Dominator - Bendertechniek

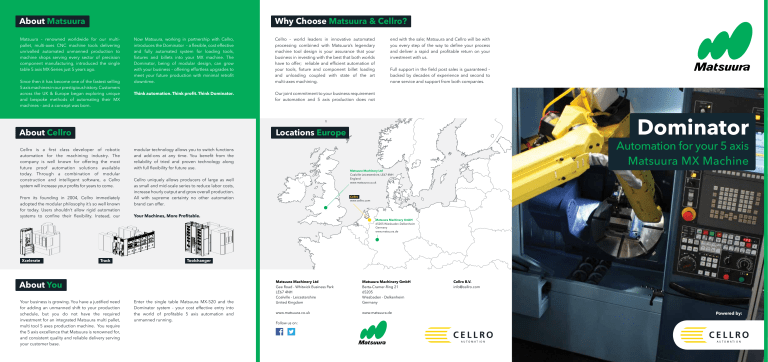

About Matsuura

Matsuura – renowned worldwide for our multipallet, multi-axes CNC machine tools delivering unrivalled automated unmanned production to machine shops serving every sector of precision component manufacturing, introduced the single table 5 axis MX-Series just 5 years ago.

Since then it has become one of the fastest selling

5 axis machines in our prestigious history. Customers across the UK & Europe began exploring unique and bespoke methods of automating their MX machines – and a concept was born.

Now Matsuura, working in partnership with Cellro, introduces the Dominator – a flexible, cost effective and fully automated system for loading tools, fixtures and billets into your MX machine. The

Dominator, being of modular design, can grow with your business – offering effortless upgrades to meet your future production with minimal retrofit downtime.

Think automation. Think profit. Think Dominator.

About Cellro

Cellro is a first class developer of robotic automation for the machining industry. The company is well known for offering the most future proof automation solutions available today. Through a combination of modular construction and intelligent software, a Cellro system will increase your profits for years to come.

From its founding in 2004, Cellro immediately adopted the modular philosophy it’s so well known for today. Users shouldn’t allow rigid automation systems to confine their flexibility. Instead, our modular technology allows you to switch functions and add-ons at any time. You benefit from the reliability of tried and proven technology along with full flexibility for future use.

Cellro uniquely allows producers of large as well as small and mid-scale series to reduce labor costs, increase hourly output and grow overall production.

All with supreme certainty no other automation brand can offer.

Your Machines, More Profitable.

Why Choose Matsuura & Cellro?

Cellro – world leaders in innovative automated processing combined with Matsuura’s legendary machine tool design is your assurance that your business in investing with the best that both worlds have to offer; reliable and efficient automation of your tools, fixture and component billet loading and unloading coupled with state of the art multi-axes machining.

Our joint commitment to your business requirement for automation and 5 axis production does not end with the sale; Matsuura and Cellro will be with you every step of the way to define your process and deliver a rapid and profitable return on your investment with us.

Full support in the field post sales is guaranteed – backed by decades of experience and second to none service and support from both companies.

Locations Europe

Matsuura Machinery Ltd

Coalville Leicestershire, LE67 4NH

England www.matsuura.co.uk

Cellro www.cellro.com

Matsuura Machinery GmbH

65205 Wiesbaden-Delkenheim

Germany www.matsuura.de

Xcelerate Track Toolchanger

About You

Your business is growing. You have a justified need for adding an unmanned shift to your production schedule, but you do not have the required investment for an integrated Matsuura multi pallet, multi tool 5 axes production machine. You require the 5 axis excellence that Matsuura is renowned for, and consistent quality and reliable delivery serving your customer base.

Enter the single table Matsuura MX-520 and the

Dominator system - your cost effective entry into the world of profitable 5 axis automation and unmanned running.

Matsuura Machinery Ltd

Gee Road - Whitwick Business Park

LE67 4NH

Coalville - Leicestershire

United Kingdom www.matsuura.co.uk

Follow us on:

Matsuura Machinery GmbH

Berta-Cramer-Ring 21

65205

Wiesbaden - Delkenheim

Germany www.matsuura.de

Cellro B.V.

info@cellro.com

Dominator

Automation for your 5 axis

Matsuura MX Machine

Powered by:

Dominator - Benefits

Matsuura 5 axis machining with Cellro

Automation – a winning combination

Future-proof investment with rapid ROI

High storage capacity; ergonomic system configuration

Utilising Fanuc® robots with high speed, precision and reliability: 99,99% uptime

Efficient use of valuable floor space – minimal footprint

Expandable – grows with your workload

& business

Versatile and flexible – Rapid re-tasking for new work

System Capacity for two MX-520 or MX-850

machines

Full support – from Matsuura and Cellro

Full training – for your operators, programmers and maintenance staff

Full warranty – machine, system and robot

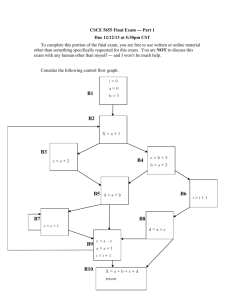

How it Works

I ntroducing an unmanned fully automated shift into your production stream is your fastest route to increased profitability, offering your company a dynamic future proof edge over your competitors.

The Dominator system has been developed to deliver multi-tasking lights out production and flexibility into a diverse array of businesses, serving a myriad of industries.

Being of modular design it can be quickly expanded in the field to accommodate new work and growth in your business. The system can even integrate a second Matsuura MX-520 5 axis machine when your future production needs demand so.

Imagine a production operative that is never sick, never tired, never on holiday and can quickly and effortlessly be taught new tasks and duties. This is

Dominator – whether it is loading and unloading pallets, billets, fixtures and tools into your machine, or added value robotic operations bespoke to your requirements between (un)loading cycles and duties, this system is destined to be your most profitable and flexible production asset, delivering a rapid return on your future proof investment.

Advanced Software

Our next generation automation software gathers real time process information from the Dominator system (tools, grippers, workpieces). The feedback is directly communicated to your operator. Any inconsistencies are detected immediately, greatly increasing efficiency and reducing error.

Configurations

The Dominator flexibly grows along with your automation needs. We offer three levels of size, which can be expanded at any time.

Modules

Dominator’s unrivalled flexibility is made possible by its modular construction and advanced software. The groundbreaking software architecture is specifically designed to adjust to any possible future hardware changes.

Pallet

Base

One machine, one loading, three storage racks and a

175 kg. robot

Tool

Your Benefit

This pallet module increases production efficiency at any time and with any product. True flexibility.

It ensures a consistently effective means to set up workpieces.

Technical Details

Our pallet module is compatible with pallets in sizes 400x400,

320x320 and 240x240 mm. To gain even more flexibility, the module allows for a second (round) pallet to be added in sizes of 120,

148 and 200 mm. This requires a chuck adapter. All pallet module variations unite effortlessly with the advanced software.

Extended

Base + two additional storage racks

Workpiece

Your Benefit

Our tool modules offer precisionengineered tool handling and storage. It communicates real-time feedback of the current process state, increasing overall production efficiency and flexibility.

Technical Details

Compatible with BT40 and HSK63.

The rack offers a supreme storage capacity of 56 tools per rack.

When your system contains two machines and tooling racks, both can work together interchangeably.

This efficient teamwork is made possible by the fully integrated tool management system, which registers current process state and tool whereabouts.

Completed

Extended + second machine

Your Benefit

You never have to interrupt the machining process ever again when supplying and discharging workpieces. The workpiece system keeps track of current supply, discharge and upcoming workpieces. This results in supreme stock flow and planning.

Technical Details

The workpiece module comes with a tray gripper and product grippers. These state of the art grippers are capable of handling workpieces ranging from 10-120 mm and a maximum weight of 7kg.

A third gripper is optional in the case of heavier workpieces.