PRELIMINARY DESIGN OF NEW CONCEPT COMPACT

advertisement

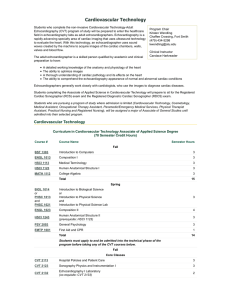

PRELIMINARY DESIGN OF NEW CONCEPT COMPACT CONTINUOUSLY VARIABLE TRANSMISSION LAU ONG YEE A project report submitted in partial fulfillment of the requirement for the award of the Degree of Master of Mechanical Engineering Faculty of Mechanical and Manufacturing Engineering Universiti Tun Hussein Onn Malaysia JANUARY 2014 v ABSTRACT Continuous Variable Transmission (CVT) system provides a solution that enable the generation of staples shifting of gear ratio regardless of the speed and torque requirement. CVT technology had been available since century ago, and it become popular among the luxury car. However, due to the certain limitation of current CVT design, CVT are not popular among the machineries. In this paper, Autodesk Inventor was used to develop a new concept of compact CVT with simple and compact. According to David G. Ullman, there are five steps in design process which start with determine of problems, planning, develop design requirement, evaluation, decision, and lastly communication of the result. Selection of the design had been going thru several processes such as House of Quality (HoQ), and development of Engineering Design Specification (EDS). In order to finalize the design, morphological chart with weighted rating method had been used. New concept of compact CVT that had been developed is less complicated compare to existing CVT system. In this new concept of compact CVT, two unit of curved surface cones are used. One unit of idler located between two cone act as rotation transmitter in this compact CVT. In addition, multiplication of the gear ratio can be achieved by using multiple cone concepts. vi ABSTRAK Kewujudan sistem tansmisi boleh laras berterusan(CVT) telah menjadikan perubahan gear lebih lancar tanpa mengira kelajuan dan tork yang diperlukan. Teknologi ini telah wujud beberapa dekad yang lalu, dan kini ia telah menjadi popular di antara kenderaan mewah. Walau bagaimanapun, disebabkan oleh batasan yang ada pada sistem tranmisi boleh laras, ia masih tidah popular di antara mesin. Dalam kajian ini, perisian Autodesk Inventor akan digunakan untuk membangunakn konsep baru CVT yang bersaiz padat dengan mekanisma yang ringkas. Merujuk kepada David G. Ullman, terdapat lima langkah dalam proses merekabentuk bermula dengan penentuan masalah, perancangan, pembangunan keperluan rekabentuk, penilaian, keputusan dan terakhir sekali ialah mengkomunikasi data atau keputusan. Dalam proses pemilihan rekabentuk perlu ada beberapa langkah yang penting iaitu House of Quality (HoQ), dan pembangunan spesifikasi kejuruteraan(EDS). Untuk mendapatkan keputusan terakhir penilaian rekabentuk , carta morfologi dengan gabungan kaedah pemberat digunakan. Konsep baru CVT padat ini telah dibangunkan dan ia adalah lebih ringkas dari segi struktur binaan jika dibandingkan dengan rekabentuk yang sedia ada. Dalam rekabentuk CVT baru ini, 2 unit kon dengan permukaan berlengkung digunakan. Manakala 1 unit idler diletakkan di antara 2 unit kon berkenaan sebagain penghantar kuasa putaran. Tambahan pula, pendaraban kuasa boleh diaplikasikan dalam konsep baru ini untuk menghasilkan tork yang lebih tinggi. vii CONTENTS TITLE i DECLARATION ii DEDICATION iii ACKNOWLEDGEMENTS iv ABSTRACT v ABSTRAK vi CONTENT vii LIST OF FIGURE x LIST OF TABLE xii LIST OF SYMBOLS ANF ABBREVIATIONS xiii LIST OF APPENDICES xiv CHAPTER 1 INTRODUCTION 1 1.1 Introduction 1 1.2 Background study 3 1.3 Problem Statement 4 1.4 Objective 4 1.5 Scope of Study 4 1.6 Project Significance 5 CHAPTER 2 LITERATURE REVIEW 6 2.1 Fundamental of CVT 2.1.1 Belt-pulley CVT 6 8 viii 2.1.2 Toroidal CVT 10 2.1.3 Cone based CVT 11 2.2 13 CVT patent 2.2.1 Patent 1 – Continuously Variable Transmission (EP Pat No. 0639732A1) 14 2.2.2 Patent 2 – Continuously variable transmISSION (US PAT NO. 5324239) 15 2.2.3 Patent 3 – Friction type continuously variable transmISSION (US PAT NO. 5746676) 17 2.2.4 Patent 4 – Continuously variable transmISSION 2.3 (US PAT NO. 5888160) 18 Available CVT Product 19 2.3.1 Nissan Xtronic 19 2.3.2 Nissan Extroid 21 2.3.3 Audi Multitronic 22 2.3.4 Warko CVT 23 2.3.5 Comparison 24 CHAPTER 3 METHODOLOGY 25 3.1 Introduction 25 3.2 Project Method 26 3.3 Project Flow Chart 27 3.4 Project Gantt Chart 28 CHAPTER 4 RESULT AND DISCUSSION 29 4.1 Introduction 29 4.2 Formulation 29 4.2.1 House of quality (HoS) 30 4.2.2 Engineering design specification(EDS) 31 4.3 33 Concept design 4.3.1 Clarifying functional requirement 33 ix 4.3.1.1 Activity analysis 33 4.3.1.2 Product component decomposition 34 4.3.1.3 Product function decomposition 35 4.3.2 Generating alternative concepts 36 4.3.3 Concept Selection 37 4.4 39 Concept Development 4.4.1 Cone 40 4.4.2 Idler 40 4.4.3 Controlling device 41 4.4.4 Casing 42 4.5 42 Generation of Concept 4.5.1 Design Concept 1 42 4.5.2 Design Concept 2 43 4.5.3 Design Concept 3 44 4.5.4 Design Concept 4 44 4.6 45 Modeling and Design Development 4.6.1 Transmission mechanism 45 4.6.2 Adjusting Mechanism 46 4.6.3 Full Assembly of Compact CVT 48 4.6.4 Double Cones Gear ratio 49 4.6.5 Multiple Cones Concept 50 4.7 51 Gear Ratio CHAPTER 5 CONCLUSION 55 5.1 Introduction 55 5.2 Recommendation 56 5.3 Conclusion 56 REFERENCES APPENDIX 57 x LIST OF FIGURE 1.1 Clutch engagement and disengagement 1 1.2 Punch Powertrain VT2 CVT gearbox 3 2.1 Comparison of RPM performance between Manual Transmission (MT) with Continuous Variable Transmission (CVT) 7 2.2 Belt-pulley CVT operations 8 2.3 Arrangement of Metal V-belt on CVT drive: (a) basic configuration ; (b) Metal v- belt structure 9 2.4 Nissan Toroidal CVT 10 2.5 Mechanism of Toroidal CVT in overdrive mode (left) and low gear mode (right) 11 2.6 Concept of using cones ring CVT 12 2.7 Open KRG transmission 12 2.8 Warko's CVT 13 2.9 CVT patent EP0639732A1 15 2.10 Position of the steel bands 16 2.11 Steel bands arrangement 16 2.12 Double cone friction CVT 17 2.13 Schematics view of continuously variable transmission 18 3.1 Project flow chart 27 3.2 Project Gantt chart 28 4.1 House of quality for the new concept of CVT 31 xi 4.2 Product component decomposition for CVT 35 4.3 Product function decomposition for CVT 36 4.4 Cone with curved surface 40 4.5 Concept of idler 41 4.6 Design concept 1 43 4.7 Design concept 2 43 4.8 Design concept 3 44 4.9 Design concept 4 45 4.10 Pair of cones in the opposite direction 46 4.11 Idler attached to the holder which controls the gear ratio 47 4.12 Complete assembly of the compact CVT 48 4.13 Arrangement of basic double cone concept of CVT 49 4.14 Multiple cones concept 50 4.15 Illustration of idler moving path 51 4.16 Relationship between gear ratio and position of the idler 52 4.17 Relationship between gear ratio and diameter of cones 52 4.18 Arrangement of idler position in multiple cones design 53 4.19 Control of the gear shifting with the movement of Idler 1 and Idler 2 54 xii LIST OF TABLE 2.1 Nissan Xtronic 20 2.2 Nissan Extroid 21 2.3 Audi Multitronic 22 2.4 Warko CVT 23 2.5 Comparison of CVT products 24 4.1 Engineering design specification for CVT 32 4.2 Activity analysis for CVT 34 4.3 Morphological matrix 36 4.4 Alternative designs combinations 37 4.5 Rating ordinal scale 38 4.6 Weighted rating of CVT 38 4.7 Weighted rating of power transmitter 39 xiii LIST OF SYMBOLS AND ABBREVIATIONS MOHE - Ministry of Higher Education CVT - Continuously Variable Transmission EDS - Engineering Design Specification HoQ - House of Quality QFD - Quality function development R - Double cones maximum ratio C - Numbers of cone xiv LIST OF APPENDICES APPENDIX TITLE PAGE A Full assemble of new concept compact CVT 61 B Cone in new concept compact CVT 62 C Idler with holder in new concept compact CVT 63 D Floating cone continuously variable transmission 64 E Cone pulley v-belt continuously variable Transmission 73 F Cone and idler continuously variable transmission 78 G Friction type continuously variable transmission 91 1 CHAPTER 1 INTRODUCTION 1.1 Introduction At the early century when cars become popular among the people, manual transmission system was introduced. For manual transmission system, drivers need to disengage the clutch (refer Figure 1.1) to disconnect the power from the engine and then continue with changing gear ratio. However, this method becomes a challenge for new driver and they need some period of the time to get used of it. Figure 1.1: Clutch engagement and disengagement [1] 2 Research and development process had been carried out by the automotive industries expert to ease the problem by inventing other types of the transmission system which named as automatic transmission system. Fluid coupling and torque converter was used to replace the clutch system and planetary gears uses to perform gear change in automatic transmission. Compared to the manual transmission, invention of automatic transmission has gradually made the driving car much easier. However, complicated gear structure had indirectly increased the weight and price of the car. After automatic transmission, semi-automatic transmission had been introduced in the market but was not popular in automotive industries because of the price and under development technology. Blooming of the economy and automotive technology had brought continuously variable transmission (CVT) to the surface. At an early stage, CVT technology was limited in low powered machinery such as scooters. Development of the materials technology and high tech machinery, people had found their way to implemented CVT technology in motorcar, and it was successfully increasing the efficiency of power transmission. Continuously variable transmission is a type of the transmission system that widely used in automobile industries. Compare to the conventional automatic transmission, CVT provides more useable power, better fuel economy and smoother driving experience. All this advantages should be credit to special features of CVT such as gear system that does not use any tooth and ability to create infinite numbers of gear ratio. With discovered of new material technology, the CVT system had gradually replaced the conventional transmission system due to it high efficiency and smooth gear shift. 3 1.2 Background study Now days, CVT can be found on most automotive industries such as scooter, tractor and also modern cars. All those benefits from CVT had attracted automotive developer including Nissan and Toyota from moving their path to CVT development. Because of CVT system does not need gear changing, it's to be benefits for those using CVT cars which able to maximize the efficiency of the engine all the time during driving. Figure 1.2: Punch Powertrain VT2 CVT gearbox [2] Over the decades, lots of research had been done on CVT, and there are successful products that already available in the market such as metal pushing belt CVT. Many CVT designs that still need on going research and development process had been patented on the different country as well. 4 1.3 Problem Statement Technology development in automotive industries had started promoting CVT to modern car. With various type of testing, it is proven that CVT may overcome the burden of changing gears in toothed gear system. Although CVT had been introduced in the market almost 10 years ago, they are still costly and only widely apply in the modern car such as the hybrid car. Usage of electric CVT in Toyota Prius may directly improve driving quality and fuel consumption, but it’s still expensive in terms of fabricating electrical machine, power electronics and battery pack[3]. Due to the high cost and numbers of part, usages of CVT in machine are very limited. 1.4 Objective To design and develop a new concept of compact CVT by the combination of current CVT system and existing patterned CVT design which with purpose to reduce size of the compact CVT for the usage of machinery. 1.5 Scope of Study The approach in designing conceptual compact CVT will be as follow: - Design a new conceptual of compact CVT with smaller size - Create three-dimensional (3D) drawing for compact CVT 5 1.6 Project Significance The design and development will be based on finding the suitable type of CVT or invent a new CVT system to combine it with the previously patterned CVT. The challenge is choosing the right type of new CVT model to be used, whereby variation of new CVT model are still required a lot of studies. The study of CVT and it innovation are needed to build a new conceptual CVT. Hence, the developed system is expected to be compatible with minimum load and torque requirement for small power machinery or vehicles. 6 CHAPTER 2 LITERATURE REVIEW 2.1 Fundamental of CVT Continuous variable transmission (CVT) or CVT-hybrid is the new kind of technology used in most modern compact and sub-compact vehicles, including minivan. This technology is differs from manual or automatic transmission system in term of its ability to adjust gear shift ratio coverage range continuously [4]. There are several types of CVT system that can be found in market, among the popular CVT are belt-pulley CVT, toroidal CVT, and cone based CVT. However, there are still many inventions of conceptual CVT system which have not been commercialized. 7 Automotive company more interest in developing CVT compare to manual or automatic because of its ability to maximize the power as well as enhance fuel efficiency. By refer to Figure 2.1, CVTs also can give more comfort drive by eliminating “shift shock” during gear change. CVT also has the capability to allow the engine to revolute almost immediately and at the same time delivers maximum torque to move the vehicles. Better control of engine's speed range may also indirectly help in reduce greenhouse emissions. Vehicles installed with CVT have many advantages; however there are a few disadvantages as well. Main problems in CVT car were user acceptance. For new CVT car user, driver may not feel the accelerations since CVT always keeps the RPM at lowest compare to manual and automatic. Transitorq, one of the machine manufacturers in the history had tried to install CVT in their machine such as lathe and bore machine. Due to the high manufacturing cost, productions of CVT base machine are limited and replace with automatic transmission system [6]. Figure 2.1: Comparison of RPM performance between Manual Transmission (MT) with Continuous Variable Transmission (CVT) [5] 8 2.1.1 Belt-pulley CVT Although there are various types of CVT in the market, most of the cars are using a pair of variable diameter pulley with belt running between them. This pair of variable diameter shaped like two cones in different directions. Figure 2.2 shows two different state of transmission with two different pulley groove width. Normally low gear state are efficient during starting out of vehicles, meanwhile overdrive gear or higher gear more to fuel efficiency. Figure 2.2: Belt-pulley CVT operations [6] Belt is usually in V-shape along the cross section, which this pattern can increase the frictional grip between the belt and the surface of the cones. Compared to metal belt, material properties of rubber belt allow it widely used in small power vehicles such as scooter and snowmobile due to its limited torque [7]. As shown in Figure 2.3, metal Vbelt are built from various numbers of small steel blocks and ridded on thin flexible steel bands. These thin flexible steel bands will in contact with the flanges of the pulleys [8]. 9 Now days, Metal V-belt are crucial in designing pulley based CVT especially on automobile that required high torque. Capabilities of metal v-belt to move the pulley at high axial thrust and directly transmit the large torque from driving pulley to driven pulley have become great benefits in CVT design [9]. Figure 2.3: Arrangement of Metal V-belt on CVT drive: (a) basic configuration ; (b) Metal v- belt structure [10] To allow the belt pulley CVT to function, each pulley should have two separate parts with coned shaped. One side of the pulley must be moveable while another will be fixed. The moving part will determine the diameter of the pulley. When it moves far from fixed part, larger groove will be created to allow V-shaped belt move inward. While the smaller the groove or width between two parts, the bigger diameter it is. Since the belt is in constant length, changing of diameter for driving pulley will subsequently produce a compression force among the v-belt. This force will transmit via v-belt and create torque which will act on the driven pulley and change the diameter of the driven pulley [11]. As driving pulley increase the radius, driven pulley will decrease its radius to maintain the tension of belt. This mechanism had allowed both pulleys to changes their radii relatively one to another, indirectly infinite number of gear ratio had been created. 10 2.1.2 Toroidal CVT Instead of belt and pulley, toroidal CVT used two discs and power roller to move the vehicles. As shown in Figure 2.4, both discs are linked with 2 rollers or wheels which located in opposite directions. Roller at toroidal CVT will have a similar function as vbelt in pulley based CVT whereby it transmits power from driving disc to driven disc. Figure 2.4: Nissan Toroidal CVT [12] Power roller can rotate in two axes, which spin in the horizontal axis to transfer power from one to another. However, roller slit in and out around the vertical axis with different angles created continuous variable gear ratio [13]. As the roller move to the highest point or close to rim of driving disc, it must be contact with the driven disc near the center of driven disc (Figure 2.5). This will result increase of speed and decrease of torque. Toroidal CVT will in low gear condition when both rollers touch the driving disc near the center and driven disc near the rim [14]. 11 Figure 2.5: Mechanism of Toroidal CVT in overdrive mode (left) and low gear mode (right) [15] 2.1.3 Cone based CVT Cone based CVT or cone ring transmission (KRG) is made from two cones shaped roller and linked by an idler or barrel shaped hub. As shown in Figure 2.6, both cone are in opposite direction and act as driving cone and driven cone. Continuous variable gear ratio is achieved by the movement of the idler that connected with a shaft. Based on the required torque, or speed idler will move in the parallel direction to its shaft. By moving Idler, diameter of the driving cone that contact with idler will change relatively to the diameter of driven cone. Instead of using the idler, cone ring transmission (Figure 2.7) had used barrel shaped hub to transmit the torque from one to another. 12 Figure 2.6: Concept of using cones ring CVT [16] Figure 2.7: Open KRG transmission [17] To overcome the weakness of cone based CVT, Warko had developed their own concept of cone based CVT by using multiple cones in a system to transmit power. It’s different with standard cone base CVT where by Warko's CVT used more than 1 set of cones to transmit power Figure 2.8 had shown the relation between numbers of cone and torque capacities that can be produced by Warko's CVT. Warko's CVT consists of 3 major parts, which are cones, barrel shaped hub in the middle and a ring. Cones will act as driving part, and barrel as driven to the vehicles. Varies of gear ratio can be obtained by moving the ring 13 along the cone. When ring moved, cones will move as well in desired pattern and maintain only touching the barrel hub at one point only. All this unique features of Warko's CVT had offer high capabilities of torques and a wide range of transmission [18]. Figure 2.8: Warko's CVT [19] 2.2 CVT patent Studies of the existing patent are one of the important parts in this study. To accomplish the objective, this study will be focus on the CVT that register under United State (US) and European (EP) patent. Studies of patent are very important to identify and track the current trend of CVT development. In the other hand, it may useful during the design process by avoid infringing the patent right [20]. 14 2.2.1 Patent 1 – Continuously Variable Transmission (EP Pat No. 0639732A1) CVT with publication Number 0639732A1 was invented on 08.08.94 by using concept belt and pulley. This invention is claimed to improve certain operating condition in previously published patent (European Patent Application 91200513). Inventors for the current patent claimed that the previous patent are not optimal and can limit the efficiency and the life of the transmission. Working principles for belt-pulley CVT had been introduced earlier in section 2.1 whereby it had two cones and connected with rubber or metal pushing v-belt. Hydraulic or electrical powers are used in belt-pulley CVT to control the groove of the pulley and create infinite gear ratio. Based on the diagram at Figure 2.9, primary pulley with sheaves 3 and 4 are fitted with shaft 2. Shaft 2 is linked to any input device such as engine or electric motor. Which means speed of the engine will bring to shaft 2 and turn the primary pulley. Torque from primary pulley will be transferred from drive belt 8 to sheaves 6, and 7 at secondary pulley. Transmission ratio can be varies by the radial position of the drive belt 8. At secondary pulley, shaft 5 is the output of torque and couple to wheel. Sheaves 4 and 6 are support by cylinder 9, 10, 11, and 12 which actuated by primary and secondary hydraulic pressure. In the other hand, sheave 4 and 6 will move respectively according to the requirement of gear ratio. Control system of this patent is done by electrical controller with hydraulic pressure and assisted by fuzzy logic. Mechanical return mechanism also is applied at this patent, by locating at the secondary pulley. Spring is used in here to return the position of sheaves 6 to the original position during electrical power shut down or emergency stop. By return the sheaves 6 to the initial state, wear and damage due to belt slip can be avoided during restart of transmission. 15 Figure 2.9: CVT patent EP0639732A1 [21] 2.2.2 Patent 2 – Continuously variable transmission (US Pat No. 5324239) Conventional belt-pulley CVT is using rubber belt or metal v-belt. Rubber belt had limited torque capacity since it’s more function as pulling the secondary pulley. Metal V-belt can produce more torque because it will act as pushing the belt; however, metal V-belt are made of numbers of the small part and straight surface of each part had decreased the area of contact. This patent US Pat No. 5324239 had invented to overcome all those weakness. Instead of using rubber belt or metal V-belt, inventor had used series of individual sized steel bands as shown in Figure 2.10. 16 Figure 2.10: Position of the steel bands [22] Figure 2.11 shows the arrangement for 5 different lengths of steels bands that sized in length and width so that uniform contact is made between the edge and the surface of the sheaves. The steel bands will be design with different size so it may place on one following with another. Compare to metal v-belt, steel bands can achieve uniform contact with the pulley in respective diameter on which they run. With the maximum surface of contact with sheaves, high torque transfer capacity is achieved. Since steel bands are made of thin spring steel, only limited elastic of the steel will occur. By this way, problems such as fatigues can be predicted and avoided to ensure long life service. Used of steel bands may also reduce the wear due to high modulus of elasticity. Figure 2.11: Steel bands arrangement 17 2.2.3 Patent 3 – Friction type continuously variable transmission (US Pat No. 5746676) The inventor of this patent is Japanese from New Technology Network (NTN) Corporation, Osaka, Japan, lead by Tatsuo Kawase. According to the patent registration, this patent is done by May 5, 1998. Base on Figure 2.12, it is a CVT which has two cones contacting the input shaft and output in a housing 1. This CVT used a different mechanism compared to previous patents whereby double cones are used. This CVT had an input shaft 2 and an output shaft 3 which support by a set of bearing in housing 1 in both end to ensure both shaft are fixed in the same axis. There are 2 unit of cone 4 which named as double cone due to it double cone shaped. When the transmission accelerates, shaft 2 will rotate, and rotation is transmitted to both double cones via input ring 7. Torque will be transfer from double cone to the drive cone 8 and shaft 3 as well. Carrier 5 will move axially to change the contact diameter between double cone 4 and drive cone 8. If the carrier 5 moved out of the permissible range, double cone would disengage with the input ring 7 or drive cone 8 and cause failure. Figure 2.12: Double cone friction CVT [23] 18 2.2.4 Patent 4 – Continuously variable transmission (US Pat No. 5888160) Assigned by Nippon Seikō Kabushiki (NSK) Ltd, a group of Japanese Inventor had registered a toroidal CVT patent on 30 March 1999. This invention is a combination of toroidal CVT with toothed gear box and interchanging usage by clutches. The toroidal CVT only functions during high turning but not during low speed turning either backward movement. Figure 2.13: Schematics view of continuously variable transmission [24] Diagram shows in Figure 2.13 are the schematics view of CVT where the upper right part is the toroidal CVT while the lower right part is toothed gear. Part with labeled 36(low speed) and 37(high speed) are the clutches which control the activation of toroidal CVT or toothed gear. Same as other CVT, this design also have an input shaft (46) and output shaft (16). The input disc is labeled with 2 and output disc labeled with 4 are connected by a power roller 8 which transmit the power from input disc 2 to output disc 4. When a 19 rotational motion reached the CVT, it would rotate the input disc as it is connected to the driving shaft 17. The disc 2 will rotate the power roller as they are attached tightly on both discs. After that, the torque will be transmitted to the output disc which are concentric with the input disc. The rotational motion transmission is basically done by friction force between discs and power rollers. Edges of power rollers which attached to the disc are in a tangential manner; therefore, speeds are transmitted at any instant of contacts. Continuous variable gear ratio can be achieved when the power rollers change their positions on discs 2 and 4. Power roller is fixed at the center of both disc, and it may move and change the angle of inclination based on the requirement RPM. The angles of the power roller will decide the contacting point which means if power rollers contacted near the larger diameter on input disc, automatically it will in contact with smaller diameter on the output disc, and vice verse. Gear ratio can be changed by varying the effective diameter of input and output, and the gear ratio is continuously variable in toroidal CVT. 2.3 Available CVT Product Several researches had been carried out toward developing transmission for vehicles that able to reduce energy consumption [25]. Until now days, there are more than hundred models of vehicles using CVT. 2.3.1 Nissan Xtronic Nissan is among the vehicle manufacturer that offers CVT to vehicles. However, Nissan with their new developed CVT, Nissan Xtronic are the first CVT install in vehicles with 3.5 liters capacity engine, and it was the third generation of Nissan belt CVT after Hyper 20 CVT. Figures 2.14 had shown the CVT for 3.5 liters engine and Figure 2.14 shows the construction of CVT belt. Table 2.1: Nissan Xtronic [26] Product Name Xtronic CVT Developer Nissan Type of CVT Belt pulley(metal pushing V-belt) Application Tiida Lafesta Nissan Teana Engine displacement(Liter) 1.5 2.5 3.5 Maximum power transfer(kW) 80 134 185 Maximum torque transfer(Nm) 148 228 326 Gear ratio 2.561 ~ 0.427 2.349 ~ 0.394 2.371 ~ 0.439 21 2.3.2 Nissan Extroid Nissan Extroid developed by Nissan to provide powerful driving performance. Compared with Nissan Xtronic, this model provide higher torque output and used in rear-wheel drive car. Figure 2.16 shows that Nissan Extroid CVT use 2 set of input/output discs and increase the output torque respectively via propeller shaft. Table 2.2: Nissan Extroid [27] [28] Product Name Extroid Developer Nissan Type of CVT Application Engine Displacement(L) Toroidal Nissan Cedric Y34 3.5 Maximum power transfer(kW) 205.94 Maximum torque transfer(Nm) 387.5 Gear ratio 2.857 ~ 0.660 22 2.3.3 Audi Multitronic In early 1999, Audi had developed a variable automatic gearbox also named as CVT gearbox and named it as Multitronic. Audi’s technical specialist had made some modification on this CVT by adopting link plate chain (Figure 2.16). Instead of using metal v-belt, link plate chain had successfully transfer torque more efficiently from input to the output disc and produce higher torque and force for the vehicle. Table 2.3: Audi Multitronic [29] Product name Developer Type of CVT Application Multitronic Audi Belt-pulley(chain belt) Audi A6 Avant Engine Displacement (L) 3.0 Maximum power transfer (kW) 150 Maximum torque transfer (Nm) 400 Gear ratio 2.404 ~ 0.382 23 2.3.4 Warko CVT During 6th International CTI Symposium of Innovative Automotive Transmissions, Warko had presented their new invention in cone CVT which named it as Warko CVT. Table 2.5 shows some information that released by Warko which using 4 cones, 6 cones and 8 cones to produce the different value of torque. Table 2.4: Warko CVT [30] Product Name Warko CVT Developer Warko Type of CVT Cone based Application Number of Cone Maximum torque transfer (Nm) Maximum power transfer (kW) Gear ratio Wind generator, agriculture machinery 4 6 8 200 300 400 45 - 149 1~8 24 2.3.5 Comparison Comparison had been done based on several CVT products to determine all possible strengths and weakness of various kind of CVT product as shown in Table 2.6. Table 2.5: Comparison of CVT products Product Audi Multitronic Nissan Extroid Warko CVT Belt pulley (Chain belt) Toroidal Cone based Nissan Tiida/Lafesta/Teana Audi A6 Avant Nissan Cedric Y34 Engine displacement(L) Max power(kW) 1.5 - 3.5 3.0 3.5 Wind generator, agriculture machinery - 80 - 185 150 205.94 45 – 149 Max torque(Nm) 148 - 326 400 387.5 200 – 400 0.427- 2.371 2.404 – 0.382 2.857 – 0.660 1–8 Type of CVT Application Gear ratio Nissan Xtronic Belt pulley (Metal pushing v-belt) 57 REFERENCES [1] W. G. Nichols, "www.procarcare.com," 1998. [Online]. Available: http://www.procarcare.com/icarumba/resourcecenter/encyclopedia/icar_resourcece nter_encyclopedia_manualtran.asp. [Accessed 16 May 2013]. [2] "Punch Power Train," 29 March 2011. [Online]. Available: http://www.punchpowertrain.com/en/products/cvt/vt2. [Accessed 9 May 2013]. [3] H. T., S. M., v. D. R. and S. A. F. A., "Design of CVT-Based Hybrid Passenger Cars," Transactions on Vehicular Technology, vol. 58, no. 2, pp. 572-587, February 2009. [4] M. J. M., Propulsion Systems for Hybird Vehicles, 1 ed., London: The Institution of Electrical Engineers, 2004. [5] D. R. T, Z. N, D. G and W. M, "Free vibrational analysis of vehicle powertrain equipped with a halftoroidal CVT," in 10th Asia-Pacific Vibration Conference, Sydney, 2003. [6] B. V., "Continuously Variable Transmission CVT," 19 September 2008. [Online]. Available: http://cvt.com.sapo.pt/performances/performances.htm. [Accessed 19 May 2013]. [7] [Online]. Available: http://www.insightcentral.net/encyclopedia/encvt.html. [Accessed 20 May 2013]. [8] C. N., A. S. and K. A. A., "A review on Control Strategy for Electro-Mechanical 58 Rubber Belt Continuousl Variable Transmissions (CVT)," in National Conference in Mechanical Engineering Research and Postgraduate Studies, Kuantan, 2010. [9] K. A. and P. D., "A Discrete Analysis of Metal-V Belt Drive," in : ASME Proceedings of the 1992 International Power Transmission and Gearing, Scottsdale, AZ, USA, 1992. [10] C. G., M. L. and M. G., "Theoretical Model of Metal V-Belt Drives During Rapid Ratio Changing," Journal of Mechanical Design, vol. 123, no. 1, pp. 111-117, March 2001. [11] S. N. and H. I., "A Review on Belt and Chain Continuously Variable Transmission (CVT) :Dynamics and Control," Mechanism and Machine Theory, vol. 44, no. 1, pp. 19-41, January 2009. [12] W. L., F. P. and H. U., "Analysis of self-induced vibrations in a pushing V-belt CVT," in 2004 International Continuously Variable and Hybrid Transmission Congress, GARCHING, 2004. [13] [Online]. Available: http://www.carbibles.com/transmission_bible_pg3.html. [Accessed 22 May 2013]. [14] [Online]. Available: http://www.nsk.com/products/automotive/drive/hcvt/. [Accessed 23 May 2013]. [15] H. W., April 2005. [Online]. Available: http://www.howstuffworks.com/cvt3.htm. [Accessed 23 May 2013]. [16] Y. H. C., January 2008. [Online]. Available: http://www.csa.com/discoveryguides/auto/review5.php. [Accessed 20 May 2013]. [17] J. W. E., 2003. [Online]. Available: http://www.gizmology.net/cvt.htm. [Accessed 23 May 2013]. [18] B. M., "The Cone Ring CVT," AutoTechnology, vol. 4, no. 2, pp. 66-69, March 2004. [19] M. A., V. M. and B. M. M., "Modern Trends in Development and Application of CVT Transmitters," Journal of Mechanical Engineering Design, vol. 11, no. 1, pp. 23-30, 2008. 59 [20] "Warko Working Principle," April 2008. [Online]. Available: http://www.warko.it/index.php?option=com_content&task=blogsection&id=1&Ite mid=17. [Accessed 24 May 2013]. [21] August 2011. [Online]. Available: http://www.epo.org/searching/essentials/about.html. [Accessed 23 May 2013]. [22] D. V., C. C. C., B. A. D. and E. F. M., "Continuously Variable Transmission". European Patent EP0639732A1, 8 August 1994. [23] V. B. and T. M., "Continuously Variable Transmission ". United State Patent US005324239A, 28 June 1994. [24] N. H., T. K., T. M., T. N. and T. S., "Friction type continuously variable transmission". Japan Patent US005746676A, 5 May 1998. [25] S. M., H. M. and H. I., "Continuously variable transmission". Fujisawa, Japan Patent US005888160A, 30 May 1999. [26] S. N. and H. I., "A review on belt and chain continuously variabletransmissions (CVT): Dynamics and control," Mechanism and Machine Theory, vol. 44, no. 1, pp. 19-41, 2009. [27] [Online]. Available: http://www.nissan- global.com/EN/TECHNOLOGY/OVERVIEW/cvt.html. [Accessed 24 May 2013]. [28] [Online]. Available: http://www.nissan-global.com/PDF/tcvt_e.pdf. [Accessed 23 May 2013]. [29] [Online]. Available: http://www.jsae.or.jp/autotech/data_e/8-11e.html. [Accessed 23 May 2013]. [30] [Online]. Available: http://www.audiworld.com/news/99/multitronic/content.shtml. [Accessed 23 May 2013]. [31] "Warko Summary Characteristics," [Online]. Available: http://www.warko.it/index.php?option=com_content&task=blogcategory&id=8&It emid=14. [Accessed 24 May 2013]. [32] National Research Council, Approaches to Improve Engineering Design, Washington: National Academies Press, 2002. 60 [33] Eggert and R. J., Engineering Design, New Jersey: Prentice Hall, 2004. [34] D. G. U., The Mechanical Design Process, 3rd Edition ed., A. Hill, Ed., New York: McGraw Hill, 2003.