Reduced-Scale Shake Table Testing of Seismic

Behaviors of Slurry Cutoff Walls

Downloaded from ascelibrary.org by Pennsylvania State University on 08/09/15. Copyright ASCE. For personal use only; all rights reserved.

Ming Xiao, Ph.D., P.E., M.ASCE 1; Martin Ledezma 2; and Jintai Wang 3

Abstract: This paper presents a reduced-scale shake table test on the seismic responses of a section of soil-cement-bentonite (SCB) slurry

cutoff wall. The geometric scale of slurry wall width was chosen as 1∶3 (model:prototype). A section of a slurry wall with dimensions of

150 cm long, 20 cm wide, and 160 cm tall was constructed and tested on a one-dimensional shake table. A 187 cm ðlongÞ × 150 cm ðwideÞ ×

180 cm (tall) steel-frame box was anchored on the shake table and contained the slurry wall and sandy soil that was compacted on both sides

of the wall. Spring-supported wood panels were installed at the bottom and on two sides of the box to create a boundary that has the stiffness

of dense sand. The slurry wall and the confining soil were instrumented with accelerometers, LVDT, linear potentiometers, and dynamic soil

stress gauges to respectively record the accelerations, vertical and horizontal deformations of the wall, and transient dynamic soil pressures on

the wall during the simulated seismic excitations. Dynamic scaling laws were implemented in the shake table testing to scale the seismic

excitation. Two shake table tests were conducted using the 1997 Loma Prieta earthquake motions and sinusoidal sweep-frequency motions

(from 0.2 to 6.0 Hz), respectively. The shake table tests provided a preliminary understanding of the seismic performances of the SCB slurry

wall in levees and earthen dams. DOI: 10.1061/(ASCE)CF.1943-5509.0000795. © 2015 American Society of Civil Engineers.

Author keywords: Slurry wall; Seismic performance; Shake table test.

Introduction

Slurry cutoff walls are commonly used as a mitigation of subsurface erosion in levees and earthen dams. Subsurface erosion in the

form of piping has been blamed for many catastrophic and highprofile failures such as the 1972 failure of the Buffalo Creak Dam in

West Virginia (Wahler 1973), the 1976 Teton Dam failure in Idaho

(Penman 1987; Sherard 1987), the 1990 Cyanide Dam failure in

North Carolina (Leonards and Deschamps 1998), the 2004 Upper

Jones Tract levee failure in northern California [California Department of Water Resources (DWR) 2004], and three levee breaches

during Hurricane Katrina in 2005 (Seed et al. 2008a, b; Sills et al.

2008). Slurry walls can provide impermeable barriers to seepage

through or beneath levees and are often considered as the first line

of defense against the initiation and progression of piping erosion

in levees. The slurries that are commonly used in the practice include the soil-bentonite (SB) slurry, cement-bentonite (CB) slurry,

and soil-cement-bentonite (SCB) slurry.

Although slurry cutoff walls have been used in the United States

for the past half a century and proved to be effective, their duringearthquake and postearthquake performances and conditions are

largely unknown. Failure of a slurry wall, as might be caused by

earthquakes, will undoubtedly subject levees, which are otherwise

protected by slurry walls, to piping erosion and subsequent breach.

1

Associate Professor, Dept. of Civil and Environmental Engineering,

Pennsylvania State Univ., University Park, PA 16802 (corresponding

author). E-mail: mxiao@engr.psu.edu

2

Staff Engineer, NCI Group, 550 Industry Way, Atwater, CA 95301.

E-mail: martinledezma07@hotmail.com

3

Graduate Student, Dept. of Civil and Environmental Engineering,

Pennsylvania State Univ., University Park, PA 16802. E-mail: jxw487@

psu.edu

Note. This manuscript was submitted on August 17, 2014; approved on

May 4, 2015; published online on July 9, 2015. Discussion period open

until December 9, 2015; separate discussions must be submitted for individual papers. This paper is part of the Journal of Performance of Constructed Facilities, © ASCE, ISSN 0887-3828/04015057(10)/$25.00.

© ASCE

For example, California’s levee system is located in the most

earthquake-prone region in the United States, adjacent to the San

Andreas Fault and other fault systems. The USGS estimated that a

magnitude 6.7 earthquake will occur in the greater San Francisco

Bay Area before the year 2032 with a 62% probability. Earthquake

damage is especially magnified during the wet season because of

flooding potential. The Phase 1 report by the Delta Risk Management Strategy (DRMS) of the California Department of Water

Resources (DRMS 2009) and the preliminary results presented by

the CALFED Bay-Delta Program (CALFED 2005) both indicated

that a large earthquake would not only cause widespread levee failures and island flooding but may also result in a multiyear disruption in the water supply and water quality. Although the threat is

realistic and present, the Delta levees have not been tested under

moderate to high seismic activities (CALFED 2000). Because of

the lack of historic damage and field and laboratory data, the dynamic responses of the built infrastructures such as levees and

slurry walls in an earthquake environment are not well understood.

Even if a levee survives a seismic shaking, the slurry wall inside the

levee could be damaged: microcracks and macrocracks can develop,

large lateral deformation can occur, and permeability may significantly increase. The damaged slurry wall may no longer serve as

a seepage barrier to existing piping channels, which may subsequently cause levee failure. Therefore, understanding the seismic

responses of slurry walls will help the evaluation of their postearthquake conditions, so that remediation measures can be timely taken.

Slurry cutoff walls are two-dimensional (2D), linear, underground structures, therefore the effects of soil-structure interaction are important. Such interactions include the dynamic soil

pressures on slurry walls, the acceleration-time histories of the

confining soil and slurry walls, the lateral deformations of

slurry walls with the seismic shaking, the possible resonance of

slurry walls with the site excitations, and dynamic settlement

of the confining soils and slurry walls. The objective of this

research is to provide a preliminary and quantitative insight of

the responses of a SCB slurry wall under simulated seismic

environments.

04015057-1

J. Perform. Constr. Facil.

J. Perform. Constr. Facil.

Table 1. SCB Slurry Mixing Ratios by Mass

Slurry cutoff wall

Piping channel

Ground shaking

Constituents

Ratios (%)

Water

Sand

Cement

Bentonite

Defloculant

31.26

61.82

5.03

1.79

0.10

Gravelly sand

Downloaded from ascelibrary.org by Pennsylvania State University on 08/09/15. Copyright ASCE. For personal use only; all rights reserved.

Sandy clay

Ground shaking

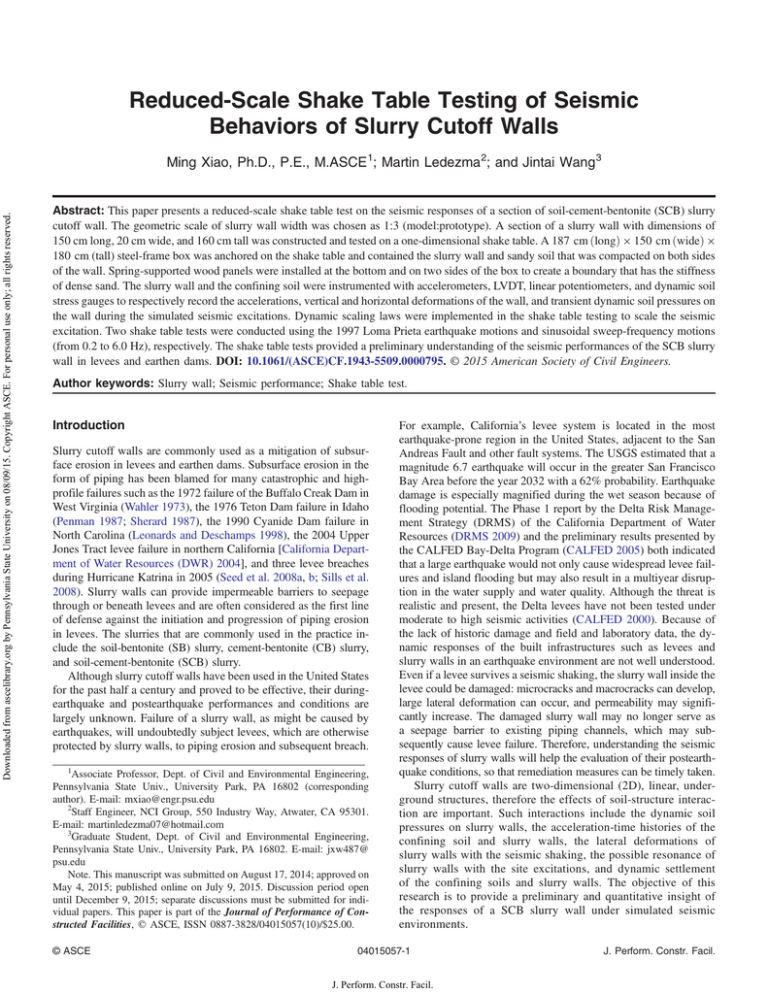

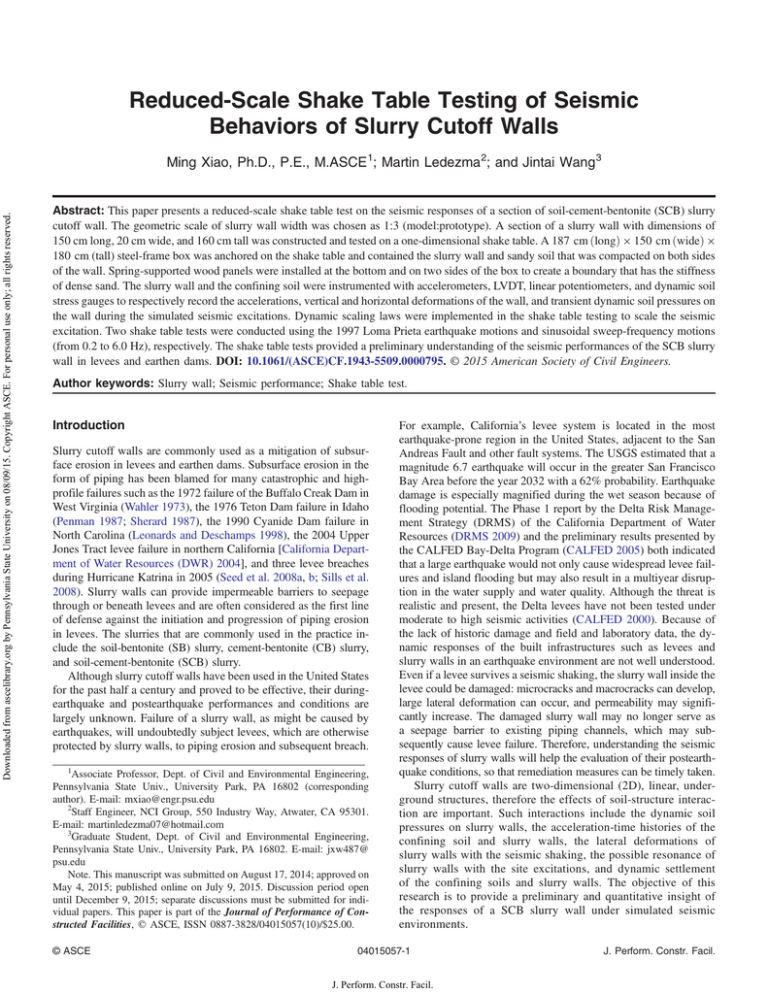

Fig. 1. Simulation of a slurry wall section on shake table

Fig. 3. Instrumentation installation

Fig. 2. Shake table test of a slurry wall section

Methodology

Materials, Experimental Setup, and Instrumentation

A section of slurry wall was constructed and tested on a shake table.

The concept is illustrated in Fig. 1. The table can simulate ground

motions based on actual earthquake records. The dimensions of the

one-dimensional (1D) shake table were 2.44 × 2.13 m (8 ×

7 ft), and the load capacity was 177.9 kN (18.14 metric ton).

The table was driven in one dimension by an actuator that provided

245 kN (55 kip) hydraulic fluid driving force through a maximum

displacement of 25.4 cm (10 in.). A steel-frame box, as shown in

Fig. 2, was bolted on the shake table and had inside dimensions of

187 cm long in the shaking direction, 150 cm wide, and 180 cm tall.

Three walls of the box were made of 2.54 cm (1.0 in.) thick plywood and the fourth wall was made of 1.27 cm (0.5 in.) thick polycarbonate sheet, so that the construction and the segmental slurry

wall responses during shake table testing can be visually observed.

A section of soil-cement-bentonite (SCB) slurry wall was tested.

The SCB slurry was prepared following the mixing ratios and procedures used in the practice. The SCB mixing ratios were obtained

from a slurry wall construction company in California and are presented in Table 1. At the end of each shake table test, large specimens of the slurry wall section were obtained, and the density was

measured. The average density of the SCB slurry wall section was

1,743 kg=m3 . The dimensions of the slurry wall section were

150 cm long, 160 cm tall, and 20 cm wide. Selection of the slurry

© ASCE

wall section was restricted by the dimensions of the container on

the shake table. Because overburden stress was not applied on the

slurry wall and adjacent soil, the slurry wall section only simulated

a section of slurry wall adjacent to ground surface in the field.

Slurry was first poured in a formwork in the box. After four weeks

of hardening, the formwork was removed, the instrumentations

were installed, and a poorly graded sand was backfilled on both

sides of the wall. The backfill was compacted at 95% of its maximum dry density of 1,813.3 kg=m3 (based on the modified Proctor

test); this compaction ensured the relative density of the confining

sand was 80%, the minimum value specified by the U.S. Army

Corps of Engineers (USACE) in the engineer manual of “Design

and Construction of Levees” (USACE 2000). The USACE manual

also stipulates “any soil is suitable for construction levees, except

very wet, fine-grained soils or highly organic soils” (USACE

2000); accordingly, the poorly graded sand can be a suitable soil

used in levees. In the test, a 22.7 kg steel plate compactor was

manually used in the compaction. As the compactor was manually

controlled, the operator was careful when compacting soils adjacent to the slurry wall to ensure the slurry wall is not damaged

by the compaction. The confining soil was compacted on both sides

simultaneously to eliminate net lateral earth pressure on the wall.

Fig. 3 shows the instrumentation installation, and Fig. 4 illustrates the detailed layout of the instrumentations. Three linear

potentiometers were used to measure the transient lateral deflections of the wall in the bottom, middle, and top sections. The potentiometer’s wire was connected to a rigid steel rod outside of the

box, and the rigid steel rod went through the box and soil and was

fixed tightly to the slurry wall surface. Since the rigid rod was not

detached from the slurry wall during shake table testing, it was expected the rod followed the same lateral movements as the slurry

wall; so, the potentiometer recorded the actual lateral displacements

of the slurry wall section. The vertical deformations of the slurry

wall and the soil on both sides of the wall during shaking were

measured by linear variable displacement transformers (LVDTs)

that were anchored on the steel-frame box. The dynamic lateral soil

04015057-2

J. Perform. Constr. Facil.

J. Perform. Constr. Facil.

FI ¼ ρL3 a

ð1Þ

FG ¼ ρL3 g

ð2Þ

FR ∼ σL2 ¼ εEL2

ð3Þ

Downloaded from ascelibrary.org by Pennsylvania State University on 08/09/15. Copyright ASCE. For personal use only; all rights reserved.

where ρ = material density; L = length; a = acceleration; g =

acceleration due to gravity; σ = stress; ε = strain; E = modulus

of elasticity. The ratio of the inertia force to the gravitational force

is known as the Froude’s number

Fr ¼

FI ρL3 a a

∼

∼

Fg ρL3 g g

ð4Þ

The ratio of the inertia force to the restoring force is known as

the Cauchy’s number

Fig. 4. Shake table configuration and instrumentation layout

Fr ¼

pressures on the wall were measured using dynamic soil pressure

cells. The accelerations of the wall and confining soil at different

elevations were measured by wire-free accelerometers, whose

dimensions were 10 × 6.3 × 2.9 cm. The wire-free accelerometers

avoided the interferences that might be caused by a wire during the

shaking. A timer was set in each accelerometer, and data recording

(100 data per second) automatically started at a predetermined time

when the shake table test was run. The instrumentations were connected to the National Instrument (NI SCXI, National Instrument,

Dallas, Texas) data-acquisition system that was located outside of

the shake table.

© ASCE

ð5Þ

To satisfy dynamic similitude, which includes geometric similitude and kinematic similitude, these two numbers must respectively

bear the same values for the model (lab scale) and the prototype

(field scale), as represented by the following expression:

FrðmodelÞ =FrðfieldÞ

¼1

CaðmodelÞ =FaðfieldÞ

ð6Þ

The above scaling law can also be expressed as

ðρLg

E Þmodel

ðρLg

E Þprototype

Dynamic Scaling Laws

Typical slurry walls in the field are 0.3–0.9 m (1–3 ft) wide depending on the width of backhoes that are used for excavation, and the

depths can vary from 5 to 30 m (15 to 100 ft). If assuming an average slurry wall width in the field is 0.6 m (2 ft), the width-to-depth

ratio may vary from 1∶7.5 to 1∶50 in the field. A section of slurry

wall on the shake table was chosen to be 20 cm wide and 160 cm

deep, so the width-to-depth ratio is 1∶8, at the lower end of the

width-to-depth ratio in the field. The effect of seismic wavelength

on the slurry wall was also considered. The wavelength is calculated using the shear wave velocity and the period. The shear wave

velocity of the top 30 m of the subsurface profile (VS30) varies

from <180 m=s for soft soils to 180–360 m=s for stiff soils (Wair

et al. 2012). The dominant earthquake frequency can range from 1

to 5 Hz. Therefore, the shear wavelength in the field can vary from

36 to 360 m, larger than the typical maximum depth of a slurry wall

of 30 m. In the lab testing, VS30 of 200 m=s was assumed for

the densely compacted soil (95% compaction based on modified Proctor test), and the simulated seismic frequency was from 0.2 to 6 Hz.

Therefore, the shear wavelength in the lab varies from 33 to 2,000 m,

also larger than the depth of the slurry wall model of 1.6 m.

Dynamic scaling laws were applied to address the similitudes of

the geometry, material properties, and loading. Scaling laws have

been widely studied and applied in the hydraulic and structural

engineering, and a wealth of literature is available. In this research,

the dynamic scaling laws followed the recommendations by

Moncarz and Krawinkler (1981).

The most important forces of a structure are inertia (FI ), gravitational (FG ), and restoring (FR ) forces, which depend on material

density, stiffness, and length, respectively, as shown as follows:

FI ρL3 a ρLa

∼

∼

E

FR εEL2

¼ 1;

ρr Lr gr

¼1

Er

also written as

ðDynamic scaling lawÞ

ð7Þ

In a true replica model, the above scaling law is satisfied. But

this scaling law poses one—but almost insurmountable—difficulty

in the selection of a suitable model material. Based on the desire to

use the same materials as in the prototype, the adequate model was

used in this research. The adequate model assumes the stresses induced by gravity loads are small and may be negligible compared

to the stress histories generated by seismic motions. So g in the

above scaling law was replaced by a. With the same E and ρ in

both model and prototype, the dynamic scaling law becomes

a

Lmodel −1

ar ¼ model ¼ L−1

r ¼

afield

Lfield

ðDynamic scaling law for adequate modelÞ

ð8Þ

In the reduced-scale shake table testing, a geometric scaling of

Lr ¼ 1∶3 was adopted, considering the available space in the steelbox on the shake table. Therefore, the acceleration induced by the

shake table should be three times of the measured acceleration

time-history in the field. The input acceleration-time history of

the shake table is controlled by the MTS system and can be defined

by the user. The dynamic scaling law for adequate model, although

the same as in centrifuge tests, is based on the assumption of negligible gravity field; while the centrifuge model fully satisfies the

dynamic scaling law without assumptions. In this research, the horizontal seismic stress is higher than the gravitational stress; therefore,

the dynamic scaling law for adequate model was adopted.

04015057-3

J. Perform. Constr. Facil.

J. Perform. Constr. Facil.

Boundary Conditions

where L = half of the length of the foundation base; B = half of

the width of the foundation base; D = foundation embedment

= height of the shake table box in this research; d = height of

foundation that is actually in contact with soil = height of the

shake table box minus the freeboard in this research

The rigid boundary of the steel-frame box did not represent the true

boundary condition of the slurry wall and its confining soil. To address this boundary condition, spring-supported wood panels were

installed at the bottom and on two sides of the box, as shown in

Figs. 4 and 5(a). The idea was to create a flexible boundary that

has the same dynamic stiffness of dense sand. Gazetas (1991) derived

the dynamic stiffness of foundations embedded in homogeneous

half-space

Downloaded from ascelibrary.org by Pennsylvania State University on 08/09/15. Copyright ASCE. For personal use only; all rights reserved.

K dynamic ¼ K static kðωÞ

h ¼ D–d=2

where E = modulus of elasticity; and ν = Poisson’s ratio

χ¼

ð9Þ

where K dynamic = dynamic stiffness; K static = static stiffness; and

kðωÞ = dynamic stiffness coefficient.

1. The following is used to calculate static stiffness (K static ):

In vertical (z) direction

2=3 1

D

A

K staticðzÞ ¼ K z 1 þ

ð1 þ 1.3χÞ 1 þ 0.2 w

Ab

21

B

ð10Þ

In horizontal (y) direction, i.e., in the direction of shaking

0.5 0.4 D

h

Aw

K staticðyÞ ¼ K y 1 þ 0.15

1 þ 0.52

B

B

L2

Ky ¼

2 GL

ð2 þ 2.5χ0.85 Þ

2−ν

where G = shear modulus of foundation soil, and

G¼

E

2ð1 þ νÞ

ð13Þ

ð14Þ

where Ab = base contact area = ð2LÞð2BÞ; Aw = area of the

four sides of the embedded foundation = dð2L þ 2BÞ).

2. The following is used to calculate the dynamic stiffness coefficient, kðωÞ:

In z direction when ν ≤ 0.4

3=4 D

kz ðωÞ ¼ kz 1 − 0.09

ð15Þ

a20

B

where kz = dynamic stiffness coefficient for arbitrarily shaped foundations on the surface of homogeneous half-space in z direction

a0 ¼

ð11Þ

where K z and K y = static stiffness for arbitrarily shaped foundations on the surface of homogeneous half-space in z and y

directions, respectively; and

2 GL

Kz ¼

ð0.73 þ 1.54χ0.75 Þ

ð12Þ

1−ν

Ab

4 L2

ωB

Vs

ð16Þ

where ω is angular frequency; V s is shear wave velocity; and a0

ranges from 0 to 2. In this research, because of the lack of shear

wave velocity data, average value of 1.0 was used for a0 to account

for general soil condition. In y direction, ky ðωÞ also depends on

D=B and a0 and can be determined using Eq. (15). Table 2 shows

the initial parameters used in calculating dynamic stiffness of flexible boundary. Table 3 shows the calculation of the dynamic stiffness of the bottom boundary, and Table 4 shows the calculation of

the dynamic stiffness of the side boundaries.

Heavy-duty compression springs in parallel were used to

achieve the required stiffness on the three boundaries. A photo of

the bottom spring panel is shown in Fig. 5(a). The springs are

equally spaced, and the layout of the springs is also shown in

Fig. 5(a). Each spring’s stiffness coefficient is 1,386.5 N=mm, the

free length is 10 cm, and the maximum travel distance is 20 mm. To

Fig. 5. Spring panels used to generate seismic stresses on the confining soil of slurry wall: (a) photo of the bottom spring panel; (b) photo of the side

spring panel

© ASCE

04015057-4

J. Perform. Constr. Facil.

J. Perform. Constr. Facil.

Table 2. Initial Parameters in Calculating Dynamic Stiffness of Flexible

Boundaries

4.5

Initial parameters

Symbols and units

Values

3.5

Given parameters

L (cm)

B (cm)

D (cm)

d (cm)

h (cm)

E (N=cm2 )

ν

G (N=cm2 )

a0

χ

83

75

180

160

80

3,500

0.4

1,250

1.0

0.90

Downloaded from ascelibrary.org by Pennsylvania State University on 08/09/15. Copyright ASCE. For personal use only; all rights reserved.

Derived parameters

Note: E¼ 3,500 N=cm2 is typical value for dense sand.

kz , using a0 as 1.0 and the chart of Gazetas (1991)

kz ðωÞ

K z (N=mm)

K staticðzÞ (N=mm)

K dynamicðzÞ (N=mm)

Values

0.8

0.66

74,606

144,441

95,500

Table 4. Calculation of Dynamic Stiffness of Side Boundaries in y

Direction

Calculated parameters

ky ðωÞ, using a0 as 1.0 and the chart of Gazetas (1991)

K y (N=mm)

K staticðyÞ (N=mm)

K dynamicðyÞ (N=mm)

Values

0.75

55,683

181,036

135,777

simulate dense sand around the confining soil, 187 springs were

needed on each side of the box, and 126 springs were needed at

the bottom. The total maximum weight of the slurry and sand backfill in the box was approximately 89,000 N. At the maximum spring

compression of 20 mm, the bottom spring-supported panel can support 1,910,000 N; this load capacity exceeds the total weight of the

slurry wall and soil in the box. In the horizontal direction, using a

horizontal acceleration of 10 g, the horizontal inertia force on the

vertical spring-supported panel is calculated as 890,000 N. The

spring-supported panel at full compression of 20 mm can sustain

2,715,540 N; this load capacity is 3.0 times the horizontal inertia

force (890,000 N) on the panel. Therefore, the springs will not be

fully compressed.

To simulate the cyclic stress variation with depth, the vertical

side spring-supported board on each side consisted of three panels

that moved independently. The side panel is illustrated in Fig. 5(b).

To reduce the friction between the slurry wall and the front and

back sides of the walls of the box, smooth Plexiglas sheets were

attached to the plywood walls of the box, so that the sides of

the slurry wall were in contact with the Plexiglas sheets. As shown

in Fig. 5(b), the bottom of the slurry wall rested on a springsupported plywood board at the bottom of the box; the transverse

cross-section of the slurry wall was in contact with the sidewalls of

the box. A plastic sheet was added between the slurry wall and the

sidewalls of the box in order to reduce interface friction and allow

relatively free movement of the wall during shaking. The top of the

slurry wall was open and had no restriction.

© ASCE

Displacement (cm)

3

2.5

2

1.5

1

0.5

0

0

0.2

0.4

0.6

Acceleration (g)

0.8

1

Fig. 6. Maximum displacements and maximum accelerations of Loma

Prieta earthquake recorded at various stations

Table 3. Calculation of Dynamic Stiffness of the Bottom Boundary in z

Direction

Calculated parameters

4

Selection of Input Seismic Excitations

In this research, the 1989 Loma Prieta earthquake (M ¼ 6.9) was

simulated, because of the earthquake’s proximity to the Sacramento-San Joaquin Delta levees and the earthquake’s well-recorded

time histories. The duration of the displacement-time history is

40 s. The earthquake’s displacement-time history and acceleration-time history data were obtained from the Pacific Earthquake

Engineering Research (PEER) Center Library of the University

of California at Berkeley and implemented into the input file to

the MTS (FlexTest SE, MTS, Eden Prairie, Minneapolis) control

system of the shake table. The seismic motions were recorded at

station 47125 in Capitola, California, at latitude of 36°58’27″ N

and longitude of 121°57’13″ W. Based on the dynamic scaling

law and using a geometric scaling factor of 3∶1 (prototype:model),

the input accelerations to the model test were three times the actually recorded accelerations in the field. Since the shake table is

controlled by displacements, the displacement-time history of the

shake table should be three times of the displacement-time history

recorded in the field. Considering the maximum displacement of

the table of 12.7 cm, the selected maximum ground motions

should be less than one third of 12.7 cm, or 4.2 cm. If the table

displacement exceeds the limit, the pump driving the actuator will

shut down. The Loma Prieta earthquake motions, in terms of

displacement-time history, velocity-time history, and accelerationtime history, were recorded at different field stations. The maximum displacement and acceleration at each station are plotted in

Fig. 6. To meet the displacement requirement and obtain the highest

possible acceleration, the station with the maximum acceleration

and displacement of 0.541 g and 2.6 cm was selected, as shown

in the circle in Fig. 6. Therefore, the maximum acceleration that the

table was expected to generate was 1.623 g. Fig. 7 shows the match

of the displacement-time history of the input file and the measured

displacements (output) of the shake table during the 40-s shaking.

Fig. 8 shows the measured acceleration-time history of the steel box

on the shake table during the 40-s shaking.

Low-amplitude (∼1.0 cm) sinusoidal excitations were also used

to investigate the fundamental seismic responses of slurry walls.

The vibration frequency increased in steps and was 0.2, 0.5, 1,

2, 3, 4, 5 and 6 Hz, with each frequency lasting 10 s. This frequency

range covers the dominant frequency range in most earthquakes.

Fig. 9 shows the measured acceleration-time history of the sinusoidal motions of the shake table. The purpose of using the sinusoidal sweep-frequency motions was twofold: (1) to determine

whether the natural frequency of the slurry wall with the soil confinement falls into the dominant frequency range of earthquakes,

and (2) to shake the slurry wall until failure if the scaled Loma

04015057-5

J. Perform. Constr. Facil.

J. Perform. Constr. Facil.

Prieta earthquake motions could not fail the slurry wall, so that the

failure mechanisms of the slurry wall can be further investigated.

Moreover, sinusoidal waves can be easily input into numerical

models for future model development.

Effect of Seismic Shaking on Slurry Wall’s Strength

Downloaded from ascelibrary.org by Pennsylvania State University on 08/09/15. Copyright ASCE. For personal use only; all rights reserved.

When casting the slurry wall section on the shake table, cylindrical

specimens with dimensions of 10.2 cm ðdiameterÞ × 20.4 cm

(height) were also cast in cylindrical molds, from the same batch

of the slurry. The cylindrical specimens were sealed and allowed to

cure for the same time period as the slurry wall. These cylindrical

specimens did not experience seismic testing. After the shake table

testing, large blocks of samples were retrieved from the slurry wall

section and carefully trimmed to the same dimensions as the cylindrical samples that did not experience shaking. Then unconfined

compression tests were conducted on both specimens in order to

determine the effects of shaking on the slurry wall’s strength. Three

pairs of such specimens were tested for simulated Loma Prieta

earthquake motions and two pairs of such specimens were tested

for sinusoidal motions.

Results and Analyses

Fig. 7. Displacement-time histories of input and output motions of

simulated Loma Prieta earthquake

1. Simulated Loma Prieta Earthquake

The lateral deflections of the three sections of the wall, relative to the table movements, are shown in Fig. 10. The lateral

deflection increased from the bottom to the top of the slurry

wall. The maximum deflections of the bottom, middle, and top

sections of the slurry wall were 0.627, 0.955, and 1.204 cm,

respectively. The trend of the lateral deflections of the three

sections of the slurry wall followed the acceleration-time history of the shake table: higher acceleration apparently induced

higher lateral deflection.

The dynamic vertical deformations of the wall and the confining soil are shown in Fig. 11. The trend of the vertical

Fig. 8. Measured acceleration-time history of the box on shake table,

from simulated Loma Prieta earthquake

Fig. 10. Slurry wall lateral deflections caused by simulated Loma

Prieta earthquake

Fig. 9. Measured acceleration-time history of the shake table caused by

sinusoidal motions with increased frequency

Fig. 11. Vertical deformations of slurry wall and confining soil caused

by simulated Loma Prieta earthquake

© ASCE

04015057-6

J. Perform. Constr. Facil.

J. Perform. Constr. Facil.

Downloaded from ascelibrary.org by Pennsylvania State University on 08/09/15. Copyright ASCE. For personal use only; all rights reserved.

Fig. 14. Dynamic lateral pressure of the spring panels on confining soil

caused by simulated Loma Prieta earthquake

Fig. 12. Exposed slurry wall after simulated Loma Prieta earthquake

Table 5. Maximum Accelerations of Slurry Wall and Confining Soil

Caused by Simulated Loma Prieta Earthquake

System

component

Accelerometer position

and number

Acceleration

(g)

Occurrence

time (s)

Slurry wall

Bottom (1)

Middle (4)

Top (5)

Bottom (2)

Bottom (3)

Top (6)

Top (7)

(8)

(9)

1.46

1.81

2.33

1.54

1.58

2.35

2.47

1.88

1.78

8.51

8.50

9.57

8.52

8.50

8.58

9.56

9.77

6.23

Confining soil

Shake table

Box

Note: The numbers in Column 2 indicate the numbering of accelerometers

as shown in Fig. 4.

Fig. 13. Dynamic lateral earth pressures on slurry wall caused by

simulated Loma Prieta earthquake

deformations followed the trend of the accelerations of the

shake table: the intense shaking within the first 15 s induced

the majority of the vertical settlement; after that, the slurry wall

and the confining soil deformed little. The maximum vertical

settlements of the soil on the left and right sides of the slurry

wall were 1.265 and 1.080 cm, respectively. The maximum

vertical deformation of the slurry wall was 0.208 cm. Other

shake table tests on slurry walls by the authors showed that

vertical deformations of a slurry wall can indicate the occurrence of cracking and the time of occurrence of the wall: when

a slurry wall broke, the top portion tended to rotate, causing

the LVDT readings to suddenly increase, showing the wall

height increased. In this shake table test, the LVDT data did

not reveal sudden increase of the wall height. After removing

the soil on both sides, the slurry wall was examined and no

apparent crack was observed. Fig. 12 shows a photo of the

exposed slurry wall after shaking.

Fig. 13 shows the dynamic lateral earth pressures on the top

section (measured at 20 cm from top) and the bottom section

(measured at 20 cm from bottom) of the slurry wall during the

shaking. Fig. 14 shows the dynamic lateral pressures of the

spring panels on the confining soil. Both figures show that

the stabilized lateral pressures were higher at the bottom than

at the top because of the higher overburden effective stress at

© ASCE

the bottom. It seems the lateral pressure that was exerted by the

spring panel on the top section of the soil fluctuated more significantly; this agrees with the higher lateral deflection of

the slurry wall at the top. However, higher lateral pressure

on the soil (from the spring panel) in the top section did not

cause higher pressure on the slurry wall (as shown in Figs. 13

and 14).

The maximum accelerations and their time of occurrence of

the slurry wall and the confining soil are listed in Table 5. The

accelerometers are numbered and are shown in Fig. 4. The

maximum acceleration of the box on the shake table was

1.78 g, slightly higher than the maximum acceleration of

the input profile (1.62 g). The data show that acceleration increased from the bottom to the top of the slurry wall as well as

in the backfill. At the top section of the slurry wall and the

confining soil, the accelerations were amplified and higher

than the acceleration of the shake table.

2. Sinusoidal Sweep-Frequency Motions

The lateral deflections of the three sections of the wall,

relative to the table movements, are shown in Fig. 15. The

maximum deflections of the bottom, middle, and top sections

of the slurry wall were 2.182, 2.222, and 4.457 cm, respectively. The bottom portion of the wall showed similar movement to the sinusoidal movements of the table, whereas the

middle and top sections deflected independently, in magnitude, with the increased frequency of the table movements—

higher acceleration of the shake table did not induce higher

lateral movement of the slurry wall in the top and middle

04015057-7

J. Perform. Constr. Facil.

J. Perform. Constr. Facil.

Downloaded from ascelibrary.org by Pennsylvania State University on 08/09/15. Copyright ASCE. For personal use only; all rights reserved.

(b)

(a)

(c)

Fig. 15. Slurry wall lateral deflections caused by sinusoidal sweep-frequency motions: (a) bottom section; (b) middle section; (c) top section

sections. In the simulated Loma Prieta excitation, however,

higher acceleration induced higher lateral displacements in

all sections of the slurry wall. It is possible that different sections of the slurry wall resonated with the table movements,

i.e., the lateral deflections were more influenced by frequency

than by accelerations.

This research attempted to obtain the natural frequency of

the slurry wall using the experimental data. The maximum

lateral deflections of the top, middle, and bottom sections

of the slurry wall under each frequency were obtained from the

potentiometer readings. The maximum lateral deflection responses with frequency are plotted in Fig. 16. When the seismic frequency is equal to the natural frequency of the slurry

wall, the lateral deflections reach maximum. Fig. 16 showed

the top, middle, and bottom sections of the slurry wall

Fig. 16. Slurry wall lateral deflection responses with frequency

© ASCE

experienced the highest lateral deflection at 0.2, 2.0, and

4.0 Hz, respectively. Those frequencies, however, may not

be the natural frequencies of the different sections of the slurry

wall, since only a narrow band of frequencies (0.2–6.0 Hz)

was tested. Nevertheless, Fig. 16 indicates the slurry wall is

a complex system and may possess different natural frequencies at different sections.

The dynamic vertical deformations of the wall and the confining soil are shown in Fig. 17. At low frequencies (0.2, 0.5,

1.0 Hz), there was almost no vertical deformation. At frequency of 3.0 Hz, the slurry wall and the confining soil both

experienced large deformations. The recorded maximum vertical deformations of the soil on the left and right sides of the

slurry wall were 4.110 cm and 5.065 cm, respectively. The

recorded maximum vertical deformation of the slurry wall

Fig. 17. Vertical deformations of slurry wall and sand backfill caused

by sinusoidal sweep-frequency motions

04015057-8

J. Perform. Constr. Facil.

J. Perform. Constr. Facil.

Table 6. Maximum Accelerations of Slurry Wall and Confining Soil

Caused by Sinusoidal Sweep-Frequency Motions

System

component

Accelerometer position

and number

Acceleration

(g)

Occurrence

time (s)

Slurry wall

Bottom (1)

Middle (4)

Top (5)

Bottom (2)

Bottom (3)

Top (6)

Top (7)

(8)

(9)

1.55

2.08

3.29

1.53

1.55

3.86

2.51

3.20

3.54

71.19

70.10

72.70

68.81

70.52

75.94

60.50

71.06

70.50

Downloaded from ascelibrary.org by Pennsylvania State University on 08/09/15. Copyright ASCE. For personal use only; all rights reserved.

Confining soil

Shake table

Box

Note: The numbers in Column 2 indicate the numbering of accelerometers

as shown in Fig. 4.

Fig. 18. Snapshot of slurry wall after sinusoidal sweep-frequency

motions

Table 7. Unconfined Compressive Strengths of Slurry Wall with and

without Being Subjected to Simulated Loma Prieta Earthquake Motions

Unconfined compressive strength (kPa)

Specimens

#1

#2

#3

Average

Without shaking

With shaking

173.40

118.52

131.69

141.20

141.56

160.23

185.58

169.79

Table 8. Unconfined Compressive Strengths of Slurry Wall with and

without Being Subjected to Sinusoidal Seismic Motions

Unconfined compressive strength (kPa)

Specimens

#1

#2

Average

Without shaking

With shaking

98.76

68.53

83.65

93.27

109.73

103.15

Fig. 19. Dynamic lateral earth pressures on slurry wall caused by

sinusoidal sweep-frequency motions

was 4.879 cm. At the end of the period with f ¼ 4 Hz

(t ¼ 60 s), the LVDT rods fell out of the LVDT tubes because

of the excessive settlements of the soil and wall; so, further

deformations of the slurry wall and the soil were not recorded.

The large settlement of sand may be caused by particle rearrangement under seismic load. It is also noted at t ¼ 51.7 s,

there was a sudden increase of the slurry wall height, this indicated a breakage of the slurry wall. When the wall broke, the

top portion rotated, pushing the LVDT rod back into the LVDT

tube; this was revealed in the LVDT readings as a sudden increase of the wall height. After removing the soil on both sides,

the slurry wall was examined, and a major crack was observed

and is shown in Fig. 18. Sand seeped into the crack throughout

the length of the wall, indicating a complete break of the top

section of the wall.

Fig. 19 shows the lateral earth pressures on the top section

(measured at 20 cm from top) and bottom section (measured at

20 cm from bottom) of the slurry wall during the shaking. At

lower frequency and accelerations, the dynamic lateral earth

pressure on the slurry wall remained unchanged. When seismic

frequency increased to 4 Hz (at t ¼ 50 s), lateral earth pressure

began to fluctuate. As expected, the lateral pressure on the bottom section of the wall is higher than that on the top section.

© ASCE

The maximum accelerations and their time of occurrence in

the slurry wall and the confining soil are listed in Table 6. The

accelerometers are numbered and are shown in Fig. 4. The data

showed that the accelerations of the slurry wall and the confining soil increased from the bottom to the top of the wall. It

should be noted that the maximum acceleration of the top section of the slurry wall occurred after the slurry wall broke. The

maximum acceleration of the top portion of the slurry wall

before the break was 1.137 g and occurred at 50.35 s, and

slurry wall broke at 51.70 s according to Fig. 17.

3. Effect of seismic shaking on slurry wall’s strength

The unconfined compressive strengths of the specimens

that were and were not subjected to simulated earthquake motions and sinusoidal motions, respectively, are summarized in

Tables 7 and 8. The preshaking specimens were made at the

same time of constructing the slurry wall; and the postshaking

specimens were obtained from the slurry wall during deconstruction. All compression tests were performed on the same

date, so that there was no time-effect on the strengths when

comparing the preshaking and postshaking specimens. The

strengths of the specimens that experienced shaking were

higher than those without shaking. The results suggested that

the shaking at least did not weaken the slurry wall. Apparently,

the preliminary compressive strength tests did not reveal the

seismic failure mechanisms of the slurry wall. A thorough

04015057-9

J. Perform. Constr. Facil.

J. Perform. Constr. Facil.

Downloaded from ascelibrary.org by Pennsylvania State University on 08/09/15. Copyright ASCE. For personal use only; all rights reserved.

material characterization of the slurry wall materials with and

without seismic excitations is needed. Such characterization

may include (1) density and water content; (2) one dimensional consolidation tests to determine the stress-void ratio

(stress-strain) relationship needed to assess volume changes

during consolidation of the slurry backfill in the model;

(3) consolidated-undrained triaxial shear strength tests with

pore pressure measurements to determine the stress-strain relationship, Young’s modulus and failure strain; (4) tension test to

derive the stress-strain relationship until failure; (5) fixed wall

permeability tests on 25 mm tall samples in consolidometers to

evaluate the relationship between hydraulic conductivity and

vertical stress under k0 conditions; and (6) flexible wall permeability tests on 70 mm tall samples to evaluate the hydraulic

conductivity under selected isotropic stresses. Although these

material characterizations were not conducted in this research,

they are under investigation in an attempt to understand the

failure mechanisms of slurry walls under various seismic

conditions.

Conclusions

This paper presents a reduced-scale shake table testing of soilcement-bentonite slurry wall. The seismic excitations used the

simulated 1989 Loma Prieta earthquake motions and low-magnitude

sinusoidal sweep-frequency motions. The Loma Prieta excitations

were scaled based on the dynamic scaling law for adequate model.

Spring-supported panels were used to simulate the sand boundary.

The slurry wall generally demonstrated increased lateral deflections

and accelerations from the bottom toward the top. A slurry wall

may possess different natural frequencies at different sections. The

simulated Loma Prieta excitation with maximum acceleration of

1.78 g did not break the slurry wall; while the sinusoidal sweepfrequency with maximum acceleration of 3.54 g broke the slurry

wall at the top portion.

The shake table results are not intended to be directly used to

evaluate the performances of slurry walls under earthquakes in field

conditions. The validity of the spring-supported boundaries needs

to be verified by numerical studies: the model can simulate the

spring-supported boundary exactly the way as in the shake table

tests and then simulate the boundary using infinitely long sandy

soil, the results from the two boundary conditions are compared

to see whether they yield the same results. Although a dynamic

scaling law was used, the scaling should be verified by numerical

analyses. Although this preliminary testing did not reveal the failure mechanisms of slurry walls under earthquakes, this paper presented a feasible testing methodology on the seismic responses of

slurry walls. A more thorough shake table testing, slurry wall

material characterizations with and without shaking, and numerical

analysis are needed to explain the failure mechanisms of slurry

walls under earthquakes.

© ASCE

Acknowledgments

The authors thank Diversified Minerals, Inc. (Oxnard, California)

for donating the bentonite and cement. The authors also thank Chris

Harris of Slurry Engineering Inc. (Sacramento, California) for

donating the deflocculation liquid and providing the mixing ratio

of the slurry.

References

CALFED. (2000). “Seismic vulnerability of the Sacramento-San Joaquin

delta levees.” CALFED Seismic Vulnerability Sub-Team, Sacramento,

CA.

CALFED. (2005). “Preliminary seismic risk analysis associated with

levee failures, Sacramento-San Joaquin delta.” California Bay-Delta

Authority and California Dept. of Water Resources, Jack Benjamin

and Associates, Sacramento, CA.

DRMS (Delta Risk Management Strategy). (2009). “Delta risk management

strategy final phase 1 report.” ⟨http://www.water.ca.gov/floodsafe/fessro/

levees/drms/phase1_information.cfm⟩ (Aug. 8, 2014).

DWR (California Department of Water Resources). (2004). “Photographs

of the Upper Jones Tract levee break in the Sacramento-San Joaquin

delta.” ⟨www.water.ca.gov/news/newsreleases/2004/061604floodpic.pdf⟩

(Dec. 16, 2009).

Gazetas, G. (1991). “Formulas and charts for impedances of surface and

embedded foundations.” J. Geotech. Eng., 117(9), 1363–1381.

Leonards, G. A., and Deschamps, R. J. (1998). “Failure of cyanide

overflow pond dam.” J. Perform. Constr. Facil., 10.1061/(ASCE)0887

-3828(1998)12:1(3), 3–11.

Moncarz, P., and Krawinkler, H. (1981). “Theory and application of experimental model analysis in earthquake engineering.” A Rep. on a

Research Project Sponsored by the National Science Foundation,

Grants ENV75-20036 and ENV77-14444, John A. Blume Earthquake

Engineering Center, Stanford Univ., Palo Alto, CA.

Penman, A. D. M. (1987). “Teton investigation: A review of existing

findings.” Eng. Geol., 24, 221–237.

Seed, R. B., et al. (2008a). “New Orleans and Hurricane Katrina. II: The

central region and the lower Ninth Ward.” J. Geotech. Geoenviron.

Eng., 134(5), 718–739.

Seed, R. B., et al. (2008b). “New Orleans and Hurricane Katrina. IV:

Orleans east bank (metro) protected basin.” J. Geotech. Geoenviron.

Eng., 10.1061/(ASCE)1090-0241(2008)134:5(762), 762–779.

Sherard, J. L. (1987). “Lessons from the Teton dam failure.” Eng. Geol., 24,

239–256.

Sills, G. L., Vroman, N. D., Wahl, R. E., and Schwanz, N. T. (2008). “Overview of New Orleans levee failures: Lessons learned and their impact on

national levee design and assessment.” J. Geotech. Geoenviron. Eng.,

134(5), 556–565.

U.S. Army Corps of Engineers. (2000). “Design and construction of

levees.” Engineer manual, Dept. of the Army, Washington, DC.

Wahler, W. A. (1973). “Analysis of coal refuse dam failure, middle Fork

Buffalo Creek, Saunders West Virginia.” National Technical Service

Rep. PB-215, Bureau of Mines, 142–143.

Wair, B. R., DeJong, J. T., and Shantz, T. (2012). “Guidelines for estimation

of shear wave velocity profiles.” PEER Rep. 2012/08, Pacific Earthquake Engineering Research Center, Headquarters at the Univ. of

California, Berkeley, CA.

04015057-10

J. Perform. Constr. Facil.

J. Perform. Constr. Facil.