FIREX®-II TECK CABLE Introduction

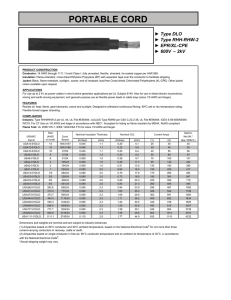

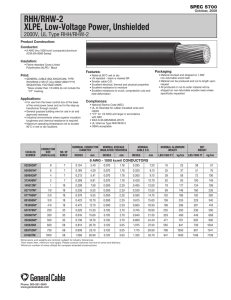

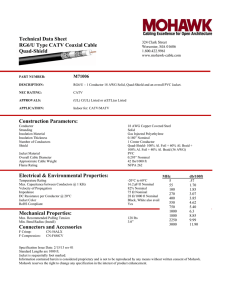

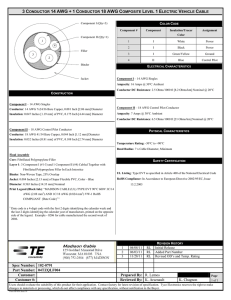

advertisement