THE LINE

Cooper Power Systems

October 1996

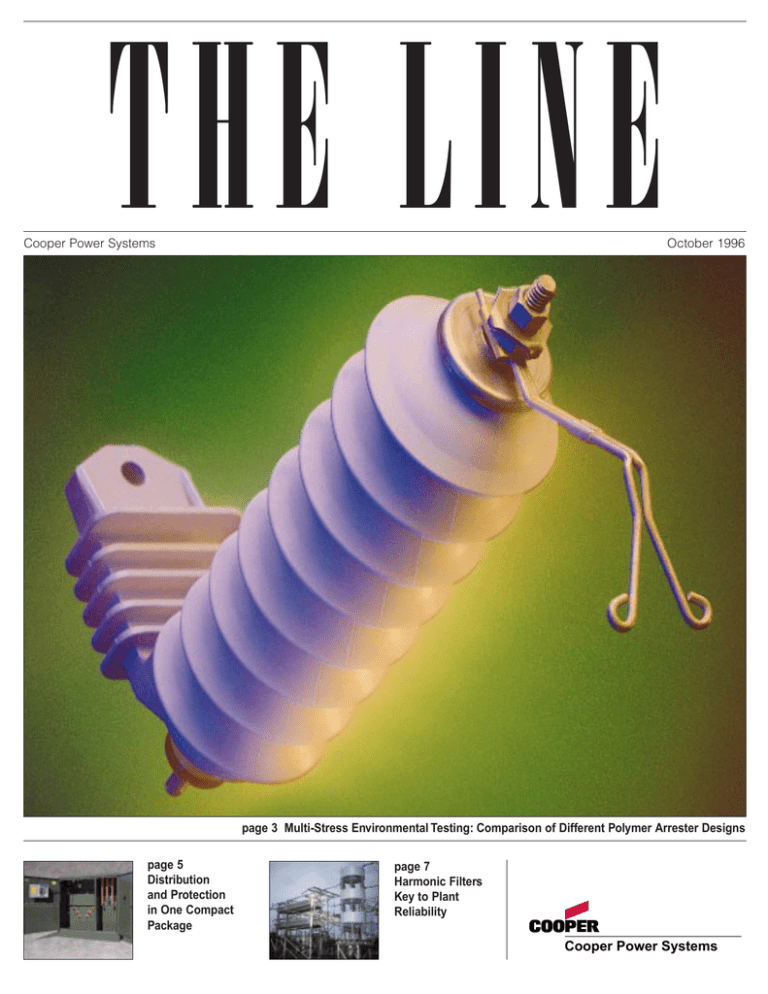

page 3 Multi-Stress Environmental Testing: Comparison of Different Polymer Arrester Designs

page 5

Distribution

and Protection

in One Compact

Package

page 7

Harmonic Filters

Key to Plant

Reliability

Cooper Power Systems

THE LINE

October 1996

Cooper Industries

Cooper Power Systems Division

THE LINE

P.O. Box 1640

Waukesha, WI 53187

October, 1996

Published by Cooper Power Systems

Editorial Board

Cooper Power Systems

W. D. Martino

President

Editor-in-Chief, Steve Benna

Marketing Manager Components &

Protective Equipment

Executive Editor, Patrick Taugher

Manager, Marketing Communications

Bob Jozwowski, Apparatus Engineer

Welcome to the Fall ‘96 issue of The Line magazine.

Jack McCall, Product Marketing

Manager, Power Capacitors

The name of the magazine was not chosen lightly. Some of you may remember

an earlier Line, published by the McGraw Edison Company for many years,

and by Line Materials Company before that. In over 50 years of publication,

The Line earned a reputation for providing important and useful information

to electrical utility industry professionals. We hope to continue that tradition

with the revival of this magazine.

Jim Quinn, Sales Director

This is an example of Cooper Power Systems’ paying attention to our customers’

challenges, and providing cost effective business solutions. Whether it’s new

product development, innovative solutions to complicated application problems,

or continuing industry education, our efforts are focused on helping you and

your company achieve lower operating costs and higher system reliability.

If you have some information you’d like to share with your fellow industry

professionals, we’d like to hear from you. Contact us at the editorial address

listed on the right, or talk to your Cooper Power Systems sales engineer.

We hope you find The new Line useful to you and your company.

Sincerely,

Ron Willoughby, Manager,

Systems Engineering

Jim Byrnes, Marketing Images

Contributing Engineers

Jeff Lindgren

Brian Steinbrecher

Daniel Wycklendt

Dave Brucker

Craig Befus

Ronald Willoughby

Reginald Mendis

Craig Wahlgren

Address questions, inquiries and

letters to:

Patrick Taugher

Cooper Power Systems

2800 Ninth Avenue

South Milwaukee, WI 53172

(414) 768-8431

FAX (414) 768-8334

Photocopy permission: Photocopy

permission extended to single copy

only. Permission for all other reprints

must be obtained from The Line editor.

©1996 Cooper Power Systems

All Rights Reserved

Design and Production by

Marketing Images, Inc.,

Waukesha, WI

Printed in USA

2300 Badger Drive

Waukesha, WI 53188-2400

414-896-2401

Systems Engineering Group

Cover Story

7

Multi-Stress Environmental Testing:

Comparison of Different

Polymer Arrester Designs

Transformer Products Group

5

Bob Schmac, Utility Marketing

Manager, Transformers

Web Site Address:

http://www.cooperps.com/

Bill Martino

President

3

Gavin McFarlane, Sales Director

Harmonic Filters

Key to Plant

Reliability

Component Products Group

9

Distribution and

Protection in One

Compact Package

New U-OPTM 600 A

Connection System

Improves Safety,

Makes Operation

Easier

Systems Engineering 1996-97 Workshop Schedule on page 4

2

THE LINE / October 1996

Component Products Group

Multi-Stress Environmental Testing:

Comparison of Different

Polymer Arrester Designs

by Jeff Lindgren

Overvoltage Protection Equipment Specialist

and Brian Steinbrecher

Manager, Overvoltage Protection Equipment

I

n recent years, an increasing percentage of surge arresters have been

produced with various polymer

housings rather than porcelain housings. Polymers, being relatively new

insulating materials for arresters, do

not have the extensive field perfor-

UltraSILTM testing

mance history that porcelain does. As

a result, accelerated aging tests were

devised to try to predict the long term

service reliability of these ‘new’ polymer materials.

Accelerated aging tests are used to

over-stress polymer insulating materi-

Figure 1

als in an attempt to predict the long

term reliability of the insulation system. Typical stresses applied in this

type of testing include: voltage, heat,

UV radiation, moisture, and contamination. Historically, accelerated aging

testing involved only a few of these

stresses not always applied concurrently. In contrast to these accelerated

aging tests, a new type of test has been

developed which involves exposure to

all of the above mentioned stresses

applied repeatedly over a continuous

time period. This testing (called multistress testing) is the most realistic and

severe type of test developed to simulate the long term exposure and stresses seen by arresters when installed and

in service.

Multi-stress testing can help predict

which polymer arrester insulating systems will provide more reliable field

performance.

This is important,

because arrester manufacturers produce polymer-housed units incorporating different housing materials. So, will

these arresters perform the same over

time? (The answer is no.) More importantly, are the tests which were used to

test porcelain insulators suitable for

Daily cycle chart

testing polymer housed arresters?

(Again, the answer is no, they do not

apply the full range of stresses seen in

the field.)

When comparing the different

polymers, all exhibit a tendency to

repel water (hydrophobicity) when

new. However, some polymer materials

lose this ability over time (just as a

waxed car tends to stop beading water

over time). This is a concern, because

if the housing does not repel water and

instead allows it to coat the surface,

significantly elevated leakage currents

(measured as increased watts loss)

flow across the housing. The excessive

leakage current leads to surface degradation that accelerates under long term

exposure and eventually leads to

arrester failure. Unlike other polymer

materials, silicone rubber retains this

hydrophobic characteristic much more

completely over time. This results in

longer service life, higher withstand

voltage levels (less flashovers), and the

lowest surface leakage currents.

Cooper Power Systems uses multistress testing to simulate the effects of

different environmental conditions on

several commercially available arrester

designs and to compare the relative performance of the different housing materials over time. By

over-stressing the

insulation system of

each arrester design

and monitoring the

surface leakage current,

multi-stress

testing shows that

excessive increases

in surface leakage

current (measured

in watts) will lead to

polymer

material

degradation

and

Weekly cycle chart eventual failure.

THE LINE / October 1996

3

Weekly Duration [h]

Severity

Voltage

SYSTEMS ENGINEERING

WORKSHOPS 1996-1997

Salt Fog

47.5

40 g /l - 0.133 l/hm3

on

Steam Fog

25.0

demineralized water

33 g /hm3

on

Rain

20.0

demineralized water

1.5 mm/min - 100 Ωm

on

Solar Radiation

48.0

1.5 kW/m2

on

Distribution OverCurrent

Protection

Pause with Voltage

25.0

on

2.1 CEU

Pause without Voltage

2.5

off

Table 1

DAT E S

Description of test cycle

&

L O C AT I O N S

Feb. 11-13, 1997

April 8-10, 1997

May 6-8, 1997*

May 6-8, 1997

Oct. 14-16, 1997*

Dallas,TX

Jackson, MS

Baltimore, MD

Atlanta, GA

Milwaukee,WI

Power Capacitor Application

Daily Average Watts/kV MCOV

1.7 CEU

Nov. 19-21, 1996

Sept. 30-Oct. 2, 1997

Dec. 2-4, 1997

Atlanta, GA

Greenwood, SC

Atlanta, GA

Distribution OverVoltage

Protection

1.7 CEU

Nov. 12-14, 1996

Oct. 28-30, 1997

Nov. 4-6, 1997

Atlanta, GA

Atlanta, GA

Milwaukee,WI

Power Quality

& Harmonic Analysis

2.1 CEU

Oct. 29-31, 1996

Oct. 28-30, 1997

Milwaukee,WI

Milwaukee,WI

Transformer Application

& Protection

2.1 CEU

March 25-27, 1997

April 15-17, 1997

Oct. 7-9, 1997

Figure 2

We tested four different arrester

housing designs: our UltraSIL™-housed

VariSTAR® arrester with its exclusive

silicone rubber housing; an Ethylene

Propylene Diene (EPDM)/silicone alloyhoused arrester, an Ethylene Propylene

Copolymer (EPM)-housed arrester and

an Ethylene Vinyl Acetate (EVA)housed arrester.

As an initial measure of leakage current, the watts loss of each arrester

while energized at MCOV was recorded

with the housing clean and dry. The

arresters were then placed into the

multi-stress test chamber simulating a

sea coast environment and energized at

MCOV. The test cycles were then run

for over 6000 hours with watts loss

measurements taken periodically. The

daily and weekly cycles involved in this

test are shown in Figure 1 on page 3.

The testing proved that the UltraSIL

housed arrester had the overall lowest

level of leakage current (watts loss) of

the designs tested. The graph shown in

4

THE LINE / October 1996

Total leakage current

Figure 2 illustrates the total leakage

current (both internal and external) for

the various arresters taken throughout

the test. The dramatic increase in

watts loss during the test for the nonsilicone rubber-housed arresters is

mainly due to leakage currents flowing

across the outside of the wet and contaminated housing surface. Housing

surface leakage current leads to degradation of the housing, which accelerates under long term exposure and

eventually leads to failure.

When selecting a polymer housed

arrester it is important to realize that

not all housing materials will perform

equally well over time. Multi-stress

testing is the best test designed to

gauge how different materials will perform over time. This testing has confirmed the superior nature of silicone

rubber for long term performance, with

no loss of insulating properties and

resistance to degradation. THE LINE

Milwaukee,WI

Atlanta, GA

Raleigh, NC

Distribution Analysis

2.8 CEU

March 11-14, 1997

April 22-25, 1997

May 13-16, 1997

Sept. 23-26, 1997

Oct. 21-24, 1997

Atlanta, GA

Denver, CO

Cincinnati, OH

Milwaukee,WI

Portland, OR

Distribution Voltage Regulation

2.1 CEU

June 10-12, 1997

Sept. 9-11, 1997

Sept. 30-Oct. 2, 1997

Toronto, ON

Milwaukee,WI

Atlanta, GA

For registration information on

Systems Engineering Workshops,

call Marilyn McGair at 414-523-3940

or 800-523-9307, or e-mail at

marilyn@marketingimages.com

* A one-day Symmetrical Components Tutorial

will precede this workshop.

Transformer Products Group

Distribution and Protection

in One Compact Package

Three-Phase Compartmental Transformer with Vacuum Fault

Interrupter (VFI) Protection Provides Competitive Advantage

by Daniel Wycklendt, Senior Market Specialist,

Dave Brucker, Apparatus Engineer

and Craig Befus, Apparatus Engineer

U

tilities have always been looking for

ways to work smarter, safer, and

cheaper. This is even truer today as

they prepare for the changing utility

marketplace.

Many have embraced

this new environment and are proactively pursuing practices and strategies

that will make them more competitive.

Competition usually begins with a singular focus — price — and then evolves

to include reliability, responsiveness,

quality, customer-focused services,

innovation and safety.

The following three cases are examples of how utilities are using new technology to meet or exceed the needs of

their customers and accomplish this in

a cost effective, competitive manner.

City of Banning

A utility preparing for the future is

the City of Banning, California, located

east of Los Angeles at the beginning of

high desert country. The municipal

utility purchases power from the

Southern California Edison grid, and

has residential, small commercial and a

few large industrial customers on their

system. One industrial customer, concerned about improper overcurrent

protection coordination and the costs

incurred from short- and long-term outages, was pressing the utility to either

eliminate the coordination problem

that was causing these outages or furnish a secondary feed to their facility.

Coordinating the overcurrent protection of the three aging banks of 4 kV

transformers was not possible with a

conventional transformer fusing and

substation relay protection scheme,

because the transformer fuses would

not operate before the substation relay

tripped. This miscoordination would

mean that half of the loop would be deenergized due to a fault on the load side

of the transformer. Meeting the customer’s demand for reliability in a traditional method would be an expensive

proposition, since it would require the

utility to build a new substation.

It was at this point that the use of

a Three-Phase Compartmental Transformer with Vacuum Fault Interrupter

(VFI) Protection was proposed to

Tim Trewyn, City of Banning Electrical

Operations Engineer.

The VFI

Transformer combines a three-phase

transformer with a three-phase vacuum

fault interrupter to provide distribution

and protection in one compact package. The major factors considered

when making this proposal were coordination, reliability, flexibility, and cost.

The VFI Transformer was able to meet

or exceed the requirements for all.

Substation

City of Banning

Overcurrent

Relay

Circuit

Breaker

VFI

XFMR

VFI

4160Y/2400

1500 kVA

480Y/277

4160Y/2400

1000 kVA

480Y/277

4160Y/2400

1000 kVA

480Y/277

Figure 1

4160Y/2400

1000 kVA

480Y/277

City of Banning

Protection coordination and reliability were achieved via the VFI TriPhase Breaker Control. The Tri-Phase

electronic breaker control is designed

so that it can be equipped to approximate one of five separate Time-CurrentCharacteristic curves. TCC curves can

be chosen to approximate either an

S & C E fuse, a McGraw-Edison K or T

link fuse, or resemble a recloser or

relay curve. The KF TCC curve was

chosen because it provided the proper

coordination with the substation relays

protecting the loop. Although each

phase of the VFI breaker can be individually set at one of over 100 minimum

trip settings, a common trip setting was

chosen. In addition, an instantaneous

trip setting could also have been chosen, thereby providing maximum coordination with the upstream protection

devices while still providing the needed

transformer protection.

The VFI breaker operation is initiated by the Tri-Phase Control when an

overcurrent condition is detected on

any of the three phases. All three interrupters are electronically controlled

and mechanically ganged together, so

that a trip signal on any one phase will

trip all three phases. This feature eliminates single-phasing of three-phase

loads and the associated ferroresonance or motor damage problems. The

VFI breaker is resettable, which makes

restoring service faster and easier.

This helps improve the availability of

service, which is an important component of reliability.

Flexibility was also a requirement.

The VFI breaker, in conjunction with

the two loadbreak switches, provides

the utility and the customer with various options for feeding and sectionalizing the loop. These options permit the

outage area and outage duration to be

minimized when a fault condition is

present.

Cost was also a driving force in the

selection of the VFI Transformer over

other alternatives. There are four factors that need to be considered when

calculating the cost of alternatives: real

estate, installation, maintenance and

operating costs.

Usable real estate was at a premium

at the site and therefore it was important to maximize its use. Because the

combination VFI breaker and transformer has a footprint basically the

same size as a conventional transformer, the space usually required for a

THE LINE / October 1996

5

separate piece of switchgear is eliminated.

Because the VFI breaker is integral

to the transformer, installation is simplified and the costs to locate and connect a separate piece of equipment are

eliminated.

Maintenance costs are reduced

because there is only one piece of

equipment, and that piece requires less

maintenance when compared with

fused switchgear or other alternatives.

Operating costs are reduced by the

use of a vacuum fault interrupter in lieu

of fuses to clear the fault. This eliminates the need to buy, stock, and

replace fuses when a fault occurs. In

addition, current trip settings can be

adjusted without de-energizing customers. This allows maintenance crews

to revise the interrupter trip settings to

accommodate load or circuit changes

without having to schedule an outage.

The VFI Transformer met the City of

Banning’s needs for protection coordination, reliability, flexibility, and cost.

In short the VFI Transformer provided a

clean, inexpensive, fast installation that

exceeded the customer requirements

for service and fulfilled the utility’s

budget constraints.

Vera Water and Power

Vera Water and Power in Spokane,

Washington, recently was given an

opportunity to provide electric power

to a new shopping center. Vera was

able to secure this customer because

they could provide them with a higher

level of reliability. Brian Dilts, Vera’s

engineer, found a creative way to use

the VFI Transformer to provide

improved sectionalizing and better

feeder protection coordination for this

important new customer, while eliminating the need to purchase additional

switchgear, vaults, and real estate.

The customer is served by an

underground feeder from the substation to the VFI transformer, the feeder

then continues underground to serve

the other customers on the loop. The

VFI Transformer specified by Vera uses

the VFI breaker to protect the downstream section of the 600A feeder

rather than protecting the transformer.

In this configuration, if a fault occurs

downstream, the VFI breaker will trip

and isolate the fault, leaving electric

service intact for the shopping center.

The VFI breaker control was

equipped with a type H TCC curve

because it provided coordination with

6

THE LINE / October 1996

the upstream portion of the circuit that

was protected by a three-phase electronic recloser at the substation and

fusing that protected the downstream

portion of the loop. Because the VFI

breaker is resettable, restoring service

for the customers affected by an outage

will be easier and faster to complete.

Substation

Vera Water

& Power

that there was no way to properly coordinate fusing on the high side of the

transformer with power fuses on the

riser pole of the 25 kV system.

Clay found that the VFI Tri-Phase

breaker control with type EF TCC curve

provided proper transformer protection and easily coordinated with both

the riser pole fuses and the substation

overcurrent relays, eliminating the

need to change the fuses and the overcurrent relay settings.

Overcurrent

Relay

Substation

El Paso Electric

Recloser

Overcurrent

Relay

VFI

Circuit

Breaker

VFI

XFMR

13,200GY/7620

750 kVA

480Y/277

Figure 2

Riser

Pole

Fusing

Vera Water and Power

If a fault condition is present when

the circuit is re-energized, the trip-free

operation feature of the VFI breaker will

prevent the breaker mechanism from

being held in the closed position. This

feature provides added operator safety

when fault locating is necessary.

In addition to being able to offer

higher reliability, reduced outage duration and outage area, Vera Water and

Power was able to provide a safer operating environment for its workers. It

was also able to save thousands of dollars when compared to conventional

construction which incorporates

switchgear separate from the transformer.

The savings came from

reduced labor, material, and equipment

costs. When the additional costs of

real estate, operating costs, maintenance and customer outages costs are

included, the VFI Transformer is an

even better choice.

EL Paso Electric

El Paso Electric provides electric

power to El Paso, Texas as well as the

city of Las Cruces, New Mexico. A

major hosiery factory in Las Cruces

recently expanded and increased electric load significantly. The factory preferred a new service drop in lieu of running a 4 kV bus through the plant to

serve

newly

installed

knitting

machines. A big problem that El Paso

Electric’s engineer Clay Doyle faced

was how to properly coordinate overcurrent protection between the transformer and the substation. It appeared

VFI

VFI

XFMR

23,900

5000 kVA

4160Y/2400

Figure 3

El Paso Electric

The VFI breaker provided the added

benefit of eliminating ferroresonance

and motor problems associated with

single-phasing of the three-phase deltawye transformer connection. Singlephasing of loads is eliminated because

a trip signal on any one phase will open

all three phases.

The VFI Transformer provides convenience, safety, and transformer or

loop overcurrent protection coordination in one compact enclosure. When

compared with two separate pieces of

equipment, the VFI Transformer has

many advantages. Many of these result

in lower Total Owning Costs due to

reduced installation, maintenance, and

operating expenses. The unit is ideal

for distribution systems, because it

meets the need for reliable service,

easy maintenance, flexibility for

load expansion, and protection against

faults and other abnormal currents.

Best of all, it simplifies installation and

requires less real estate than conventional distribution transformer/switchgear packages. The VFI Transformer is

a competitive solution that enables utilities to meet or exceed the needs of

their customers while still meeting

their own budget constraints.

THE LINE

Systems Engineering Group

Harmonic Filters

Key to Plant Reliability

by Ronald D. Willoughby, PE

Manager, Systems Engineering

and S. Reginald Mendis

Power Systems Staff Engineer

Filter Design

Harmonic currents may be prevented from flowing into the power system

by one of two methods: 1) Use of a

high series impedance to block them;

or 2) diverting them by means of a low

impedance shunt path. The most practical approach is usually shunt filters.

The most common shunt filters, the single-tuned and high-pass filters, are the

simplest to design and the least expensive to implement. Their general layout

is shown in Figure 1.

C

C

L

C

L

C1

R

L

IMPEDANCE MAGNITUDE

(POWER OF 10)

FREQUENCY

Filter Alone

IMPEDANCE MAGNITUDE

(POWER OF 10)

C1

C2

R

R

L

C2

R

A

B

A)

B)

C)

D)

E)

Figure 1

FREQUENCY

Filter and System

R

C

D

E

Single-tuned filter

First order high-pass filter

Second order high-pass filter

Third order high-pass filter

C-Type high-pass filter

Common shunt filters

The single-tuned or notch filter is

probably the most common shunt filter.

A typical frequency response plot is

shown in Figure 2.

The high-pass filter is so named

because of its characteristic low

impedance above a corner frequency

as shown in Figure 3. This filter will

shunt a large percentage of all harmonics at or above the corner frequency.

Frequently, one high-pass filter whose

corner frequency is located at the lowest harmonic to be eliminated is used

for all filtering. However, two factors

may discourage such an application: 1)

The minimum impedance of the highpass filter in its passband never

achieves a value comparable to that of

the single-tuned filter at its notch frequency; and 2) the shunting of a per-

Figure 2

Typical frequency response of a

notch filter

centage of all the system harmonics

through one filter may require that

filter to be significantly overrated

when compared to the fundamental

frequency.

IMPEDANCE

MAGNITUDE

(POWER OF 10)

H

armonics have been shown to have

detrimental effects on equipment

including transformers, rotating

machinery, switchgear, capacitors,

fuses,

and

protective

relays.

Transformers, motors, and switchgear

may experience increased losses and

excessive heating. Induction motors

may refuse to start or may run at subsynchronous speeds. Circuit breakers

may fail to interrupt currents from

improper coil operation. Capacitors

may prematurely fail from increased

dielectric stress and heating. Time-current characteristics of fuses can be

altered, and protective relays may

experience erratic behavior.

Electronic power converters have

become one of the major sources of

harmonics in industry today. These

converters operate at a low power factor, usually making it necessary to also

apply shunt capacitors for reactive

compensation.

Harmonic filters are effective in

minimizing harmonic voltage distortion

caused by nonlinear loads. However,

different configurations should be considered before making the final design

decision. Among the performance criteria are current and voltage ratings of

the filter components, and the effect of

filter and system contingency conditions.

The general procedure in analyzing

any harmonic problem is to identify the

worst harmonic condition, design a

suppression scheme and recheck for

other conditions.

A good computer program for harmonic analysis is essential for most

investigations. It should be able to

model nonlinear loads, perform multiple-source solutions, and execute frequency scans. An example of such a

program is the V-HARMTM harmonics

analysis program by Cooper Power

Systems.

FREQUENCY

Figure 3

Typical frequency response of a

high-pass filter

Design Equations

The impedance of the filter branch

is given by:

THE LINE / October 1996

7

Resonance occurs when the imaginary part is equal to zero, at which time

the impedance is limited by the value R.

The frequency for which the filter is

tuned is given by the value of f that

results in series resonance. This frequency is given as:

The quality factor, Q, of a filter is a

measure of the tuning sharpness and is

represented by:

IMPEDANCE

MAGNITUDE

(POWER OF 10)

where the reactances at the resonance

frequency are given by XLr and XCr.

Q=100

Q=7

Q=0

Q=4

FREQUENCY

Figure 4

Scan plots for a 4.7th harmonic

notch filter with various values of Q

Design Considerations

Filter interaction with the source

impedance results in a parallel resonant peak.

For inductive source

impedances ( LS ), this point occurs at

a frequency below that at which the filter is tuned and is given by:

For multiple parallel single-tuned filters, one resonance peak will exist for

each filter. The resonance peak also

has its own value of Q as given by:

The proximity of the parallel resonance peak and the filter notch is

dependent entirely on the source

inductance. This in turn is a function of

the available three-phase fault MVA.

Figure 5 shows how the response for

Figure 5

8

the same 4.7th harmonic filter varies

for different values of available shortcircuit MVA.

The problem associated with these

adjacent resonance points is one of filter detuning. If a filter is tuned exactly

at the frequency of concern, then an

upward shift in the tuned frequency

will result in a sharp increase in

impedance as seen by the harmonic.

Should the resonance peak shift

upward enough to coincide with the

harmonic of concern, the resulting voltage amplification may be disastrous.

Therefore, it is advantageous to

tune a filter to a frequency somewhat

below the desired frequency. This will

provide sufficient harmonic filtering

action, yet will allow acceptable operation in the event detuning takes place.

Typically, filter banks are tuned to

approximately 3-to-10 percent below

the desired frequency.

Response of a 4.7th harmonic

filter for different values of MVAsc

THE LINE / October 1996

Filter Component Ratings

Capacitors

The allowable overload limits of

capacitors based on standards are:

kvar

rms voltage

sum of peak voltages

rms current

135 %

110 %

120 %

180%

All of these parameters should be

checked when applying capacitors in a

harmonic environment, especially if

they are parts of a filter. The use of an

inductor in series with a capacitor

results in a voltage rise at the capacitor

terminals according to the following:

n = tuned harmonic of the filter

When calculating the maximum

voltage rise, worst conditions should

be used: maximum system voltage

together with maximum capacitance

tolerance (typically 8 %) and maximum

inductor tolerance (typically 5%).

Taking these tolerances into account

will yield the maximum voltage rise

across the reactor.

If a capacitor is used in a system

with voltage lower than the capacitor

rating, the following formula should be

used to determine the effective kvar:

The presence of a filter reactor

changes the effective kvar output as

follows:

If reactive compensation is required

from the filter, the designer will likely

perform several iterations before finally deciding on the capacitor ratings.

The current limit may be lower than

standards (180% by standards)

because individual capacitor units are

usually fused at 125-165% of their rating.

When designing a filter, the limits on

the rms voltage and currents, and the

arithmetic sum of the peak voltages on

the capacitor bank, should be close to

100% of rating for normal conditions.

Tuning Reactor

Reactors used for filter applications

are usually built with an air core, which

provides linear characteristics with

respect to frequency and current. A

±5% tolerance in the reactance is usually acceptable for industrial power system applications. The 60-Hz X/R ratio

is usually between 25 and 150. A series

resistor may be used to lower this ratio

if desired.

The reactor should be rated to

withstand a short circuit at the point

between the reactor and the capacitor.

The reactor insulation (BIL) should be

similar to that of power transformers

connected at the same voltage level.

Parameters to include when specifying a reactor are the following: fundamental current; harmonic current

spectrum; short-circuit current; X/R

ratio; system voltage; and BIL.

Filter Selection and

Performance Evaluation

Before any filter scheme is specified, a power factor study should be

done to determine if any reactive compensation requirements are needed. If

power factor correction is not necessary, then a minimum filter can be

designed; one that can handle the fundamental and harmonic currents and

voltages without consideration for

reactive output. Sometimes, more than

one tuned filter is needed. If so, the filter system must be designed for the

possibility of having specific filter

branches out of service.

While the effectiveness of a filter

installation ultimately depends on the

degree of harmonic suppression, it also

involves consideration of alternate system configurations. As the supplying

utility reconfigures its system, the

continued on page 11

Component Products Group

New U-OPTM 600 A

Connection System

Improves Safety,

Makes Operation Easier

A new 15 and 25 kV class, 600 A deadfront connector provides

increased safety and easier operation for field personnel —

the U-OPTM Visible Break Connector System.

by Craig Wahlgren

Molded Rubber Products Specialist

T

he U-OP connector system was

designed with safety in mind.

Safety in a 600 A connector system

requires that you be able to easily

achieve a visible break and visible

ground before beginning repair work on

underground cable. Maximum safety

requires that the visible ground be in

place while the visible break is

achieved. The U-OP connector satisfies

these requirements without having to

move heavy 600 A underground cable.

The U connector is constructed so that

one leg is 3” longer than the other. This

allows the U-OP connector system to be

used with different types of apparatus

bushings, some of which may protrude

different distances from the equipment

frontplate than others. To assure that

the U connector is properly seated

when installed, the deadbreak junction’s bracket and the parking stand are

installed on studs that are welded to

the frontplate of the equipment.

The U-OP connector system kit

consists of:

• A U connector (Figure 1).

The U connector has EPDM rubber

molded over an aluminum or copper

buss. There are tulip contacts inside

each rubber leg of the U that mate with

probes mounted on the bushings on

which the U is installed. The U connector has a stainless steel shaft between

the two rubber legs that threads onto a

mating stud attached to the apparatus,

securing the U connector in place. The

shaft has a handle for shotgun stick

operation for installation or removal.

Figure 2

• A two-bushing 600 A deadbreak

junction.

• A parking stand.

Figure 1

U connector

Connector system

Typical U-OP Application/Operation

The U-OP connector can be used in

many different applications. In a deadfront switchgear application, the 600 A

apparatus bushing and a T-OPII™ 600 A

connector are typically used with the UOP connector kit to form the complete

connector system (see Figure 2). The

T-OPII connector consists of a

T-Body, compression lug, and loadbreak

reducing tap plug (LRTP). The LRTP

provides a 200 A interface on which a

200 A protective cap, 200 A loadbreak

elbow, or Metal Oxide Varistor (MOV)

elbow arrester can be installed during

normal system conditions.

In a typical padmount switchgear

application, the current path during

normal system operation is through the

apparatus bushing, through the U connector, through the two way junction,

through the T-OPII connector, and into

the underground cable.

When isolating underground cable

that needs repair, the equipment’s

switch must first be opened to de-energize the unit. The switch or other

device at the far end of the cable should

also be opened, so that the cable is

completely de-energized. The protective cap, elbow, or arrester mounted on

the T-OPII’s LRTP is then removed. A

test probe can then be inserted into the

LRTP to verify that the system is deenergized. A fault close rated (to 10 kA)

grounding elbow can be installed onto

the LRTP.

At this point, the cable can be isolated, using a protective cap or arrester, or

it can be grounded with a regular

grounding elbow.

The visible ground will be in place

while the visible break is being

obtained, providing maximum safety to

operating personnel.

An insulated or grounded standoff

bushing can be installed in the parking

stand. A shotgun stick is then used to

grasp the U connector’s handle and

rotate it to remove the U connector

from connecting the deadbreak junction to the apparatus bushing. The

U connector can then be reoriented 90°

and re-installed to connect the apparatus bushing to either the insulated or

grounded standoff bushing (see Figure

3). A 600 A U-OP protective cap should

then be installed on the upper bushing

of the deadbreak junction to cover it

and protect the interface. When a safe

visible break and visible ground have

been achieved on the other end of the

cable, repair work can safely be performed on the cable.

THE LINE / October 1996

9

Figure 3

An insulated standoff bushing or a

grounded standoff bushing may be

used in the parking stand in the process above. In either case, all bushings

will either be grounded or covered with

insulated protective caps or the U connector before work is performed on the

system. Tag out procedures can then

be followed to ensure that the cable or

equipment cannot be re-energized accidentally.

Once the cable has been repaired,

the operation steps are reversed to

make the U-OP and switchgear ready to

be energized again.

Rotating the U connector for visible break

bushing to the grounded standoff bushing, an external visible break is

achieved. Some types of deadfront

equipment rely on a viewing window to

detect opened switch contacts internal

to the equipment. With this equipment,

a visible break isolating the switchgear

There are many features to the U-OP

connector that make it the safest 600 A

connector system available.

Visible Ground

The use of the T-OPII connector in conjunction with the U-OP provides maximum safety and protection for line

crews. The LRTP not only provides a

location for a 200 A protective cap, tap,

or elbow arrester, but it also provides

access to the cable via a test probe to

ensure that the system is de-energized

before removing the U connector and

subsequently performing repair work

on the cable. It also provides a 200 A

interface on which a 200 A grounding

elbow or fused grounding elbow can be

installed (see Figure 4). This achieves

the desired visible ground for the cable,

not only while the cable is being

repaired but also while the U connector

is being removed.

Visible Break

When the U connector is removed from

its normal operating position and reinstalled to bridge from the apparatus

10

THE LINE / October 1996

Figure 4

While many utilities are successful in

using connector systems to move feeder cable to obtain a visible break, the

U-OP connector eliminates the need to

move the feeder cable, which is often

heavy and stiff. This ergonomic benefit

greatly simplifies lineperson operating

practices. Florida Power Corporation

and other utilities have specified U-OP

on their pad mounted switchgear

because of the safe operation it provides. They believe it gives them the

best method for getting a visible break

without having to move 1000 MCM

cable. They also like the fact that they

can test to ensure the system is deenergized and they can get a visible

break with the LRTP. A Florida Power

Corporation line foreman says that his

line personnel have been very pleased

with the initial installations of U-OP and

their operation.

Easy Operation

The easy operation of the U-OP connector also increases the safety of the

system. The mechanical advantage provided by the threaded

U-OP shaft easily separates the rubber interfaces, minimizing the

possibility of problems

associated with having

to separate stuck interfaces. Not having to

physically

separate

stuck interfaces also

decreases the time

needed to operate the

Installing grounding elbow on T-OP II connector connector system.

is not obtained. There are also other

connector systems available that do

provide an external visible break, but

the components between which there

is supposed to be a visible break are

held together with metal brackets.

Cooper Power Systems believes that an

external visible break using components that are not bracketed together is

the best alternative.

The U-OP connector system allows

the visible ground to be in place while

the visible break is being achieved.

Other connector systems are available

which do not allow a visible ground to

be in place while the connector system

is being operated and the visible break

is being obtained.

The visible break is provided by the

U-OP connector without having to

move the 600 A underground cable.

Deadfront Construction

The U-OP connector is a deadfront system used on deadfront apparatus.

Deadfront equipment is inherently

dependable because all current-carrying parts are enclosed in insulated

EPDM rubber during normal operation.

The highly conductive ground shield,

when connected to ground with a drain

wire, keeps the exterior surfaces of the

connector system at ground potential,

minimizing exposure to shocks or discharges. Also, deadfront equipment is

very reliable - it is very unlikely that

faults will be caused by animals or

floods bridging between phases or from

phase to ground. Most importantly,

safety is maximized by prevention of

accidental contact with conductors,

which could result in equipment failure

and possible bodily harm.

Cable Termination Tolerances

When underground cable is terminated

into a T-Body, the cable may be cut so

that it is slightly too long or too short.

It can then be more difficult to install

the T-Body onto the apparatus bushing

if it is not perfectly aligned. This problem is exacerbated with connector systems that have to be moved often to

provide a visible break or that rely on

the removable portion of the connector

to be directly connected to the T-Body.

The U-OP minimizes the dependency on precise cable termination

because the cable never has to be

moved.

Also, the effect of cantilever force

on the bushing is minimized because

the U-OP is never directly connected to

the T-Body. In the switchgear application discussed above, the T-Body is

installed onto one bushing of a two

bushing 600 A junction while one side

of the U connector is installed onto the

other bushing of the junction. The

EPDM rubber will flex if forces are

applied on one bushing of the junction,

minimizing the effect on the positioning

of the other bushing. The U connector

will remain easy to install even if the TBody is putting cantilever force on the

other bushing of the 2 way junction.

Reliability Increased Due

to Clean Rubber Interfaces

While the underground cable is being

repaired, the U connector is installed

so that it bridges from the apparatus

bushing to an insulated or grounded

standoff bushing. During both normal

operation or de-energization, the U connector is always installed onto mating

bushings, keeping interfaces free of

contaminants, and therefore increasing

reliability.

Other connector systems with

removable pieces are not installed on

mating bushings during de-energization, making additional care necessary

to keep the interfaces clean.

Tag Out Procedures

The U-OP connector allows tag out

operation of the system because the

disconnection,

isolation,

and/or

grounding is under the control of the

on-site operators. The full array of

operating devices that can be used with

the U-OP connector, such as grounding

elbows, operating and test tools, insulated protective caps, insulated standoff bushings, and grounded standoff

bushings make it easy for the operator

to follow traditional safety practices

and existing operating rules.

Application Versatility

There are many configurations in which

the U-OP can be installed. If the phase

to phase spacing between apparatus

bushings does not allow for the U-OP to

be configured as in Figure 2, it is possible to install the junction, apparatus

bushing, and parking stand either vertically or in other ways to fit it to the

apparatus.

The U-OP connector system can be

installed on various types of equipment, including:

•Pad mounted switchgear including

many retrofit applications

•Heavily loaded 3Ø transformers

•Pad mounted capacitors

•Separable splicing in vault

applications

•Above ground sectionalizing

Using a 3 way junction instead of a two

way junction, a bushing extender can

be used with a meter to provide SCADA

access.

The U-OP connector system provides

all of the advantages of existing 600 A

connector systems plus much more —

it is the safest 600A connector system

available.

It provides:

•Visible ground

•External visible break (with the

visible ground already in place)

•No moving of 600 A cable

•Mechanical advantage for easy,

quick operability.

Contact your Cooper Power Systems

Sales Engineer for more information

about the U-OP connector system.

THE LINE

Harmonic continued from page 8

impedance, looking back to the source

from the plant’s standpoint, will

change. Similar effects will be seen

with the plant running under light versus heavy loading conditions, with

split-bus operation, etc. Therefore, the

filtering scheme must be tested under

all reasonable operating configurations.

First, the connected utility should

be contacted to determine the minimum and maximum available threephase fault MVA at the point of connection to the plant. This will allow the calculation of minimum and maximum values of source impedances. Second, a

list should be drawn up consisting of all

reasonable operating contingencies.

Frequency scans of these contingencies

should be made. A frequency scan

should be made at each problem node

in the system, with harmonic injection

at each point where harmonic sources

exist. This allows easy evaluation of

the effects of system changes on the

effective tuning.

Of particular importance is the variability of parallel resonance points

(peaks) with regard to changing system

parameters. For example, if for maximum system load a resonance peak

exists at the 6th harmonic, but at 50%

load it exists at only the 4.8th harmonic, then at some loading in between resonance will occur exactly at the fifth, a

characteristic harmonic for variablespeed drives. This will require either a

redesign of the filter or special operating rules that will minimize the effect of

this resonance point.

Abnormal system conditions such

as frequent transformer energizations,

back-to-back switching of capacitors or

filters should also be analyzed to check

the filter component ratings.

Traditional performance criteria are

the total harmonic distortion (THD)

factor and the telephone influence factor (TIF). THD is an rms value of the

distortion component of the fundamental frequency voltage wave due to harmonics. TIF measures the likelihood of

high-frequency harmonics on the

power lines inducing noise on adjacent

telephone lines.

The duties that all filter components see must be checked. If a

device’s rating is exceeded, then that

device must be reselected or the filter

must be redesigned. An unbalanced

protection scheme is generally

required to detect filter unbalances and

trip the bank to prevent damaging overvoltages. THE LINE

THE LINE / October 1996

11

Together We Can Take A

Blue Sky Idea And Bring

It Down To Earth.

Every day at Cooper, our customers

are the inspiration for our innovation.

Here are just a few examples.

They began as what-if’s and I-wish’s from our customers.

What if you could combine a distribution transformer and the

overcurrent protection of a vacuum fault interrupter into one safe,

convenient, space-saving package? (We did.)

I wish someone would find an alternative to oil or SF6

insulation for switchgear applications. (Presenting our new

maintenance-free solid dielectric VCS epoxy-encapsulated

vacuum switch.)

How to get visible break on pad-mounted switchgear without moving heavy 600-Amp cable? (Spec our U-OP™ connector

system.)

Isn’t there a way to design polymer arresters which are

safe, reliable, virtually indestructible, and also simple enough to

allow for quick customization and just-in-time delivery? (Let us

tell you about our revolutionary new UltraSIL™.)

How about a transformer that eliminates problems with

harmonics? (Ask for Cooper’s R-Tran K-Plus™ transformer.)

A high-energy distribution class arrester with current-limiting

fuse protection to mount at the customer’s meter? A latch indicator insert that gives a visible indication that the elbow is properly

latched? And, please, an indicator for the indicator to distinguish

which have indicators? (Consider it done.)

The list of customer-driven innovations from Cooper goes

on. All of which work to reduce downtime. Enhance power quality. Improve safety. Ensure reliability. Lower maintenance costs.

And save you money. That’s not just down-to-earth. It’s all the

way down to your bottom line. And it’s why our customers tell us

they can count on Cooper Power Systems down the line.

Share some of your own ideas.

You Can Count On Cooper Power Systems Down The Line

Web Site Address: http://www.cooperps.com

BULK RATE

Cooper Power Systems

Quality from

Cooper Industries

P.O. Box 1640

Waukesha, WI 53187 USA

Printed on recycled paper.

U.S. POSTAGE

PAID

Waukesha, WI

Permit No. 554