arc-flash - Littelfuse

advertisement

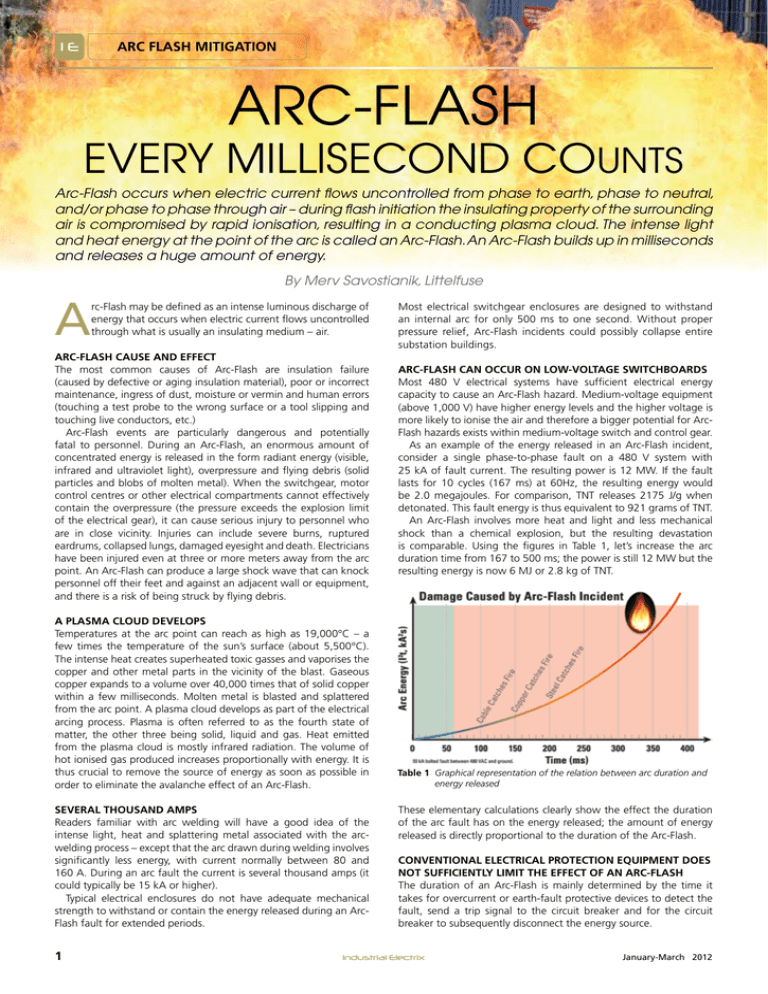

Arc Flash Mitigation IE ARC-FLASH EVERY MILLISECOND COUNTS Arc-Flash occurs when electric current flows uncontrolled from phase to earth, phase to neutral, and/or phase to phase through air – during flash initiation the insulating property of the surrounding air is compromised by rapid ionisation, resulting in a conducting plasma cloud. The intense light and heat energy at the point of the arc is called an Arc-Flash. An Arc-Flash builds up in milliseconds and releases a huge amount of energy. By Merv Savostianik, Littelfuse A rc-Flash may be defined as an intense luminous discharge of energy that occurs when electric current flows uncontrolled through what is usually an insulating medium – air. Arc-Flash Cause and Effect The most common causes of Arc-Flash are insulation failure (caused by defective or aging insulation material), poor or incorrect maintenance, ingress of dust, moisture or vermin and human errors (touching a test probe to the wrong surface or a tool slipping and touching live conductors, etc.) Arc-Flash events are particularly dangerous and potentially fatal to personnel. During an Arc-Flash, an enormous amount of concentrated energy is released in the form radiant energy (visible, infrared and ultraviolet light), overpressure and flying debris (solid particles and blobs of molten metal). When the switchgear, motor control centres or other electrical compartments cannot effectively contain the overpressure (the pressure exceeds the explosion limit of the electrical gear), it can cause serious injury to personnel who are in close vicinity. Injuries can include severe burns, ruptured eardrums, collapsed lungs, damaged eyesight and death. Electricians have been injured even at three or more meters away from the arc point. An Arc-Flash can produce a large shock wave that can knock personnel off their feet and against an adjacent wall or equipment, and there is a risk of being struck by flying debris. A plasma cloud develops Temperatures at the arc point can reach as high as 19,000°C – a few times the temperature of the sun’s surface (about 5,500°C). The intense heat creates superheated toxic gasses and vaporises the copper and other metal parts in the vicinity of the blast. Gaseous copper expands to a volume over 40,000 times that of solid copper within a few milliseconds. Molten metal is blasted and splattered from the arc point. A plasma cloud develops as part of the electrical arcing process. Plasma is often referred to as the fourth state of matter, the other three being solid, liquid and gas. Heat emitted from the plasma cloud is mostly infrared radiation. The volume of hot ionised gas produced increases proportionally with energy. It is thus crucial to remove the source of energy as soon as possible in order to eliminate the avalanche effect of an Arc-Flash. several thousand amps Readers familiar with arc welding will have a good idea of the intense light, heat and splattering metal associated with the arcwelding process – except that the arc drawn during welding involves significantly less energy, with current normally between 80 and 160 A. During an arc fault the current is several thousand amps (it could typically be 15 kA or higher). Typical electrical enclosures do not have adequate mechanical strength to withstand or contain the energy released during an ArcFlash fault for extended periods. 1 Most electrical switchgear enclosures are designed to withstand an internal arc for only 500 ms to one second. Without proper pressure relief, Arc-Flash incidents could possibly collapse entire substation buildings. Arc-Flash Can Occur on Low-Voltage Switchboards Most 480 V electrical systems have sufficient electrical energy capacity to cause an Arc-Flash hazard. Medium-voltage equipment (above 1,000 V) have higher energy levels and the higher voltage is more likely to ionise the air and therefore a bigger potential for ArcFlash hazards exists within medium-voltage switch and control gear. As an example of the energy released in an Arc-Flash incident, consider a single phase-to-phase fault on a 480 V system with 25 kA of fault current. The resulting power is 12 MW. If the fault lasts for 10 cycles (167 ms) at 60Hz, the resulting energy would be 2.0 megajoules. For comparison, TNT releases 2175 J/g when detonated. This fault energy is thus equivalent to 921 grams of TNT. An Arc-Flash involves more heat and light and less mechanical shock than a chemical explosion, but the resulting devastation is comparable. Using the figures in Table 1, let’s increase the arc duration time from 167 to 500 ms; the power is still 12 MW but the resulting energy is now 6 MJ or 2.8 kg of TNT. Table 1 Graphical representation of the relation between arc duration and energy released These elementary calculations clearly show the effect the duration of the arc fault has on the energy released; the amount of energy released is directly proportional to the duration of the Arc-Flash. Conventional Electrical Protection Equipment Does Not Sufficiently Limit the Effect of an Arc-Flash The duration of an Arc-Flash is mainly determined by the time it takes for overcurrent or earth-fault protective devices to detect the fault, send a trip signal to the circuit breaker and for the circuit breaker to subsequently disconnect the energy source. Industrial Electrix January-March 2012 IE Fast acting fuses may disconnect the circuit from the energy source in 8 ms or less when subjected to the high short-circuit currents usually appearing in three-phase symmetrical bolted cases, while other devices may take much longer to operate and remove the source of energy. But unbalanced, single-phase and high-impedance fault currents are lower than three-phase bolted-fault currents, so protection devices may not necessarily detect and limit arc-fault current and will require more time to clear the fault. In many cases the protection devices at main distribution points are coordinated with downstream protection systems. This means that there may be a considerable time delay before the standard overcurrent and earth-fault protection devices at the main distribution point operate, to allow a downstream protection device to clear the fault first. Arc-Flash Protection Strategies Although there are a few options available, most of the protection strategies have disadvantages: When users order new metal-enclosed switchgear they could specify that the switchgear must be type tested to IEC 60298. According to this standard it is possible to specify an internal arc rating with fault times of 100, 500 or 1,000 ms. One should bear in mind that the cost of the switchgear increases drastically for longer arc ratings (the price could be double for a 1s rating when compared with a 100 ms rating). The reasoning behind this: it is expected that the standard protection will detect and clear the fault within the designed internal withstand time (say 500 ms). Although the switchgear is designed to remain intact in the event of an internal arc (at least for the specified internal arc rating time) it will not prevent internal damage which would definitely lead to extended electrical outages. Arc-resistant switchgear loses its rating when a cubical door is open, or not properly closed. In most cases Arc-Flash faults occur at the cable crutches, inside the cable compartment which means that this area falls outside the busbar protection zone. The busbar protection will not operate for Arc-Flash occurring inside the cable compartments. This solution is also rather expensive, requiring complicated modifications and additional equipment (e.g. CTs, relays, etc) if intended to be installed on existing switchgear panels. protective clothing The third means of protection is protective clothing. Human errors when performing work on live equipment are one of the most common causes of Arc-Flash. It is possible to protect personnel from some of the Arch-Flash hazards by ensuring that they wear proper personal protective equipment (PPE). PPE includes clothing, gloves, insulated tools, face protection, and glasses. However, workers may not always wear cumbersome PPE, and if they do, it may not protect them against the blast of an Arc-Flash event, which can break bones, puncture organs, and propel workers into walls or equipment. Figure 3 Arc-Flash point sensors or fiber-optic sensors are strategically placed in all compartments of a switchgear cabinet. dedicated Arc-Flash relay Perhaps the most reliable solution is an Arc-Flash relay. A dedicated Arc-Flash relay and optical sensors can be retrofitted to electrical cabinets to ensure that an Arc-Flash in any compartment is detected and that the source of electrical energy is removed in the shortest possible time. This solution provides the best advantages in terms of effectiveness, cost, and ease of installation. This equipment is specifically designed to detect an Arc-Flash and to issue a trip (almost instantaneously) to the main circuit breaker. The duration of the Arc-Flash is reduced to the mechanical opening time of the circuit breaker. The operating time of modern circuit breakers is in the region of 35 to 60 ms. Figure 2 An Arc-Flash sensor installed inside a switchgear cabinet. high-impedance bus protection Another protection strategy is a dedicated busbar protection scheme, such as high-impedance bus protection (based on the circulating current principle). This type of protection would typically detect a fault inside the protected zone in 40 to 65 ms (plus the breaker operation time). The disadvantage of this solution is that it is regarded as a zone protection scheme, which means that the protected zone is limited to the actual position of the current transformers (mounted inside the switchgear). www.powertrans.com.au Comply with the Law In Australia, the Occupational Health and Safety (Safety Standards) Regulations 1994 clearly require the identification and elimination or minimisation of risk. According to the Regulation, “An employer must identify any risk of injury from (a) the existence or use of electricity in the workplace; and (b) the existence, operation or use of electrical installations at the workplace.” There is a duty to control risk; “…the employer must…either: (i) take measures to eliminate the risk; or (ii) if it is not reasonably practical to eliminate the risk – take measures to minimise the risk as far as reasonably practicable.” An Arc-Flash relay comprehensively protects the functional reliability of the distribution board and at the same time helps to eliminate workplace electrical risk. The Benefits of Arc-Flash Relays As mentioned above, the consequences of an Arc-Flash in a power system can be disastrous. Within a very short time (milliseconds) after a fault occurs, pressures and temperatures rise to levels that can easily destroy the metal housing surrounding the equipment. The energy released by such a fault is enough to cause sheet metal to melt or evaporate and a serious fire could follow. Industrial Electrix 2 IE By installing reliable and fast acting Arc-Flash detecting and protection equipment in the electrical switchgear and distribution systems, plant owners will enhance the safe operation of the equipment. Arc-Flash detection equipment protects both personnel and equipment and reduces repair and reconstruction costs. System downtime is shortened due to the fact that the amount of damage caused by the Arc-Flash is limited. Therefore the total cost of ownership is drastically reduced. Installing and maintaining Arc-Flash protection equipment may also help reduce insurance premiums and possibly workers compensation and insurance claims. How an Arc-Flash Relay Works The Arc-Flash relay uses light-sensitive sensors to detect an arc flash. These sensors consist of two silicon photo cells encapsulated in a transparent polyester body, or consist of a “leaky” optical fibre that captures light and transmits it to a photo cell. The sensors are strategically placed in the various cubicles or drawers inside the switchboard. An Arc-Flash relay system should have an integrated three-phase current-measurement capability. Although it is not a requirement for the system to operate, this capability increases the system reliability (minimise spurious tripping). The theory behind this is that when an Arc-Flash occurs the electrical current feeding into the fault will increase drastically. Two conditions need to be fulfilled before the relay trip signal is sent to the circuit breaker: a current flow that exceeds the normal operating current of the system and a signal from an optical Arc-Flash sensor that has reacted to a high-intensity light source. Some systems also offer a circuit-breaker fail function which makes it possible to trip the upstream supply breaker after a time delay of 50 to 150 ms if the overcurrent and arc signal remains after 3 Figure 4 The PGR-8800 from Littelfuse is an example of an Arc-Flash relay used in new equipment or to retrofit existing switchboards. It is simple to install and straightforward to commission. This model can be supplied from an external power supply (or fed from station batteries) at 110 to 250 VAC/DC or 12 to 48 VDC. The system provides continuous surveillance of the complete system including the connected sensors. Any system faults, e.g. a faulty sensor cable, is indicated by a flashing LED, an alarm contact, and is logged and reported. A USB connection provides easy access to configuration settings and a realtime event log with detailed diagnostic information about events such as configuration changes, test, reset and power cycling. the circuit breaker was supposed to open (meaning that the circuit breaker has failed to trip). There are two types of Arc-Flash sensors available: point sensors and optical fibre sensors. In some systems, the condition of the sensors (optical fibre sensors included) is continuously monitored. Industrial Electrix January-March 2012