Primetals Technologies Japan, Ltd.

A joint venture of Siemens,

Mitsubishi Heavy Industries and Partners

Tokyo office:

Shintamachi Bldg.

34-6, Shiba 5-Chome, Minato-ku,

Tokyo 108-0014, Japan

Phone: +81-3-5765-5231

Hiroshima Works:

6-22, Kanonshin-Machi, 4-Chome, Nishi-ku,

Hiroshima 733-8553, Japan

Phone: +81-82-291-2181

primetals.com

Brochure No. : June 2015/T05-0-N086-L4-P-V1-EN

Printed in Japan

© 2015 Primetals Technologies Ltd. All rights reserved.

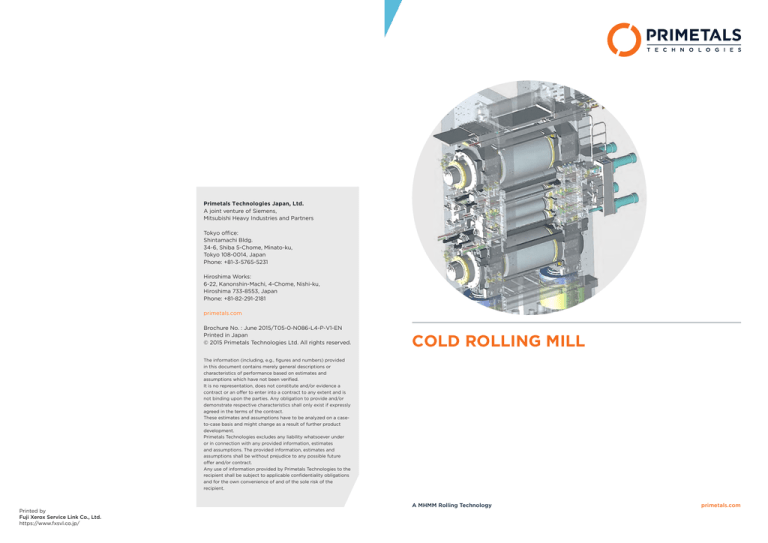

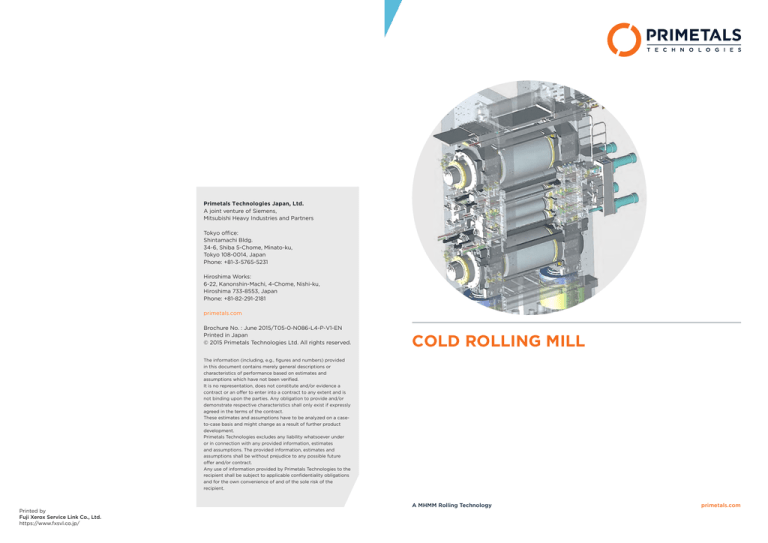

COLD ROLLING MILL

The information (including, e.g., figures and numbers) provided

in this document contains merely general descriptions or

characteristics of performance based on estimates and

assumptions which have not been verified.

It is no representation, does not constitute and/or evidence a

contract or an offer to enter into a contract to any extent and is

not binding upon the parties. Any obligation to provide and/or

demonstrate respective characteristics shall only exist if expressly

agreed in the terms of the contract.

These estimates and assumptions have to be analyzed on a caseto-case basis and might change as a result of further product

development.

Primetals Technologies excludes any liability whatsoever under

or in connection with any provided information, estimates

and assumptions. The provided information, estimates and

assumptions shall be without prejudice to any possible future

offer and/or contract.

Any use of information provided by Primetals Technologies to the

recipient shall be subject to applicable confidentiality obligations

and for the own convenience of and of the sole risk of the

recipient.

A MHMM Rolling Technology

Printed by

Fuji Xerox Service Link Co., Ltd.

https://www.fxsvl.co.jp/

primetals.com

COLD ROLLING MILL

CONTENTS

We are pleased to introduce our Cold Rolling Technologies developed to meet recent market requirements.

2XUFXVWRPHUVZLOOHQMR\WKHEHQH´WVIURPRXUVWDWHRIWKHDUWWHFKQRORJLHVKLJKTXDOLW\SURGXFWVZLWKVWDEOHRSHUDWLRQ

1. TANDEM COLD MILL (TCM)

……… P3

-

P10

……… P11

-

P16

……… P17

-

P18

IRU&DUERQVWHHO+LJK6WUHQJWKVWHHO6LOLFRQVWHHO

7LQSODWHDQG6WDLQOHVVVWHHO

Recent Market Trend

Production capacity : over 800 Kton/year

5HFHQWO\$XWRPRELOHPDQXIDFWXUHUVKDYHEHHQ

GHYHORSLQJHOHFWUL´HGYHKLFOHVZLWKOLJKWVWHHO

body structure designs that reduce mass and

WKHUHIRUHJUHHQKRXVHJDVHPLVVLRQVRYHUWKH

YHKLFOH

VHQWLUHOLIHF\FOH

2. REVERSING COLD MILL (RCM)

7KH6WHHO0DUNHWLVWUHQGLQJWRZDUGVWKLQQHUDQG

harder products. Facilities are required to

produce these products in higher volumes and

under stable operating conditions.

IRU&DUERQVWHHO+LJK6WUHQJWKVWHHO6LOLFRQVWHHO

7LQSODWHDQG6WDLQOHVVVWHHO

4XRWHGIURP:RUOG$XWR6WHHO

3URGXFWLRQFDSDFLW\DSSUR[.WRQ\HDU

Market

0XFK7KLQQHU*DXJHV

6LJQL´FDQWO\+DUGHU0DWHULDO

+LJKHU3URGXFWLYLW\

Excellent Product Quality

3. DOUBLE COLD REDUCTION MILL (DCR)

PDLQO\IRU7LQ3ODWH

Production capacity : approx. 200 Kton/year

Solution

6WDEOHRSHUDWLRQZLWK

6PDOOHU:RUN5ROO

+L8&00,//

('&E\:56

.H\7HFKQRORJLHVGHYHORSHGLQFOXGH

UCM-MILL +L8QLYHUVDO&URZQ&RQWURO0LOO

HYROP-F: +\GUDXOLF5ROO3RVLWLRQLQJZLWK)09

EDC by WRS : (GJH'URS&RQWUROE\:RUN5ROO6KLIWLQJ

Carrousel Tension Reel

Double AS-U : 6KDSHFRQWUROV\VWHPIRU&OXVWHU0LOO

4. TEMPER/SKINPASS MILL (TPM/SPM)

……… P19 - P20

IRU&DUERQVWHHO+LJK6WUHQJWKVWHHO7LQSODWH

DQG6WDLQOHVVVWHHO

3URGXFWLRQFDSDFLW\DSSUR[.WRQ\HDU

,QOLQH7HPSHU6NLQSDVVPLOOLVSDUWRI&RQWLQXRXV$QQHDOLQJ

/LQH&$/DQG&RQWLQXRXV+RW'LS*DOYDQL]LQJ/LQH&*/

5. CLUSTER MILL

……… P2 1

-

P26

IRU&DUERQVWHHO+LJK6WUHQJWKVWHHO6LOLFRQVWHHO

7LQSODWH6WDLQOHVVVWHHODQG&RSSHU$OOR\

Production capacity : approx. 100 Kton/year

'RXEOH$68

1

+L&OXVWHU5ROOLQJ0LOO

Carrousel Tension Reel

2

1. TANDEM COLD MILL (TCM)

SUPPLY REFERENCE LIST & PRODUCT CATEGORY

Silicon Steel

Carbon

Technology Applied To Cold Rolling Mill

Feature of Mill Type

Mill Type

WR

Bender

IMR

Bender

WR

Shift

IMR

Shift

User

Mill Type

UCM

UCM-MILL was added intermeided Roll Bender mechanism to HCM-MILL.

UCMW-MILL was added work roll shift mechanism to UCM-MILL.

For production of high quality strip,

roll management is a critical issue.

For this purpose, fully automatic high

speed roll changing equipment is

provided for the TCM.

Delivery Strip Handling Device

The endless rolled strip is divided by the

high speed ROTARY SHEAR and

re-wound into coils.

The CARROUSEL type TENSION REEL

FRQ´JXUDWLRQLVDSSOLHGWRVXSSRUW

continuous coil changeover during

continuous rolling in the mill section.

Coil changeover operation is achieved

through automatic control blocks for

reliability and ease of operation.

Inspection Station

HYROP-F System

HYROP-F System consists of

- Direct operated servo valve, FMV (Force Motor

Valve), specially developed for rolling mill

- Hydraulic push up cylinder with built-in precise

position detector

- Well arranged hydraulic piping for high response

- Exclusively designed Control System By the

combination of each component,

high performance and reliable roll load system

are realized.

To produce high surface quality

VWULSDKLJKHI´FLHQF\LQVSHFWLRQ

station at the TCM exit end is

essential. Vertical elevator type and

various other types of inspection

stations, such as the inline type,

ZHUHGHYHORSHGIRUHI´FLHQW

two-side inspection.

Products

Start-up

2006

Sheet

1982

27

Benxi Steel

(China)

2

Nisshin Steel

(Sakai)

Galva.

1985

28

Wuhan Steel

(China)

Silicon

&

Sheet

2006

3

Kawasaki Steel

(Mizushima)

Sheet

1986

29

Maanshan Steel

(China No.2)

Galva

&

Sheet

2007

4

NKK

(Fukuyama)

Sheet

1987

30

Union Steel

(Korea)

Galva

&

Sheet

2007

5

POSCO

(Pohang No.2)

Sheet

1987/

2003/

2007

31

Shougang Jingtang

Steel (China)

Galva

&

Sheet

2009

6

UPI

(USA)

Tin

&

Sheet

1988

32

Jiuquan Steel

(China)

Galva

&

Sheet

2009

7

I/N Tek

(USA)

Sheet

1989

33

POSCO Vietnam

(Vietnam)

Galva

&

Sheet

2009

8

POSCO

(Kwangyang No.1)

Sheet

1988/

2006

34

SeverStal

(USA)

Galva

&

Sheet

2010

9

POSCO

(Kwangyang No.2)

Sheet

1990/

2009

35

Baoshan Steel

(China BST)

Sheet

2010

10

Nippon Steel

(Yawata)

Galva

&

Sheet

1990

36

Guangzhou JFE

(China)

Galva

&

Sheet

2010

11

POSCO

(Kwangyang No.3)

Tin

&

Sheet

1991

37

Shougan Qian'an

(China)

Sheet

2010

12

DOFASCO

(Canada)

Tin

&

Sheet

1992

38

China Steel

(Taiwan No.3 PLCM)

Galva

&

Sheet

2011

13

China Steel

(Taiwan)

Sheet

1992/

2007

39

Shougang Jingtang

Steel (China No.3)

Tin

&

Sheet

2013

14

Sumitomo Metal

(Kashima No.2)

Galva

&

Sheet

1993

40

Wuhan Steel

(China)

Tin

2013

CVC

15

TON YI

(Taiwan)

Tin

&

Sheet

1995

41

Panzhihua Steel

(China)

Galva

&

Sheet

2013

16

ERDEMIR

(Turkey)

Sheet

1995

42

Hyundai HYSCO

(Korea)

Galva

&

Sheet

2013

17

NKK/TCRSS

(Thailand)

Galva

&

Sheet

1997

43

POSCO Maharashtra

(India)

Galva

&

Sheet

2013

Sheet

1997

44

Ternium

(Mexico)

Galva

&

Sheet

2013

1998

45

Shanxi Taigang

Stainless Steel

(China)

Silicon

&

Sheet

2013

1998

46

Baoshan Steel

(China Zhanjiang)

Galva

&

Sheet

2016

BaoTou Steel

(China No.2)

Galva

&

Sheet

2015

Galva

&

Sheet

2015

Tin

&

Sheet

2016

Silicon

&

Sheet

2017

18

HYROP

YROP System componen

component

Mill Type

User

Nippon Steel

(Hirohata)

PC

The UCM-MILL makes it possible to roll

products with straight rolls, allowing rapid

start ups.

See, page 5, 6.

No.

1

HCMW

UCMW

Products Start-up

Galva

&

Sheet

HCM

Roll Changing Equipment

3

Stainless

CONTINUOUS TANDEM COLD MILLS newly installed in the world after 1980

No.

Application of the UCM-MILL makes possible to roll all products with straight rolls, which will allow to

get rapid start up. The operators can derive most stable rolling and shape controllability. Thanks to the

horizontal rigidity created by shifting of intermediate roll, the user can control strip thickness deviation

without jeopardizing the shape of the strip.

The mill is equipped with a high response

Hydraulic Roll Positioning Device (HYROP-F),

Laser Doppler type speed measuring device

and X-ray type thickness gauge meters. This

equipment, combined with a high performance,

up-to-date Automatic Gauge Control (AGC)

V\VWHPZLWKPDVVµRZFRQWUROFDQDFKLHYHWKH

KLJKHVWVWDQGDUGVIRU´QLVKHGWKLFNQHVV$WWKH

exit of the mill, a modern designed shape

measuring sensor and Automatic Shape Control

(ASC) system is installed to guarantee the

UHTXLUHGµDWQHVVRIWKH´QLVKHGVWULS

Tin

POSCO

(Kwangyang No.4)

19

Hyundai Pipe

(Korea)

20

SUS/NSC

(Thailand)

Galva

&

Sheet

Tin

&

Sheet

21

Baoshan Steel

(No.3)

Sheet

2000

47

22

TATA Steel

(India)

Galva

&

Sheet

2000

48

23

Nisshin Steel

(Toyo)

Galva

&

Sheet

2000

49 Tosyali Toyo Steel

(Osmaniye, Turkey)

24

Maanshan Steel

(China No.1)

Galva

&

Sheet

2004

50

25

Baoshan Steel

(No.4)

Galva

&

Sheet

2005

26

Lianyuan Steel

(China)

Galva

&

Sheet

2005/

2010

Notes

: Shiftable roll

: Future plan

Guangxi Steel

(Fang cheng gang,

China)

Baoshan Steel

(Zhanjiang No.2,

China)

Market Share

Supplied

by

PTJ

Supplied

by

Others

Total

50plants

(64%)

28plants

(36%)

78plants

(100%)

PTJ

(64%)

Above Primetals Technologies Japan, Ltd. supply of 50

plants since 1980 will mark 64% on the world share of

the major Continuous TCM during this period

4

1. TANDEM COLD MILL (TCM)

1.1 UCM-MILL The Simple Approach to Best Performance

:LGH*DXJH5ROOLQJ

8&00,//VIXQFWLRQRQDYHU\VLPSOHLGHD,QRUGHUWRFRUUHFWWKHµDWQHVVDQGFURZQSUR´OHSUREOHPVFDXVHGE\ZRUNUROOGHµHFWLRQLQ

1DUURZ*DXJH5ROOLQJ

FRQYHQWLRQDOPLOOVWKH8&00,//DVVKRZQKHUHXVHVVKLIWDEOHLQWHUPHGLDWHUROOVWRVKDUSO\UHGXFHWKHXQGHVLUDEOHFRQWDFWDUHDWKDWLV

UHVSRQVLEOHIRUZRUNUROOGHµHFWLRQ8&00,//JLYHVPLOORSHUDWRUVJUHDWHUµDWQHVVFRQWURODQGVLPSOHRSHUDWLRQ

Intermediate Roll shifting

at Welding Point

Flying Gauge (Width) Change for Continuous Rolling

6LPSOH,QWHUPHGLDWH5ROO6KLIWPDLQWDLQVWKHEHVWSHUIRUPDQFHDWWKHYDULRXVFRQGLWLRQVRIWKHVWULS

8&00,//DFKLHYHVHYHUVWDEOHUROOLQJWKDWUHGXFHVWKHVWULSEUHDNDJHDQGH[WHQGVWKHUROOFKDQJHLQWHUYDO

4Hi-MILL

(L>W)

IDEAL MILL

L (Fixed)

(L=W)

UCM-MILL

L

W

Rolling load

Rolling load

(Changed)

Rolling load

Rolling load

%DFNXSUROO

%DFNXSUROO

Intermediate

roll bending

Intermediate roll

Work roll

Strip

Strip

Work roll

Work roll

Work roll

bending

bending

IMR

Shifting

8QGHVLUDEOH

FRQWDFWDUHD

8QGHVLUDEOH

FRQWDFW

DUHDLVHOLPLQDWHG

8&00,//

Flat

:RUNUROOGHµHFWLRQLVUHGXFHG

:KHQZRUNUROOGHµHFWLRQLVLQFUHDVHG

1 6RPHNLQGVRI,QLWLDOFURZQVDUHQHFHVVDU\IRUZRUNUROOV

1 . Straight Work, Intermediate

:RUNUROOLQYHQWRU\LVKLJK

DQG%DFNXSUROOVFDQEHXVHG

5HGXFWLRQRIZRUNUROOGLDPHWHULVGLI´FXOW

:RUNUROOGLDPHWHUFDQEHUHGXFHG̔+HDY\UHGXFWLRQLVSRVVLEOH

:RUNUROOEHQGLQJLVLQHIIHFWLYH

5

(GJHZDYH

̔5ROOLQYHQWRU\LVLPSURYHG

3. Work roll and intermediate roll

EHQGLQJDUHHIIHFWLYH

̔([FHOOHQWVKDSHFRQWUROFDSDELOLW\LVDFKLHYHG

(GJHGURSLVUHGXFHG

̔<LHOGLVLQFUHDVHG

6

1. TANDEM COLD MILL (TCM)

7KH7DQGHP&ROG0LOOIRU&DUERQVWHHOHVSHFLDOO\IRUDXWRPRWLYHDSSOLFDWLRQVUHTXLUHVWKHFDSDELOLW\WRUROOZLWKKLJKUHGXFWLRQUDWLRV

IRUH[WUHPHO\GHHSGUDZQPDWHULDORUUROOXQGHUKLJKORDGFRQGLWLRQVIRUKLJKVWUHQJWKVWHHO)RUVXFKUHTXLUHPHQWVDVWDQGV

Severstal NA (After 2014, AK Steel) PL-TCM (Dearborn, USA)

8&00,//RUDVWDQGVFRQ´JXUDWLRQKDVEHHQDSSOLHGLQFDVHRIH[WUHPHO\KLJKVWUHQJWKVWHHOV&RPELQHGZLWKD8&00,//IHDWXULQJ

VPDOOZRUNUROOVDQGDKLJKUHVSRQVH+<523)V\VWHPSURGXFWLRQRIWKHVHPDWHULDOVLVDFKLHYHGZLWKH[FHOOHQWJDXJHDQGVKDSH

MAIN SPECIFICATION

accuracy.

No.

1.

Item

2.

Speed

Carbon steel

Tin Hiten 980

Hiten 1180 or more

No.3

No.4

No.5

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

: Entry

Width

WRPP

Coil weight

0D[NJ

Pickling speed

: Max. 290 m/min

Rolling speed

0D[PPLQ

Strip dividing speed

: Max.

Laser Beam Welder

4.

Pickling Type

R

i BoxO

Type

Mill Type

to 6.35 mm

: Delivery 0.37 (0.30) to 2.67 mm

Welder Type

Mill configuration for High strength steel (for reference)

No.2

Thickness

3.

5.

No.1

: Hot Rolled Carbon Steel

Material

Main Feature

7KHZLGWKUDQJHUHTXLUHGIRUDXWRPRWLYHDSSOLFDWLRQVLVTXLWHODUJH,QRUGHUWRIXO´OOVXFKUHTXLUHPHQWV

the UCM-MILL's excellent shape controllability is an indispensable key technology.

6XUIDFHTXDOLW\ZLWKRXWUROOPDUNVDQGPLQLPDOUHVLGXDORLODQGLURQ´QHVDUHDOVRLPSRUWDQWIRU

DXWRPRWLYHDSSOLFDWLRQV7KHPLOOJXLGHV\VWHPDQGFRRODQWV\VWHPFRQ´JXUDWLRQKDVEHHQFDUHIXOO\

developed based on our vast experience to meet these requirements.

Description

Material

No.1

: 6Hi MILL (UCM)

No.2

: 6Hi MILL (UCM)

No.3

: 6Hi MILL (UCM)

No.4

: 6Hi MILL (UCM)

No.5

: 6Hi MILL (UCM)

250 m/min

No.6

LINE CONFIGURATION

UCM

Tension Leveller

Pickling Tank

TCM (5 Stands UCM)

Rotary

No.1 No.2 No.3 No.4 No.5 Shear

Side Trimmer

In-Line

Inspection

Welder

Looper

Looper

Looper

Pay-off Reel

Carrousel TR.

Hyundai Steel PL-TCM (Korea)

MAIN SPECIFICATION

No.

1.

Item

Material

Description

Material

: Hot Rolled Carbon Steel

Thickness

: Entry

1 .6։5.0 mm

: Delivery 0.30։2.3 mm

Width

WRPP

Coil weight 0D[NJ

2.

Speed

Pickling speed

: Max. 200 m/min

Rolling speed

0D[PPLQ

Strip dividing speed

: Max.

3.

Welder Type

Laser Beam Welder

4.

Pickling Type

R

i BoxO

Type

5.

Mill Type

No.1

: 6Hi MILL (UCM)

No.2

: 6Hi MILL (UCM)

No.3

: 6Hi MILL (UCM)

No.4

: 6Hi MILL (UCM)

No.5

: 6Hi MILL (UCM)

No.6

: 6Hi MILL (UCM)

250 m/min

LINE CONFIGURATION

Tension Leveller

Pickling Tank

Welder

Side Trimmer

TCM (6 Stands UCM)

No.1 No.2 No.3 No.4 No.5 No.6

Rotary Shear

Looper

Looper

Pay-off Reel

7

Carrousel TR.

Looper

8

1. TANDEM COLD MILL (TCM)

1.2 Silicon steel [Shougan Corporation / Qian’an (China)]

1.3 Tin plate [Wuhan Iron & Steel No.4 (China)]

MAIN SPECIFICATION

For Electrical (Silicon) Steels

Shougan Corporation has installed Coupled

Continuous Pickling and Tandem Cold Mill for the

electrical (Silicon) steel.

During rolling of hard material, the thickness

decreases sharply at the edge area. This is called

edge drop and is caused by longitudinal deviation of

WKHZRUNUROOµDWWHQLQJ(VSHFLDOO\IRUHOHFWULFDOVWHHO

rolling, minimized edge drop is essential. To reduce

the edge drop, the UCMW-MILL, is applied which

consists of a work roll shift mechanism added to the

8&00,//FRQ´JXUDWLRQ

Work rolls are shifted by means of hydraulic cylinders

provided in each shifting block on the drive side of

WKHPLOO2SWLPXPUROOJDSSUR´OHLVDFKLHYHGE\

combining work roll shifting, intermediate roll

shifting, work roll bending, and intermediate roll

bending.

No.

Item

Description

: Hot Rolled Carbon Steel

Material

(QWU\ 1.8 to 3.5 mm

Thickness

1.

Material

: Delivery

0.15 to 0.55 mm

: 700 to 1,300 mm

Width

Coil weight : Max. 28,600 kg

By properly adapting all of the components, including the

UCM-MILL, mill guide, drive system, and coolant system, high

speed and stable rolling has been achieved.

Pickling speed

: Max.

Rolling speed

: Max. 2,000 m/min

Strip dividing speed

: Max.

2.

Speed

3.

Welder Type

Laser Beam Welder

4.

Pickling Type

Jet Bath

5.

Mill Type

No.1

: 6Hi MILL (UCM)

No.2

: 6Hi MILL (UCM)

No.3

: 6Hi MILL (UCM)

No.4

: 6Hi MILL (UCM)

No.5

: 6Hi MILL (UCM)

220 m/min

260 m/min

LINE CONFIGURATION

Tension Leveller

Pickling Tank

Side Trimmer

TCM (5 Stands UCM)

No.1 No.2 No.3 No.4 No.5

Welder

Rotary Shear

MAIN SPECIFICATION

No.

Looper

Item

Thickness

1.

Looper

Description

Material

Material

0.35 to 0.65 mm

: 750 to 1,300 mm

1.4 Stainless steel [Baoshan Stainless Steel (China)]

Coil weight : Max. 30,000 kg

2.

Speed

Pickling speed

: Max.

Rolling speed

: Max. 1,200 m/min

Strip dividing speed

: Max.

3.

Welder Type

Laser Beam Welder

4.

Pickling Type

Shallow

5.

Mill Type

Looper

Pay-off Reel

(QWU\ 2.0 to 3.0 mm

: Delivery

Width

Carrousel TR.

: Special Steel

200 m/min

MAIN SPECIFICATION

300 m/min

No.

Description

Material

No.1

: 6Hi MILL (UCMW)

No.2

: 6Hi MILL (UCMW)

No.3

: 6Hi MILL (UCMW)

No.4

: 6Hi MILL (UCMW)

No.5

: 6Hi MILL (UCMW)

1.

LINE CONFIGURATION

Material

(QWU\WRPP

: Delivery

Width

0.3 to 3.0 mm

: 730 to 1,630 mm

Coil weight : Max. 30,000 kg

2.

Built for Cold Rolled Strip for electrical (silicon) steel

applications.

6SHFL´FDOO\WKHSLFNOLQJWDQNFRQVLVWVRIXQLTXHO\

designed shallow bath tanks for easier removal of silicon

sludge.

The UCMW-MILL minimizes edge drop through the addition

of a work roll shifting mechanism.

: Hot Rolled (Pickled) Stainless Steel

: Hot Rolled (Pickled) Carbon Steel

Thickness

UNIQUE FEATURES

Work Roll Shift Mechanism

Item

When Carbon steel and Stainless steel are processed on the

same line, the Tandem Cold Mill is usually applied in the form of

a continuous TCM without pickling line due to the difference in

the pickling process between carbon and stainless steels.

7RPHHWVHYHUHVXUIDFHTXDOLW\UHTXLUHPHQWVWKHPLOOJXLGH

and coolant system design are optimized.

3.

4.

Speed

Welder Type

Mill Type

(QWU\VSHHG

: Max. 650 m/min

Rolling speed

: Max.1,300 m/min

Strip dividing speed

: Max. 300 m/min

Laser Beam Welder

No.1

: 6Hi MILL (UCM)

No.2

: 6Hi MILL (UCM)

No.3

: 6Hi MILL (UCM)

No.4

: 6Hi MILL (UCM)

No.5

: 6Hi MILL (UCM)

LINE CONFIGURATION

Tension Leveller

Pickling Tank

Welder

Side Trimmer

TCM (5 Stands UCM)

No.5 No.4 No.3 No.2 No.1

TCM (5 Stands UCMW)

No.1 No.2 No.3 No.4 No.5

Welder

Rotary Shear

Pay-off Reel

Rotary Shear

Looper

Looper

Carrousel TR.

Pay-off Reel

9

Looper

Carrousel TR.

Looper

10

2. REVERSING COLD ROLLING MILL

3ULPHWDOV7HFKQRORJLHV-DSDQ/WGKDVDSSOLHGWKH8&00,//LQD5HYHUVLQJFRQ´JXUDWLRQIRUDSSOLFDWLRQV

with annual production capacities of 100,000 to 400,000 ton/y. The Reversing Cold Rolling Mill allows for the

SURGXFWLRQRIKLJKTXDOLW\SURGXFWVZLWKWKHFDSDELOLW\RIµH[LEOHUROOLQJIRUPDQ\NLQGVPDWHULDODQGWKLFNQHVV

combinations. Our mills have been rolling these products, combining easy operation and rapid start-ups under

stable conditions, since 1974.

2.2 Equipment layout

Main Feature

This mill is equipped with advanced an Automatic Gauge Control system (AGC) using a high response

Hydraulic Roll Positioning Device (HYROP) and X-ray type thickness gauge meters to obtain a higher

WROHUDQFHVWDQGDUGRI´QLVKHGWKLFNQHVV

In addition, to achieve high quality strip shape, this mill is equipped with an Automatic Shape Control

system (ASC), which includes multi-zone cooling headers at the entry side of the mill and shape

measuring sensors on the delivery side.

No.1 RCM in Everbright (China)

Strip of 0.15t x 1,000w

2.1 Start-up advantage

In addition to these technologies, based on our vast

H[SHULHQFHRXUFXVWRPHUVEHQH´WIURPTXLFNVWDUWXSV

and stable rolling conditions for high quality products.

Actual Rolling Speed of RCM

No.

Actual Rolling Speed (mpm)

0.25t

1200

0.30t 0.40t

0.29t

1000

0.40t

0.55t

0.55t

800

0.55t

0.70t

1.00t

0.85t

0.70t

600

0.85t

0.85t

400

1.15t

1.5t

200

1.15t

0

0

5

10

15

20

Date after 1st. Rolling (days)

11

25

Supply Record of UCM-MILL for Reversing Cold Rolling Mill

for Carbon steel and Silicon steel from 1974

30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Customer

Hitachi Metals, Yasugi, Japan

Toyo Kohan, Kudamatsu, Japan

Borcelik, Turkey

Jiangsu Jiagnan Industrial Group, China

Changshu Ev erbright Material Technology, China

Changshu Xingdao Adv anced Building Material, China

Changshu Ev erbright Material Technology, China

Beijing Shougang, China

Yantai North Steel, China

Maanshan Iron & Steel, China

Maanshan Iron & Steel, China

China Changshu Xinghai Advanced Building Material, China

China Changshu Xingyu Advanced Building Material, China

China Changshu Xinghai Advanced Building Material, China

Zhejiang Southeast Metal Sheet, China

Tainjin No.1 Steel, China

Tainjin No.2 Steel, China

Maanshan Iron & Steel, China

ACCIL Auto Steel Pv t. Limited, India.

Mill Type

Start-up

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

UCM

HYPER-UCM

UCM

2000

2001

2004

2005

2005

2007

2008

2006

2006

2007

2008

2008

2008

2008

2010

2010

2010

2013

2015

12

2. REVERSING COLD ROLLING MILL

2.3.1 Mill Type

2.3 Copper rolling

6PDOOZRUNUROOLVHVVHQWLDOIRU8OWUDWKLQ&RSSHUDQG%UDVV´QLVKLQJUROOLQJDQGLQRUGHUWRSURGXFHYHU\VWULFW

VXUIDFHTXDOLW\FRLOVHJPHQWHGVXSSRUWUROOVDUHQRWSUHIHUDEOH

+L8&00,//LVWKHPLOOZKLFKUHDOL]HVWKHVHUHTXLUHPHQWV

UCM-MILL

CR-MILL

ZR-MILL

7KHWKUHHW\SHVRIFRSSHUUROOLQJPLOOVVKRZQRQWKHOHIW

DUHDYDLODEOHIRUGLIIHUHQWPDWHULDOJDXJHVVKDSHDQG

VXUIDFHTXDOLWLHV

2IWKHVHWKH8&00,//FRPELQHVDFRVWHIIHFWLYH

VROXWLRQZLWKDZLGHUDQJHRIFDSDELOLWLHV

Main Feature

7KHIHDWXUHRI+L8&00,//

PPRIYHU\VPDOOZRUNUROOGLDPHWHUHQDEOHVWRSURGXFH

PLFURQPHWHURIXOWUDWKLQPDWHULDOZLWKRXWVHJPHQWHGVXSSRUW

rolls

5ROOLQJRLOLVVSUD\HGIURPHQWU\VLGHDQGQRQFRQWDFWW\SHVWULS

ZLSLQJV\VWHPLVHTXLSSHGDWH[LWVLGHZKLFKDFKLHYHWRSURGXFH

YHU\VWULFWVXUIDFHTXDOLW\

$XWRPDWLFVWULSVKDSHFRQWURO$6&ZLWK)XVV\FRRODQWFRQWUROLV

HTXLSSHGZKLFKFRQVLVWRIZRUNUROOEHQGHULQWHUPHGLDWHUROO

EHQGHUDQGVSRWZRUNUROOFRROLQJV\VWHP

H[3URGXFWLRQ

UCM-MILL

STRIP WIDTH

Effective for strip edge shape

1)

WR Bending Effect

Pre-set Control for each width

2)

IMR Shift Effect

Effective for middle shape of strip

3)

IMR Bending Effect

M type

Effective for every part shape of strip

1)+2)+3)

W type

2.3.2 Strip Shape Control Function for UCM-MILL

13

3URYLGHGE\+LWDFKL/WG

14

2. REVERSING COLD ROLLING MILL

2.4.2 High Strength Spindle

2.4 HYPER UC-MILL

7KH+<3(58&0,//ZDVGHYHORSHGWRDFKLHYHKLJKSHUIRUPDQFHRIVWULSJDXJHDQGµDWQHVVFRQWUROIRU+LJK

Strength Steel (HSS) rolling. This technology is also applicable for rolling high grades of non-grain oriented silicon

steel and tin products. The technology development is based on the following concepts:

- Optimized roll diameter combination (work, intermediate and back-up rolls)

:RUN5ROO'ULYHQ6\VWHP

WRDFKLHYHKLJKµDWQHVVFRQWUROODELOLW\

- Development of a high strength spindle for WORK ROLL DRIVE

Main Feature

Optimized Combination of Work,

Intermediate and Back-up Rolls

When investigating the combination of roll diameter,

there are two major limitations such as load limit to

PDLQWDLQJRRGVWULSµDWQHVVDQGORDGOLPLWGXHWRWKH

contact stress between rolls. The graph on the right

shows the relationship between these limits. The

hatched part is the maximum allowable rolling force.

The graph also shows the calculated reduction ratio at

the maximum allowable load. The graph shows that the

HYPER UC-MILL covers the range of the highest

achievable reduction;

MH Spindle

Load Limit due to roll contact stress

A high strength spindle called the "MH Spindle" was

developed, with a strength 2.7 times stronger than a

conventional universal joint type spindle. The "MH Spindle"

makes it possible to drive the work rolls of the HYPER

UC-MILL, even though the work roll diameter is much smaller

than compared to a standard UCM-MILL. The spindle strength

comparison is shown on the left.

Load Limit due to strip shape

Reduction Ratio under

above limit condition

2.4.3 1st Stand (Maanshan Steel/China)

Maanshan Steel in China has started commercial

production in 2013 as the 1st HYPER UC-MILL

HYPER UC-MILL

Conventional UCM-MILL

0.12

0.15

0.18

0.21

0.24

0.27

Type

Material

Product Thickness

Width Range

0.30

(Work Roll Diameter) / (Strip Width)

: Reversing Single Stand

: Silicon Steel

: 0.35 - 0.65 mm

: 900 - 1,280 mm

(Work Roll Diameter)/(Strip Width) = 0.18 - 0.24

2.4.1 Reference (Comparison of Work Roll Diameter)

Sm

Work Roll Diameter / Strip Width

0.5

all

er

2.4.4 Qualification test of "MH Spindle"

W

0.4

or

kR

ol

lD

iam

0.3

4XDOL´FDWLRQWHVWZDVSHUIRUPHGDWWKHFROGUROOLQJWHVWPLOO

et

er

Passline

0.2

0.1

15

L

IL

L

-M

IL

C

-M

U

M

ER

HYPER UC-MILL

YP

6H

iU

C

C

iH

6H

Standard UCM-MILL

H

C

on

ve

nt

io

M

na

-M

l4

IL

H

L

i

0

16

3. DOUBLE COLD REDUCTION MILL

The DCR/Temper mill is designed to meet the customer's needs for double cold reduction and two-stand temper rolling. The DCR

process, after reduction in a tandem cold mill, further reduces the annealed strip on the No.1 stand and temper rolls the strip on the No.2

3.2 A-COMPANY

stand. This process imparts the desired mechanical strength to the strip. In two-stand temper rolling, the strip is temper rolled in both the

No.1 and No.2 stands to the required elongation ratios to obtain the desired mechanical characteristics.

Features

High Productivity

- High Speed Rolling

- Automatic Strip Threading

Main Feature

High Quality Products

- ASC with UCM function

- High Response Push Up System (HYROP-F)

- High Response AC Motor

- Up-to-date AGC & AEC techniques

AEC : Automatic Elongation Controll

UCM-MILL's function on DCR/Temper rolling :

Both mill stands are of 6Hi UCM-MILL design for excellent shape controllability, heavy reduction

capability, and stable rolling.

NO.

EQUIPMENT

NO.1 std

For Ultra-Thin Products

- Two kinds of Work Rolls : Large/Small Diameter

NO.2 std

6Hi UCM-MILL

Large WR & Small WR (option)

1

Mill Type

2

AGC System

Applied

Applied

(option)

3

Coolant System

Applied

Applied

(option)

4

Skinpass oil System

Applied

Applied

(for West Temper) (for West Temper)

Specification

No.

Operation Mode

1

No.1 std

Reduction (Wet)

1. Mill Operation Mode

DCR (Double Cold Reduction) & Wet Temper rollingխ

No.2 std

0DLQ0LOO6SHFL´FDWLRQ

- Product thickness

: ։ 0.25 mm

- Strip Width

: ։ 1,270 mm

- Max. speed

: Approx. 2,000 m/min

- Capacity

: Approx. 270,000 ton/year

Wet Temper

DCR

5

WR/IMR Change

6

BUR Bearing

7

Shape Control System

Automatic

Automatic

Roller Bearing

Roller Bearing

-

Applied

2

Reduction (Wet) Reduction (Wet)

3

Wet Temper

Wet Temper

Wet Temper

3.1 BAOSTEEL (Cold Rolling Sheet Steel Plant)

SUPPLY REFERENCE

Features

High Productivity

- High Speed Rolling

High Quality Products

- ASC with UCM function

- High Response Push Up System (HYROP-F)

- High Response AC Motor

- Up-to-date AGC & AEC techniques

- Dry and Wet Multi-function Rolling Mode

- High Performance Dust Exhaust System

For Thinner and Harder Products

- Two kinds of Work Rolls : Large/Medium Diameter

No.

1

NO.

1

2

17

Operation Mode

NO.1 std

NO.2 std

Reduction (Wet)

(25~35%)

Dry Temper

Reduction (Wet)

(25~35%)

Wet Temper

Dry Temper

Dry Temper

Wet Temper

Wet Temper

DCR

Temper

0DLQ0LOO6SHFL´FDWLRQ

- Product thickness

: 0.10 ։ 0.80 mm

- Strip Width

: 700 ։ 1,050 mm

- Max. speed

: 1,500 m/min (TPM)

1,200 m/min (DCR)

- Capacity

: Approx. 250,000 ton/year

Nagoya

Mill Type

Application Start-up

TPM

DCR

1965

Comb.

No.

User

Mill Type

Application Start-up

13

Ton-Yi Industrial

Corporation (Taiwan)

TPM

1994

1968

14

Toyo Kohan

Kudamatsu

DCR

1995

2

Nisshin Steel Co., Ltd.

Sakai

3

Nippon Steel Corp

Nagoya

TPM

1970

15

Bao Steel

China

TPM

1998

4

JFE Steel

Chiba

TPM

DCR

1971

16

POSCO

Pohang, Korea

TPM

DCR

2002

5

Toyo Kohan

Kudamatsu

TPM

DCR

1974

17

Bao Steel

Yichang, China

TPM

DCR

2002

6

CSN (Brazil)

TPM

1981

18

POSCO

Pohang, Korea

TPM

2005

7

Nippon Steel Corp.

Yawata

TPM

1981

19

Erdemir

(Revamping), Turkey

TPM

DCR

2005

8

JFE Steel

Chiba

TPM

1983

20

S Company

(Revamping), Thailand

DCR

9

JFE Steel

Kurashiki

TPM

1983

21

WIN Steel

Wuhan, China

TPM

2 01 4

TPM

1990

22

WIN Steel

Wuhan, China

TPM

2 01 4

TPM

DCR

1991

23

Tosyali Toyo Steel

Osmaniye, Turky

TPM

DCR

2016

TPM

1992

Specification

1. Mill Operation Mode

DCR (Double Cold Reduction) & Temper rolling

User

Nippon Steel Corp

10

11

12

TATA Steel (Netherland)

(Former Hoogovens)

Nippon Steel Corp

Nagoya (Revamping)

POSCO

Kwangyang, Korea

INLINE

2013

BATCH

18

4. TEMPER/SKINPASS MILL (TPM/SPM)

Several types of SPMs have been supplied for Tin plate, Sheet, as well as Galvanized plate applications, to meet

a variety of customer requirements. Both Batch type and In-line SPMs are available. Recent application are as

follows:

4.2 Inline CAL Skinpass Mill

Features

Basic Mill application

- 6MB, UCM-MILL

- Excellent elongation, shape control, and stable rolling

- Wide range of materials from soft steel (IF steel) to

high strength steel (1470MPa) can be rolled with one straight roll

- High speed roll changing

- Fume exhaust system

6Hi UCM-MILLs are supplied in response to recent requirements to roll harder material, such as hard tin

plate and HSS, with improved strip shape control capability. 4Hi MILLs have been provided for rolling of

softer steel grades.

Examples of SPM type and application for different materials (Hardness)

Harder

Mill Type or Application

6SHFL´F5ROOLQJ)RUFHWRQmm)

WRQmm

WRQmm

FI

FI

Fw

Fw

FI

Fw

FI

FI

FI

FI

Fw

FI

WRQmm !WRQmm

Fw : WR Bender

4Hi MILL

Mill Type

F I : IMR Bender

HCM MILL

4.3 Inline CGL Skinpass Mill

UCM MILL

6MB-MILL

6Hi MILL with Effective Bender

UCM-MILL

: IMR Shift

Conventional

Batch SPM

Application

Current Requirement

Conventional

Current

Requirement

CAL

Basic Mill type for each products and facility

- Tin plate : 2 stands 6Hi UCM-MILL

- Sheet

: Single stand 6Hi UCM-MILL or 5MB*, 6MB*

- CGL

- CA&GL

: Single stand 4Hi MILL or 5MB*

: Single stand 6Hi UCM-MILL

* 5MB for CGL and 6MB for CAL are available for cost merit reasons

4.1 Inline temper Mill

Features

-

2 stand 6Hi HCM, UCM-MILL

Excellent elongation, shape control, and stable rolling of thin strip

Wide range of materials from T2 to T5 grade can be rolled with one straight roll

High speed roll changing

Dust exhaust system with polisher for Dry rolling

4Hi MILL & High pressure spray type polisher

No.2 ROLL

POLISHER

- 5MB, 4Hi MILL application for the better quality

- High pressure spray type polisher

High pressure (20 MPa) demi-water spray

Better roll surface quality for WR & BUR

Effective spray with less splashing

- Brush roll type polisher

- High speed roll changing

No.2 MILL

No.1 MILL

No.1 ROLL POLISHER

Features

FI

FI

Fw

Fw

5MB-MILL

5Hi MILL with Effective Bender

SUPPLY REFERENCE

No.1 ANTI CRIMPING ROLL

No.1 ROLL POLISHER

No.2 ROLL POLISHER

19

No.

CROSS BREAKING ROLL

Layout

1

2

3

4

5

Customer

%$26+$1,52167((/&KLQD

%(1;,,52167((/&KLQD

167((/-DSDQ

SOME COMPANY

*8$1*=+28-)(67((/&KLQD

Mill Type

Start-up

Inline (CAL) UCM (6Hi)

CAL, UCM (6Hi)

CGL & CAPL UCM (6Hi)

CGL & CAL UCM (6Hi)

CAL, UCM (6Hi)

2004

2006

2006

2009

2010

20

5. CLUSTER MILL

5.1.2 Comparison of strip shape controllability (calculated)

5.1 Advanced ZR-MILL/20Hi (KZR)

Our company produces Advanced ZR-MILL/20Hi (KZR), Advanced Split Housing ZR-MILL/20Hi (HZ) and CR MILL/12Hi (CR) for

&OXVWHU0LOO7KHVH&OXVWHU0LOOVXWLOL]HVXOWUDVPDOOGLDPHWHUZRUNUROOVWRHI´FLHQWO\UROOKLJKKDUGQHVVPDWHULDOVVXFKDV6WDLQOHVV

steel, Silicon steel strips, High carbon steel and Copper alloy. Our company have actual result more than one handred mills for

Single AS-U

Cluster mill.

Double AS-U

Main Feature

(I-unit)

(I-unit)

200

200

-5 scale

LoZer Limit

150

242 I-unit

150

88 I-unit

The Advanced ZR-MILL (KZR) is a mill for the cold rolling of hot-rolled coils of stainless steel and other hard

PDWHULDOVWRWKHGHVLJQDWHGSURGXFWWKLFNQHVVDQGVWULSVKDSHDFFXUDF\7KHXOWUDVPDOOGLDPHWHUUROOVDUH´UPO\

supported in a 20Hi roll cluster arrangement and are contained inside a mono-block structure housing. As the result,

this mill makes high mill modulus come true .

With a conventional ZR-MILL, the bending system for the backing bearing shafts that control the shape (the AS-U

system) contains only 2 (shafts B, C) of the 4 upper backing bearing shafts (shafts A, B, C, D). As a result, the strip

VKDSHFRQWUROFDSDELOLW\LVLQVXI´FLHQWDQGWKHUHDUHSUREOHPVZKLFKPDNHKLJKVSHHGUROOLQJZLWKKLJKUROOLQJ

UHGXFWLRQGLI´FXOW7RUHVROYHWKLVZHGHYHORSHGDQGSURGXFHGWKH$GYDQFHG=50,//.=57KLVPLOOLVHTXLSSHG

ZLWKDGRXEOH$68V\VWHPIRUWZRXSSHUEDFNLQJEHDULQJVVKDIWV$DQG%WRJHWKHUZLWKEHDULQJVKDIWV&DQG'

DQGDOVRLQFOXGHVQHZDXWRPDWLFVKDSHFRQWUROWKDWXWLOL]HVIX]]\ORJLFFRQWURO%HFDXVHWKLV.=50,//LVFDSDEOHRI

KLJKVSHHGUROOLQJZLWKKLJKUROOLQJUHGXFWLRQLWFDQGHOLYHUDERRVWWRSURGXFWLYLW\IRUUROOLQJRIVWDLQOHVVVWHHODQG

other hard materials.

100

50

100

50

0

-600

-400

-200

0

0

200

400

600

-600

0

-400

-50

Our Technology

Features

Capability & Effect

-100

Width

-200

0

200

400

0

600

-50

+5 scale

Upper Limit

-100

Width

a) Convention ZR MILL (single AS-U)

b) KZR-MILL (double AS-U)

Strip Shape control capability of Double AS-U is 2.8 times as high as

conventional single AS-U system (=242/88)

5.1.3 Actual Result

Features

KZR MILL

-

5.1.1 Layout

Customer

Mill Type

Mill Speed

Product

Completion

: NIPPON METAL INDUSTRY CO., LTD. Kinuura, Japan

: KZR-MILL/ZR21AN-52

: 800 m/min

: Stainless Steel 0.2 mm1,320 mm

: 1991

Features

L.H TENSION REEL

ZR-MILL

R.H TENSION REEL

FEED LEVELLER

-

Customer

Mill Type

Mill Speed

Product

Completion

: NISSHIN STEEL CO., LTD. Sakai, Japan

: KZR-MILL/ZR21AN-52

: 800 m/min

: Special Steel 0.2 mm1,300 mm

: 2008

PAY OFF REEL

21

22

5. CLUSTER MILL

5.2 Advanced Split Housing ZR-MILL/20Hi (HZ)

5.2.2 Main Feature of HZ-MILL

Main Feature

6) Measuring Rolling

Force by Load Cell

1 ) Double AS-U &

1 st IMR Shifting during

Because the housing is split into upper and lower sections, there is a large gap between the upper and lower work

rollers. This makes threading and the strip cutting cobble process easier.

In a conventional ZR-MILL (ZR), the 20Hi rollers are supported in a cluster arrangement and are contained inside a

mono-block structure housing. Although this structure is compact, the gap between the upper and lower work rolls

is small, and extra work is required in some cases for the threading and the strip cutting cobble processes.

For this reason, we developed and produced the Advanced Split Housing ZR-MILL (HZ) which splits the

mono-block housing into an upper and lower section, supported by 2 outer housings. Because this HZ Mill has a

housing that is split into an upper and lower section, the gap between the upper and lower work rolls is large,

facilitating the threading and the strip cutting cobble processes. In addition, unlike the mono-block ZR-MILL, the

work rolls can be used in nearly their full range regardless of the diameter of intermediate rolls 1 and 2, for greater

operability. For above reason, HZ MILL receives especially a high evaluation for Silicon steel and special steel rolling.

Improved Pre-set

Accuracy

High Shape Control Ability

(2.4։2.8 times Larger than

Single AS-U)

4) More free roll

diameter combination

5) Neuro/Fuzzy

Shape Control

More Easy Operation

High Speed Stable Rolling

by Control of AS-U & 1st

IMR Shifting

2) Large roll

-open

clearance Approx.

80mm

3) High Response by

Direct Main Cylinder

5.2.1 HZ-MILL Construction

More easy strip

threading and

disposal broken strip

Improved Gauge

Accuracy

Features

1 ) High Shape Control Ability by Double AS-U

2) More easy strip threading and disposal broken strip by Large roll-open clearance

3) Improved Gauge Accuracy by High response direct main cylinder

4) More easy Operation by more free roll diameter combination

5) High Speed Stable Rolling by Neuro/Fuzzy shape control

6) Improved Pre-set Accuracy by measuring Rolling Force by Load Cell

Backing

Bearing Shaft

Assembly

5.2.3 HZ-MILL Actual Result

Outer Housing

Double AS-U

Device

Passline

Adjustment

Device

Top

Inner

Housing

Features

-

21 type HZ-MILL for 4 feet

Standard roll diameter:

Work roll dia. : ħ80mm

1st IMR dia.

: ħ138mm

2nd IMR dia.

: ħ235mm

B.BRG dia.

: ħ406.4mm

Width

: Max.1,300mm

Max. R.S..F

: 10.8 MN

HZ-MILL Inner Housing

Bottom

Inner

Housing

Main Jack

23

Features

-

Customer

Mill Type

Mill Speed

Product

Completion

: Shougang Co.,LTD., China

: HZ-MILL/HZ21N-51

: 800m/min

: Silicon Steel 0.17mm1,300mm

: 2011

24

5. CLUSTER MILL

5.3 CR-MILL/12Hi (CR)

5.3.2 Shape Control Capability

Main Feature

Actuator for Shape Control

The CR MILL/12Hi (CR) is a mill originally developed for the cold rolling of stainless steel, copper alloys,

and nickel alloys. There are fewer roll levels than in a conventional ZR-Mill/20Hi and the CR MILL is

superior in strip shape control characteristics. A large usable range of work roll diameters allows rolling of

a vast variety of materials, including soft, hard and ultrathin, under stable and highly precise operating

conditions. The CR MILL has been adopted to roll copper alloys and, in particular, full-hard materials.

The Top and Bottom Back Up Roll Frames are split and allow for automatic roll changes, easier strip

threading, and easier maintenance. In addition, an oscillation function has been added to the intermediate

roll, preventing backup bearing marks from being transferred to the strip. This mill is used for materials

which have strict surface requirements.

Conversion of an existing 4Hi MILL housing to a CR MILL is possible.

=խFeatures of the CR MILLխ=

the CR MILL contains 12 rolls in a Cluster type arrangement,

the CR MILL achieves excellent strip shape control through split type BUR, bending control of IMR, and

leveling control with push up cylinder,

the CR MILL is capable of high-reduction rolling through the use of small diameter work rolls.ħ120։ħ45

BUR Crown Push Out

BUR Crown

Control

٥Top/Bottom Different Segmentation

٥Individual Push Out of Each Bearing

Bender Force

IMR Bender

٥High Response Hydraulic Control

٥Non-Symmetrical Bender (WS/DS)

٥No Tapering on IMR

Levelling (DS-WS)

Levelling

٥Quick Response Hydraulic AGC

٥Easy Operation

(DS)

(WS)

Individual Push Out of BUR

Top/Bottom BUR different Segmentation

5.3.1 Construction

CR-MILLխ

Actual Data of strip shape control accuracy

խխխխխխխխGreen deviation rangeխp5I -unit

խխխխխխխխYellow deviation rangeխp10I -unit

BUR Crown

Control Motor

Individual Push Out of BUR

Shape Controlling Function can be more powerful, by Top and Bottom BURs

having Same Controlling Function, to Push-Out Each BUR bearing individually

WR

5.3.3 CR-MILL Actual Result

Chockless Work Roll (WR)

Features

-

Mill Drive

Pinion Stand

Customer

Mill Type

Mill Speed

Product

Completion

: Mitsubishi Electric Metecs Co., Ltd., Japan

: CR-MILL

: 600 m/min

: Copper alloy : 0.05mm900mm

: 2007

Top BUR Frame

Intermediate Roll (IMR)

Top BUR Frame

Features

-

BUR

25

Bottom BUR Frame

12Hi Cluster Rolling Mill (CR-MILL)

Customer

Mill Type

Mill Speed

Product

Completion

: Outokumpu Stainless AB, Sweden

: CR-MILL

: 800 m/min

: StainlessSteel : 0.1mm1,100mm

: 2006

26