progress of fabrication by metallic arc

welding has now become so familiar that it is

rather surprising that some degree of standardisation of the t ypes of flu x coating used has not

yet begun to develop. Manufacturers of electrodes

offer the welding industry a very large variety of

products and the range appears to be expanding,

rather than contracting, into a number of recognised

t ypes. The reasons for this lie partly with the

inspection authorities, partly with the users of

electrodes, and partly also with the manufacturers

t hemselves. The inspection authorities are content

to specify certain physical properties which the

electrodes intended for use on work under their

supervision must attain. Provided that their

requirements, which , of course, are the subject of

continuous research and development, are satisfied,

they have not attempted as yet to formulate any

rules as to the constitution of the flux. The

consumer of electrodes, in addition to the foregoing

requirements, has problems of his own connected

with operative difficulties and the economic aspect

of fabri cation, which do a great deal to influence

the production of a variety of types. Finally , the

manufacturer has developed his product as a

resul t of difficult and complicated experimental

work which lacks, so far, t he solid backing of a

volume of academic work bearing on the particular

problems encountered. These conditions naturally

make for a wide range of products and secrecy as

to their composition and methods of manufacture.

In order to simplify the approach to the subject,

it is proposed to confine this article to the arc

welding of mild steel only, to endeavour to classify

broadly the types of electrode available and to

examine t he c har~cteristics of t he t ypes of elect rode which have been developed to fill engineering

requirements. In the first place, the term mild

steel should be defined as including t he b ulk of the

low carbon steel used for general engineering

purposes and largely covered by L loyds specifications for steel for shipbuilding, similar Admiralty

and other government department requirements,

and the various British Standard Specifications

for structural steel, boiler plate, &c. All this

material is of a maximum of 0·25 per cent. carbon

content, and in consequence is practically immune

to any serious modification in its properties as a

result of the t hermal disturbance inevita.bly introduced by a fu sion welding process. This has been

an important factor in t he rapid development of

the metallic arc process since it has concentrated

attention on a low carbon weld metal, capable of

developing adequate strength together with high

ductility and toughness.

The flux coating on a metallic arc electrode

fulfils a variet y of functions, among which the most

important are its effect (1) in controlling the

electrical characteristics of t he arc ; (2) in modifying

t he mechanism of metal fusion and consequently

transmission across t he arc; (3) on the metallurgical reactions occurring in the molten weld metal

during its passage th rough the arc, and (4) on the

shape and surface finish of the resultant welding

bead. Other subsidiary effects could also be

defined, but it is obvious that the combination of

physical, electrical, and metallurgical conditions

gives a wide choice of possible fluxes. In addition

to the technical reasons, the operative a nd economic

factors are also extremely important. The former

often necessitate different electrodes for reasons

of ease of handling and application. The latter

T

controls such items as speed, cost, and efficiency.

This diversity is further increased by the inevitable time lag due to conservat ism, and for this

reason many out -dated types of electrode often

remain in use and continue to be manufactured.

The classification of fluxes is complicated by

the necessity for considering methods of manufacture. T he majority of modern flu xes consist of

a mixture of minerals, chemicals, and alloys

homogeneously bonded with an alkaline silicate

solution. Subsequent drying gives a hard cement

of reasonable permanence, though all fluxes sufft'r

deterioration if stored for any length of time under

excessively damp conditions, especially where the

atmosphere contains in addition a high proportion

of carbon dioxide.

The earliest fluxes, of course, were much simpler

in composition than t hose in general use to-day,

and often consisted of simple iron oxide-silicate

mixtures. The fact t hat iron oxide silicate compounds are found occurring naturally as a grade of

blue asbestos led to the extensive use of this

mater ia l, as a flux in itself, and the ease with which

it could be applied as a close cord winding gave it

considerable popularity. Such wrapped electrodes

continue to be made, though the advance in the

metallurgy of weld metal has compelled the

abandonment of the earlier contentions of

superiority attributed to the use of a natural

compound as compared with synthetic materials.

From the nature of alkaline silicate solutions

and the general a nalogy to the manufacture of

refractory materials, it is obvious that in t he

manufacture of a paste flux there are several

methods of handling the problem of coating a wire

satisfactorily. For instance, the dry flux mixture

may be suspended as a slurry in a dilute solution

and the wire coated by dipping, as in the manufacture of candles, or a stiffer mixture may be

applied by pressing, rolling, or extrusion through a

die. I n modern practice the majority of electrodes

are made by extrusion of the flux as a paste through

a suitable die, though the dipping process survives

for certain special types of work. The extrusion

process makes use both of the original patented

continuous winding of cotton, asbestos, or other

suitable material to ensure absolute concentricity

of flu x and core wire, and of plain extrusion without

winding, the latter process giving a homogeneous

cylinder of flux round t he electrode. Representat ive electrodes of each type are easily recognised

by their appearance.

The silicate solutions used as the binding agent

are either. sodium or potassium silicates, used

separately or mixed in various proportions, varying

in composition and specific gravity according

to the ratio of all(ali to silica, which has t he

properties of final strength, permanence and

fusibility most congeni~l to the flux powder

employed. I n the case of plain extruded electrodes, where the nature of the flux may not be

such as to form a smooth-flowing paste, it is

sometimes desirable to incorporate with t he

silicate solution some organic compound, which

vapourises easily without appreciable effect on

the quality of the weld metal, in order to assist in

the flow of paste through the extrusion die, and

in the production of a smooth even coating on t he

final electrode. Other non-organic materials may

also be used for this purpose.

The actual compositions of the flux powders

remain, in the vast majority of cases, manu-

..

MA.Rcn 8, 1940

facturers' secrets and little information has been

published on the subject. The general principles

of electrode flux compositions, however, are fairly

well known, and in most commercial mild steel

electrodes they usually consist of mixtures of

mineral silicates, ferro-alloys, metallic oxides,

fluorides, and carbonates, together with organic

compounds, apart from those used to assist extrusion . Economic conditions demand that the

materials should be plentiful and reasonably cheap

so that natural minerals, rather than prepared

chemicals, are more frequently used.

Apart from the chemical and physical properties

determining the value of a flux ingredient, one

essential is that it should be inert t o the silicate

used as a binder. If it has any tendency to

cementing action, or t o combination with silicate

to for~ a more complex compound, premature

set ting is experienced and the paste loses plasticity

and becomes unworkable. Similarly, compounds

of a strong acid and a weak base are liable to · be

attacked by the excess alkalinit y of the silicate

with the precipitation of gelatinous silica and

again complete loss of plasticity. This practical

requirement l imits the adoption, without special

t reat ment, of many materials which would otherwise be useful as flux ingredients. An example of

t he tendency to double silicate formation is calcium

hydroxide which will, in a short time, cause a silicate

bound paste to set to a hard cement. Similarly,

some chlorides, e.g. aluminium chloride, are acid

in reaction and cause instantaneous separation of

gelatinous silica from the silicate. Even milder

acid radicles, e.g. boric acid in combination with

weak bases, may have this effect though special

protective t reatments can in some cases be developed. Except in certain cases, however, the

flux material need not be completely water

insoluble, so long as the product of solution has a

neu t ral reaction.

The most frequently used of t he various mat erials

are as follows : -Of the silicates kaolin, the soda

and pot ash felspars, less frequen tly the lime bearing

variet ies which have higher melting points, the

pyroxenes such as enstatite [(MgFe) O.Si0 2 ] and

diopside (CaO MgO 2Si02 ), t he amphiboles,

particularly the various grades of asbestos represented in this class, potash, and more rarely

magnesian mica (the sodium mica, paragonite, is

not commercially available), minerals of the talcserpentine group which also includes t he Canadian

asbestos, chrysotile, and occasionally less plentiful

materials such as some grades of garnet. Of t he

met allic oxides, t he various different grades of iron

oxide are widely l..lSed, including hematite of

varying silica content, magnetite and those grades

known as micaceous iron oxide owing to their

mode of occurrence. Other frequently used

met allic oxides are the various oxides of manganese,

t it anium oxide, either as r utile, which is usually

of at least 95 per cent. purity or as the various

grades of ilmenite which are available, and

occasionally zirconium oxide. As explained previously , calcium oxide, or rather t he hydroxide,

cannot readily be used in conjunction with silicate

solutions but , owing to its much greater insolubility, caustic magnesia obtained by calcining

magnesite reacts very much more slowly and is

consequently a practicable material.

Most of t he better known ferro-alloys are regular

constituen ts of flux coatings as a means of introducing alloying elements. The most familiar

and importan t of these are t he ferro-manganese

alloys, bot h low carbon electric furnace quality,

or t he low grade form containing up to 6 per cent. of

combined carbon. The main use of manganese as

distinct from an alloying material, is as a deoxidant,

just as in steel making, and most high grade

electrodes contain a sufficient proportion to

compensate for that oxidised out of the weld metal

during exposure to the high temperature of the arc.

Ferro-silicon is also used for a similar purpose,

but here trouble is often encountered oWing to its

suscept ibility to chemical attack by the alkaline

silicate solutions, unless special precautions are

taken. Ferro-titanium andferro-vanadium, though

expensive, may also be used for deoxidation in

combinat ion wit h some of these alloys. Other

ferro-alloys, or pure metals, are used where an

alloy steel deposit is being made up synthetically,

or where the loss during welding has to be compensated for.

The carbonates used include all the forms of

calcium carbonate commercially available, such as

limest one of high purity, calcite, crushed marble

powder , and precipitated forms of carbonate.

Dolomite and magnesite are extensively used

and the latter may also be used in the calcined

form since its insolubility and low reactivity as

THE

225

ENGINEER

compared with calcium oxide render it practicable.

Calcined or dead burnt dolomite has to be specially

t reated owing to its high calcium oxide content and

consequent reactivity with silicate solutions.

Manganese carbonate, as rhodochrosite is frequently employed as a flux constituent and there

is a wide usage of the various mineral oxides of

manganese, notably braunite (Mn2 0 3 ) hausmannite (Mn3 0 4) and pyrolusite (Mn0 2). The

former two are often calcined to eliminate organic

matter and ensure reasonable constancy of composition. Chalybite natural iron carbonate is rarely

used since it is practically always found associated

with phosphate impurities. Similarly, the natural

barium carbonate, witherite, is often associated

with lead and sulphur, and on this account may be

unsafe to use. Lead impurit ies are undesirable

because of their generally low boiling points and

the danger of poison associated with them, and

sulphur, of course, because of its known deleterious

action on steel. Another carbonate which has

been proposed and used to some exten t is strontium

carbonate, found as the mineral strontianite, but

as the latter is not particularly abundant the

chemically produced material must be used and

price considerations interfere. I n addition the

alkaline carbonate of sodium and potassium are

extensively employed.

Besides the oxides of manganese and iron, other

metallic oxides are also employed. By far t he

most important of these is the di-oxide of titanium,

found as the mineral rutile (the other crystalline

varieties, brookite and anatase, are comparatively

rare). Zirconia, a similar higher melting point

material has been proposed and used to a small

extent and aluminium oxide has also a certain value,

but neither of these materials approaches rutile

in propert ies or popularity as a flux constituent.

The compounds of titanium in nature are scarce,

compared wit h t he silicates, and only t he various

grades of ilmenite, compounds of iron and tit anium

oxides, form an alternative supply of any

abundance. Sphene or t itanite, calcium silicotitanate (CaO Si0 2 T i0 2 ) is a possible alternative

but is little used on account of irregularity of

supply and composition. It is also liable to

be contaminated with p hosphates. Perovskite,

the pure calcium titanate, would probably be

useful but does not appear to occur in commercial

quantities.

I n addition to t he mineral constituents and

binding agents used in fl uxes t here are, in many

cases, organic materials incorpora ted for various

reasons. B riefly, these can be divided into two

types ; first, t hose added for their effect on the

mechanical behaviour of t he flux either in improving smoothness in extrusion , final flexibility of

the coating after drying, or for other reasons

connect ed with t he manufacturing process.

Secondly, the large class of cellulosic and similar

compounds used in so-called gas shielded electrodes. The theory behind t he use of these

latter materials, which are all based on t he presence

in the electrode flux of a material based on the

(C6 H 10 0 5 )x type of molecule, is t hat under the

condit ions obtaining in t he metallic arc, primary

decomposit ion occurs into a mixture of carbon

monoxide and hydrogen which surrounds the

molten metal and slag wit h an intensely reducing

atmosphere, serving to exclude contaminat ion by

oxygen and nitrogen . Owing to the large p roportion of hydrogen present in this arc atmosphere

it is also claimed t hat the electrical resistance t o

the passage of an arc is increased, resulting in a

higher arc volt age, more overall consumption of

energy in t he arc and consequently q uicker welding.

There has been, and con tinues to be, some cont roversy as to the j ustification of some of these claims

for the effect of these compounds. It has been

repeatedly p roved that plain slag fluxes, wit hout

any additions of this type of organic matter , can

produce weld metal equally low in nitrogen content .

Observation also suggests t hat there is little to

choose between high qualit y electrodes, with or

without gas shielding additions, from t he point

of view of iron oxide and other non-metallic

inclusions. Further, the highest physical properties in t he weld metal are obtainable from

each type. What is definite, however, is that the

nature of t he welding arc obtained from so-called

gas shielding additions is often very different from

that observed in plain slag electrodes. I t is

possible, in cases where the proportion of such

material is high, to obtain a very harsh direct arc

suitable for making welds on unprepared edges in

steel of substantial thickness or, in short, to use a

t rade term, having high " penetration "-an

obviously valuable feature for some classes of work.

Finally, having given a general outline of the

range of materials used in arc welding fluxes for

steel, the question of classification arises. It

would appear at first sight t hat it would be a simple

matter to classify bases as acid, basic, and neutral,

according to a preponderance of acid oxides, such

as silica, basic oxides, such as lime, or neut ral

materials. This method, however, has its

objectiop.s, one of them being that reactions in

the arc take place at much higher t emperatures

than in steel making pract ice and it is by no means

certain t hat the reactions occurring are truly

parallel. I t appears preferable, therefore, t o

adopt some system of classification dependent on

t he nature of t he const ituents used in the flux

coating and t he character of t he resultant slag.

The following system is tentat ive only and does not

presume to include every t ype of electrode which

has been proposed or used for mild steel, nor does

it claim to deal with other t han British practice.

It does, however, cover t he majority of electrodes

in general use in this count ry and it is felt that it

may be of some assist ance t o users in assisting in

recognising t he various t ypes encountered . In

the first place t wo main divisions of electrode

coat ings must be recognised .

1. Arc Stabilisers only.

2. True Fluxes.

Applied as an ultra. thin wash only.

In which the coating may be light

or heavy, but fulfils the true function

of a. flux in modifying the action of

the atmosphere on the molten metal

to a greater or lesser extent.

Arc stabiliser coatings represent coatings applied ·

purely for electrical reasons, and have long been

substantially displaced from all bu t the most unimportant work. Owing, however, to the difficulties encountered in t he combination of an adequate flux with a continuous automatic welding

process a fair amount of welding is st ill carried

out using materials of this character to improve the

behaviour of the arc.

True fluxes in addition t o exercising their

effect on the electrical characterist ics of the arc

are employed for t heir metallurgical and mechanical

effect on t he deposit. According to whether t hey

contain cellulosic matter and are of t he so-called

gas shielded type, or rely on t he fl.uxing properties

of t he chemicals or minerals t hey cont ain, they

may be divided into:

1. Slag Shielded types.

2. Gas Shielded types.

Further, fluxes may be sub-divided by method of

manufacture, i.e. dipped, wrapped, wound, extruded

or plain extruded. It is probably best , therefore,

to keep met hod of manufacture and composition

of coating separate. The following is the final

proposed method.

1.

2.

3.

4.

Cl<usijication by Method of Manufacture.

Main head

Sub.head

Remarks

Dipped Process.

(a) Wash coating Singleverylightdip

nearly a lways too

small in quantity to

act as a true flux.

Usually an arc sta.

biliser only, e.g.

CaC08 and other

carbonates.

(/1) H eavy coating Several dips to give

a. coating thickness

of the same average

as extruded electrodes.

\\'rapped Process.

{a) Single

1\!e.teria.ls such as

coating.

blue asbestos which

lend

themselves

readily to ap plication to t he electrode

as e. yarn winding.

(b) Double

Two different coatcoating.

ings may be employed, the outer

one being similar to

(a), and the inner a

paste or other type.

Wound Extruded.

Cotton,

various

types of asbestos,

pa:per or other celluloslC material, all of

which may be re.

inforced with wire,

or wire itself may

be employed. The

winding agent forms

an open spiral round

the rod and the dux

is extruded into t he

spaces by passage

through a die under

pressure.

Plain Extruded.

A paste is extruded

directly on to the

rod, forming an un.

interrupted sleeve

of dux. Very stiff

pastes and high

pressures are usually employed and

a smooth intense

arc obtained. R ods

of this type are

difficult to bend

without breaking off

the coating.

T YPES OF F LUX COATING E MPLOYED

The constituent sub-heading gives t ype constituents only, e.g. where titanium oxide-silica

F

•

alloy is quoted it is intended to convey that a

metal oxide of the titanium type is used in conjunction with some silicate bearing mineral or

minerals in combination and the possible variations

in composition are almost infinite.

Type

I. Arc Stnbilis('lrs.

2.

log • hielded.

3. Gaa Shielded.

MARcH 8, 1940

THE ENGINEER

226

Constituent

Description

Car bona~ Ti01 See manufacture.

and similar

materials.

Iron OxideMixtures of various iron

Silica.

oxides and silica or silico.tes are used in various proportions. Blue

asbestos wrapped electrodes also come into

t.his olassincation, though

in this case a compound

instead of separate const.ituent.s is used. Tho

coating is oxidising and

in consequence the weld

metal contains little or

no manga.nese and low

carbon. It thus approximates in composition

to pure iron, though

porosity and slag inclusions may be frequent.

Electrodes of this class

are usually sold because

of the running properties

and finish obtainable on

the weld metal.

I ron OxideBasically similar to group

Silica Alloy.

(o) but of wider scope,

less oxidising in nature

and often modified by

carbonates and other

oxides. Electrodes of this

class contain de-oxidising

ferro-alloys, usually ferromanganese, and as a

result the weld metal

composition approaches

that of ordinary mild

steel. The slag of t his

type of weld metal is

usually inflated and very

easily removed.

Titanium Oxide- Titanium oxide, usually

Alloy.

in the form of rutile,

forms a large proportion

of the flux, together with

ferro -manganese

and

other alloys and 6uxing

constituents, such as

silicates. The high rutile

conten t results in fiat surface deposit of excellent

appearance and a solid

but easily removed slag.

T itanium Oxide- D iffers from the previous

ilica Alloy.

class of rod in tbat on

the average much less

titanium oxide and more

silicates are used. The

result is a slag of greater

adap tability for " three

position" welding.

Fluorides and

Fluorides are typical of

other chemicals. neutral mat.erials which

may be used to make an

effective flu.x.

Nal ural

calcium

fluoride or fluor.

sp ar •s a common example.

They are little

used in the case of mild

steel though useful in

non-ferrous metals and

special alloy steels.

As haa been explained,

this term applies to

electrodes in which in

addition to a mineral slog

an organic material of tho

cellulose class is incorporated. This organic

material is claimed to

decompose into carbon

monoxide and hydrogen

surrounding the arc with

a reducing atmosphere

and thus excluding oxide

and nitride contamination.

In consequence

the oxidising non-alloy

types are not represented

in this class, nor do

fluoride fhu:es find any

appreciable favour in

conjunction with such

material. Gas shielded

electrodes,

therefore,

usually fall into the t hree

middle classes of the slag

shielded type.

(a) Iron

Oxide-SilicaAlloy.

(b) Titanium Oxide-Alloy.

(c) Titanium

OxideSilica-Alloy.

The above classification is naturally somewhat

general in its scope and cannot, of course, be

claimed to include all the commercial electrodes on

the market. It will be found, however, that most

of the better known types can be placed in one or

the other of the e classifications and a little experience with the operation of an electrode and the

ob ervation of the type of slag produced from

known types soon enables the experienced engineer

to recognise the class of flux used. It is, for

instance, comparatively easy to distinguish an

all-silicate fiux from one containing high proportions

of titanium oxide, or to recognise the presence of

high proportions of fluorides. It is to be hoped

t hat as development of the use of welding occurs

this question of classification of types of fluxes will

be considered by the appropriate authorities and

some standard proposed wh ich will reduce the very

wide variety at presen t available.

Subn1erged Barriers for Shore

Protection

By E.

E.

R.

ITH its frontage of approximately 35 miles

along the west side of Lake Michigan, the

city of Chicago, U.S.A., has a serious problem in

protecting its shore line fr om devastation and

erosion by the waves and currents of heavy storms,

more especially those from the north-east, which

have a sweep of 100 miles or so across the open

lake. Nearly 30 miles of this lake fr ontage consists

of public parks, extending north and south of the

mouth of the Ch icago River. This river mouth is

closed and controlled by a navigation lock, and

the regulated flow is from the lake and through

or " up " the river. A large water area adjacent

to the mouth of the river is a ship and yacht

harbour, protected by a concrete breakwater. In

this area is a masonry pier nearly a mile long,

having ships' berths, two-storey transit sheds, and

large recreation spaces for public use. Private

property, steel works, industrial plants, and railway

lines occupy some relatively short portions of the

lake frontage. There are occasional sand beaches

W

TRAT.MAN

storms, interlocking concrete sheet piles were

driven along the toe of the paved beach. But

here again the waves would break or displace the

piles, forming gaps through which the water would

drive in with force and blow up the paving in

great blocks. A small portion of t he frontage

has a concrete sea wall of limited height, generally

with loose r ock filling in front, along t he lake

bottom. None of these protective works provided

facilities for bathing, but with the growth of the

city and the development of its lake-front parks,

it became very desirable to increase the extent of

sand beaches.

Some twelve years ago an experiment was tried

by building off-shore protective works out in

deep water, instead of along the shore line, the

structure consisting of a submerged barrier or

breakwater. The theory was-and it seems to

have been proved by experience-that t he sweep

of the waves would be broken up by the obstruction,

so that their destructive force would be dissipated

New Pier

•

605 fl . Rad. -

-.

Former

Jetty No. 1

,,

\ ,, aocH

\~

,,

•

''THl EHOINICA"

FIG. I - SHORE

\\

-----

,,

Sea

\\..

Former

... ~ ...- ---~,___,.,., .,....,

---

PR O TECTI O N

W O RKS

for bathing and recreation, but they are liable to

severe erosion by storms, although the ravages

are in some cases remedied by pumping in great

quantities of sand from large hydraulic or suction

hopper dredges. Jetties have been used in some

places for protection, but generally without much

effect.

A large proportion of this lake-front park area

consists of made land, filled in gradually from time

to time. Usually a bulkhead or sea wall was built

in the water along an adopted shore line and filling

by tipping was carried on until it reached the

bulkhead, which then became the line of shore

protection . One of the earliest forms of construction for the construction of bulkheads, and

also for water front protection of existing land,

consisted of two parallel rows of timber piles,

connected by longitudinal waling timbers and

transverse wooden struts and iron tie-rods, with

rough rock filling for the space between the rows

and a capping of massive quarry blocks laid at

random to give an irregular surface approximately

5ft. above the water level. In time, however,

some of the piles would be loosened or broken by

wave action and ice pressure, and the bottom

eroded by waves or undertow, so that the rock

filling would settle, perhaps breaking or displacing

more piles, so that breaches would be formed.

Repair of such construction was not an easy

matter, and in many cases it was neglected.

Another p lan was to build a flatly sloping paved

beach, consisting of concrete poured in place in

large slabs, or of deep stone block paving on a

concrete base. The slope was about 1 in 12, and

the toe-a little above normal water-level-was

protected by a line of timber piles and sheet piling.

I n some places, mainly for reconstruction after

ON

THE

..

... .....,........ • .. -

L I N C OLN

__Wall

,._,.....,.-- ... -·--'- _ _,. e.

PARK

FRONTAGE

or expended in the semi-enclosed stretch of water

between the barrier and the shore. Furthermore,

the retreating water would oppose the incoming

waves. In addition, the undertow flowing back

along the bottom would strike the inner side of t he

submerged barrier and thus be compelled to rise

vertic&lly, t his upward flow assisting to break up

the s'veep of water shoreward over the barrier.