Safety, operation and performance of grid

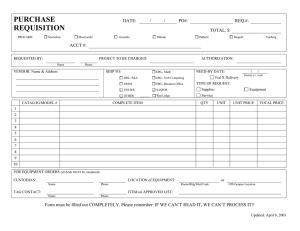

advertisement