UNIVERSITY OF CALGARY An Investigation of Solids Deposition

advertisement

UNIVERSITY OF CALGARY

An Investigation of Solids Deposition from Two-Phase Wax–Solvent–Water Mixtures

by

Adebola Sadiq Kasumu

A THESIS

SUBMITTED TO THE FACULTY OF GRADUATE STUDIES

IN PARTIAL FULFILMENT OF THE REQUIREMENTS FOR THE

DEGREE OF DOCTOR OF PHILOSOPHY

DEPARTMENT OF CHEMICAL AND PETROLEUM ENGINEERING

CALGARY, ALBERTA

APRIL, 2014

© ADEBOLA S. KASUMU 2014

Abstract

This study presents an investigation of the thermophysical behaviour and deposition tendency of

“waxy” mixtures, with and without the addition of water as a liquid phase. In the first part, the

wax precipitation temperature (WPT) of several compositions of a multi-component waxy

mixture (comprising a multi-component paraffinic wax dissolved in a multi-component solvent)

was measured at controlled cooling rates. Results indicated that the WPT of a waxy mixture is

not a constant property, as it varied with the cooling rate. Experimental results were used to

express the WPT as a function of the cooling rate and mixture composition. With the WPT being

dependent on the cooling rate, it may not correspond to the thermodynamic liquidus temperature

for the liquid-to-solid phase transformation process.

The deposition of solids from single-phase and two-phase waxy mixtures (second phase

being water) was studied using two different experimental apparatuses. A flow-loop apparatus

was used to study the effects of water content, wax mixture and coolant temperatures, and flow

rate, in two-phase waxy mixtures flowing under turbulent flow conditions. A cold finger

apparatus was used to further investigate the effects of time and stirring rate on wax deposition in

single-phase waxy mixtures, and the effect of water content in two-phase waxy mixtures.

In both sets of experiments, the water content of the deposit was found to be not related

to the water content of the waxy mixture. The deposit mass (on a water-free basis) decreased

with an increase in Reynolds number, the mixture temperature, and/or the coolant temperature.

The deposit mass both increased and decreased with the water content of the waxy mixture,

depending on the deposition time. Results showed the solids deposition from waxy mixtures to

be a fast process; for example, 56% of the deposition process in the cold-finger experiments was

completed in 0.07% of the time to reach steady-state. The deposition data were analyzed with a

ii

steady-state heat-transfer model, which also indicated that the liquid–deposit interface

temperature was close to the wax appearance temperature (WAT) of the waxy mixture. The

predictions from a transient heat-transfer model, based on the moving boundary formulation,

matched satisfactorily the effect of time on the deposition process in the cold-finger experiments.

Overall, the results of this study confirm that the deposition process from waxy mixtures is a

relatively very fast process, and is primarily thermally-driven.

iii

Acknowledgements

I would like to express my sincere gratitude and appreciation to my thesis supervisor, Dr.

Anil K. Mehrotra, for giving me the opportunity to work on this project, and for his

understanding, mentorship, guidance, patience, support, and unflinching willingness to help in all

circumstances throughout the period of my program.

I want to thank Dr. Jalel Azaiez and Dr. Maen Husein for accepting to be on my

supervisory committee. I extend my sincere appreciation to Mr. Jean-Marc Labonté, Ms. Ligaya

Aguinaldo, Mr. George Nerier, Ms. Elaine Baydak, Mr. Paul Stanislav, Ms. Paige Deitsch, Mr.

Mike Grigg, Mr. Andrew Sutton, Mr. Brian Moerke and other departmental staff for their

assistance at various times during my program.

I would like to thank Mr. Sridhar Arumugam, Dr. Hamid Bidmus, Mr. Nelson Fong, Ms.

Samira Haj-Shafiei, Ms. Dalia Serafini, Dr. Nitin Bhat and Dr. Poornima Jayasinghe for their

helpful suggestions and informative discussions. I gratefully acknowledge the financial support

from the Natural Sciences and Engineering Research Council of Canada (NSERC), the Centre

for Environmental Engineering Research and Education (CEERE), and the Department of

Chemical and Petroleum Engineering. I acknowledge the support from scholarships and awards,

including the Dean's Entrance Scholarship, the Queen Elizabeth II Doctoral Scholarship, FGS

Travel Award, the Department of Chemical and Petroleum Engineering Graduate Award, the

Pipeline Engineering Centre Graduate Scholarship, and the Teaching Assistant Excellence

Award.

Lastly, I want to thank members of my family, my father, mother, wife and three lovely

children for their prayers, selfless support, dedication, patience, love and encouragement, not

only during this program, but throughout my life. I couldn't have done it without you!

iv

Alhamdu lillahi rabbi alAAalameen (All praises and thanks be to Allah, the Lord of the worlds)

So, verily, with every difficulty, there is relief:

Verily, with every difficulty there is relief.

(Quran 94: 5 - 6)

v

Table of Contents

Abstract ............................................................................................................................... ii

Acknowledgements............................................................................................................ iv

Table of Contents............................................................................................................... vi

List of Tables ..................................................................................................................... xi

List of Figures and Illustrations ........................................................................................ xii

List of Symbols, Abbreviations and Nomenclature......................................................... xvi

CHAPTER ONE: INTRODUCTION..................................................................................1

1.1 Introduction................................................................................................................1

1.2 Objectives and Scope of Study ..................................................................................5

CHAPTER TWO: LITERATURE REVIEW......................................................................9

2.1 Paraffin Waxes...........................................................................................................9

2.1.1 Classification .....................................................................................................9

2.1.2 Crystal Structure ..............................................................................................10

2.1.3 Physical and Thermal Properties .....................................................................11

2.1.3.1 Enthalpy of Fusion.................................................................................14

2.1.3.2 Heat Capacity.........................................................................................14

2.1.3.3 Thermal Conductivity ............................................................................15

2.2 Wax Precipitation ....................................................................................................17

2.2.1 Crystallization..................................................................................................18

2.2.1.1 Nucleation ..............................................................................................18

2.2.1.2 Crystal Growth.......................................................................................19

2.2.2 Wax Appearance Temperature (WAT) ...........................................................20

2.2.3 WAT Measurement Techniques......................................................................20

2.2.4 Wax Precipitation Temperature (WPT)...........................................................24

2.2.5 Wax Disappearance Temperature (WDT).......................................................24

2.2.6 Pour Point Temperature (PPT) ........................................................................25

2.2.7 Rheology..........................................................................................................25

2.3 Wax Deposition .......................................................................................................26

2.3.1 Mechanism of Wax Deposition .......................................................................27

2.3.1.1 Molecular Diffusion...............................................................................27

2.3.1.2 Heat Transfer .........................................................................................28

2.3.2 Structure of the Wax Deposits.........................................................................29

2.3.3 Factors Affecting Wax Deposition..................................................................30

2.3.3.1 Effect of Composition............................................................................30

2.3.3.2 Effect of Temperatures ..........................................................................32

2.3.3.3 Effect of Flow Rate and Shear Rate.......................................................33

2.3.3.4 Effect of Deposition Time and Aging....................................................35

2.3.3.5 Effect of Surface Properties ...................................................................36

2.3.3.6 Effect of Emulsion Characteristics ........................................................37

2.3.4 Experimental Techniques for Wax Deposition ...............................................38

2.3.4.1 Flow Loop Experiments.........................................................................39

2.3.4.2 Cold Spot or Finger................................................................................39

2.3.4.3 Draft Tube Assembly.............................................................................40

vi

2.3.4.4 Co-axial Shearing Cell...........................................................................40

2.3.5 Wax Deposition Modeling ..............................................................................40

2.4 Control and Remediation .........................................................................................43

2.4.1 Mechanical Methods .......................................................................................43

2.4.2 Thermal Methods.............................................................................................44

2.4.3 Chemical Method ............................................................................................45

2.4.4 Biological Methods .........................................................................................46

2.4.5 Cold Flow of "Waxy" Crude oils ....................................................................46

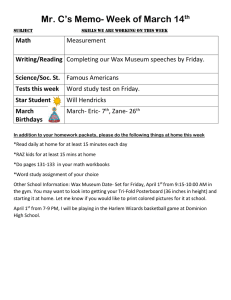

CHAPTER THREE: EXPERIMENTAL...........................................................................48

3.1 Materials ..................................................................................................................48

3.1.1 Paraffin Waxes ................................................................................................48

3.1.2 Solvents ...........................................................................................................49

3.1.3 Comparison of Compositions of Waxes and Solvents ....................................54

3.2 Wax–Solvent Mixtures ............................................................................................54

3.2.1 WPT Measurements ........................................................................................55

3.2.2 WAT, WDT and PPT Measurements ..............................................................56

3.3 WPT–Cooling Rate Experimental Apparatus..........................................................60

3.3.1 Heating Bath ....................................................................................................60

3.3.2 Cooling Bath....................................................................................................60

3.3.3 Cooling Rate Controller ..................................................................................60

3.3.4 Copper Pour Point Tubes.................................................................................62

3.3.5 Underwater Lighting .......................................................................................62

3.3.6 Thermocouple Data Acquisition System.........................................................65

3.4 WPT–Cooling Rate Experiments.............................................................................66

3.4.1 Experimental Procedure for WPT–Cooling Rate Experiments.......................66

3.4.2 Design of Experiments for WPT–Cooling Rate Experiments.........................67

3.5 Flow Loop Wax Deposition Experimental Apparatus.............................................69

3.5.1 Flow Loop Design ...........................................................................................69

3.5.2 Heating Bath and Associated Apparatus .........................................................74

3.5.3 Cooling Bath and Associated Apparatus .........................................................74

3.5.4 Wax Mixture Reservoir ...................................................................................77

3.5.5 Wax Mixture Stirrer ........................................................................................77

3.5.6 Photo/Contact Tachometer ..............................................................................78

3.5.7 Wax Mixture Centrifugal Pump ......................................................................78

3.5.8 Wax Deposition Section ..................................................................................79

3.5.9 Wax Mixture Flow Regulator..........................................................................83

3.5.10 Flow Sensor and Rate Meter .........................................................................84

3.5.11 Wax Mixture Sample Drain...........................................................................84

3.6 Associated Equipment and Measurements ..............................................................85

3.6.1 Centrifuge ........................................................................................................85

3.6.2 Temperature Measurements ............................................................................85

3.6.3 Density Measurements ....................................................................................86

3.6.4 Viscosity Measurements..................................................................................86

3.6.5 Titrator.............................................................................................................86

3.6.6 GC Analysis of Samples..................................................................................87

3.7 Flow Loop Experiments...........................................................................................88

vii

3.7.1 Experimental Procedure for Flow Loop Experiments.....................................88

3.7.2 Experimental Design for Flow Loop Experiments..........................................90

3.8 Cold Finger Wax Deposition Experimental Apparatus ...........................................93

3.8.1 Cold Finger Design..........................................................................................93

3.9 Associated Equipment and Measurements ..............................................................98

3.9.1 Microscopy ......................................................................................................98

3.10 Cold Finger Experiments .......................................................................................98

3.10.1 Experimental Procedure for Cold Finger Experiments .................................98

3.10.2 Experimental Design for Cold Finger Experiments ....................................100

CHAPTER FOUR: RESULTS OF WPT–COOLING RATE EXPERIMENTS.............102

4.1 Effect of Cooling Rate ...........................................................................................103

4.1.1 Significance of Cooling Rate.........................................................................105

4.2 Effect of Composition............................................................................................109

CHAPTER FIVE: RESULTS OF TWO-PHASE FLOW LOOP WAX DEPOSITION

EXPERIMENTS .....................................................................................................112

5.1 Steady State Heat Transfer Model .........................................................................112

5.2 Estimation of Heat Transfer Coefficients, hh and hc ..............................................118

5.3 Properties of Wax–Solvent, Wax–Solvent–Water Mixtures and Deposit Samples ................................................................................................................121

5.3.1 Density of Wax–Solvent and Wax–Solvent–Water Mixtures.......................121

5.3.2 Specific Heat Capacity of Wax–Solvent and Wax–Solvent–Water

Mixtures .........................................................................................................124

5.3.3 Viscosity of Wax–Solvent and Wax–Solvent–Water Mixtures ....................127

5.3.4 Density of Deposit Samples ..........................................................................130

5.4 Thermal Steady State .............................................................................................131

5.5 Estimation of Liquid–Deposit Temperature (Td) and Deposit Thermal Conductivity (kd)..................................................................................................135

5.6 Effect of Deposit-layer Thickness (xd) on the Rate of Heat Transfer (q) and the Inside Tube-wall Temperature (Twi) ....................................................................137

5.7 Effect of Process Conditions on Flow Loop Wax Deposition...............................139

5.7.1 Effect of Water Content on Deposit Mass.....................................................139

5.7.1.1 Effect of Th on Deposit Mass...............................................................141

5.7.1.2 Effect of Tc on Deposit Mass ...............................................................142

5.7.1.3 Effect of Flow Rate or Reynolds Number on Deposit Mass ...............142

5.7.2 Effect of Wax Mixture Water Content on Deposit Water Content ...............144

5.7.3 Effect of Reynolds Number on Deposit Water Content ................................146

5.7.4 Effect of Reynolds Number on Deposit Mass per unit Area.........................148

5.8 Homogeneity and Stability of Wax–Solvent–Water Mixtures in the Flow Loop .150

CHAPTER SIX: RESULTS OF TWO-PHASE COLD FINGER WAX DEPOSITION EXPERIMENTS .....................................................................................................152

6.1 Steady-State Heat Transfer Model.........................................................................152

6.2 Estimation of Heat Transfer Coefficient, hh ..........................................................158

6.3 Density of Deposit Samples...................................................................................158

6.4 Estimation of Deposit Thermal Conductivity (kd) .................................................161

viii

6.5 Effect of Deposit-layer Thickness (xd) on the Rate of Heat Transfer (q) ..............163

6.6 Effect of Process Conditions on Cold Finger Wax Deposition .............................165

6.6.1 Effect of Water Content on Deposit Mass.....................................................167

6.6.2 Effect of Deposition Time on Deposit Mass .................................................169

6.6.3 Effect of Stirring Rate on Deposit Mass........................................................169

6.6.4 Effect of Wax Mixture Water-Content on Deposit Water-Content...............172

6.6.5 Effect of Time on Deposit Water-Content ....................................................174

6.7 Short-Duration Experiments ..................................................................................176

6.8 Homogeneity of Wax–Solvent–Water Mixtures During Cold Finger

Experiments .........................................................................................................178

6.9 Aging of Deposit Samples .....................................................................................180

6.9.1 Deposit Sample Microscopy..........................................................................180

6.9.2 Deposit Sample GC Analysis ........................................................................186

CHAPTER SEVEN: PREDICTIONS FROM TRANSIENT HEAT-TRANSFER MODEL

.................................................................................................................................189

7.1 Moving Boundary Problem Formulation...............................................................190

7.2 Model Development for Transient (Unsteady-State) Wax Deposition .................191

7.2.1 Energy Balance Equations and Heat Transfer Considerations......................191

7.3 Model for Transient Heat Transfer during Cold Finger Wax Deposition .............193

7.3.1 Boundary and Initial Conditions ...................................................................196

7.3.1 Thermodynamic Considerations....................................................................197

7.3.2 Simulation Procedure ....................................................................................198

7.3.3 Estimation of Liquid and Solid Phase Properties ..........................................199

7.3.4 Numerical Solution Methodology .................................................................199

7.4 Model Predictions ..................................................................................................200

7.4.1 Predicted WAT Values..................................................................................200

7.4.2 Deposit Thickness Profiles ............................................................................202

7.4.3 Deposit Temperature Profiles........................................................................206

CHAPTER EIGHT: CONCLUSIONS AND RECOMMENDATIONS.........................208

8.1 Conclusions............................................................................................................208

8.2 Recommendations..................................................................................................212

REFERENCES ................................................................................................................214

APPENDIX A: WAX PRECIPITATION TEMPERATURE MEASUREMENT DATA .....................................................................................................................227

APPENDIX B: HEAT TRANSFER COEFFICIENT DATA .........................................229

APPENDIX C: PHYSICAL PROPERTIES DATA........................................................233

APPENDIX D: FLOW LOOP EXPERIMENTAL DATA .............................................236

APPENDIX E: COLD FINGER EXPERIMENTAL DATA ..........................................239

ix

APPENDIX F: ESTIMATION OF LIQUID MIXTURE AND DEPOSIT PHASE

PROPERTIES IN TRANSIENT MODEL .............................................................243

APPENDIX G: COPYRIGHT PERMISSIONS..............................................................247

x

List of Tables

Table 3.1

Composition of wax samples used in this study...........................................50

Table 3.2

Composition of solvents. ..............................................................................52

Table 3.3

Selected physical and chemical properties of Norpar13 (Imperial Oil

MSDS) and Linpar1416V (APCO Industries Ltd. MSDS) ..........................53

Table 3.4

Experimentally determined WAT, WDT, and PPT Values..........................58

Table 3.5

Operating Conditions for WPT–Cooling Rate Experiments ........................68

Table 3.6

Conditions of flow loop wax deposition experiments (Wax concentration = 6 mass%, WAT = 28 °C )...................................................92

Table 3.7

Conditions of cold finger wax deposition experiments (Wax concentration = 10 mass%, WAT = 32 °C)................................................101

Table 5.1

Density regression constants for equation 5.9. ...........................................122

Table 5.2

Regression constants for equation 5.10, the specific heat capacity of mixtures of Bernardin Parowax in Linpar1416V. ......................................126

Table 5.3

Viscosity regression constants for viscosity equation 5.11. .......................129

Table 5.4

Average Reynolds number, Re, estimated average liquid–deposit interface temperature, Td, and average deposit thermal conductivity,

kd, at different hot and cold stream temperatures . .....................................136

Table 6.1

Density regression constants for equation 6.9. ...........................................160

Table 6.2

Average estimated deposit thermal conductivities for deposits from 12 h and 24 h experiments. ..............................................................................162

Table 6.3

Deposit mass per unit area, Ω for 5 min, 12 h and 24 h experiments.........166

Table 6.4

Deposit mass per unit area for short-duration experiments of 30 s and 2 min, in comparison to the deposit mass per unit area at 12 h..................177

xi

List of Figures and Illustrations

Figure 3.1

Composition of solvents and wax samples. ....................................................... 51

Figure 3.2

Comparison of WAT values for Parowax–Norpar13 mixtures, and WAT, WDT and PPT values for Bernardin Parowax–Linpar 1416V mixtures (Kasumu and

Mehrotra, 2013) .................................................................................................................... 59

Figure 3.3

Bath.

Haake D8 Immersion Circulator immersed in a Haake DC1-V Refrigerated 61

Figure 3.4

Haake PG 20 Temperature Programmer ............................................................ 61

Figure 3.5

Fabricated copper tube used for WPT measurements........................................ 63

Figure 3.6

Underwater LED light, model QL-72C. ............................................................ 64

Figure 3.7

Schematic of bench-scale apparatus for flow loop wax deposition experiments. .......................................................................................................................... 72

Figure 3.8

Bench-scale setup for flow loop wax deposition experiments........................... 73

Figure 3.9

Coolant bath with the annealed copper tubing connected to coolant bath recirculator. ........................................................................................................................... 76

Figure 3.10

Position of Wax mixture centrifugal pump........................................................ 79

Figure 3.11

Cross-section of Aluminum deposition tube (Fong, 2007)................................ 80

Figure 3.12

Picture of entrance flange. a) inner side, b) outer side (Fong, 2007)................. 81

Figure 3.13

Plexiglass body of wax deposition section. a) Side view, b) Front view: entrance section (Fong, 2007)............................................................................................... 82

Figure 3.14

Plexiglass body of wax deposition section (Fong, 2007)................................... 83

Figure 3.15

Schematic of cold finger apparatus. ................................................................... 95

Figure 3.16

Assembled cold finger apparatus. ...................................................................... 96

Figure 3.17

Dismantled cold finger apparatus. ..................................................................... 97

Figure 4.1

Variation of WPT with cooling rate for different Conros Parowax–Norpar13 mixture compositions.......................................................................................................... 104

Figure 4.2

Comparison of calculated and experimental WPT values for Conros Parowax–Norpar13 mixtures (dotted curves show 95% confidence limits)....................... 107

xii

Figure 4.3. The effect of cooling rate on the wax precipitation temperature and liquid-to-solid phase transformation for w29 = 6 mass%. ........................................................................... 108

Figure 4.4

Variation of WPT with Parowax–Norpar13 mixture composition at different cooling rates as predicted by Equation 4.1. ........................................................................ 110

Figure 5.1

Temperature profile during wax deposition..................................................... 114

Figure 5.2

Predicted effects of deposit-layer thickness on fractional thermal resistances (kd = 0.38 W m–1 K–1

, Re = 10000)..................................................................................... 117

Figure 5.3

Comparison of experimental and correlated overall heat transfer coefficient, Ui, for wax mixtures (obtained from experiments performed under non-depositing conditions)........................................................................................................................... 120

Variation of the density of Bernardin Parowax-Linpar1416V mixtures with

Figure 5.4

Temperature. ....................................................................................................................... 123

Figure 5.5

Specific heat capacities of Bernardin Parowax-Linpar1416V mixtures. ......... 125

Figure 5.6

Viscosities of various Bernardin Parowax-Linpar1416V mixtures at wax concentrations from 0-10 mass%........................................................................................ 128

Figure 5.7

Variation of deposit mass per unit area, with time for extended experiments. ........................................................................................................................ 132

Approach to thermal steady-state during deposition shown by the difference

Figure 5.8

in coolant temperature for 1-hour experiments at Thi = (WAT+7ºC) and Tci = (WAT–

10ºC) for wax mixtures with 0, 10, 20 and 30 vol% water content. ................................... 134

Figure 5.9

Predicted effect of deposit-layer thickness (xd) on the rate of heat transfer and inside tube-wall temperature (Twi)................................................................................ 138

Figure 5.10Effect of the water content in the wax mixtures on the deposit mass per unit area, Ω................................................................................................................................. 140

Figure 5.11

Variation in the deposit mass at different water contents; (a) Effect of waxy

mixture temperature, Th, (b) Effect of coolant temperature, Tc, and (c) Effect of Reynolds number, Re.......................................................................................................... 143

Figure 5.12 .......... Comparison of the water content of deposit to the water content of the wax mixture ......................................................................................................................... 145

Figure 5.13

Variation of the water content of the deposits with Reynolds Number, Re..... 147

Figure 5.14

Variation of water-free deposit mass per unit area, Ω, with Reynolds

number, Re, for all deposition experiments at Th = (WAT+7 ºC) and Tc = (WAT–10 ºC). 149

xiii

Comparison of the water content of the waxy mixture in the reservoir with Figure 5.15

the water content of the waxy mixture flowing in the flow-loop. ...................................... 151

Predicted effects of deposit-layer thickness on fractional thermal resistances Figure 6.1

(0% water content). ............................................................................................................. 157

Figure 6.2

Predicted effect of deposit-layer thickness (xd) on the rate of heat transfer, q,

for Th = (WAT+3) oC, (Tc = WAT–15) oC, and hh = 980 W m-1 K-1. .................................. 164

Figure 6.3

Effect of the water content in the wax mixtures on the deposit mass per unit

area, Ω, at different deposition times.................................................................................. 168

Variation of deposit mass per unit area, Ω with deposition time, t. (a) single

Figure 6.4

phase mixtures at stirring rates of 250 and 500 rpm; (b) two-phase mixtures at a constant stirring rate of 500 rpm. ...................................................................................................... 171

Comparison of the water content of deposit to the water content of the wax Figure 6.5

mixture for different deposition times. ............................................................................... 173

Figure 6.6

Variation of the water content of the deposits with time, for different wax mixture water content. ........................................................................................................ 175

Comparison of the water content of the waxy mixture in the reservoir with Figure 6.7

the water content of samples taken. .................................................................................... 179

Figure 6.8

Microscopy pictures of deposit sample from 5 min experiment at 500 rpm stirring rate. ......................................................................................................................... 182

Microscopy pictures of deposit sample from 12 h experiment at 500 rpm Figure 6.9

stirring rate. ......................................................................................................................... 183

Microscopy pictures of deposit sample from 5 min experiment at 250 rpm Figure 6.10

stirring rate. Scale is the same as that of Figure 6.8............................................................ 184

Figure 6.11

Microscopy pictures of deposit sample from 12 h experiment at 250 rpm stirring rate. Scale is the same as that of Figure 6.8............................................................ 185

Figure 6.12

GC analyses of 10 mass% wax mixture and deposit samples from 5 min experiment and 12 h experiments at 500 rpm stirring rate. ................................................ 187

GC analyses of 10 mass% wax mixture and deposit samples from 5 min Figure 6.13

experiment and 12 h experiments at 250 rpm stirring rate. ................................................ 188

Figure 7.1

Cross-sectional view of wax deposition on cold finger with different phases and their relative temperatures............................................................................................ 195

Figure 7.2

Predicted and experimental values of WAT for Bernardin Parowax–

Linpar1416V mixtures. ....................................................................................................... 201

xiv

Figure 7.3... Deposit thickness profile from transient heat transfer model compared to deposit thickness from experimental data for single-phase experiments at 250 and 500 rpm. 204

Deposit thickness profile from transient heat transfer model compared to Figure 7.4

deposit thickness from experimental data for two-phase experiments 500 rpm................. 205

Figure 7.5

Predictions of temperature profile across the deposit layer at different deposition times, ranging from 5 min to 24 h. .................................................................... 207

xv

List of Symbols, Abbreviations and Nomenclature

a1, a2 = regression constants in eq 5.9 b1, b2 = regression constants in eq 5.11 c1, c2 = regression constants in eq 5.10. d1, d2, d3 = regression constants in eq 5.13 e1, e2 = regression constants in eq 6.9 f1, f2, f3 = regression constants in eq 4.1 A = surface area (m2) Ah = Actual flow rate (gal min–1) Ai = inside surface area of tube (m2) Cc = average specific heat capacity of coolant (J kg–1 K–1) Ch = average specific heat capacity of wax–solvent (hot) mixture (J kg–1 K–1)

Cp,L = paraffin liquid heat capacity (J K–1 kmol–1)

Cp,LCH2 = empirical specific heat capacity methylene contribution (J K–1 kmol–1)

Cp,LCH3 = empirical specific heat capacity methyl contribution (J K–1 kmol–1)

Cw = volume fraction concentration of wax out of solution at the wall

D = internal pipe diameter (m)

Dm, DB = diffusion coefficient (m2 s–1)

Fc = Flowrate of coolant (m3 s–1)

Fh = Flowrate of wax-solvent solution (m3 s–1) hc = heat transfer coefficient for coolant (W m–2 K–1) hh = heat transfer coefficient for wax–solvent (hot) mixture (W m–2 K–1) kd = average thermal conductivity of deposit (W m–1 K–1) xvi

km = thermal conductivity of metal (W m–1 K–1) kw = Wada and Jamieson thermal conductivity (W m–1 K–1)

L = length of aluminum or copper tube (m)

M = molar mass (kg kmol–1)

md = mass of deposited wax (kg)

m c = mass rate of coolant (kg s–1)

m h

= mass rate of wax–solvent mixture (kg s–1)

n = carbon number

Oh = Rate meter reading (gal min–1)

q = rate of heat transfer at steady state (W)

qgain = rate of heat gain by the coolant from the surroundings, (W)

Rc = thermal resistance of coolant (K W–1)

Rd = thermal resistance of deposit layer (K W–1)

Rh = thermal resistance of wax–solvent mixture (K W–1)

Rm = thermal resistance of metal tube wall (K W–1)

Re = Reynolds number

r2 = coefficient of determination

ri = inside metal tube radius (m)

ro = outside metal tube radius (m)

T = temperature (°C or K)

Tc = average temperature of coolant 0.5Tci + 0.5Tco (°C)

Tci = inlet temperature of coolant (°C)

Tco = outlet temperature of coolant (°C)

xvii

Td = average temperature at the interface of deposit and wax–solvent mixture or oil (°C) Tdavg = average deposit temperature ≡ 0.5(Td+Twi) (°C)

Th = average temperature of wax–solvent mixture 0.5Thi + 0.5Tho (°C)

Thi = inlet temperature of wax–solvent mixture (°C)

Tho = outlet temperature of wax–solvent mixture (°C)

Twi = temperature at the inside metal tube surface (°C)

Two = temperature at the outside metal tube surface (°C)

t = time (s)

Ui = overall heat transfer coefficient based on tube inside surface area (W m–2 K–1) xd = deposit layer thickness (m) Greek Letters

, , = empirical constants in eq 5.8

= viscosity of wax–solvent mixture (Pa s)

c = viscosity of continuous phase (Pa s)

m = viscosity of mixxture (Pa s)

ρsoln = density of wax–solvent mixture (kg m–3)

ρd = density of deposit (kg m–3)

φd = volume fraction of dispersed phase

θc = ratio of coolant (convective) thermal resistance and total thermal resistance

θd = ratio of deposit (conductive) thermal resistance and total thermal resistance

θh = ratio of wax–solvent mixture (convective) thermal resistance and total thermal resistance

θm = ratio of tube-wall (conductive) thermal resistance and total thermal resistance

xviii

= mass of deposit per unit deposition surface area (kg m–2)

= Jamieson factor

Acronyms

GC = gas chromatograph

PPT = Pour point temperature (°C)

WAT = wax appearance temperature (°C)

WPT = wax precipitation temperature (°C)

WDT = wax disappearance temperature (°C)

xix

Chapter One: Introduction

1.1 Introduction

Crude oils are complex mixtures containing several components, including paraffins,

aromatics, naphthenes, asphaltenes and resins. The higher molecular weight paraffins (or n­

alkanes) are referred to as waxes. At reservoir conditions, with temperatures in the range of 70­

150°C and pressures in the range of 50-100 MPa, these waxes remain dissolved in the crude oil,

which behaves as a Newtonian fluid (Lee, 2008). At the lower temperatures and pressures that

exist during crude oil transportation, the high molecular weight n-alkanes or waxes tend to form

macro and micro crystalline structures that precipitate out of the oil and deposit on the cooler

walls of the pipeline (Venkatesan et al., 2005). The precipitated wax imparts complex nonNewtonian and nonlinear characteristics to the flow properties of the crude oil (Chang and

Boger, 1998).

The temperature at which the first crystals of paraffin wax start to appear in the crude oil

is called the Wax Appearance Temperature (WAT) or the Cloud Point Temperature (CPT). It has

been shown that a "waxy" mixture containing as small as 2 mass% of wax is sufficient to

undergo deposition (Holder and Winkler, 1965a), provided the temperature of the contact surface

is less than or equal to the WAT of the crude oil or "waxy" mixture. Determination of the WAT

and the amount of wax precipitated at a given temperature are critical for understanding the

crude oil rheology and solids deposition (Ronningsen et al., 1991; Hansen et al., 1991; Pedersen

et al., 1991; Roehner and Hanson, 2001).

Wax deposition, which occurs when a “waxy” crude oil or mixture is exposed to a

temperature below the solubility temperature of the wax in the crude oil is a serious problem

1

during the production, transportation and processing of crude oil because wax deposition can

damage oil reservoir formations and wells, and cause blockage of pipelines and process

equipment. The deposition of wax in pipelines and process equipment leads to increased pressure

drop, increased pumping power requirements and/or reduction in pumping efficiency. In extreme

cases, the pipeline can become completely blocked, leading to "pump attack". Wax deposition

can be compared to the accumulation of cholesterol in the human blood vessels, which leads to

the obstruction of blood flow through the body from the heart. In severe cases, this will

ultimately lead to a heart attack. Wax deposition problems are more severe in cold environments,

most notably in subsea conditions, where temperatures at the bottom of the ocean can reach 4 oC

(Venkatesan et al., 2005). With deepwater oil recovery becoming increasingly more prevalent,

the implication is that crude oil is transported over greater distances and that the exposure to low

temperatures is increased. Problems associated with wax precipitation and deposition are

expected to become worse and so is the cost of its control and remediation. In an extreme case,

repeated wax deposition problems forced an oil platform to be abandoned at a cost of $100

million (Singh et al., 2000). The United States Minerals Management Service states that severe

wax related plugs were reported in Gulf of Mexico flow lines between 1992 and 2002 (Makagon

et al., 2003). The U.S. Department of Energy (DOE) states that the remediation of plugged

pipelines in water at depths of 400 m can cost $1 million/mile (Venkatesan et al., 2005). Finding

effective control and mitigation measures for the problem of wax deposition, especially in subsea

pipelines, is thus very important.

Wax-related problems are typically dealt with by using mechanical, thermal, chemical

and/or any combination of these methods (Svetgoff, 1984; McClafin and Whitfil, 1984; Woo et

al., 1984; Bernadiner, 1993; Hunt, 1996; Ferworn et al., 1997; Bello et al., 2006). In recent

2

years, other unconventional methods, such as bacterial and electromagnetic treatments,

(Balakirev et al., 2001; Towler and Rebbapragada, 2004), piezoelectric energy (Sulaiman et al.,

2011), and vacuum-insulated tubing (Singh et al., 2007) have also been tried with limited

success. All of these methods have their limitations and increase the production and processing

costs considerably. For example, chemical treatments are highly selective to a particular „waxy‟

mixture considered (Ferworn et al., 1997). An emerging technology proposed to control wax

deposition is “cold flow”. In this method, crude oil is subjected to systematic cooling to

precipitate wax crystals, giving rise to a slurry that is transported through pipelines. Several

reasons have been suggested for the reduced deposition of solids observed during “cold flow”.

These include reduced thermal driving force, the preferential crystallization of wax onto the

suspended solid crystals flowing in the slurry that act as nucleation sites, and a lowering of the

WAT of the remainder liquid phase (Merino-Garcia and Correra, 2008; Bidmus and Mehrotra,

2009; Deo, 2011).

The process of deposit formation from 'waxy' mixtures or crude oils is complex, and it

may involve several processes and considerations, such as crystallization kinetics, mass transfer,

heat transfer, fluid dynamics, rheology, solid–liquid multiphase equilibria, and thermophysical

and transport properties (Cole and Jessen, 1960; Turner, 1971; Burger et al., 1981; Coutinho,

1995; Creek et al., 1999; Singh et al., 2000; Bidmus and Mehrotra, 2004; Fong and Mehrotra,

2007). A number of mechanisms have been suggested for explaining the process of wax

deposition and for estimating the amount of deposition that will occur in a system under a

particular set of operating conditions. These include molecular diffusion, shear dispersion,

Brownian diffusion, gravity settling, and heat transfer. Of these, molecular diffusion and heat

transfer are currently regarded as the most relevant mechanisms. In the molecular diffusion

3

mechanism, it is assumed that deposits are formed as a result of the radial transport of wax

molecules due to a radial concentration gradient (Burger et al., 1981; Majeed et al., 1990;

Svendson, 1993; Creek et al., 1999; Kok and Saracoglu, 2000; Singh et al., 2000-2001; RamirezJaramillo et al., 2004; Farayola et al., 2010). Another inherent assumption in the molecular

diffusion modeling approach is that the deposit–liquid interface temperature is variable, which is

predicted to increase with deposit growth from an initial value close to the pipe-wall temperature

and ultimately to the WAT at steady state.

More recently, heat transfer has been identified as a more important mechanism or

approach for wax deposition. In the heat-transfer mechanism, the deposit formation and growth

is taken to be a (partial) solidification or freezing process involving crystallization (Bott and

Gudmunsson, 1977; Ghedamu et al., 1997; Cordoba and Schall, 2001; Bidmus and Mehrotra,

2004; Parthasarathi and Mehrotra, 2005; Bhat and Mehrotra, 2005; Fong and Mehrotra, 2007;

Mehrotra and Bhat, 2007; Tiwary and Mehrotra, 2009; Bidmus and Mehrotra, 2009; Kasumu and

Mehrotra, 2013; Arumugam et al., 2013). In the models based on the heat-transfer approach,

involving (partial) freezing or solidification, the release of the latent heat of phase change

accompanies the growth of a wax deposit layer close to the pipe wall, which is held at a

temperature lower than the WAT of the flowing “waxy” crude oil. An assumption made in the

heat-transfer mechanism is that the liquid–deposit interface temperature is equal to the WAT of

the crude oil, or waxy mixture, throughout the deposition process. This assumption has been

confirmed through measurements involving batch cooling experiments under static and sheared

conditions (Bidmus and Mehrotra, 2008a; Bidmus and Mehrotra, 2008b). It is pointed out that

the heat-transfer based deposition mechanism is able to explain solids deposition under both “hot

flow” (where the oil temperature > WAT) and “cold flow” (where the oil temperature < WAT)

4

conditions (Bidmus and Mehrotra, 2009; Bidmus and Mehrotra, 2012). Under steady-state

conditions, the liquid–deposit interface temperature in both the molecular diffusion approach and

the heat transfer approach is taken to be equal to the WAT, which has been confirmed from

several experimental investigations (Bidmus and Mehrotra, 2004; Parthasarathi and Mehrotra,

2005; Fong and Mehrotra, 2007; Tiwary and Mehrotra, 2009; Bidmus and Mehrotra, 2008a;

Bidmus and Mehrotra, 2008b; Bidmus and Mehrotra, 2009; Kasumu and Mehrotra, 2013).

Most wax deposition studies have focused on single-phase oil and two-phase oil–gas

flow. However, water is inevitably found in the produced oil and its fraction in the oil stream,

called the water-cut, generally increases with the lifetime of a production well. The wax

deposition process is not well established for two-phase oil–water flow conditions, perhaps due

to the increased complexity caused by the addition of the water phase and the difficulty in

obtaining consistent results with oil–water mixtures (Couto et al.; 2008). Various researchers

have reported different results on the effect of water on wax deposition (Li et al., 1997; AbdelWaly, 1999; Gao, 2003; Sarica and Volk, 2004; Couto et al., 2008; Bruno et al., 2008; Zhang et

al., 2010a; Zhang et al., 2010b; Hoffmann et al., 2012; Kasumu and Mehrotra, 2013;

Panacharoensawad and Sarica, 2013).

1.2 Objectives and Scope of Study

Crude oils are complex mixtures with varying compositions and properties, depending on

the source. Solutions of multi-component paraffin waxes dissolved in multi-component solvents

at various concentrations were used to represent complex paraffinic crude oils. This enhanced the

isolation and understanding of the variables that were studied without introducing additional

uncertainties, in addition to eliminating the limitations that sometimes accompany the use of

actual crude oil samples. In this study, novel experimental apparatuses were assembled and

5

procedures were developed to study the deposition of wax from wax–solvent and wax–solvent–

water mixtures of known compositions under various operating conditions. The main objectives

of the study were:

1. To prepare well-defined mixtures of multi-component waxes in paraffinic solvents, that

were used to represent “waxy” crude oils.

2. To measure and correlate physical properties of the materials and mixtures used.

3. To design and fabricate experimental apparatuses that were suitable, effective and

economical in achieving the objectives of this study.

4. To investigate the onset of wax precipitation and to express the wax precipitation

temperature as a function of cooling rate and mixture composition.

5. To investigate the effects of the presence of water, and other process variables on wax

deposition in a two-phase turbulent flow wax deposition process using a flow loop

apparatus.

6. To confirm that the deposition process in the flow loop apparatus, for both single- and

two-phase mixtures, can be explained using a simple steady-state heat transfer model.

7. To investigate the effects of water, time and shear rate on the wax deposition process in

both single- and two-phase mixtures using the cold finger wax deposition apparatus.

8. To confirm that the deposition process in the cold finger wax deposition apparatus, for

both single- and two-phase mixtures, can be explained using a simple steady-state heat

transfer model.

9. To model the transient behavior of the cold finger wax deposition process and compare

the predictions with experimental results.

6

Chapter 2 presents a critical review of the existing literature on wax deposition from

crude oils and paraffinic mixtures. The literature review presented includes the classification and

properties of paraffinic waxes, crystallization, the rheological behavior of "waxy" crude oils, and

mechanisms of wax deposition. It also includes methods for measuring the wax appearance

temperature (WAT), factors affecting wax deposition, methods for studying the wax deposition

process, structure and properties of wax deposits, and the methods of remediation and control of

wax deposition.

In Chapter 3, a detailed description of the experimental apparatuses and associated

equipment used, and experimental procedures applied in the various parts of this study are

presented. The three sets of experiments carried out in this study are discussed, namely WPT–

cooling rate experiments, one- and two-phase flow loop wax deposition experiments, and oneand two-phase cold finger wax deposition experiments. The design of experiments, materials

used, sample preparation methods, and methods of analyses for each set of experiments are also

described in this chapter.

In Chapter 4, results are presented from the WPT–cooling rate experiments. The effects

of cooling rate and composition on the wax precipitation temperature of "waxy" are discussed.

Results reported in this chapter have been published recently in Fuel by Kasumu et al. (2013).

In Chapter 5, the equations used to represent the physical properties of the systems

studied are presented. The physical properties studied include Bernardin Parowax–Linpar1416V

(and Bernardin Parowax–Linpar1416V–water) mixture density and viscosity, the correlations

used to estimate the specific heat capacity, and the deposit density correlation that was used to

determine deposit thickness. Results from the flow loop wax deposition experiments are also

presented. The steady-state heat transfer model used for the wax deposition process is described.

7

Effects of process parameters such as the water content of the wax mixture, wax mixture

temperature, coolant temperature, and flow rate or Reynolds number, and the deposition time are

described. Data regarding the liquid–deposit interface temperature and the deposit thermal

conductivity are also reported and discussed. Results reported in this chapter have been

published recently in Energy & Fuels by Kasumu and Mehrotra (2013).

In Chapter 6, results from the cold finger wax deposition experiments are presented.

Effects of process variables such as stirring rate, time (aging) and water content are discussed.

The steady-state heat transfer model is used to analyze the steady state experimental data from

the cold finger experiments.

In Chapter 7, a transient-state mathematical model is presented, which is based on the

model presented by Bhat and Mehrotra (2005) that utilizes the moving boundary problem

framework. The transient model was modified and used to describe the growth of the deposit

layer on the outside of a cylindrical pipe with time. Predictions from this model are presented

and compared with the experimental results from the cold finger wax deposition experiments.

Chapter 8 presents a summary of the important conclusions and contributions of this

study. Also included are recommendations for future work in this area of research.

8

Chapter Two: Literature Review

Crude oils are complex mixtures containing several different components, including

alkanes, aromatics, naphthenes, resins, high molecular weight waxes and asphaltenes. Crude oils

containing high fractions of paraffins or waxes, are called paraffin-base or “waxy” crude oils,

while those with a significant amount of asphaltenes are called asphalt-base or “asphaltic” crude

oils (Singh et al., 1999). High molecular weight paraffin waxes are soluble in crude oil under

reservoir conditions of high pressure and temperature. However, at lower conditions of pressure

and temperature during extraction of crude oil, precipitation and deposition of paraffin wax

within the reservoir as well as in the well-bore can occur. Wax deposition will also occur in

production pipelines when the pipeline wall temperature becomes lower than the wax appearance

temperature (WAT) of the flowing "waxy" crude oil (Chen et al., 1997).

2.1 Paraffin Waxes

2.1.1 Classification

Paraffin wax is mostly derived from petroleum crude oil. These petroleum waxes can be

classified as micro-crystalline wax or macro-crystalline/paraffin wax (Srivastava et al., 1993).

Paraffin waxes are a mixture of normal alkanes (n-alkanes) of different chain length (C18C65)

that tend to form clusters and precipitate from crude oil, under suitable conditions, to form wax

solids. Microcrystalline waxes consist of a mixture of iso-alkanes, n-alkanes, and cyclo-alkanes.

Iso-alkanes also form clusters and precipitate from crude oils; however, they tend to delay the

formation of a deposit due to their branched nature, and therefore produce unstable wax solids.

Cyclo-alkanes, or naphthenes, are stiff and bulky in nature and tend to disrupt the wax nucleation

process during deposit formation (Hammami and Raines, 1999).

9

Since paraffin waxes are made up of mainly n-alkanes, they are considered a natural

starting point for understanding the physical and thermal properties of the wax. The n-alkanes

are linear chains of aliphatic hydrocarbons belonging to a family of compounds, the paraffin

series. In this series all members contain carbon and hydrogen in a ratio given by the formula

CnH2n+2 (Turner, 1971). An important characteristic of high molecular weight n-alkanes is their

low solubility in paraffin-base, aromatic, naphthene-base, and other oil solvents at room

temperatures.

2.1.2 Crystal Structure

Below their melting point or melting point range, paraffins form a crystalline structure

from either their individual compounds or mixtures with one another. Their crystals are mainly

rhombic or monoclinic in shape and usually display a low order of symmetry (Mozes et al.,

1982). Crystallization starts when paraffins are cooled to temperatures below their melting

point, with nucleus formation (nucleation), which occurs in parallel with the crystal growth. The

relative rates of nucleation and crystal growth determine the final structure of the paraffin wax.

Similar to many other crystalline substances, the paraffin wax crystal structure changes further at

the equilibrium transition temperature, which is below the melting point.

C21 to C36 n-alkanes display a well-defined transition point below their melting point

where the α-phase, which is stable below the melting point, changes into the β-phase with the

release of a relatively large amount of heat (Mazee, 1949). Generally, n-alkanes between C19

and C29 having an odd number of carbon atoms have an orthorhombic structure at ambient

temperature. However, n-alkanes between C18 and C26 with even carbon numbers have a triclinic

structure, while those between C28 and C36 have a monoclinic structure. The different structural

10

morphologies are determined by the carbon number, thermal history, temperature and purity of

the sample (Turner, 1971; Srivastava et al., 1993).

Crystals of paraffin wax appear in three different characteristic forms, namely plates,

needles and mal-crystalline shapes. Crystals with the mal-crystalline shape are small

underdeveloped crystals that often agglomerate. The conditions of crystallization and the

chemical composition of the wax determines the form of the wax crystal. Turner (1971) reported

that fast cooling tends to produce needles and mal-crystalline forms while slow crystallization

favors the growth of plates. It is most likely that all the forms are typically produced during a

single crystallization, but with one of them usually being the predominant one under a given set

of conditions. It was found that the size of the crystal varies with the composition of the system

(Anderson 2001).

2.1.3 Physical and Thermal Properties

Paraffins or n-alkanes belong to a homologous series where each successive member of

the series is different from the next by the CH2 group. They are relatively inert and have little

affinity for most chemical reagents, thus the name „paraffins‟, which is derived from the Latin

words for “little affinity.” They are less dense than water and do not dissolve easily in water.

An alkane molecule is held together entirely by covalent bonds, which are directed in a

symmetrical way, such that the slight bond polarities tend to cancel out resulting in either a nonpolar or very weakly polar molecule. The non-polar molecules are held together by weak and

short-range van der Waals forces that act only between the surfaces of the molecules. Thus, it is

observed that the larger the n-alkane molecule (implying a larger surface area), the stronger the

11

intermolecular forces (Morrison and Boyd, 1992). That is why, as shown in Table 2.1, there is a

smooth gradation in physical properties of n-alkanes as the carbon number increases.

The first four members of the group, with carbon numbers C1 to C4 are gases at 20°C and

atmospheric pressure, while the C5 to C17 members are liquids and members with higher carbon

numbers higher than C17 are solids under the same conditions. The density of succeeding

members of the group increases rapidly initially, but levels off at about 800 kg/m3. The boiling

point increases with molecular weight, however, the rate of increase decreases progressively for

each additional CH2. For this reason, the lower n-alkanes are more easily separated by fractional

distillation than the higher members of the homologous series. A slight irregularity exists at the

beginning of the series, with ethane and propane having a lower melting point than methane.

After that, the melting point increases with molecular weight for the higher n-alkanes. Branched

alkanes or iso-alkanes do not show the same gradation in physical properties, and they usually

have a lower melting and boiling point than their corresponding n-alkane. This is due to the

reduced surface area of their molecules.

12

Table 2.1

Physical properties of some n-alkanes (Barton and Ollis, 1979)

Compound

Formula

Melting point

Boiling point

d420

(°C)

(°C)

(g cm-3)

Methane

CH4

–182.6

–161.6

0.4240 (at b.p.)

Ethane

C2H6

183.3

88.5

0.5462 (at b.p.)

Propane

C3H8

187.1

42.2

0.5824 (at b.p.)

Butane

C4H10

138.4

0.5

0.6011 (at 0°C)

Pentane

C5H12

129.7

36.1

0.6263

Hexane

C6H14

94.0

68.7

0.6594

Heptane

C7H16

90.5

98.4

0.6838

Octane

C8H18

56.8

125.7

0.7026

Nonane

C9H20

53.7

150.8

0.7177

Decane

C10H22

29.7

174.1

0.7301

Dodecane

C12H26

9.7

216.3

0.7487

Tetradecane

C14H30

5.5

253.6

0.7627

Hexadecane

C16H34

18.1

287.1

0.7733

Octadecane

C18H38

28.0

317.4

0.7767

Eicosane

C20H42

36.4

345.1

0.7777

Pentacosane

C25H52

53.3

259*

0.7785

Triacontane

C30H62

66.0

304*

0.7795

Tetracontane

C40H82

81.4

Pentacontane

C50H102

92.1

421*

Hectane

C100H202

115.3

*

*

Values obtained at 15 mm Hg.

13

2.1.3.1 Enthalpy of Fusion

The latent heat of fusion is the energy involved during the transition between solid and

liquid phases. Even though n-alkanes may also undergo solid-to-solid phase changes, involving

latent heat of transition, it has been suggested that heats of transition can be ignored for most

industrial purposes (Mullin 1973). While it has generally been observed that the latent heat of

fusion for n-alkanes increases linearly with their molecular weight, there is some disagreement as

to whether this increase is for only odd- or even-numbered n-alkanes, or for both (Hammami,

1994).

Dollhopf et al. (1981) observed that the plot of ΔHtot (the sum of heats of fusion and

transition) versus 1/n gave straight lines of the form

for even n:

3

H tot H 1

n

2.1

for odd n:

4.4

H tot H 1

n

2.2

where ΔH∞ is the melting enthalpy of polyethylene, extrapolated from the linear plots of the

experimental data for odd- and even-numbered paraffins, and has a value of 4.12 kJ/mol CH2.

High molecular weight n-alkanes have relatively high values of latent heat of fusion, in the range

about 150–300 kJ/kg. They are thus thought to be a useful means of energy storage and/or

thermal protection (Haji-Sheikh et al., 1982).

2.1.3.2 Heat Capacity

The heat capacity of paraffins is an important factor in the determination of the amount of

thermal energy associated with a given temperature change in a paraffinic mixture.

Some

empirical correlations have been developed to describe the heat capacities of paraffins up to

14

polyethylene in the solid and liquid states, as a function of temperature. Heat capacity values for

paraffins up to tritriacontane (C33) were obtained using a calorimeter (Finke, 1954; Huffman,

1931; Parks, 1930; Spaght, 1932). Various equations, empirical in nature, were proposed by

some researchers (Broadhurst, 1962; Karasz and Hamblin 1963; Pan et al., 1986; Wunderlich

and Dole, 1957; and Richardson, 1965) to describe the heat capacities of paraffins up to

polyethylene in the solid and liquid states as a function of temperature. A summary and

comparison of all these equations was provided by Dole (1967). Jin and Wunderlich (1991)

proposed equations 2.3a - 2.3c relating the heat capacity to carbon number (n), temperature, and

the empirical contributions from CH2 and CH3 groups. It was reported that the heat capacities in

the liquid state can be generated within an rms error of ±1.7%.

CH 3

C p ,l 2C p ,l

CH 2

( n 2 )C p ,l

2.3a

2

2C CH

p ,l 17.33 0.04551T

2.3b

3

2C CH

p,l 30.41 0.01479T

2.3c

where Cp,l is the specific heat capacity of the pure liquid component in J mol K, T is

temperature in K. However, there was no noticeable odd/even carbon number effect on the

liquid heat capacities.

2.1.3.3 Thermal Conductivity

The thermal conductivity is an important parameter because the deposition of waxes in

flowing crude oil is believed to be a thermally driven process (Kasumu and Mehrotra, 2013;

Fong and Mehrotra, 2007; Parthasarathi and Mehrotra, 2005; Bidmus and Mehrotra, 2004;

15

Guthrie et al., 2004; Cordoba and Schall, 2001a; Ribeiro et al., 1997; Brown et al., 1993; Khan

et al., 1993; Sharma et al., 1982).

The thermal conductivity of over 83 organic liquids were measured by Filippov (1968)

over a temperature range, and the results were tabulated. Dick and McCready (1954) also

measured the thermal conductivity of over 19 organic compounds, it was observed that thermal

conductivity increased with increasing chain length while it decreased in the presence of side

chains for molecules with the same carbon number. Data obtained by Filippov (1968) and Wada

et al. (1985) also agree with Dick and McCready‟s (1954) observations. Tufeu et al. (1968)

found the thermal conductivity of the alcohols to initially decrease rapidly with carbon number

and then increase slowly from C5. Missenard (1968) plotted the thermal conductivity data at 0°C

against the carbon number for organic acids, alcohols, organic iodide derivatives and n-alkanes.

While each group had a different smooth curve, all the curves converged to a common limiting

value between 0.155 to 0.160 W m–1 K–1.

Measurements of thermal conductivity of paraffins have shown an increase with

temperature (le Roux et al., 1974; Haji-Sheikh et al., 1982).

However, in each case an

irregularity or initial decrease in the thermal conductivities was noticed at certain temperatures,

depending on the paraffin wax composition. These temperatures were usually within the range

at which a solid-solid phase transition occurred in the waxes. This peculiar behavior of thermal

conductivity was attributed to the release of latent heat. The data by Wada et al. (1985) and

Vásquez and Briano (1993) also indicate that the thermal conductivities of liquid paraffins and

petroleum fractions decrease with temperature. Wada et al. (1985) found that the thermal

conductivity for n-alkanes such as n-undecane (n-C11), n-tetradecane (n-C14), n-pentadecane (n­

C15), n-hexadecane (n-C16) ranged from 0.120.15 W m–1 K–1 depending on the temperature.

16

Stryker and Sparrow (1990) found the thermal conductivity value of solid n-eicosane (n-C20) to

be 0.380.42 W m–1 K–1, depending on the temperature and the method of sample preparation.

Warth (1956) gave the following relationship for estimating the thermal conductivities of

paraffins in terms of their average molecular weight:

k w 2.4 10 4 M

2.4

Wada (1985) gave a basic relationship for paraffins up to C16 as follows:

kw = An2 + Bn + C – [D(1/n)2 + E(1/n) + F]T

2.5

where kw is the thermal conductivity (W m–1 K–1), A–F are constants, n is carbon number, and T

is temperature (range: 20–90 °C). Jamieson (1979) also developed a correlation in the form of:

kw = A(1 + B 1/3 + C2/3 + D

where = 1 – T/Tc, Tc is the critical temperature, A is the pseudo-critical thermal conductivity, B

is a constant, C = 1 – 3B, and D = 3B. Equation 2.6 is valid for paraffins with carbon number up

to 25 and a temperature range of melting point to 0.9Tc. Typical conductivity values for paraffin

hydrocarbons reported in literature range from 0.10 to 0.42 W m–1 K–1 (Dick and McCready,

1954; Missenard, 1968; Filipov, 1968; Jamieson et al., 1974; Stryker and Sparrow, 1990;

Bidmus, 2003; Fong and Mehrotra, 2007).

2.2 Wax Precipitation

Paraffins precipitate as wax deposits in crude oils due to either evaporation of volatile

light components, or a drop in the temperature of the system (Svetgoff, 1984). Wax precipitation

occurs during the formation of solid wax crystals out of solution from a liquid phase, while wax

deposition occurs during the formation and growth of a layer of precipitated solid on a surface

(Hammami et al., 2003). Even though precipitation is necessary for deposition to occur, it is

17

possible to have wax precipitation without causing wax deposition. Furthermore, whereas

precipitation is mainly a function of thermodynamic variables such as composition, pressure and

temperature, deposition also depends on heat and mass transfer, flow hydrodynamics, and solidsolid and surface-solid interactions (Hammami et al., 2003). Normal paraffins are the most

readily precipitated, during the cooling of a “waxy” mixture, followed by naphthenes and iso­

paraffins, while aromatics tend to stay in the liquid phase (Pan et al., 1996).

2.2.1 Crystallization

As the temperature of a liquid crude oil is decreased, the energy of molecular motion

decreases, and the molecules move closer together. As time progresses, the molecules begin to

have a more ordered arrangement with the degree of order mostly determined by the shapes of

the molecules and their ability to fit together in adjacent positions (Turner, 1971). Typically, a

degree of super-saturation is required before the beginning of precipitation. At the WAT (or

freezing point in the case of a melt), the short-range intermolecular attractive forces are greater

than the energy of molecular motion and the molecules are bound together into a crystal. The

two distinct stages involved during this process, namely nucleation and growth (Hammami,

1994), are discussed in the following sub-sections.

2.2.1.1 Nucleation

The process of crystallization starts with the formation of a nucleus, which is the smallest

stable particle of wax crystal possible under the system conditions. As the liquid temperature is

decreased, molecules form an ordered arrangement of clusters of adjacently aligned chains.

Molecules continue to attach and detach from these ordered sites until the clusters become stable

after having reached a critical size. This process of attaching and detaching of molecules is

18

called nucleation and the stable clusters formed are the nuclei. Any smaller particle emerging

from the liquid would be unstable and tends to re-dissolve into the solution (Turner, 1971).

Nucleation may be spontaneous (homogenous nucleation), or it may be induced artificially

(heterogeneous nucleation). Homogenous nucleation is mainly a thermal process that usually

occurs from a pure sample with nucleation sites that are time dependent.

Heterogeneous

nucleation may be either thermal or athermal and all the nucleation sites are activated

instantaneously (Turner, 1971). Heterogeneous nucleation occurs either on the surface of a wall

or as a result of foreign particles in the solution.

2.2.1.2 Crystal Growth

If the temperature is kept at or below the WAT (or freezing point), following the

formation of the nuclei, more molecules attach themselves successively to the nucleation sites,

becoming part of the growing lamellar structure. Nearby molecules locate suitable parts of the

nucleation sites where they can fit into in an orderly manner. Intermolecular attractive forces

draw these molecules into place. Once in place, these molecules themselves provide suitable

sites to receive other molecules. A site having the highest possible number of neighboring

molecules bordering its position will be favored due to the higher magnitude of the attractive

forces occurring there (Keating, 1964). Growth occurs most easily at the edge of a partially

completed layer of molecules. During the crystallization of paraffins, a monomolecular layer is

formed by the side-by-side addition of molecules to form each consecutive layer, which is a

relatively fast process. The initial addition of a subsequent layer on an existing layer is slower,

because further growth on a geometrically perfect crystal only occurs if the clustering of

molecules on the surface nucleates a new layer (Hammami, 1994).

19

2.2.2 Wax Appearance Temperature (WAT)

The highest temperature at which the first wax crystals start to appear, upon cooling of a

“waxy” crude oil or mixture, is called the wax appearance temperature (WAT). The WAT is an

important parameter in wax precipitation and deposition. The WAT is also called the cloud point

temperature (CPT) and is essential for determining the tendency of crude oil towards wax

precipitation and deposition (i.e., crude oils with a high WAT will be more likely to undergo wax

precipitation and deposition). No wax precipitation or deposition will occur as long as the crude

oil temperature is above the WAT. Once the temperature drops below the WAT, wax molecules

will begin to crystallize out of solution and wax deposition can occur. Factors that favor an

increase in WAT also tend to favor increased wax deposition.

An important distinction exists between the liquidus temperature and the experimentally

determined WAT. The liquidus temperature defines the true solid–liquid phase boundary,

whereas the experimental WAT is the temperature at which the first crystals are detected upon

cooling. This value can vary depending on the sensitivity of the measurement technique, thermal

or cooling history and the cooling rate; hence, it can be very subjective. The experimental WAT

would be lower that the liquidus temperature and should be within the solid–liquid phase

envelope (Bhat and Mehrotra, 2004).

2.2.3 WAT Measurement Techniques

The WAT of a “waxy” crude oil sample is the highest temperature that wax solids can be

detected when the sample is cooled. Different equipment and methods have been developed to