BACnet Automation Interface Module (Serial

advertisement

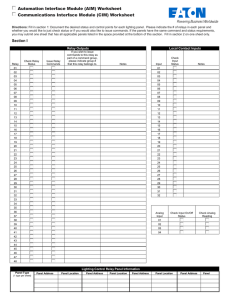

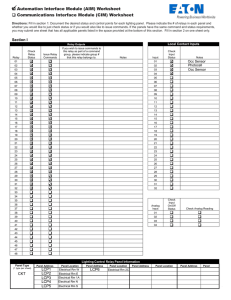

Installation Sheet General Information BACnet Automation Interface Module (Serial Version) Model# AIM-BAC-SER The BACnet Automation Interface Module provides a communications link between the Greengate System lighting control panel and a system that uses the BACnet Protocol. This allows a BACnet based system to have the ability of turning On or Off relays or groups of relays within a Greengate System as well as get status from relays or switches. The BACnet Automation Interface Module is custom configured for your job site’s needs as to what relays and groups it will control or monitor. Before You Begin The BACnet AIM ships without the motherboard installed in the enclosure unless the desired programming has been given to the factory prior to shipment. As each site is pre-configured, it will be necessary to provide technical support with the necessary programming information to ship the motherboard to the site. Please see the end of this document to obtain the paperwork that must be filled out for the configuration of this unit. The unit will be pre-configured for the protocol, baud rate and connection type for your site based on the information provided to us. A system integrator mapping table will be provided including a header for information on details on the configured protocol type, i.e. BACnet over Ethernet, BACnet over IP, BACnet over MS/TP or BACnet over ARCnet. Each BACnet AIM unit has the capability of commanding and monitoring a total of 1200 points. Please note that your AIM unit has been preconfigured for your site’s panels and desired points to command and monitor. Please refer to the systems integrator mapping table for the information on how the BACnet points relate to the Greengate lighting control points. This document describes the installation process for the AIM unit. Questions should be referred to Cooper Controls Technical Support Department. Getting Started 1. Do not discard these installation instructions. Please keep for future reference and operation information. 2. Use only as intended and at the listed voltage. 3. All installation and service must be performed by qualified personnel or service technicians. 4. Install in accordance with the National Electrical Code and any other codes which may apply. 5. Installation and wiring information contained in this document is based on industry-accepted standards and practices. If conflicts exist between these instructions and any applicable codes or ordinances, please contact Cooper Controls before proceeding with the installation. Cooper Controls 203 Cooper Circle, Peachtree, GA 30269 800-553-3879 www.coopercontrol.com Figure 1: Automation Interface Module in Enclosure Mounting the AIM Unit 1. Choose a dry location convenient within 6 feet of the Greengate lighting controller that also has access to the BACnet network. 2. Mount the enclosure on a firm surface using the predrilled mounting holes. 3. Low voltage connections for the Greengate panel and the BACnet connection to the AIM enclosure should be done through conduit. Bring wiring in conduit through the left, top or upper right side. The lower right corner of the enclosure is reserved for the high-voltage power connection. 4. Remove all cuttings and dirt before providing power to the AIM unit. Wiring the AIM to the Greengate Panel Wiring Notes: 1. All low-voltage wiring must be run in separate conduit from line-voltage wiring. 2. Disconnect power from the AIM. 3. Connect the provided RJ11 to 5 position terminal block cable to the RS-232 com port on the lighting panel. Connect the pre-wired 5 position terminal block to the Port S2 position on AIM motherboard. Without Keypad Display 24Vac, 24VA, 1A, 50-60 Hz 26Vdc, 10W, 0.4A Use Copper Conductors Only Class 2 54-019111- CAN RX CAN TX J1 L1 Ground 3V Lithium Battery CR-123A 10/100 BaseT Ethernet Port E1 BLUE 24V AC/DC Power L2 On RED 100 LAN Off External Gnd Battery +3V LINK P1 C BT485 L4 L5 L6 L7 L8 STATUS L22 L23 L24 L25 L26 L9 L10 L27 L28 L11 L12 L13 L14 L15 L16 L17 L18 L19 L31 L32 L33 L34 L35 L36 L37 Net + Net - BACnet ® Over ARCNET156 KBaud OEMPrtl Pro BT485 2 wire Shield L29 L30 Gnd Rnet + Rnet +12V Sense Gnd Rnet + Rnet +12V Tx Rx Local Access Port S2 (MFR Connection) Rx n/c DTR n/c DCD Signal Gnd EIA-232 EIA-485 BT485 BACnet Tx BACnet Rx Archive Valid Port S1 Tx Port S1 Rx Low Battery 4 wire EIA-232 Signal 1 Rx - DCD 2 n/c Rx + DTR Net- 3 Net+ 5 n/c 4 EIA-232 EIA-485 Rnet 485 232 Net+ Tx Net- Port S1 (BMS Connection) ® Error Codes MSTP on S1 Default Enhanced Access 0 = Download Required on Rnet and Port S2 IP Address IP Address 1 = Control Program Error On Assigned +100 2 = RAM Full Default Off 0 3 = Comm Setup Error 1 4 = System Error 8 = Formatting Module Status 2 1 2 3 4 5 6 7 8 Power LED 485-2w 485-4w PTP on S2 Enable Enable Disable Disable 3 4 5 Chase = OK Blinking Dot = 'Run' Option Comm Open Energy Management Equipment Module Address (ARCNET, MSTP, IP) 10's Format 9 1's 0 1 9 2 3 2 3 7 8 0 1 7 8 L21 5 6 POWER Ext. Batt. Int. Batt. 4 PCI 2002 L3 R 88FO E143900 TYPE: 002001 Made in USA 4 5 6 J4 1 2 3 A 4 5 6 B 7 8 9 C * 0 # D ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC LOCAL J5 REMOTE CH17 CH18 CH19 CH20 CH21 CH22 CH23 CH24 CH25 CH26 CH27 CH28 CH29 CH30 CH31 CH32 J6 CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8 CH9 CH10 CH11 CH12 CH13 CH14 CH15 CH16 ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF ON +24 OFF VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC VDC TB2 TB3 REMOTE PWR +24 GND Figure 2: Greengate LiteKeeper Panel Wiring to the AIM Wiring the AIM to the BACnet System The AIM has been pre-configured to a specific BACnet connection type per paperwork received from the site. Please install according to the type of BACnet that appears at the top of your mapping table. Wiring Notes 1. All low-voltage wiring is Class 2 wiring. 2. All low-voltage wiring must be run in separate conduit from line-voltage wiring. 3. Test all low-voltage wiring for shorts to AC ground before connection to the AIM unit. BACnet PTP Please contact Technical Support regarding the possibility of doing a BACnet over PTP connection. BACnet over ARC156 The ARCnet port is located on the left side of the AIM unit. Check the communications wiring for shorts and grounds. Connect the communications wiring to the ARCnet port Network +, Network -, and Shield terminals making certain to use the same polarity through the network segment. 4. Follow the manufacturer‘s recommendations for wire type and distance limitations for your BACnet system. Connecting the BACnet Network to the AIM 1. Disconnect power from the AIM. 2. Check all wiring for shorts and grounds prior to connection to the AIM unit. 3. Connect the BACnet connection see the following sections regarding the available BACnet configurations available. BACnet MS/TP BACnet MSTP is set up using the bit switches on the bottom of the AIM unit. If the factory has been notified that this type of connection is required, this will be pre-configured for the unit on site. The MS/TP port’s default baud rate is of 76800kbps. Please check the mapping table paperwork for the AIM to check if a different baud rate setting has been configured per request at the site. Port S1 is used for a MS/TP connection. Check the communications wiring for shorts and grounds. Connect the communications wiring to Port S1 Network + and Network - terminals making certain to use the same polarity through the network segment. Verify that the port S1 jumper has been configured for a 2 wire RS-485 connection and the Dipswitch #4 has been turned ON to enable MSTP. Page 2 BACnet over IP or over Ethernet The BACnet over IP or Ethernet connection is made to the top left corner of the AIM unit. Baud rates are auto-detect 10M/100Mbps. If using BACnet over IP, please refer to the Mapping Tables provided with the pre-configured unit to see what IP address has been assigned to the AIM. Powering the AIM Unit 1. Connect the neutral wire to the wire with the appropriate color coding for the voltage being used: White/Black=120VAC 2. Connect the solid black wire to the dedicated branch circuit that is powering the transformer. Power Switch 3. Module Status Indicator: This LED display in normal run condition will show a chase light that tracks around the outside of the display with a flashing red dot LED in the bottom right corner. If a number displays in this window, please contact Technical Support for further assistance. 4. Power indication LED. 5 6 4 Power Supply Wiring Figure 3: AIM Power Components 7 3 2 8 9 1 LED indicator lights The AIM motherboard and the Greengate Interface board both have LED lights that can help with diagnostics. These are explained below. 11 AIM Unit LEDs The AIM unit has LEDs for diagnostics in several locations on the board. This includes the LEDs on the front casing of the AIM unit as well as some LEDs next to various ports on the board and an LED display that may indicate error codes. Please refer to the following drawing that indicates the location of the LEDs and their functions. 1. AIM Port S2 (Greengate Connection) Transmit and Receive LEDs. 2. AIM LED stack - the following LEDs are diagnostic indicators: Archive Valid - should be lit after a minute or two of the AIM being powered up. If this LED does not light up a few minutes after power up, please contact technical support. Port S1 TX and Port S1 RX - AIM port transmit and receive indicators for the MSTP port if being used. In addition, the top two LEDs will indicate the ARC156 TX and RX if ARCnet is being used. 10 AIM Item Reference 1. AIM Diagnostic LEDs 2. Greengate Port Transmit and Receive LEDs 3. Greengate Port Connection to LiteKeeper 4. BACnet over ARCnet Connection Port. 5. BACnet over Ethernet or BACnet over IP connection. 6. AIM Power Connection 7. AIM Power Switch 8. BACnet over MSTP Connection to the AIM 9. Power Connection 10. Power Transformer 11. AIM Status Indicator LED Display Page 3 Automation Interface Module (AIM) BACnet Worksheet Directions: Fill in section 1. Document the desired status and control points for the panel. Fill in Section 2 for the desired BACnet protocol parameters Section I Relay Outputs Local Contact Inputs Relay Check Relay Status Issue Relay Commands 01 31 32 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Notes Input Check Input Status 01 31 32 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Notes Lighting Control Relay Panel Information Job Name OTHER INFORMATION: Page 4 Panel Type Panel Name Panel Location Section II Automation Interface Module (AIM) Setup Information (Fill in on one sheet only) I will be using BACnet over IP (Please provide the following information for proper configuration) IP Address Subnet Mask I will be using BACnet over Ethernet (Please provide the following information for proper configuration. Please note – the MAC address information of the unit will be provided on the final mapping table once the unit is configured) BACnet Network Number Default Gateway IP Address Desired BACnet Device Object Instance ID# BACnet Network Number Desired BACnet Device Object Instance ID# I will be using BACnet over ARC156 (Please provide the following information for proper configuration) I will be using BACnet over MS/TP (Please provide the following information for proper configuration) Desired ARCnet Address Desired MS/TP Address (must be between 0-99) BACnet Network Number BACnet Network Number Desired BACnet Device Object Instance ID# Desired BACnet Device Object Instance ID# What is the desired baud rate? What is the desired Max Master setting? (default is 127) Cooper Controls will provide a mapping table that will permit the BMS to control the lighting control system via BACnet points. Changes to the BACnet mapping is not permitted during site startup. Any changes to the BACnet mapping requested during or after site startup will result in an engineering services fee. Please Fax completed worksheets to Technical Support: 1-800-954-7016. Page 5 All products manufactured by Cooper Controls and identified with the Greengate brand are warranted to be free from defects in material and workmanship and shall conform to and perform in accordance with Seller’s written specifications for a period of : • Five (5) years from date of shipment for all occupancy sensors. • Three (3) years from date of factory invoice for our hardware and software on Lighting Control Panels. • We warranty all our standard relays for a period of 10 years from date of factory invoice. We guarantee the performance of our system to specifications or your money back. This warranty will be limited to the repair or replacement, at Seller’s discretion, of any such goods found to be defective, upon their authorized return to Seller. This limited warranty does not apply if the goods have been damaged by accident, abuse, misuse, modification or misapplication, by damage during shipment or by improper service. There are no warranties, which extend beyond the hereinabove-limited warranty, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY AND THE IMPLIED WARRANTY OF FITNESS. No employee, agent, dealer, or other person is authorized to give any warranties on behalf of the Seller or to assume for the Seller any other liability in connection with any of its goods except in writing and signed by the Seller. The Seller makes no representation that the goods comply with any present or future federal, state or local regulation or ordinance. Compliance is the Buyer’s responsibility. The use of the Seller’s goods should be in accordance with the provision of the National Electrical Code, UL and/or other industry or military standards that are pertinent to the particular end use. Installation or use not in accordance with these codes and standards could be hazardous. Cooper Controls 203 Cooper Circle, Peachtree, GA 30269 800-553-3879 www.coopercontrol.com P/N: 9850-000370-00