ADCP-80-512 • Issue 2 • September 1999

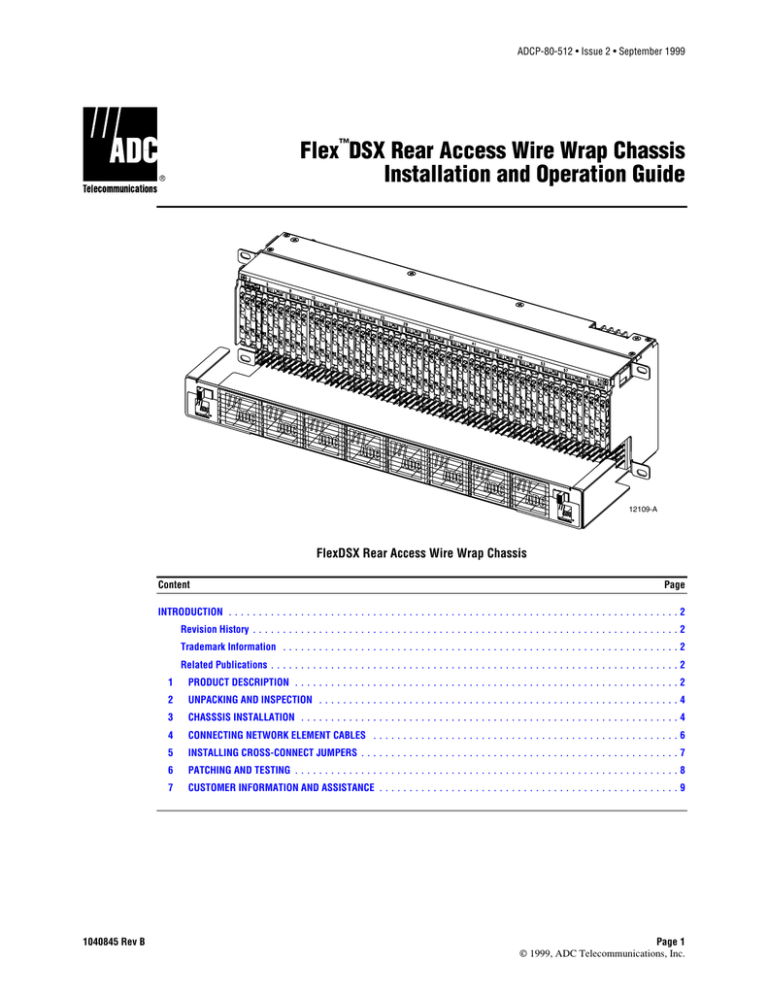

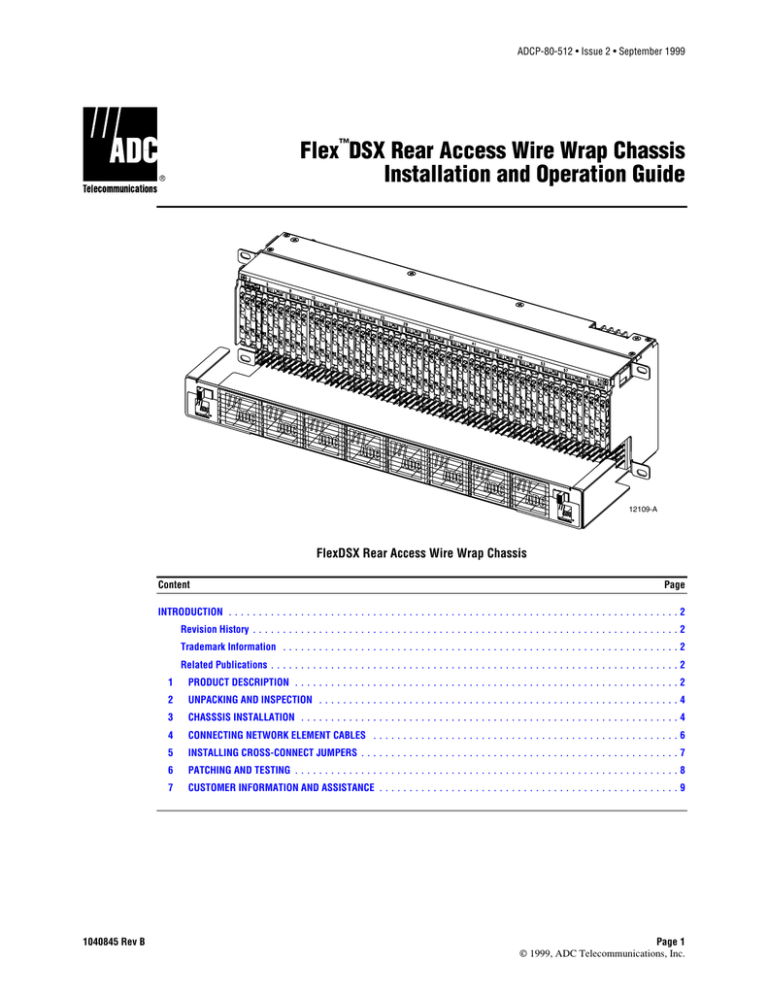

Flex™DSX Rear Access Wire Wrap Chassis

Installation and Operation Guide

12109-A

FlexDSX Rear Access Wire Wrap Chassis

Content

Page

INTRODUCTION ........................................................................... 2

Revision History ....................................................................... 2

Trademark Information .................................................................. 2

Related Publications .................................................................... 2

1040845 Rev B

1

PRODUCT DESCRIPTION ................................................................ 2

2

UNPACKING AND INSPECTION ............................................................ 4

3

CHASSSIS INSTALLATION ............................................................... 4

4

CONNECTING NETWORK ELEMENT CABLES ................................................... 6

5

INSTALLING CROSS-CONNECT JUMPERS ..................................................... 7

6

PATCHING AND TESTING ................................................................ 8

7

CUSTOMER INFORMATION AND ASSISTANCE .................................................. 9

Page 1

© 1999, ADC Telecommunications, Inc.

ADCP-80-512 • Issue 2 • September 1999

INTRODUCTION

This manual describes the ADC FlexDSX Rear Access Wire Wrap Chassis, and provides

procedures for unpacking, installing, and operating this product.

Revision History

ISSUE

DATE

REASON FOR CHANGE

Issue 1

01/99

Original.

Issue 2

09/99

Revised to add electrical ratings and warning. Product name change.

Trademark Information

ADC and ADC Telecommunications are registered trademarks of ADC Telecommunications, Inc.

FlexDSX is a trademark of ADC Telecommunications, Inc.

Related Publications

Title

1

ADCP Number

FlexDSX System Planning and Application Guide

80-511

DSX-1 Operational Procedures

80-514

PRODUCT DESCRIPTION

The FlexDSX Rear Access Wire Wrap Chassis is an individual frame module for the

FlexDSX Front Cross-Connect System. Figure 1 shows the front of the chassis, with its wirewrap field for cross-connect termination and bantam jack field for test, patch, and monitor

access.

As shown, the chassis has a horizontal wire way for cross-connect wires and a hinged front

door with a label for recording cross-connect terminations. The chassis is 132.1 mm (5.2 in.)

high, 482.6 mm (19.0 inches) wide, and 149.9 mm (5.9 inches) deep.

The chassis requires a connection of 48 volts DC nominal at 1.0 amps maximum to provide

power for the cross-connect tracer lamps located on each circuit module. When a patch cord is

inserted in the MON OUT port on one of a cross-connect circuit, the tracer lamps on both

ends of the circuit blink off and on.

Figure 2 shows the chassis rear with its wire wrap terminals for Network Element (NE)

terminations. Each chassis provides test and patch access for 64 NE terminations.

Page 2

© 1999, ADC Telecommunications, Inc.

ADCP-80-512 • Issue 2 • September 1999

BANTAM JACK FIELD

(TEST, PATCH, AND

MONITOR ACCESS)

MOUNTING TAB

(FOUR PLACES)

CIRCUIT POSITION 1

(64 POSITIONS PER CHASSIS)

HORIZONTAL

WIRE WAY FOR

CROSS-CONNECT

WIRES

DOOR LATCH

(TWO PLACES)

HINGED FRONT DOOR

WITH LABEL

WIRE-WRAP

CROSS-CONNECT

TERMINATION FIELD

12110-A

Figure 1. FlexDSX Chassis Main Components (Front View)

48V

48V RET

SHIELD

GND

48V BATTERY

TERMINAL BLOCK

EQUIPMENT FIELD (WIRE WRAP

PINS SHOWN FOR REFERENCE.

A VARIETY OF EQUIPMENT

FIELD TYPES ARE AVAILABLE). CIRCUIT MODULES ARE

AUTOMATICALLY POWERED

WHEN PLUGGED INTO CHASSIS

ONE CIRCUIT MODULE

BACKPLANE.

(16 PER CHASSIS)

CHASSIS

GROUND LUG

12111-A

Figure 2. FlexDSX Rear Access Wire Wrap Chassis (Rear)

Page 3

© 1999, ADC Telecommunications, Inc.

ADCP-80-512 • Issue 2 • September 1999

Figure 3 shows an individual circuit for even position jack card. For odd position jack card,

refer to ADCP-80-511, “FlexDSX System Planning and Application Guide.”

EVEN JACK CARD

JACK MOUNT AND REAR INTERFACE ASSEMBLY

-48V

-48V

TL

TL

RET

RET

R

R

TRACER

LAMP

MON OUT

F

R

O

N

T

OUT

IN

T

T

SG

SG

RO

RO

XRO

XRO

XTO

XTO

TO

TO

TI

TI

XTI

XTI

XRI

XRI

RI

RI

MON IN

T

T

R

R

TL

T

CROSS

CONNECT

OUT

R

IN

T

R

-48V

RET POWER

SG

R

E

A

R

T

OUT

R

EQUIPMENT

T IN

R

12112-A

Figure 3. FlexDSX Rear Access Wire Wrap Circuit Diagram

2

UNPACKING AND INSPECTION

Unpack the FlexDSX chassis carefully, checking it for damage. If any item is damaged, file a

claim with the commercial carrier and consult ADC Customer Service. Keep the damaged

shipping containers for use in the claim. Even though no damage is evident, save the shipping

container for use if the equipment requires shipment at a future date.

3

CHASSIS INSTALLATION

Warning: FlexDSX products are designed to be located in a dedicated restricted access

communication equipment area. Never install equipment in a wet location or during a

lightning storm. When installing or modifying telephone lines, disconnect lines at the network

interface before working with uninsulated wires or terminals.

1. Determine where the chassis will be placed on the rack. Refer to Figure 4 for correct

chassis position.

Page 4

© 1999, ADC Telecommunications, Inc.

ADCP-80-512 • Issue 2 • September 1999

45

UPPER HORIZONTAL

TROUGH

FUSE PANEL

40

CHASSIS POSITION 12

35

CHASSIS POSITION 11

CHASSIS POSITION 10

HOLE SPACINGS

AT INTERVALS OF

44.6 MM (1.75 IN)

30

CHASSIS POSITION 9

CHASSIS POSITION 8

25

2200 MM

(86.61 IN.)

CHASSIS POSITION 7

20

CHASSIS POSITION 6

CHASSIS POSITIONS

1 THOUGH 12

IN OVERHEAD CABLING ENVIRONMENT,

PLACE FIRST CHASSIS IN POSITION 12

AND SUBSEQUENT CHASSIS

IN POSITIONS 11, 10, 9, ETC.,

WORKING DOWNWARD.

IN RAISED FLOOR CABLING ENVIRONMENT,

PLACE FIRST CHASSIS IN POSITION 1

AND SUBSEQUENT CHASSIS

IN POSITIONS 2, 3, 4, ETC.,

WORKING UPWARD.

CHASSIS POSITION 5

15

CHASSIS POSITION 4

CHASSIS POSITION 3

10

CHASSIS POSITION 2

5

CHASSIS POSITION 1

LOWER HORIZONTAL

TROUGH

102.6 MM

(4.04 IN.)

12113-A

464.3 MM

(18.28 IN.)

MINIMUM OPENING

Figure 4. FlexDSX Chassis Positions

2. Align the top and bottom mounting tabs on each side of the chassis with the slotted holes

in the vertical cable guide, as shown in Figure 5. (Cable rings do not have to be

removed.) Fasten the chassis to the bay using two #12-24 - 0.375 inch (9.5 mm) machine

screws on each side of the chassis.

Page 5

© 1999, ADC Telecommunications, Inc.

ADCP-80-512 • Issue 2 • September 1999

3. Ground the chassis per local practice. A ground lug is available on the rear of the chassis

(refer to Figure 2 to identify the ground lug).

VERTICAL CABLE

GUIDE

MOUNTING TAB

RACK HOLE SPACINGS

AT INTERVALS OF

44.6 MM (1.75 IN.)

CHASSIS

ALIGN TOP AND BOTTOM

MOUNTING TABS

WITH SLOTTED HOLES

IN VERTICAL CABLE GUIDES.

FRONT VIEW

12114-A

Figure 5. Installing the Chassis

4. Connect the 48V Terminal Block on the rear of the chassis to the respective circuit on

the fuse panel as indicated in Figure 6. Also, check to ensure that the dummy fuses have

been removed from the fuse panel and replaced with the correct type fuses (0.5 GMT).

-48V (RED)

.

TO FIRST CHASSIS INSTALLED

(ON TOP OR BOTTOM OF RACK)

.

48V RET (BLACK)

SHIELD

GND

FUSE PANEL

TO SUBSEQUENT CHASSIS

TERMINAL BLOCK

(LEFT TO RIGHT

IN THE ORDER INSTALLED)

ROUTE ALONG RACK

THROUGH POWER WIRE

GUIDE/RETAINERS;

REFER TO SYSTEM MANUAL.

12115-A

CHASSIS 48V BATTERY

TERMINAL BLOCK

Figure 6. Connecting the Chassis to the Fuse Panel

4

CONNECTING NETWORK ELEMENT CABLES

1. Route the network element transmit and receive cables to the chassis following

instructions in ADCP-80-511, “FlexDSX System Planning and Application Guide.”

2. Prepare the individual wires to be terminated on the chassis by clipping off the ends

cleanly and stripping back the insulation about 4 cm (1.6 in.).

3. Terminate each transmit/receive (OUT/IN) circuit as follows:

Page 6

© 1999, ADC Telecommunications, Inc.

ADCP-80-512 • Issue 2 • September 1999

a.

b.

c.

d.

Identify the chassis pins to be used for termination. Figure 7 shows the Tip Out

(TO), Ring Out (RO), Tip In (TI), and Ring In (RI) pins for one NE termination.

Label the twisted pair for the network element transmit signal and route the wires to

the upper pins identified TO and RO.

Label the twisted pair for the network element receive signal and route the wires to

the lower pins identified TI and RI.

Connect each individual wire to the pin. ADC recommends using five stripped turns

plus one turn with insulation on three corners of the wire wrap pin (see Figure 7).

INSULATION

(ONE TURN ON

THREE CORNERS OF PIN)

STRIPPED WIRE

(FIVE TURNS)

RECOMMENDED

WIRE WRAP (ONE PIN)

TO

RO

TI

RI

REAR VIEW

WIRE WRAP

EQUIPMENT TERMINATION

FIELD (SHADED AREA

SHOWS PIN DESIGNATIONS

FOR CIRCUIT ONE)

12116-A

Figure 7. Termination Pins for One Network Element

Transmit/Receive (OUT/IN) Circuit

5

INSTALLING CROSS-CONNECT JUMPERS

To cross-connect between circuit modules for two network elements, use the wire-wrap pins

on the bottom front of the chassis, identified in Figure 8. Between the two circuit modules,

cross-connect the IN and OUT wires, as shown in Figure 9.

Page 7

© 1999, ADC Telecommunications, Inc.

ADCP-80-512 • Issue 2 • September 1999

LED

MONITOR OUT

OUT

PATCH AND TEST

JACK FIELD

IN

MONITOR IN

SHADED AREA IDENTIFIES

ONE CIRCUIT

TRACER LAMP

TO

WIRE WRAP

CROSS-CONNECT

FIELD

RO

TI

RI

FRONT VIEW

12117-A

Figure 8. Cross-Connect Wire Wrap Field

and Patch and Test Jack Field

GREEN

TL

BLUE

TO

BLUE-WHITE OUT RO

ORANGE

ORANGE-WHITE

TWISTED PAIRS

5 CONDUCTOR

JUMPER WIRE

TL

TI

IN

TO

RI

RO

CROSS-CONNECT

TERMINAL BLOCKS

OUT

TI

RI

IN

11893-B

Figure 9. Cross-Connect Wire Routing

6

PATCHING AND TESTING

For patching and testing. use the patch and test jackfield identified above in Figure 8. Refer to

ADCP-80-514, “DSX-1 Operational Procedures,” for individual procedures such as in-service

and out-of-service patching.

Page 8

© 1999, ADC Telecommunications, Inc.

ADCP-80-512 • Issue 2 • September 1999

7

CUSTOMER INFORMATION AND ASSISTANCE

For customers wanting information on ADC products or help in using them, ADC offers the

services listed below. To obtain any of these services by telephone, first dial the central ADC

telephone number, then dial the extension provided below.

The central number for calls originating in the U.S.A. or Canada is 1-800-366-3891. For calls

originating outside the U.S.A. or Canada, dial country code “1” then dial 612-946-3000.

Sales Assistance

Extension 3000

• Quotation Proposals

• Ordering and Delivery

• General Product Information

Systems Integration

Extension 3000

•

•

•

•

•

•

•

Complete Solutions (from Concept to Installation)

Network Design and Integration Testing

System Turn-Up and Testing

Network Monitoring (Upstream or Downstream)

Power Monitoring and Remote Surveillance

Service/Maintenance Agreements

Systems Operation

BCG Technical Assistance Center

Extension 3475

E-Mail: technical@adc.com

•

•

•

•

•

•

Technical Information

System/Network Configuration

Product Specification and Application

Training (Product-Specific)

Installation and Operation Assistance

Troubleshooting and Repair

Product Return Department

Extension 3748

E-Mail: repair&return@adc.com

• ADC Return Authorization number and instructions

must be obtained before returning products.

Product information may also be obtained using the ADC web site at www.adc.com or by

writing ADC Telecommunications, Inc., P.O. Box 1101, Minneapolis, MN 55440-1101, U.S.A.

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In

no event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting ADC’s Technical Assistance Center at 1-800-366-3891, extension

3475 (in U.S.A. or Canada) or 612-946-3000 (outside U.S.A. and Canada), or by writing to ADC Telecommunications, Inc.,

Attn: Technical Assistance Center, Mail Station #71, P.O. Box 1101, Minneapolis, MN 55440-1101, U.S.A.

© 1999, ADC Telecommunications, Inc.

All Rights Reserved

Printed in U.S.A.

Page 9