Proposals for new regulations requiring the notification

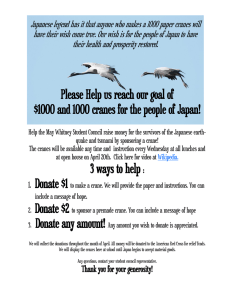

advertisement