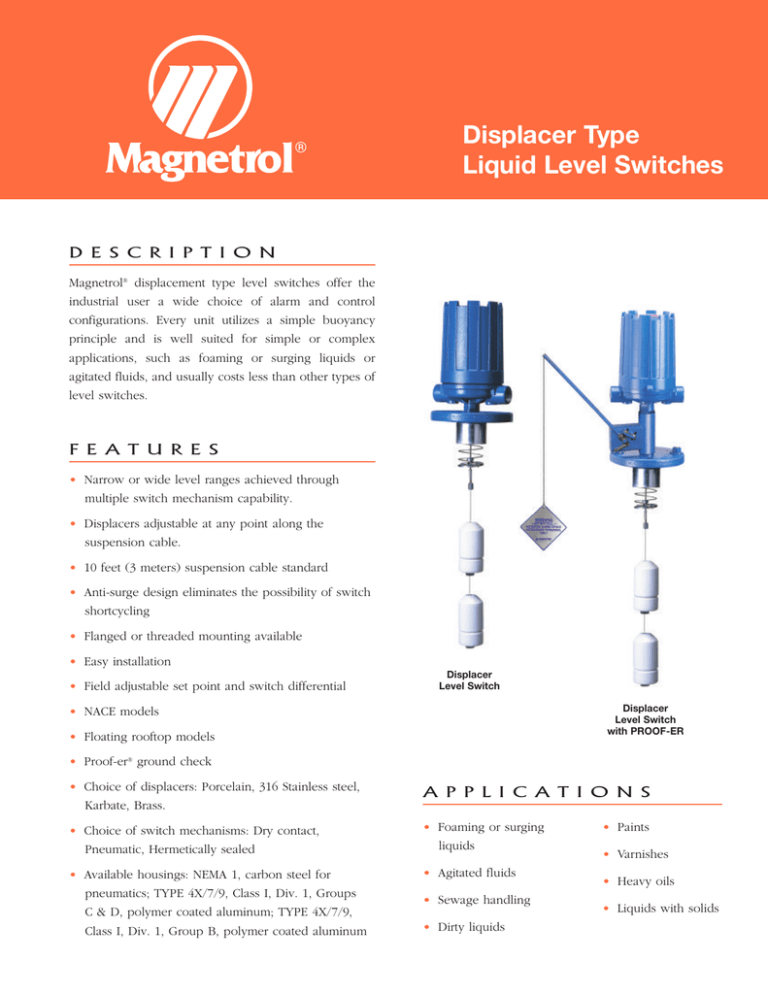

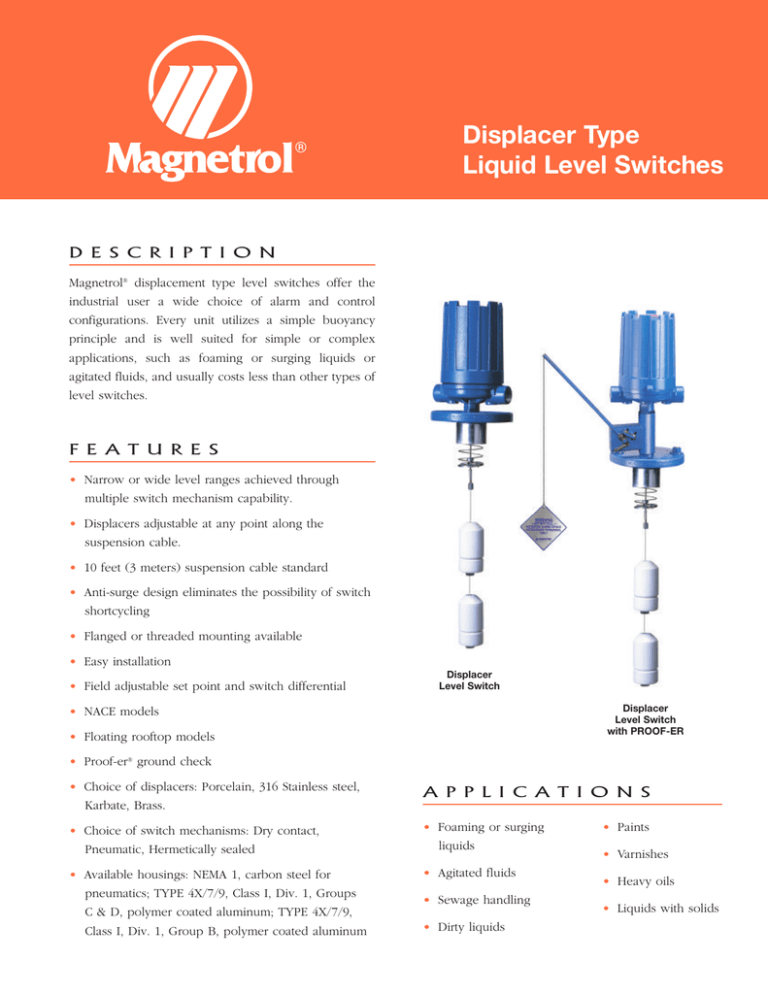

Displacer Type

Liquid Level Switches

D E S C R I P T I O N

Magnetrol® displacement type level switches offer the

industrial user a wide choice of alarm and control

configurations. Every unit utilizes a simple buoyancy

principle and is well suited for simple or complex

applications, such as foaming or surging liquids or

agitated fluids, and usually costs less than other types of

level switches.

F E A T U R E S

• Narrow or wide level ranges achieved through

multiple switch mechanism capability.

• Displacers adjustable at any point along the

suspension cable.

• 10 feet (3 meters) suspension cable standard

• Anti-surge design eliminates the possibility of switch

shortcycling

• Flanged or threaded mounting available

• Easy installation

• Field adjustable set point and switch differential

Displacer

Level Switch

Displacer

Level Switch

with PROOF-ER

• NACE models

• Floating rooftop models

• Proof-er® ground check

• Choice of displacers: Porcelain, 316 Stainless steel,

Karbate, Brass.

A P P L I C A T I O N S

• Choice of switch mechanisms: Dry contact,

Pneumatic, Hermetically sealed

• Foaming or surging

liquids

• Available housings: NEMA 1, carbon steel for

pneumatics; TYPE 4X/7/9, Class I, Div. 1, Groups

C & D, polymer coated aluminum; TYPE 4X/7/9,

Class I, Div. 1, Group B, polymer coated aluminum

• Agitated fluids

• Sewage handling

• Dirty liquids

• Paints

• Varnishes

• Heavy oils

• Liquids with solids

T E C H N O L O G Y

Operation is based upon simple buoyancy, whereby a

spring is loaded with weighted displacers which are

heavier than the liquid. Immersion of the displacers in

the liquid results in buoyancy force change, which

moves the spring upward.

Pivot

6

4

Return

Spring

3

Since the spring moves only when the level moves on a

displacer, spring movement is always a small fraction

of the level travel between displacers .

5

A magnetic sleeve is connected to the spring and

operates within a non-magnetic barrier tube . Spring

movement causes the magnetic sleeve to attract a pivoted magnet , actuating a switch mechanism located

outside the barrier tube. Built-in limit stops prevent over

stroking of the spring, under level surge conditions.

P R O O F - E R

Rising

Level

2

Falling

Level

C O N T R O L S

The purpose of the PROOF-ER is to check the operation

of a displacer control without having to raise the level in

the tank. This is accomplished by pulling downward on

the PROOF-ER chain. A spring-loaded lever arm then lifts

F L O A T I N G

1

R O O F T O P

The floating rooftop control is designed for installation on

“barrier” (floating roof) tanks. The control will be furnished with a brass weight displacer to prevent sparking.

the switch actuator simulating a high or high-high level

condition. When the chain is released, the PROOF-ER

returns the actuator to its previous position to resume normal operation.

C O N T R O L S

A hollow brass displacer is required if the control is to

actuate in liquid as well as by the barrier. Consult factory

for other options.

D I S P L A C E R S

Stainless steel displacers are rated 720 psig @ +100° F

(50 bar @ +38° C).

Karbate displacers are limited to a minimum temperature

of +32° F (0° C) and a maximum temperature of +300° F

(+149° C).

D I S P L A C E R S

S U S P E N S I O N

Displacers are field-adjustable at any point along the

suspension cable (10 feet (3 meters) 316 stainless steel is

2

Do not use porcelain displacers on non-vented boiler

water condensate systems over +200° F (+93° C). Stainless

steel or Karbate is recommended.

C A B L E

standard). Monel® and Hastelloy® materials are available.

Consult the factory for longer lengths.

S I N G L E

S E R I E S

S W I T C H

A 1 0

A N D

M O D E L S

S E R I E S

A 1 5

SERIES A10

PUMP OR VALVE CONTROL

WIDE DIFFERENTIAL TYPE

SERIES A15

LEVEL ALARM APPLICATIONS

NARROW DIFFERENTIAL TYPE

These wide differential units are factory calibrated to

actuate as a liquid level reaches a given displacer and

to deactuate when the level reaches a second

displacer.

These instruments are factory calibrated to operate over

a narrow level differential band and are ideally suited

for liquid level alarm applications on either high or

low level.

The minimum differential band is approximately 6 in.

(152 mm) in water and varies somewhat with liquid specific gravity. The maximum differential is determined by

the length of the displacer suspension cable.

The operating level is fully adjustable simply by

repositioning the displacer along its suspension cable.

The differential band varies slightly with liquid

specific gravity.

D U A L

S E R I E S

S W I T C H

B 1 0

A N D

M O D E L S

S E R I E S

B 1 5

SERIES B10

WIDE DIFFERENTIAL TYPE

SERIES B15

NARROW DIFFERENTIAL TYPE

These wide differential tandem units are factory calibrated

with a choice of several operating sequences designed to

meet virtually any application.

These instruments utilize two switches — each actuated

at a different level and each calibrated with a narrow

differential band.

OPERATING SEQUENCES

Model B10 units are available with a choice of switch

operating sequence. Five of the most popular

sequences are described on page 8. When ordering,

specify operating sequence number and specific gravity

of the liquid.

T R I - S W I T C H

S E R I E S

C 1 0

A N D

M O D E L S

S E R I E S

C 1 5

SERIES C10

WIDE DIFFERENTIAL TYPE

SERIES C15

NARROW DIFFERENTIAL TYPE

These wide differential type switches are designed to

provide three electrically separate control signals in a

selected sequence as liquid level varies.

These instruments are factory-calibrated to operate over

a narrow level band while providing three electrically

separate control signals as liquid level varies.

These units come factory-calibrated with a choice

of several operating sequences combining wide and

narrow level differential.

3

A G E N C Y

A P P R O V A L S

AGENCY

APPROVED MODEL

AREA CLASSIFICATION

FM

All with an electric switch mechanism and a housing

listed as Type 4X/7/9 Class I, Div 1, Groups C & D

Class II, Div 1, Groups E, F & G

All with an electric switch mechanism and a housing

listed as Type 4X/7/9 Class I, Div 1, Group B

Class I, Div 1, Groups B, C & D

Class II, Div 1, Groups E, F & G

All with a Series HS or F electric switch

mechanism and a housing listed as CSA Type 4X

Class I, Div 2, Groups B, C & D

All with an electric switch mechanism and a housing

listed as Type 4X/7/9 Class I, Div 1, Groups C & D

Class II, Div 1, Groups E, F & G

All with an electric switch mechanism and a housing

listed as Type 4X/7/9 Class I, Div 1, Group B

Class I, Div 1, Groups B, C & D

Class II, Div 1, Groups E, F & G

All with an electric switch mechanism and an

ATEX housing ATEX II 2 G EEx d IIC T6

94/9/EC

IEC Ex Ex d IIC T6

IP66

All models

Installation Category II

Pollution Degree 2

CSA

ATEX / IEC Ex CE

Low Voltage Directives

2006/95/EC

per Harmonized Standard

EN 61010-1/1993 & Amendment No. 1

Controls with two or more HS or H1 switches are not ATEX approved.

IEC Installation Instructions:

The cable entry and closing devices shall be Ex d certified suitable for the conditions of use and correctly installed.

For ambient temperatures above +55° C or for process temperatures above +150° C, suitable heat resistant cables shall be used.

Heat extensions (between process connection and housing) shall never be insulated.

Special conditions for safe use:

When the equipment is installed in process temperatures higher than +85° C the temperature classification must be reduced

according to the following table as per IEC60079-0.

Maximum Process

Temperature

Temperature

Classification

< 85° C

T6

< 100° C

T5

< 135° C

T4

< 200° C

T3

< 300° C

T2

< 450° C

T1

These units are in conformity with IECEx KEM 05.0020X

Classification Ex d IIC T6

Tambient -40° C to +70° C

P R E S S U R E / T E M P E R A T U R E

Threaded Models

R A T I N G S

800 psig @ +100° F (55 bar @ +38° C)

250 psig @ +400° F (17 bar @ +204° C)

Flanged Models

Limited to the pressure rating of the selected flange

or displacer. Cast iron flanges are flat face type

conforming to ANSI dimensional specifications.

Low Pressure PROOF-ER Models

25 psig @ +200° F (1.7 bar @ +93° C)

Medium Pressure PROOF-ER Models

125 psig @ +300° F (8.6 bar @ +149° C)

Models with stainless steel displacers are rated 720 psig @ +100° F (50 bar @ 38° C).

4

S P E C I F I C A T I O N S

S W I T C H

M E C H A N I S M S

A N D

E N C L O S U R E S

SERIES B, C, D, O & Q DRY CONTACT SWITCHES

• Series “B”, “C”, “O” and “Q” switches are general

purpose units with a selection of maximum liquid

temperature ratings

• Series “D” switch is designed for high DC current

applications

SERIES J & K PNEUMATIC SWITCHES

• Suited for process industry applications in hazardous

locations or where electrical power is not available

• Series “J” bleed type switch is intended for

general purpose applications

• Series “K” switch is specially designed to

provide non-bleed operation with a high

degree of vibration resistance

SERIES HS, F & 8 HERMETICALLY SEALED SWITCHES

SWITCH ENCLOSURES

• Entire mechanism and contacts are contained within a

positively pressurized capsule with series ‘HS’

• TYPE 4X/7/9 aluminum enclosures

• Ideal for use in salt and other corrosive atmospheres

• Designed and approved for Class I, Div. 1, Groups

C & D and Class I, Div. 1 Group B

• Available in two models, one with easy access

terminals, another with 12" (305 mm) long exposed

wiring leads which may be field connected away from

the switch enclosure

• Optional housing heaters and drains

available for some enclosures

• Pneumatic switch mechanisms available with

a NEMA 1 enclosure

BASIC ELECTRICAL RATINGS

Voltage

Switch Series and Non-Inductive Ampere Rating

B

C

D

F

HS

O

Q

120 VAC 15.00 15.00 10.00 0.25

5.00

15.00 15.00

240 VAC 15.00 15.00

5.00

15.00 15.00

24 VDC

—

—

8

1.00

—

6.00 10.00 10.00 4.00

5.00

—

6.00

3.00

120 VDC

0.50

1.00 10.00 0.30

0.50

1.00

0.50

—

240 VDC

0.25

0.50

0.25

0.50

0.25

—

3.00

—

5

S P E C I F I C A T I O N S

MODEL

A10

DIMENSIONAL

DATA

AND

ACTUATION

LEVELS

INCHES (MM)

Outline Dimensions

Threaded Mounting

Flanged Mounting

A

B

A

B

Displacer

Type

Porcelain

5.00

(127)

122.00

(3098)

7.00

(177)

124.00

(3149)

Stainless Steel

or Karbate

4.75

(120)

122.00

(3098)

6.75

(171)

124.00

(3149)

Displacer Type

C

D

E

Porcelain

2.56 (65)

7.25 (184)

3.62 (91)

Stainless Steel

or Karbate

2.50 (63)

9.00 (228)

4.50 (114)

Electrical Connections

TYPE 4X/7/9, Group B: 1" NPT

NEMA 1 Pneumatic: 1⁄4" NPT

STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY

Displacer

Type

0.60

0.70

0.80

0.90

Liquid

Temp.

°F

F

G

F

G

F

100

5.30 (134)

1.50 (38)

4.10 (104)

1.20 (30)

3.20 (81)

1.10 (27)

2.50 (63)

200

300

400

—

—

—

—

—

—

4.80 (121)

—

—

2.00 (50)

—

—

3.80 (96)

4.30 (109)

—

1.80 (45)

2.40 (60)

—

3.00 (76)

3.40 (86)

3.40 (86)

Stainless

Steel

or Karbate

100

200

300

7.00 (177)

—

—

2.40 (60)

—

—

5.30 (134)

5.90 (149)

—

2.00 (50)

2.80 (71)

—

4.10 (104)

4.70 (119)

5.10 (129)

1.80 (45)

2.50 (63)

3.10 (78)

Stainless

Steel

400

500

—

—

—

—

—

—

—

—

—

—

—

—

Porcelain

G

F

1.00

G

F

G

1.00 (25)

2.00 (50)

0.90 (22)

1.60 (40)

2.10 (53)

2.60 (66)

2.50 (63)

2.90 (73)

2.90 (73)

1.50 (38)

1.90 (48)

2.40 (60)

3.10 (78)

3.60 (91)

4.00 (101)

1.60 (40)

2.20 (55)

2.70 (68)

2.40 (60)

2.80 (71)

3.20 (81)

1.40 (35)

2.00 (50)

2.40 (60)

4.40 (111)

—

3.20 (81)

—

3.60 (91)

3.90 (99)

2.90 (73)

3.30 (83)

Note: All levels ±0.25" (6).

5.93

(151)

5.93

(151)

3.87

(98)

8.46

(214)

10.12

(257)

Elect.

Conn.

8.46

(214)

10.12

(257)

Elect.

Conn.

Plug

3.13

(79)

3.87

(98)

Plug

Flange

2 1/2" NPT

A Min.

A Min.

B

Max.

Rising Level

Actuation

D

E

F

Falling Level

Actuation

G

C

Model A10

with Threaded Mounting

6

B

Max.

Rising Level

Actuation

D

E

F

Falling Level

Actuation

G

C

Model A10

with Flanged Mounting

S P E C I F I C A T I O N S

MODEL

A15

DIMENSIONAL

DATA

AND

ACTUATION

LEVELS

*

INCHES (MM)

Outline Dimensions

Threaded Mounting

Flanged Mounting

A

B

A

B

Displacer

Type

Porcelain

5.62

(142)

122.00

(3098)

7.62

(193)

124.00

(3149)

Stainless Steel

or Karbate

5.62

(142)

122.00

(3098)

7.62

(193)

124.00

(3149)

Displacer Type

C

D

Porcelain

2.56 (65)

7.25 (184)

Stainless Steel

or Karbate

2.50 (63)

9.00 (228)

Electrical Connections

TYPE 4X/7/9, Group B: 1" NPT

NEMA 1 Pneumatic: 1⁄4" NPT

STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY

0.50

Displacer Liquid

Temp.

Type

°F

0.60

E

F

E

0.70

0.80

0.90

1.00

F

E

F

E

F

E

F

E

F

2.10 (53)

2.60 (66)

—

—

—

1.60 (40)

2.10 (53)

2.40 (60)

4.50 (114)

4.90 (124)

5.20 (132)

5.60 (142)

—

3.90 (99)

4.30 (109)

4.60 (116)

1.70 (43)

2.10 (53)

2.40 (60)

2.80 (71)

—

1.40 (35)

1.80 (45)

2.10 (53)

3.90 (99)

4.30 (109)

4.50 (114)

4.80 (121)

5.10 (129)

3.40 (86)

3.70 (93)

4.00 (101)

1.70 (43)

2.10 (53)

2.30 (58)

2.60 (66)

2.90 (73)

1.20 (30)

1.60 (40)

1.80 (45)

3.50 (88)

3.80 (96)

4.10 (104)

4.30 (109)

4.60 (116)

3.00 (76)

3.30 (83)

3.60 (91)

1.50 (38)

1.80 (45)

2.10 (53)

2.30 (58)

2.60 (66)

1.10 (27)

1.40 (35)

1.70 (43)

3.20 (81)

3.50 (88)

3.70 (93)

3.90 (99)

4.20 (106)

2.70 (68)

3.00 (76)

3.20 (81)

1.40 (35)

1.70 (43)

1.90 (48)

2.10 (53)

2.40 (60)

1.00 (25)

1.30 (33)

1.50 (38)

Stainless

Steel

or Karbate

100

200

300

400

500

100

200

300

—

—

5.10 (129)

—

—

5.60 (142)

—

—

—

—

—

—

—

—

—

5.40 (137) 2.00 (50) 4.50 (114)

6.00 (152) 2.60 (66) 5.00 (127)

6.40 (162) 3.00 (76) 5.30 (134)

Stainless

Steel

400

500

6.90 (175) 3.50 (88) 5.70 (144) 2.80 (71) 4.90 (124) 2.40 (60) 4.30 (109) 2.10 (53) 3.80 (96) 1.90 (48) 3.40 (86) 1.70 (43)

—

—

6.10 (154) 3.20 (81) 5.20 (132) 2.80 (71) 4.60 (116) 2.40 (60) 4.10 (104) 2.20 (55) 3.70 (93) 2.00 (50)

Porcelain

Note: All levels ±0.25" (6).

*See page 21 for PROOF-ER and/or floating rooftop switch dimensions.

5.93

(151)

5.93

(151)

3.87

(98)

6.25

(159)

7.94

(201) Elect.

Conn.

Plug

3.13

(79)

6.25

(159)

7.94

(201)

Elect.

Conn.

Plug

2 1/2" NPT

Flange

A Min.

B

Max.

3.87

(98)

A Min.

Rising Level

Actuation

D

E

Falling Level

Actuation

F

C

Model A15

with Threaded Mounting

B

Max.

Rising Level

Actuation

D

E

Falling Level

Actuation

F

C

Model A15

with Flanged Mounting

7

S P E C I F I C A T I O N S

M O D E L

B 1 0

D I M E N S I O N A L

D A T A

INCHES (MM)

Outline Dimensions

Threaded Mounting

Flanged Mounting

A

B

A

B

Displacer

Type

MODEL B10 WITH DISPLACER

ARRANGEMENTS 3, 4, AND 5

Displacer Type

C

D

E

F

Porcelain

4.88

(123)

122.00

(3098)

6.88

(174)

124.00

(3149)

Porcelain

2.56

(65)

5.02

(127)

5.02

(127)

5.02

(127)

Stainless Steel

or Karbate

4.75

(120)

122.00

(3098)

6.75

(171)

124.00

(3149)

Stainless Steel

or Karbate

2.50

(63)

6.00

(152)

6.00

(152)

6.00

(152)

MODEL B10 WITH DISPLACER

ARRANGEMENTS 1 AND 2

Displacer Type

C

Electrical Connections

D

Porcelain

2.56 (65) 10.04 (255) 5.02 (127)

Stainless Steel

or Karbate

2.50 (63) 12.00 (304) 6.00 (152)

5.93

(151)

TYPE 4X/7/9

Group B: 1" NPT

E

5.93

(151)

3.87

(98)

8.46

(214)

10.12

(257)

Elect.

Conn.

8.46

(214)

10.12

(257)

Elect.

Conn.

Plug

3.13

(79)

3.87

(98)

Plug

Flange

2 1/2" NPT

A Min.

A Min.

B

Max.

B

Max.

C

Model B10

with Threaded Mounting

8

C

Model B10

with Flanged Mounting

S P E C I F I C A T I O N S

M O D E L

B 1 0

A C T U A T I O N

L E V E L S

INCHES (MM)

B10 STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY WITH DISPLACER ARRANGEMENT 1

Displacer

Liquid

Type

Temp. ° F

Level

0.60 - 0.64

0.65 - 0.71

0.72 - 0.73

0.74 - 0.82

0.83 - 0.92

0.93 - 1.00

1.01 - 1.07

H

7.79 - 7.04

(197 - 178)

2.62 - 2.19

(56 - 55)

2.01 - 1.89

(51 - 48)

7.91

(200)

3.06

(77)

2.76

(70)

7.66

(194

2.88

(73

1.86

(47

7.72

(196

2.95

(74

2.72

(69

7.22

(133

2.91

(73

1.68

(42

6.56

(166

2.25

(57

2.45

(62

F

—

—

—

G

—

—

—

H

—

—

—

6.91

(175

2.71

(68

1.63

(41

6.73

(170

2.54

(64

2.39

(60

7.48

(189

3.29

(83

3.14

(79

6.73

(180

2.99

(75

1.45

(36

6.37

(161

2.63

(66

2.13

(54

7.04

(178

3.30

(83

2.80

(71

5.55

(140

2.21

(56

1.30

(33

6.15

(156

2.81

(71

1.90

(48

6.75

(171

3.41

(86

2.50

(63

F

—

—

—

—

—

—

G

—

—

—

—

—

—

H

—

—

—

—

—

—

4.97

(126

1.90

(48

1.02

(25

5.02

(127

1.94

(49

1.58

(40

5.57

(141

2.50

(63

2.13

(54

6.12

(155

3.05

(77

2.68

(68

Level

1.08 - 1.12

1.13 - 1.17

1.18 - 1.27

1.28 - 1.30

1.31 - 1.39

1.40 - 1.50

4.47

(113

1.59

(40

0.96

(24

4.66

(118

1.79

(45

1.48

(37

5.18

(131

2.31

(58

1.99

(50

5.70

(144

2.82

(71

2.51

(63

6.22

(157

3.34

(84

3.03

(76

4.90

(124

2.16

(54

0.92

(23

4.33

(109

1.58

(40

1.41

(35

4.82

(122

2.08

(52

1.90

(48

5.32

(135

2.57

(65

2.40

(60

5.81

(147

3.07

(77

2.89

(73

4.57

(116

1.94

(49

0.88

(22

4.32

(109

1.69

(42

1.35

(34

4.79

(121

2.16

(54

1.82

(45

5.26

(133

2.63

(66

2.30

(58

5.74

(145

3.11

(78

2.77

(70

3.99

(101

1.57

(39

0.81

(20

4.29

(108

1.87

(47

1.24

(31

4.73

(120

2.31

(58

1.68

(42

5.17

(131

2.74

(69

2.12

(53

5.60

(142

3.18

(80

2.55

(64

4.23

(107

1.86

(47

0.79

(20

4.13

(104

1.76

(44

1.22

(30

4.56

(115

2.19

(55

1.64

(41

4.98

(126

2.61

(66

2.07

(52

5.41

(137

3.04

(77

2.50

(63

3.77 - 3.33

(95 - 84)

1.56 - 1.26

(39 - 32)

0.74 - 0.69

(18 - 17)

3.93 - 3.47

(99 - 88)

1.71 - 1.40

(43 - 35)

1.14 - 1.06

(28 - 26)

4.32 - 3.84

(109 - 97)

2.11 - 1.78

(53 - 45)

1.54 - 1.43

(39 - 36)

4.72 - 4.22

(119 - 107)

2.51 - 2.15

(63 - 54)

1.94 - 1.81

(49 - 45)

5.12 - 4.59

(130 - 116)

2.91 - 2.52

(73 - 64)

2.33 - 2.18

(59 - 55)

F

100

G

H

F

200

G

Porcelain

300

400

-

6.65

168)

2.28

57)

1.70

43)

6.71

170)

2.34

59)

2.49

63)

-

7.06

179)

2.81

71)

1.65

41)

6.41

162)

2.16

54)

2.42

61)

-

5.81

147)

2.03

51)

1.47

37)

5.66

143)

1.87

47)

2.15

54)

6.34

161)

2.55

64)

2.83

71)

-

5.65

143)

2.28

57)

1.31

33)

5.33

135)

1.95

49)

1.92

48)

5.93

150)

2.56

65)

2.53

64)

-

4.86

123)

1.76

44)

1.21

30)

5.42

137)

2.32

58)

1.77

44)

5.98

151)

2.87

72)

2.32

58)

-

4.53

115)

1.63

41)

0.97

24)

4.57

116)

1.67

42)

1.49

37)

5.10

129)

2.19

55)

2.01

51)

5.62

142)

2.72

69)

2.53

64)

Note: All levels ±0.25" (6).

Displacer

Liquid

Type

Temp. ° F

F

100

G

H

F

200

G

H

F

Porcelain

300

G

H

F

400

G

H

F

500

G

H

-

4.20

106)

1.43

36)

0.92

23)

4.39

111)

1.62

41)

1.42

36)

4.89

124)

2.12

53)

1.92

48)

5.39

136)

2.62

66)

2.42

yt61)

5.89

149)

3.12

79)

2.92

74)

-

4.64

117)

1.99

50)

0.88

22)

4.08

103)

1.43

36)

1.36

34)

4.56

115)

1.91

48)

1.84

46)

5.04

128)

2.39

60)

2.32

58)

5.52

140)

2.86

72)

2.79

70)

-

4.05

102)

1.60

40)

0.81

20)

3.81

96)

1.36

34)

1.25

31)

4.25

107)

1.80

45)

1.69

42)

4.69

119)

2.24

56)

2.13

54)

5.13

130)

2.68

68)

2.57

65)

-

3.89

98)

1.50

38)

0.80

20)

4.18

106)

1.80

45)

1.23

31)

4.61

117)

2.23

56)

1.66

42)

5.04

128)

2.66

67)

2.08

52)

5.47

138)

3.09

78)

2.51

63)

-

3.82

97)

1.59

40)

0.74

18)

3.73

94)

1.49

37)

1.15

29)

4.13

104)

1.90

48)

1.55

39)

4.53

115)

2.30

58)

1.95

49)

4.93

125)

2.70

68)

2.35

59)

Note: All levels ±0.25" (6).

9

S P E C I F I C A T I O N S

M O D E L

B 1 0

A C T U A T I O N

L E V E L S

( c o n t . )

INCHES (MM)

B10 STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY WITH DISPLACER ARRANGEMENT 1 (cont.)

Displacer

Type

Liquid

Temp. ° F

100

Level

0.50 - 0.58

0.59 - 0.71

0.72 - 0.79

0.80 - 0.85

0.86 - 1.00

1.01 - 1.03

F

9.91 - 7.72

(251 - 196)

3.46 - 2.16

(86 - 54)

2.51 - 2.16

(63 - 54)

10.22 - 7.98

(259 - 202)

3.76 - 2.42

(95 - 61)

3.67 - 3.16

(93 - 80)

9.19 - 6.62

(233 - 168)

3.72 - 2.08

(94 - 52)

2.13 - 1.77

(54 - 44)

7.74 - 7.44

(196 - 188)

2.27 - 1.89

(57 - 48)

3.11 - 2.58

(78 - 65)

9.68 - 7.25

(245 - 184)

4.30 - 2.70

(109 - 68)

4.03 - 3.40

(102 - 86)

8.44 - 7.16

(214 - 181)

3.96 - 3.07

(100 - 77)

1.74 - 1.59

(44 - 40)

7.50 - 6.30

(190 - 160)

3.02 - 2.22

(76 - 56)

2.55 - 2.32

(64 - 58)

8.31 - 7.04

(211 - 178)

3.83 - 2.96

(97 - 75)

3.36 - 3.06

(85 - 77)

7.66 - 6.86

(194 - 174)

3.63 - 3.07

((92 - 77)

1.57 - 1.48

(39 - 37)

6.15 - 5.44

(156 - 138)

2.12 - 1.64

(53 - 41)

2.29 - 2.16

(58 - 54)

6.88 - 6.12

(174 - 155)

2.84 - 2.32

(72 - 58)

3.02 - 2.84

(76 - 72)

6.71

(170

2.96

(75

1.46

(37

6.97

(177

3.22

(81

2.13

(54

7.65

(194

3.89

(98

2.81

(71

4.82

(122

1.63

(41

1.24

(31

9.11 - 7.77

(231 - 197)

4.63 - 3.69

(117 - 93)

4.16 - 3.79

(105 - 96)

7.60

(193

3.57

(90

3.75

(95

8.32 - 6.32

(211 - 160)

4.57 - 3.09

(116 - 78)

3.48 - 3.00

(88 - 76)

9.00 - 6.90

(228 - 175)

5.24 - 3.67

(133 - 93)

4.16 - 3.58

(105 - 90)

G

H

F

Stainless

Steel

and

Karbate

200

G

H

300

400

Stainless

Steel

500

F

—

G

—

H

—

F

—

—

G

—

—

H

—

—

F

—

—

—

—

G

—

—

—

—

H

—

—

—

—

-

6.80

172)

3.01

76)

3.53

89)

-

4.93

125)

1.71

43)

1.25

31)

5.15

130)

1.93

49)

1.84

46)

5.73

145)

2.51

63)

2.42

61)

Note: All levels ±0.25" (6).

Actuation

Actuation

E

Upper

Switch

Actuation

D

F

F

Upper

Switch

G

Lower

Switch

Actuation

Actuation

Lower

Switch

Actuation

D

G

E

H

Model B10

Displacer Arrangement 1

10

H

Model B10

Displacer Arrangement 2

-

—

—

—

—

—

—

—

—

—

—

—

—

4.61

117)

1.48

37)

1.22

30)

S P E C I F I C A T I O N S

M O D E L

B 1 0

A C T U A T I O N

L E V E L S

( c o n t . )

INCHES (MM)

B10 STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY WITH DISPLACER ARRANGEMENT 2

Displacer

Type

Liquid

Temp. ° F

100

Level

0.60 - 0.64

0.65 -0.71

0.72 - 0.73

0.74 - 0.82

0.83 - 0.92

0.93 - 1.00

1.01 - 1.07

F

2.77 - 2.01

(70 - 51)

7.27 - 6.84

(184 - 173)

2.67 - 2.53

(67 - 64)

3.15

(80)

7.71

(195)

3.40

(86)

2.63

(66

7.54

(191

3.29

(83

2.96

(75

7.60

(193

3.36

(85

2.67

(67

7.56

(192

3.73

(94

1.77

(44

6.90

(175

3.07

(77

2.58 - 1.42

(65 - 36)

7.36 - 6.68

(186 - 169)

3.64 - 3.32

(92 - 84)

2.64 - 1.47

(67 - 37)

7.19 - 6.52

(182 - 165)

3.46 - 3.16

(87 - 80)

3.39 - 2.15

(86 - 54)

7.94 - 7.20

(201 - 182)

4.21 - 3.84

(106 - 97)

3.16 - 1.94

(80 - 49)

7.64 - 6.93

(194 - 176)

4.32 - 3.93

(109 - 99)

2.79 - 1.61

(70 - 40)

7.28 - 6.60

(184 - 167)

3.96 - 3.61

(100 - 91)

3.47 - 2.22

(88 - 56)

7.95 - 7.21

(201 - 183)

4.63 - 4.21

(117 - 106)

1.82

(45

6.86

(174

3.90

(99

2.79

(70

7.46

(189

4.50

(114

3.39

(86

8.06

(204

5.10

(129

1.69

(42

5.15

(130

2.42

(61

1.56

(39

5.19

(131

2.46

(62

2.11

(53

5.75

(146

3.02

(76

2.67

(67

6.30

(160

3.57

(90

G

H

F

200

G

H

Porcelain

300

400

-

1.62

41)

6.93

176)

3.05

77)

1.93

49)

6.99

177)

3.10

78)

-

2.51

63)

7.46

189)

3.68

93)

1.62

41)

6.81

172)

3.03

76)

-

1.04

26)

6.41

162)

3.65

92)

1.94

49)

6.97

177)

4.21

106)

2.50

63)

7.53

191)

4.77

121)

F

—

—

—

G

—

—

—

H

—

—

—

F

—

—

—

—

—

—

G

—

—

—

—

—

—

H

—

—

—

—

—

—

Level

1.08 - 1.12

1.13 - 1.17

1.18 - 1.27

1.28 - 1.30

1.31 - 1.39

1.40 - 1.50

1.16

(29

4.84

(122

2.29

(58

1.68

(42

5.04

(128

2.49

(63

2.19

(55

5.56

(141

3.01

(76

2.71

(68

6.08

(154

3.52

(89

3.23

(82

6.59

(167

4.04

(102

2.04

(51

5.41

(137

2.97

(75

1.31

(33

4.84

(122

2.39

(60

1.81

(45

5.33

(135

2.89

(73

2.30

(58

5.82

(147

3.38

(85

2.80

(71

6.32

(160

3.88

(98

1.68

(42

5.20

(132

2.86

(72

1.71

(43

4.94

(125

2.60

(66

2.19

(55

5.41

(137

3.07

(77

2.66

(67

5.89

(149

3.55

(90

3.13

(79

6.36

(161

4.02

(102

1.04

(26

4.82

(122

2.66

(67

1.75

(44

5.12

(130

2.97

(73

2.18

(50

5.56

(138

3.40

(84

2.62

(61

5.99

(152

3.84

(97

3.05

(77

6.43

(163

4.28

(108

2.05

(52

5.11

(129

3.01

(76

1.56

(39

5.01

(127

2.91

(73

1.98

(50

5.44

(138

3.33

(84

2.41

(61

5.87

(149

3.76

(95

2.84

(72

6.29

(159

4.19

(106

1.50

(38

4.81

(122

2.84

(72

1.53

(38

4.96

(125

2.99

(75

1.93

(49

5.36

(136

3.39

(86

2.33

(59

5.76

(146

3.79

(96

2.73

(69

6.16

(156

4.19

(106

-

1.23

31)

4.89

124)

2.31

58)

1.11

28)

4.92

124)

2.35

59)

1.63

41)

5.45

138)

2.87

72)

2.15

54)

5.97

151)

3.39

86)

Note: All levels ±0.25" (6).

Displacer

Type

Liquid

Temp. ° F

F

100

G

H

F

200

G

H

F

Porcelain

300

G

H

F

400

G

H

F

500

G

H

-

0.89

22)

4.68

118)

2.22

56)

1.38

35)

4.88

123)

2.41

61)

1.88

47)

5.37

136)

2.91

73)

2.38

60)

5.87

149)

3.41

86)

2.88

73)

6.37

161)

3.91

99)

-

1.75

44)

5.24

133)

2.88

73)

1.05

26)

4.68

118)

2.33

59)

1.52

38)

5.16

131)

2.80

71)

2.00

50)

5.64

143)

3.28

83)

2.48

62)

6.12

155)

3.76

95)

-

1.10

27)

4.85

123)

2.68

68)

1.13

28)

4.62

117)

2.44

61)

1.57

39)

5.06

128)

2.88

73)

2.01

51)

5.49

139)

3.32

84)

2.45

62)

5.93

150)

3.76

95)

-

0.92

23)

4.75

120)

2.63

66)

1.62

41)

5.05

128)

2.93

70)

2.05

37)

5.48

130)

3.36

80)

2.48

48)

5.91

150)

3.79

96)

2.91

73)

6.34

161)

4.21

106)

-

1.56

39)

4.84

122)

2.85

72)

1.09

27)

4.75

120)

2.76

70)

1.49

37)

5.15

130)

3.16

80)

1.90

48)

5.55

140)

3.56

90)

2.30

58)

5.95

151)

3.97

100)

-

0.97

24)

4.51

114)

2.67

67)

1.00

25)

4.65

118)

2.82

77)

1.37

34)

5.03

127)

3.19

81)

1.74

44)

5.40

137)

3.56

90)

2.11

53)

5.77

146)

3.93

99)

Note: All levels ±0.25" (6).

11

S P E C I F I C A T I O N S

M O D E L

B 1 0

A C T U A T I O N

L E V E L S

( c o n t . )

INCHES (MM)

B10 STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY WITH DISPLACER ARRANGEMENT 2 (cont.)

Displacer

Type

Liquid

Temp. ° F

Level

F

100

G

H

F

Stainless

Steel

and

Karbate

200

G

H

300

400

Stainless

Steel

500

0.50 - 0.58

3.77

(95

9.46

(240

3.73

(94

4.22

(107

9.76

(247

4.03

(102

-

0.59 - 0.71

1.60

40)

8.16

207)

3.21

81)

1.98

50)

8.42

213)

3.47

88)

4.10

(104

9.72

(246

4.86

(123

1.74

(44

8.27

(210

3.41

(86

4.87

(123

10.30

(261

5.52

(140

-

1.38

35)

8.08

205)

4.04

102)

1.44

36)

6.88

174)

2.84

62)

2.26

57)

8.70

220)

4.66

118)

0.72 - 0.79

0.80 - 0.85

0.86 - 1.00

1.01 - 1.03

4.43

(112

9.96

(252

5.97

(151

3.74

(94

9.02

(229

5.04

(128

4.55

(115

9.83

(249

5.84

(148

-

2.97

75)

9.07

230)

5.44

138)

2.35

59)

8.22

208)

4.59

116)

3.08

78)

8.96

227)

5.33

135)

4.58

(24

9.63

(244

6.05

(153

2.17

(55

8.12

(206

4.53

(115

2.89

(73

8.84

(224

5.26

(133

-

3.60

91)

9.07

230)

5.69

144)

1.33

33)

7.64

194)

4.27

108)

2.02

51)

8.32

211)

4.95

125)

3.42

(86

8.96

(227

5.63

(143

3.89

(98

9.22

(234

5.88

(149

4.56

(115

9.89

(251

6.56

(166

-

1.26

31)

7.71

195)

4.84

122)

1.66

42)

7.93

201)

5.06

128)

2.24

56)

8.51

216)

5.64

131)

1.13

(28

7.63

(193

4.79

(121

5.35

(135

10.63

(270

6.65

(168

-

3.82

97)

9.69

246)

6.06

153)

3.62

(91

9.57

(243

5.99

(152

-

2.70

68)

9.01

228)

5.63

143)

5.24

(133

10.57

(183

7.24

(183

5.91

(150

11.24

(285

7.91

(200

-

2.82

71)

9.09

157)

6.22

157)

3.41

86)

9.67

245)

6.80

172)

F

—

G

—

H

—

F

—

—

G

—

—

H

—

—

F

—

—

—

—

G

—

—

—

—

H

—

—

—

—

Note: All levels ±0.25" (6).

Actuation

E

F

Upper

Switch

Actuation

Lower

Switch

Actuation

D

G

H

Model B10

Displacer Arrangement 2

12

-

0.88

22)

7.48

189)

4.70

119)

—

—

—

—

—

—

—

—

—

—

—

—

S P E C I F I C A T I O N S

M O D E L

B 1 0

A C T U A T I O N

L E V E L S

( c o n t . )

INCHES (MM)

B10 STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY WITH DISPLACER ARRANGEMENTS 3, 4, AND 5

Displacer Liquid

Temp. Level 0.60 - 0.64 0.65 - 0.71 0.72 - 0.73 0.74 - 0.82 0.83 - 0.92 0.93 - 1.00 1.01 - 1.07

Type

°F

G

100

H

J

G

200

H

J

Porcelain

2.77 - 2.01

(70 - 51)

2.24 - 1.81

(56 - 45)

2.01 - 1.89

(51 - 48)

3.15

(80)

2.69

(68)

2.76

(70)

2.63

(66

2.51

(63

1.86

(47

2.96

(75

2.57

965

2.72

(69

-

1.62

41)

1.90

48)

1.70

43)

1.93

49)

1.96

49)

2.49

63)

2.67

(67

2.53

(64

1.68

(42

1.77

(44

1.87

(47

2.45

(62

-

2.51

63)

2.43

61)

1.65

41)

1.62

41)

1.78

45)

2.42

61)

2.58

(65

2.34

(59

1.63

(41

2.64

(67

2.16

(54

2.39

(60

3.39

(86

2.92

(74

3.14

(79

-

1.42

36)

1.66

42)

1.47

37)

1.47

37)

1.50

38)

2.15

54)

2.15

54)

2.18

55)

2.83

71)

3.16

(80

2.62

(66

1.45

(36

2.79

(70

2.25

(57

2.13

(54

3.47

(88

2.93

(74

2.80

(71

-

1.94

49)

1.91

48)

1.31

33)

1.61

40)

1.58

40)

1.92

48)

2.22

56)

2.18

55)

2.53

64)

1.82

(45

1.84

(46

1.30

(33

2.79

(70

2.44

(61

1.90

(48

3.39

(86

3.04

(77

2.50

(63

-

1.04

26)

1.38

35)

1.21

30)

1.94

49)

1.94

49)

1.77

44)

2.50

63)

2.50

63)

2.32

58)

G

—

—

—

H

—

—

—

J

—

—

—

G

—

—

—

—

—

—

H

—

—

—

—

—

—

J

—

—

—

—

—

—

300

400

1.69

(42

1.53

(38

1.02

(25

1.56

(39

1.40

(35

1.58

(40

2.11

(53

1.95

(49

2.13

(54

2.67

(67

2.68

(68

2.68

(68

-

1.23

31)

1.26

32)

.097

24)

1.11

28)

1.14

28)

1.49

37)

1.63

41)

1.66

42)

2.01

51)

2.15

54)

2.34

59)

2.53

64)

Actuation

D

G

Upper

Switch

Actuation

E

H

Lower

Switch

Actuation

F

J

Model B10

Displacer

Arrangement 3

Note: All levels ±0.25" (6).

Displacer Liquid

Temp. Level 1.08 - 1.12 1.13 - 1.17 1.18 - 1.27 1.28 - 1.30 1.31 - 1.39 1.40 - 1.50

Type

°F

G

100

H

J

G

200

H

J

G

Porcelain

300

H

J

G

400

H

J

G

500

H

J

Note: All levels ±0.25" (6).

1.16

(29

1.22

(30

0.96

(24

1.68

(42

1.42

(36

1.48

(37

2.19

(55

1.93

(49

1.99

(50

2.71

(68

2.45

(62

2.51

(63

3.23

(82

2.97

(75

3.03

(76

-

0.89

22)

1.06

26)

0.92

23)

1.38

35)

1.25

31)

1.42

36)

1.88

47)

1.75

44)

1.92

48)

2.38

60)

2.25

57)

2.42

61)

2.88

73)

2.75

69)

2.92

74)

2.04

(51

1.78

(45

0.92

(23

1.31

(33

1.21

(30

1.41

(35

1.81

(45

1.70

(43

1.90

(48

2.30

(58

2.20

(55

2.40

(60

2.80

(71

2.69

(68

2.89

(73

-

1.75

44)

1.61

40)

0.88

22)

1.05

26)

1.06

26)

1.36

34)

1.52

38)

1.53

38)

1.84

46)

2.00

50)

2.01

51)

2.32

58)

2.48

62)

2.49

63)

2.79

70)

1.68

(42

1.57

(39

0.88

(22

1.71

(43

1.31

(33

1.35

(34

2.19

(55

1.79

(45

1.82

(45

2.66

(67

2.26

(57

2.30

(58

3.13

(79

2.73

(69

2.77

(70

-

1.10

27)

1.23

31)

0.81

20)

1.13

28)

0.99

25)

1.25

31)

1.57

39)

1.43

36)

1.69

42)

2.01

51)

1.87

47)

2.13

54)

2.45

62)

2.31

58)

2.57

65)

1.04

(26

1.19

(30

0.81

(20

1.75

(44

1.50

(38

1.24

(31

2.18

(50

1.93

(49

1.68

(42

2.62

(61

2.37

(60

2.12

(53

3.05

(77

2.80

(71

2.55

(64

-

0.92

23)

1.12

28)

0.80

20)

1.62

41)

1.42

36)

1.23

31)

2.05

37)

1.85

46)

1.66

42)

2.48

48)

2.28

57)

2.08

52)

2.91

73)

2.71

68)

2.51

63)

2.05

(52

1.49

(37

0.79

(20

1.56

(39

1.39

(35

1.22

(30

1.98

(50

1.81

(45

1.64

(41

2.41

(61

2.24

(56

2.07

(52

2.84

(72

2.67

(67

2.50

(63

-

1.56

39)

1.21

30)

0.74

18)

1.09

27)

1.12

28)

1.15

29)

1.49

37)

1.52

38)

1.55

39)

1.90

48)

1.92

23)

1.95

49)

2.30

58)

2.33

59)

2.35

59)

1.50

(38

1.18

(29

0.74

(18

1.53

(38

1.33

(33

1.14

(28

1.93

(49

1.73

(43

1.54

(39

2.33

(59

2.13

(54

1.94

(49

2.73

(69

2.53

(64

2.33

(59

-

0.97

24)

0.89

22)

0.69

17)

1.00

25)

1.03

26)

1.06

26)

1.37

34)

1.40

35)

1.43

36)

1.74

44)

1.77

44)

1.81

45)

2.11

53)

2.15

54)

2.18

55)

Actuation

D

G

Upper

Switch

Actuation

E

H

Lower

Switch

Actuation

F

J

Model B10

Displacer Arrangement 4

Actuation

D

G

Upper

Switch

Actuation

E

H

Lower

Switch

Actuation

F

J

Model B10

Displacer Arrangement 5

13

S P E C I F I C A T I O N S

M O D E L

B 1 0

A C T U A T I O N

L E V E L S

( c o n t . )

INCHES (MM)

B10 STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY WITH DISPLACER ARRANGEMENTS 3, 4, AND 5

Displacer

Type

Liquid

Temp. ° F

Level

G

100

H

J

G

Stainless

Steel

and

Karbate

200

H

J

300

400

Stainless

Steel

500

0.50 - 0.58

0.59 - 0.71

0.72 - 0.79

0.80 - 0.85

0.86 - 1.00

1.01 - 1.03

3.77

(95

3.46

(87

2.51

(63

4.22

(107

3.76

(95

3.67

(93

4.10

(104

3.72

(94

2.13

(54

1.74

(44

2.27

(57

3.11

(78

4.87

(123

4.30

(109

4.03

(102

4.43

(112

3.96

(100

1.74

(44

3.74

(94

3.02

(76

2.55

(64

4.55

(115

3.83

(97

3.36

(85

-

2.97

75)

3.07

77)

1.59

40)

2.35

59)

2.22

56)

2.32

58)

3.08

78)

2.96

75)

3.06

77)

4.58

(24

3.63

(92

1.57

(39

2.17

(55

2.12

(53

2.29

(58

2.89

(73

2.84

(72

3.02

(76

-

3.60

91)

3.07

77)

1.48

37)

1.33

33)

1.64

41)

2.16

54)

2.02

51)

2.32

58)

2.84

72)

3.42

(86

2.96

((75

1.46

(37

3.89

(98

3.22

(81

2.13

(54

4.56

(115

3.89

(98

2.81

(71

-

1.26

31)

1.71

43)

1.25

31)

1.66

42)

1.93

49)

1.84

46)

2.24

56)

2.51

63)

2.42

61)

1.13

(28

1.45

(36

1.24

(31

5.35

(135

4.63

(117

4.16

(105

-

3.82

97)

3.69

93)

3.79

96)

3.62

(91

3.57

(90

3.75

(95

-

2.70

68)

3.01

76)

3.53

89)

5.24

(133

4.57

(116

3.48

(88

5.91

(150

5.24

(133

4.16

(105

-

2.82

71)

3.09

78)

3.00

76)

3.41

86)

3.67

93)

3.58

90)

-

1.60

40)

2.16

54)

2.16

54)

1.98

50)

2.42

61)

3.16

80)

-

1.38

35)

2.08

52)

1.77

44)

1.44

36)

1.89

48)

2.58

65)

2.26

57)

2.70

68)

3.40

86)

G

—

H

—

J

—

G

—

—

H

—

—

J

—

—

G

—

—

—

—

H

—

—

—

—

J

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

Note: All levels ±0.25" (6).

Actuation

D

Actuation

D

G

G

Upper

Switch

Upper

Switch

Actuation

E

Upper

Switch

Actuation

E

H

Actuation

J

Model B10

Displacer

Arrangement 3

14

Actuation

E

H

H

Lower

Switch

F

Actuation

D

G

Lower

Switch

Lower

Switch

Actuation

F

Actuation

F

J

J

Model B10

Displacer

Arrangement 4

Model B10

Displacer

Arrangement 5

-

0.88

22)

1.31

33)

1.22

30)

S P E C I F I C A T I O N S

MODEL

B15

DIMENSIONAL

DATA

AND

ACTUATION

LEVELS

*

INCHES (MM)

Outline Dimensions

Threaded Mounting

Flanged Mounting

A

B

A

B

Displacer

Type

Porcelain

5.50

(139)

123.00

(3124)

7.50

(190)

125.00

(3175)

Stainless Steel

or Karbate

5.88

(149)

123.00

(3121)

7.88

(200)

125.00

(3175)

Displacer Type

C

D

E

Porcelain

2.56 (65)

7.25 (184)

5.02 (127)

Stainless Steel

or Karbate

2.50 (63)

10.50 (266)

6.00 (152)

Electrical Connections

TYPE 4X/7/9, Group B: 1" NPT

B15 STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY

Displacer

Type

Stainless

Steel or

Karbate

Liquid

Temp.

°F

F

G

0.70

H

J

F

G

0.80

H

J

100

9.50 (241)

5.00 (127)

4.90 (124)

1.30 (33)

7.60 (193)

3.70 (93)

4.30 (109)

1.10 (27)

200

—

—

—

—

8.20 (208)

4.30 (109)

5.00 (127)

1.80 (45)

Note: All levels ±0.25" (6).

*See page 21 for PROOF-ER and/or floating rooftop switch dimensions.

Displacer

Type

Liquid

Temp.

°F

F

G

H

J

F

G

H

J

Porcelain

100

5.50 (139)

2.00 (50)

3.70 (93)

1.00 (25)

5.00 (127)

1.70 (43)

3.50 (88)

0.80 (20)

100

5.50 (139)

2.00 (50)

3.70 (93)

1.00 (25)

4.90 (124)

1.70 (43)

3.40 (86)

0.90 (22)

Stainless

Steel

200

6.00 (152)

2.70 (68)

4.20 (106)

1.50 (38)

5.40 (137)

2.20 (55)

4.00 (101)

1.50 (38)

300

6.40 (162)

3.10 (78)

4.70 (119)

2.00 (50)

5.70 (144)

2.50 (63)

4.40 (111)

1.90 (48)

400

—

—

—

—

6.10 (154)

2.90 (73)

4.90 (124)

2.40 (60)

100

5.50 (139)

2.00 (50)

3.70 (93)

1.00 (25)

4.90 (124)

1.70 (43)

3.40 (86)

0.90 (22)

200

6.00 (152)

2.70 (68)

4.20 (106)

1.50 (38)

5.40 (137)

2.20 (55)

4.00 (101)

1.50 (38)

300

6.40 (162)

3.10 (78)

4.70 (119)

2.00 (50)

5.70 (144)

2.50 (63)

4.40 (111)

1.90 (48)

Karbate

0.95

Note: All levels ±0.25" (6).

1.00

*See page 21 for PROOF-ER and/or floating rooftop switch dimensions.

5.93

(151)

5.93

(151)

3.87

(98)

8.46

(214)

10.12

(257)

Elect.

Conn.

Elect.

Conn.

Plug

2 1/2" NPT

Flange

A Min.

A Min.

B

Max.

8.46

(214)

10.12

(257)

Plug

3.13

(79)

3.87

(98)

Rising Level

Actuation

D

F

H

Rising Level

Actuation

D

F

Falling Level

Actuation

G

E

B

Max.

Rising Level

Actuation

J

Falling Level

Actuation

C

Model B15

with Threaded Mounting

Falling Level

Actuation

G

E

H

Rising Level

Actuation

J

Falling Level

Actuation

C

Model B15

with Flanged Mounting

15

S P E C I F I C A T I O N S

MODEL

C10

DIMENSIONAL

DATA

INCHES (MM)

MODEL C10 WITH ALL DISPLACER ARRANGEMENTS

Outline Dimensions

Threaded Mounting

Flanged Mounting

A

B

A

B

Displacer

Type

Porcelain

6.38

(965)

123.00

(3124)

8.38

(212)

125.00

(3175)

Stainless Steel

or Karbate

5.75

(146)

123.00

(3124)

7.75

(196)

125.00

(3175)

5.93

(151)

Displacer Type

C

13.11

(332)

14.81

(376)

MODEL C10 WITH DISPLACER

ARRANGEMENTS A, B, AND C

Elect.

Conn.

D

E

F

G

5.93

(151)

3.87

(98)

13.11

(332)

14.81

(376)

Elect.

Conn.

Plug

3.87

(98)

Plug

3.13 (79)

Flange

2 1/2" NPT

Porcelain

2.56

(65)

6.42

(163)

5.02

(127)

5.02

(127)

3.62

(91)

Stainless Steel

or Karbate

2.50

(63)

6.00

(152)

6.00

(152)

4.50

(114)

4.50

(114)

A Min.

A Min.

MODEL C10 WITH DISPLACER

ARRANGEMENTS D AND F

B

Max.

B

Max.

Displacer Type

C

D

E

F

Porcelain

2.56

(65)

14.44

(367)

5.02

(127)

3.62

(91)

Stainless Steel

or Karbate

2.50

(63)

12.00

(304)

4.50

(114)

4.50

(114)

MODEL C10 WITH DISPLACER

ARRANGEMENTS E AND G

C

C

Displacer Type

C

D

E

F

Porcelain

2.56

(65)

6.42

(153)

5.02

(127)

8.65

(219)

Stainless Steel

or Karbate

2.50

(63)

6.00

(152)

6.00

(152)

9.00

(228)

Model C10

with Threaded Mounting

Model C10

with Flanged Mounting

Electrical Connections

TYPE 4X/7/9, Group B:

1" NPT

S P E C I F I C A T I O N S

M O D E L

C 1 0

A C T U A T I O N

L E V E L S

C10 STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY WITH DISPLACER ARRANGEMENTS A, B, AND C

Actuation

D

Actuation

Actuation

D

H

D

H

H

Upper

Switch

Actuation

E

Upper

Switch

J

Upper

Switch

Actuation

E

Actuation

E

J

J

Middle

Switch

Middle

Switch

Actuation

F

Actuation

F

K

Actuation

L

Model C10

Displacer Arrangement A

16

Actuation

F

K

Lower

Switch

G

Middle

Switch

K

Lower

Switch

Lower

Switch

Actuation

G

L

Model C10

Displacer Arrangement B

Actuation

G

L

Model C10

Displacer Arrangement C

S P E C I F I C A T I O N S

M O D E L

C 1 0

A C T U A T I O N

L E V E L S

( c o n t . )

C10 STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY WITH

DISPLACER ARRANGEMENTS A, B, AND C

0.58

Displacer Liquid

Type

Temp.

° F (° C)

PLEASE REFER TO

PAGE 16 FOR

DISPLACER

ARRANGEMENTS

A, B, AND C.

Porcelain

Stainless

Steel

or

Karbate

100

(37.8)

200

(93)

100

(37.8)

0.60

0.70

H

J

K

L

H

J

K

L

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

4.5 3.7 3.2 2.3 3.8 3.2 3.0

(114) (94) (81) (58) (97) (81) (76)

H

J

0.80

K

L

H

J

K

L

2.0

(51)

1.9

(48)

1.7

(43)

—

—

—

2.2 4.2 3.8 2.1 1.9 1.8

(56) (107) (97) (53) (48) (46)

2.2

(56)

1.3

(33)

1.7

(43)

2.5 2.2 2.2 2.0 2.3

(64) (56) (56) (51) (58)

—

—

—

—

—

200

(93)

—

—

—

—

—

—

—

—

—

—

—

—

3.2

(81)

2.9

(74)

2.5

(64)

2.3

(58)

300

(149)

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

Note: All levels ±0.25" (6).

0.90

Displacer Liquid

Type

Temp.

° F (° C)

PLEASE REFER TO

PAGE 16 FOR

DISPLACER

ARRANGEMENTS

A, B, AND C.

Porcelain

Stainless

Steel

or

Karbate

Actuation

D

Upper

Switch

G

J

K

L

H

K

J

K

1.20

H

1.4 2.1

(36) (53)

2.7 2.8

(78) (71)

1.9 1.8

(48) (45)

1.4

(36)

1.7

(43)

1.3

(33)

3.0

(76)

1.7

(132)

3.1

(79)

200

(93)

3.6 3.6 1.7 2.0 1.7 2.3 1.1

(91) (91) (43) (51) (43) (58) (27)

1.8

(46)

—

—

—

—

300

(149)

3.4 3.0 2.4 2.7 1.6 1.8 1.7

(86) (76) (61) (69) (41) (46) (43)

2.4

(61)

—

—

—

—

3.0 2.4 2.7 1.5 1.4

(76) (61) (69) (38) (36)

3.2

—

—

—

— (157)

3.1 3.2 2.5 1.5 1.3

(79) (81) (64) (38) (33)

J

1.10

L

100

(37.8)

200

(93)

100

(37.8)

H

1.00

L

H

J

K

L

1.7

(43)

2.1

(53)

1.1

(28)

—

—

—

2.2

(56)

1.9

(48)

1.2

(30)

—

—

—

—

—

—

—

—

2.6 2.5 1.2 1.7

(66) (64) (30) (43)

1.7 2.3 1.6

(53) (58) (40) —

3.2 2.5 1.3 1.6

(81) (64) (33) (41)

Note: All levels ±0.25" (6).

Actuation

H

Middle

Switch

Actuation

E

J

Lower

Switch

Actuation

F

C10 STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY WITH

DISPLACER ARRANGEMENTS D AND F

Displacer Liquid

Type

Temp.

°F

Porcelain

100

Stainless

Steel

or

Karbate

100

K

Model C10

Displacer

Arrangement D

200

0.58

G

H

0.60

J

K

G

H

0.70

J

K

G

7.50

— (190)

9.90 3.70 3.20 2.30 9.20 3.20 3.00 2.20 8.90

(251) (93) (81) (58) (233) (81) (76) (55) (226)

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

0.80

H

J

K

G

H

J

K

2.60

(66)

3.80

(96)

2.20

(55)

2.10

(53)

2.00

(50)

1.90

(48)

6.90

(175)

6.70

(170)

2.40

(60)

2.20

(55)

1.90

(48)

1.30

(33)

1.70

(43)

1.70

(43)

—

—

—

7.40 2.90 2.50 2.30

(187) (73) (63) (58)

Note: All levels ±0.25" (6).

Actuation

D

Upper

Switch

G

Actuation

Displacer Liquid

Type

Temp.

°F

H

E

Actuation

F

K

Model C10

Displacer

Arrangement F

Stainless

Steel

or

Karbate

J

K

G

1.20

H

J

K

G

H

J

K

1.80

(45)

3.10

(78)

1.90

(48)

2.10

(53)

2.80

(71)

1.80

(45)

1.40

(35)

1.70

(43)

1.30

(33)

6.10

(154)

5.20

(132)

6.40

(162)

3.00

(76)

2.10

(53)

3.20

(81)

2.50

(63)

2.30

(58)

2.50

(63)

1.20

(30)

1.60

(40)

1.30

(33)

G

H

J

K

200

7.60 3.60 1.70 2.00 5.90 2.30 1.10 1.80

(193) (91) (43) (50) (149) (58) (27) (45) —

—

—

—

—

—

—

—

300

7.00 3.00 2.40 2.70 5.40 1.80 1.70 2.40

(177) (76) (60) (68) (137) (45) (43) (60) —

—

—

—

—

—

—

—

200

J

Lower

Switch

H

1.10

100

Porcelain

Actuation

G

1.00

6.60 2.80 2.70 1.50 5.20

(167) (71) (68) (38) (132)

6.20

—

—

—

— (157)

7.20 3.20 2.50 1.50 5.50

(182) (81) (63) (38) (139)

100

Middle

Switch

0.90

5.00 2.10 2.10 1.10

(127) (53) (53) (27)

—

—

—

—

5.20 2.20 1.90 1.20

(132) (55) (48) (30)

Note: All levels ±0.25" (6).

17

S P E C I F I C A T I O N S

M O D E L

C 1 0

A C T U A T I O N

L E V E L S

( c o n t . )

INCHES (MM)

Actuation

C10 STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY WITH

DISPLACER ARRANGEMENTS E AND G

D

G

Upper

Switch

Actuation

E

H

Middle

Switch

Porcelain

100

Stainless

Steel

or

Karbate

100

Actuation

F

Lower

Switch

Actuation

J

K

Model C10

Displacer Arrangement E

Actuation

Upper

Switch

Middle

Switch

J

Stainless

Steel

or

Karbate

H

J

K

G

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

H

J

K

G

H

J

K

2.20

(55)

3.80

(96)

5.80

(147)

6.60

(167)

1.90

(48)

2.50

(63)

2.30

(58)

1.80

(45)

2.00

(50)

2.20

(55)

5.50

(139)

5.80

(147)

2.10

(53)

2.20

(55)

—

—

—

3.20 2.90 7.00 3.40

(81) (73) (177) (86)

0.90

Actuation

G

H

1.00

J

K

G

1.10

1.20

H

J

K

G

H

J

K

1.40

(35)

2.70

(68)

1.90

(48)

5.70

(144)

6.40

(162)

6.30

(160)

1.90

(48)

3.60

(91)

3.40

(86)

3.00

(76)

1.70

(43)

3.10

(78)

2.60

(66)

1.70

(43)

3.20

(81)

6.10

(154)

5.90

(149)

7.00

(177)

3.60

(91)

3.40

(86)

4.40

(111)

G

H

J

K

200

3.60 3.60 6.20 3.00 1.70 2.30 5.60 2.70

(91) (91) (157) (76) (43) (58) (142) (68) —

—

—

—

—

—

—

—

300

3.40 3.00 6.90 3.70 1.60 1.80 6.20 3.30

(86) (76) (175) (93) (40) (45) (157) (83) —

—

—

—

—

—

—

—

L

M

K

Model C10

Displacer Arrangement G

G

100

200

Actuation

Lower

Switch

K

0.80

3.00 2.40 6.30 3.20 1.40

(76) (60) (160) (81) (35)

3.20

—

—

—

— (81)

3.10 3.20 7.00 3.80 1.30

(78) (81) (177) (96) (33)

100

Actuation

J

0.70

Note: All levels ±0.25" (6).

Porcelain

F

H

0.60

2.50

(63)

4.50 3.70 7.70 2.80 3.80 3.20 7.50 2.70 4.20

(114) (93) (195) (71) (96) (81) (190) (68) (106)

200

G

H

G

Displacer Liquid

Type

Temp.

°F

D

E

0.58

Displacer Liquid

Type

Temp.

°F

1.70 1.70 5.70 3.40

(43) (43) (144) (86)

—

—

—

—

1.60 2.20 6.40 4.00

(40) (55) (162) (101)

Note: All levels ±0.25" (6).

S P E C I F I C A T I O N S

MODEL

C15

ACTUATION

LEVELS

INCHES (MM)

C15 STANDARD ACTUATING LEVELS AND LIQUID SPECIFIC GRAVITY

Displacer

Type

Liquid

Temp.

°F

0.65

0.70

0.80

G

H

J

K

L

M

G

H

J

K

L

M

Porcelain

0 to +130

—

—

—

—

—

—

—

—

—

—

—

—

Stainless

Steel

or Karbate

0 to +130

G

H

J

K

6.20 1.40 5.30 1.00 3.80 0.90

(157) (35) (134) (25) (96) (22)

7.70 2.20 6.10 2.00 4.90 1.40 6.70 1.60 5.50 1.60 4.60 1.30 6.50 2.00 5.20 1.60 4.30 1.10

(195) (55) (154) (50) (124) (35) (170) (40) (139) (40) (116) (33) (165) (50) (132) (40) (109) (27)

Note: All levels ±0.25" (6).

Displacer

Type

Liquid

Temp.

°F

0.90

Porcelain

0 to +130

6.20 1.90 5.00 1.40 3.60 1.00 4.60 0.70 4.00 0.80 3.30 0.90 4.20 1.10 3.80 1.00 3.10 0.90

(157) (48) (127) (35) (91) (25) (116) (17) (101) (20) (83) (22) (106) (27) (96) (25) (78) (22)

Stainless

Steel

or Karbate

0 to +130

6.60 2.60 5.20 1.80 4.00 1.20 4.60 1.00 4.00 1.00 3.60 1.10

(167) (66) (132) (45) (101) (30) (116) (25) (101) (25) (91) (27)

G

H

J

K

1.00

L

M

G

H

J

K

1.10

L

M

Note: All levels ±0.25" (6).

Displacer

Type

Liquid

Temp.

°F

Porcelain

0 to +130

Note: All levels ±0.25" (6).

18

1.20

G

H

J

K

1.25

L

M

G

H

J

K

L

M

4.50 1.60 3.70 1.10 2.90 0.90 3.90 1.10 3.30 0.90 2.80 0.80

(114) (40) (93) (27) (73) (22) (99) (27) (83) (22) (71) (20)

G

—

H

—

J

—

K

—

L

—

M

—

S P E C I F I C A T I O N S

MODEL

C15

DIMENSIONAL

DATA

AND

ACTUATION

LEVELS

INCHES (MM)

OUTLINE DIMENSIONS

Threaded Mounting

Flanged Mounting

A

B

A

B

Displacer

Type

Porcelain

Stainless Steel

or Karbate

7.75

(196)

125.00

(3175)

9.75

(247)

127.00

(3225)

7.25

(184)

124.00

(3149)

9.25

(234)

126.00

(3200)

Displacer Type

C

D

E

F

Porcelain

2.56

(65)

7.25

(184)

6.42

(163)

5.02

(127)

Stainless Steel

or Karbate

2.50

(63)

9.00

(228)

7.50

(190)

6.00

(152)

Electrical Connections

TYPE 4X/7/9, Group B:

5.93

(151)

5.93

(151)

3.87

(98)

13.11

(332)

14.81

(376)

Elect.

Conn.

1" NPT

3.87

(98)

13.11

(332)

14.81

(376)

Elect.

Conn.

Plug

Plug

3.13 (79)

Flange

2 1/2" NPT

A Min.

A Min.

Rising Level

Actuation

D

G

D

H

Falling Level

Actuation

B

Max.

Rising Level

Actuation

E

J

Rising Level

Actuation

F

Falling Level

Actuation

M

C

Model C15

with Threaded Mounting

G

H

Falling Level

Actuation

B

Max.

Rising Level

Actuation

E

J

Falling Level

Actuation

K

L

Rising Level

Actuation

Falling Level

Actuation

K

Rising Level

Actuation

F

L

Falling Level

Actuation

M

C

Model C15

with Flanged Mounting

19

M O D E L

S E R I E S

N U M B E R

A 1 5

A N D

B 1 5

F O R

F L O A T I N G

R O O F

D E T E C T I O N

PART NUMBER CODE

Part Number Code

Function

Materials of Construction

A15 –1

Narrow differential, Single Stage

B15 –1

Narrow differential, Dual Stage

Carbon steel process connection,

300 series ss trim, 400 series sleeve

TANK CONNECTION

Tank Connection

Code

Connection Type

E2

21⁄2" NPT Threaded

H2

4" 125 lb. FF cast iron flange

H3

4" 150 lb. RF carbon steel flange

K2

6" 125 lb. FF cast iron flange

K3

6" 150 lb. RF carbon steel flange

DISPLACER MATERIAL AND PROOF-ER OPTION

Displacer Type and Material Code

Liquid &

Floating Roof

Floating Roof Only

Brass

Hollow Brass PROOF-ER Type

P

R

Without PROOF-ER

Q

T

Low Pressure PROOF-ER

Available on model A15 only. Suitable for process liquids with SG greater than or equal to 0.40.