Anodizing Aluminum

advertisement

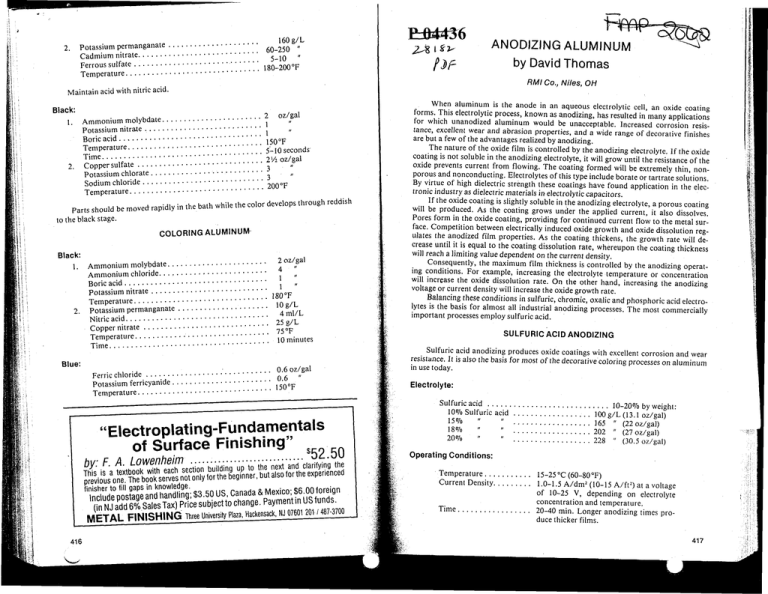

Potassium permanganate ..................... ........................... Cadmium nitrate. ............................. Ferrous sulfate.............................. Temperature. 2. €YM436 160 g/L A N O D I Z I N G ALUMINUM by David Thomas m 3 IkL 60-250 5-10 " 180-200"F I' RMI Go., Niles, OH Maintain acid with nitric acid. Black: 1. ...................... Ammonium molybdate. Potassiumnitrate.. ......................... Boric a c i d . . ............................... 21 Temperature. Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Coppersulfate ............................. Potassium chlorate. ........................ Sodiumchloride.. .......................... Temperature.. ............................. 150°F 5-10 seconds 2% oz/gal 3 3 200°F .............................. 2. When aluminum is the anode in an aqueous electrolytic cell, an oxide coating forms. This electrolytic process, known as anodizing, has resulted in many applications for which unanodized aluminum would be unacceptable. Increased corrosion resistance, excellent wear and abrasion properties, and a wide range of decorative finishes are but a few of the advantages realized by anodizing. The nature of the oxide film is controlled by the anodizing electrolyte. If the oxide coating is not soluble in the anodizing electrolyte, it will grow until the resistance of the oxide prevents current from flowing. The coating formed will be extremely thin, nonporous and nonconducting. Electrolytes of this type include borate or tartrate solutions. By virtue of high dielectric strength these coatings have found application in the electronic industry as dielectric materials in electrolytic capacitors. If the oxide coating is slightly soluble in the anodizing electrolyte, a porous coating will be produced. As the coating grows under the applied current, it also dissolves. Pores form in the oxide coating, providing for continued current flow to the metal surface. Competition between electrically induced oxide growth and oxide dissolution regulates the anodized film properties. As the coating thickens, the growth rate will decrease until it is equal to the coating dissolution rate, whereupon the coating thickness will reach a limiting value dependent on the current density. Consequently, the maximum film thickness is controlled by the anodizing operating conditions. For example, increasing the electrolyte temperature or concentration will increase the oxide dissolution rate. On the other hand, increasing the anodizing voltage or current density will increase the oxide growth rate. Balancing these conditions in sulfuric, chromic, oxalic and phosphoric acid electrolytes is the basis for almost all industrial anodizing processes. The most commercially important processes employ sulfuric acid. oz/gal '0 1 Parts should be move& rapidly in the bath while the color develops through reddish to the black stage. COLORING ALUM INUM Black: ..................... 1. Ammonium Ammonium molybdate. chloride. ........................ ............................... 2. Blue: Boricacid.. ........................... Potassium nitrate .............................. Temperature. ..................... Potassium permanganate ................................ Nitric acid. ............................. Copper nitrate ............................. Temperature.. .................................... Time. ............................. Ferric chloride ....................... Potassium ferricyanide .............................. Temperature. 24 oz/gal " 1 11 I 1 " 180 "F 10 g/L 4 ml/L 25 g/L 75'F 10 minutes SULFURIC ACID ANODIZING Sulfuric acid anodizing produces oxide coatings with excellent corrosion and wear resistance. It is also the basis for most of the decorative coloring processes on aluminum in use today. 0.6 oz/gal 0.6 " 150°F Electrolyte: I "Electroplating-Fundamentals of Surface Finishing" SF;? F;n by: F. A. Lowenheim ............................. JL.W This is a textbook with each section building u p to the next and clarifying the previous one. The book serves not only for the beginner, but alSO for the experienced finisher to fill gaps in knowledge. \nc\ude postage and handling; $3.50 US, Canada &Mexico; $6.00 foreign (in NJ add 6% Sales Tax) Price subjectto change. Payment in USfunds. METAL FINISHING Three University Plaza, Hackensack, NJ 07601 201 / 487-3700 416 I Sulfuric acid . . . . . . . 10% Sulfuric acid . 15% " 18% " 20% " . . . . . . . . . . . . . . . . 10-20% by weight: . . . . . . . . . . . . 100g/L (13.1 oz/gal) 202 . . . 228 oz/gal) . (27 (30.5 odgal) " Operating Conditions: Temperature. . . . . . . . . . . 15-25°C (60-80°F) Current Density. . . . . . . . . 1.0-1.5 A/dm2 (10-15 A/ft2) at a voltage of 10-25 V, depending on electrolyte concentration and temperature. . . . 20-40 min. Longer anodizing times produce thicker films. Equipment: Tanks-Electrolyte tanks are usually lead-lined steel, stainless steel or plastic-lined (PVC, neoprene or polyethylene) steel. Lead-lined or stainless steel tanks may be used as cathodes, but adequate distance between the work and tank must be maintained to prevent shorting. Cathodes-Lead, aluminum, or stainless steel. Aluminum cathodes should be removed from the solution during “down” time. Temperalure Conlrol-Often neglected, this is very important in control of oxide film properties. For the most consistent results, the temperature should be maintained within 5 1 “C. Since as much as 50 kJ/dm2 (425 Btu/ft’) of heat may be evolved during the anodizing process, many sulfuric acid electrolytes may require refrigeration. However, for normal anodizing (25°C or higher), cold water circulated through a tube-type heat exchanger made of titanium or lead is usually sufficient. Titanium, by virtue of its lighter weight and higher strength, is often more economical than lead. To ensure maximum corrosion resistance, the titanium should be made anodic during both anodizing and latent periods. A small voltage source ,and a lead cathode are usually quite sufficient for long heat exchanger life. Agiration-To prevent locally high temperatures and possible burning of the work, agitation must be provided. Air agitation, used in the electroplating industry, is acceptable so long a s the air is clean (no oil). Mechanical agitation of the anode is also acceptable. Anode Racks-The most common racks for anodizing are aluminum or titanium. If aluminum is to be used it should be the same alloy as the work, or an aluminum that does not contain current-robbing alloying. elements such as copper. By virtue of its good mechanical characteristics, 6063 is a very good alloy for use as a general racking material. Titanium has gained wide use in the anodizing industry because the thin, tightly ad- Specialists in engineering, plant design and waste treatment. Distributors and manufacturersof plating, anodizing and electropolishingwpplies andchemicals. HARD COAT ANODIZING ELECTROPOLISHING SOLUTIONS FILTERS PULSE PLATING AUTOMATIC PLATING LINES PUMPS TANKS IMMERSION HEATERS TREATMENT SYSTEMS 418 - Y TITANIUM I ANODIZING RACKS The industry’s largest selection of racks, splines, clips, tips, clamps and fasteners. Most shipped from stock within hours! W Over 90 disc rack styles H Over 160 box and piano rack styles W Over 60 utility rack styles Over 130 varieties of clips, tips and clamps H Complete design and fabrication services on \ your custom rack needs W Automatic rack loading and unloading tools W Sales representatives serving the entire U.S., Europe and the Far East. I Call or write for c a t a l o g ca VULCANIUM We’re with you start to finish 3045 Commercial Avenue Northbrook. IL 60062-1997 U.S.A. 3121498-3111 FAX 312-498-3392 Telex 210043 I “The Canning Handbook-Surface Finishing TechnoIogy ” by: W. Canning PIC. $69.95 This handbook was first published in 1889 as a 16-page booklet for electroplaters.The expanded 23rd edition has been issued with the title changed to “Surface Finishing Technology.” It is divided into groups of chapters on polishing, electroplating, lacquering and bronzing, safety and tables of data. A valued addition to any plater’s bookshelf. Include postage and handling $3.50 US, Canada & Mexico; $6.00 foreign (in NJ add 6% Sales Tax) Price subject to change. Payment in US funds. herent oxide on titanium prevents current flow from the rack itself. This restricts current flow to contact puints between the aluminum workpiece and the titanium rack. Since there is no current flowing from the rack to the solution, overall power requirements may be lower; however, it must be emphasized that only commercially pure titanium should be used for racking. Substitution of a titanium alloy will result in poor corrosion resistance and short rack life. A properly designed, commercially pure titanium anodizing rack will last much longer than a similar aluminum rack. Power Supply-For normal sulfuric acid anodizing, a rectifier or motoc generator capable of 25 V and 0.5-5 A/dm* &SO A/ftz) is usually sufficient. However, barrier films for electrolytic capacitors, chromic acid anodizing, phosphoric acid anodizing and oxalic acid anodizing may require voltages as high as 150 V. The variety of anodizing processes to be performed will dictate the voltage and power requirements of the power supply used. Oxide Coating Properties-Anodizing process conditions have the greatest influence on oxide coating properties. Use of low acid concentrations and temperatures favor less porous, harder oxide coatings, while higher acid concentrations, increased solution temperatures and anodizing times (favoring electrolyte-induced oxide dissolution) favor more porous, even powdery oxide coatings. Generally, any change in operating conditions that will increase the oxide dissolution rate will result in softer, more porous coatings. However, when considering any change in anodizing conditions it must be emphasized that one anodizing condition cannot be changed without affecting the other anodizing conditions. With regard to anodizing conditions, the alloy being anodized can have a significant effect on the relationship between potential and current density. This effect may be quite significant from a practical sense, as the desire to anodize several different aluminum alloys simultaneously (as on a fabricated part, for example) might lead to undesirable; if not disastrous, anodizing results. Everything From Basic Tanks To Comdete Modules HBS is your economical one-stop source for everything from off-the-shelf accsssories to completely pre-tested and pre-wired anodizing modules 100% ready for action! Systems Include: Type I, 11, & 111 Tanks to specification Anodizing For: Refrigeration & heating equip. Industrial Built-in exhaust system Aerospace Dc pcwer supply Mi/ifary/Gw Pre & post processing tanks Architwtuml Secondary containment For more information on this and thousands of other electroplating items-call or write for our comprehensive catalog! METAL FINISHING Three University Plaza Hackensack, NJ 07601 201 1487-3700 421 420 CHROMIC ACID ANODIZING The chromic acid anodizing process has been used largely on aircraft, for preparation for painting. I t has excellent corrosion resistance and there is no need for postanodic sealing, and it can accept certain dyes for coloring if the surface does not need to be painted. Operating Conditions: Temperature . . . . . . . . . . . 24"-35 "C (75 "-95°F) Current Density ........ 1.0-2.0A/dm2 (10-20 A/ftz) at 40-60 V Time . . . . . . . . . . . . . . . . . 40-60 min Electrolyte: Chromic acid ( 0 0 , ) . . . . . . . . . . . . . . 50-100 g/L (6.7-13.4 oz/gal) Note: Technical grade CrO, is acceptable Equipment: Operating Conditions: (same as for sulfuric acid anodizing) PHOSPHORIC ACID ANODIZING Because of large pore size. oxide coatings produced in diluie phosphoric acid provide an excellent surface for electrodeposition of metal coatings. This anodizing technique can offer several advantages over generally used preplating techniques like the zincate treatment. Equipment: (same as for sulfuric acid anodizing) Electrolyte: Operating Procedure: 3-20 vol 70phosphoric acid (s.g. = 1.63) (50-325 g/L - 7-44 oz/gal) The workpiece to be anodized is made the anode and mild steel, aluminum, or stainless steel plates are made the cathode. The tank itself may also be used as the cathode. During the first I O minutes the potential is increased from 0 to 40 V. When the potential reaches 40 V, anodizing is continued for 20 minutes. At this potential the current denbity will range between 0.3 and 0.5 A/dm* (3-5 A/ftz). After 20 minutes the potential is increased from 40-50 V during the next 5 minutes and held at 50 V for 5 minutes. Oxide Coating Properties: The chromic acid anodizing process produces a thin, relatively soft oxide film exhibiting corrosion resistance midway between that of unsealed and sealed sulfuric acid oxide coatings; however, these oxides are much more easilv penetrated and have lower abrasion resistance. The coating is usually a dark greenishlsometimes gray, sometimes difficult to dye and does not require sealing. OXALIC ACID ANODIZING Although used sparingly in the US, the oxalic acid anodizing process is still widely used in Japan. The process is somewhat more expensive than the, sulfuric acid process, but can produce thicker oxide coatings (:SO pn-2 mils) without the need for low electrolyte temperatures (e.&, below 20°C). Another often desirable feature of the process is the production of gold or bronze finishes on several aluminum allow. Electrolyte: 3-10 wgt Vo oxalic acid (3 wgt Vo is probably the most comnlonly used concentration). Sanford Process Corp. Operating Conditions: Temperature .......................... .30 "-35 "C (85 "-95 "F) Current density - determined by applied cell potential from 50-60 V Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I 5-30min introduces for use in most corrosive environments 1 flooded with imitation clambs and their acomDanvina .,...~ cini" -.- " and promises. And. like m a n-, v imitations they don'f .... CHEM-CLAMP I -- ~ --- Metal Finishers are being THE STAINLESS STEEL ~ i '2 -0 I ;;IP )ual Tipped Duraclamp Samples available I-" Abrasion, Corrosion, Dielectric Problems VI 0 65 North Ave., Watick, MA 01760 U.S.A. World Known F'or Research To Practice .....Build Your Bottom Line..... 422 !?s Try one -you'll have it forever! I W = Gk gv *2 A m 9o m :~:~E~oY:;:&r,c"r -0, z 423 Special Considerations: HARD ANODIZING PROCESS When using phosphoric acid anodizing asda pretreatment for plating, several precautions must be exercised. First, the workpiece must be thoroughly rinsed after anodizing. Any residual phosphoric acid left in the oxide pores will result in poor metal deposit adhesion. Second, the oxide coating must not be allowed to dry before plating. Complete drying closes up the porous structure, removing the anchoring points and reducing the metal plating adhesion to near zero. Third, because of the higher power input, refrigeration of the electrolyte and adequate bath agitation are essential for satisfactory results. If the temperature is allowed to increase beyond 40°C (104°F). the plated metal adhesion will be significantly lowered. By decreasing the oxide film dissolution rate, it is possible to produce very thick (up to 250 pm), hard coatings. The hard anodizing process exploits this phenomenon by lowering the temperature of a conventional sulfuric acid electrolyte to On-3 "C (32"-38"F). The oxide coatings that are produced using this technique are much thicker, harder and more wear resistant. Electrolyte: 15 vol To sulfuric acid (165 g/L - 22 oz/gal) Operating Conditions: !SEAL1NG Because of the porous structure obtained in commercial sulfuric acid anodizing, sealing is required. Chromic and phosphoric acid processes do not require sealing and, in fact, may be adversely affected by sealing. Oxalic acid processes may or may not be sealed. Sealing in distilled or deionized (DI)water at or near boiling is by far the simplest method. This is usually the preferred method for sealing dyed, anodized aluminum. For enhanced corrosion resistance a dichromate seal is often used. With this type of sealing there are two processes involved: 1) adsorption of chromate and 2) closing or sealing of the oxide pores, which locks in the chromate. Temperature. .......... . O"-3 "C (32"-38"F) Current Density. ....... .2-2.5 A/dm' (20-25 A/ftz) To maintain this current density the potential rises from 20-25 V to 40-60 V. Time. ............... .60-200 minutes, thickness is very nearly a linear function of time. Equipment: Same as conventional sulfuric acid anodizing, wifh the addition of greater refrigeration capacity to maintain low temperature requirements. External heat exchangers with high Btu-reduction ratings are used in large installations. Midway between the simple distilled or DI water sealing process and the dichromate sealing qrocess is the nickel/cobalt acetate sealing process. While this technique does not contain the corrosion resistance of the dichromate process, it can be much more effective than the simple water seal when water impurities like silica (S~OZ) are present. It is often possible to use tap water with the nickel/cobaltacetate technique, in contrast to the high purity water required for the simple water sealing technique. Typical Processes: Water Seal: distilled or DI water -<lo0 ppm Si?, (water purity is very important). 95"-100"C(200"-212"~ Temperature ....................... 30min Time ............................. Dichromate Seal: KICr20, ......................... NaCO, .......................... o r N a O H ........................ Temperature. ..................... Time.. ........................... Nlckel/Cobalt Acetate Seal:Nickel acetate .................. Cobalt acetate. .................. Boric acid. .................... p H 5-6 Temperature. ................... Time. .......................... ~~ 424 100 g/L (13.40z/gal) 18 " (2.4oz/gal) 13 " (1.7oz/gal) 9Oo-9S0C (194O-203 O F ) 2-4min 5-5.8 g/L (0.67-0.78 oz/gal) 1 g/L (0.13 odgal) 8-8.4 g/L (1.1 oz/gal) 7Oo-9O"C (158'"-194"F) 15-20 min AI uminum' by:A. W.Brace & P. G. Sheasby $85.00 This second edition starts off with a discussion of anodizing as a business and follows with chapters on cleaning and brightening, the various types of anodizing processes, oxide coloring, sealing, process testing and coating properties. Include postage and handling $3 50 US, Canada & Mexico, $6 00 foreign (in NJ add 6% Sales Tax) Price subject to change. Paymentin US funds ' Strongest and longest life clamp. We stock 4 sizes. Lowest prices Only supplier with 3 types of tips to cover every type of process. -Ceramic -Plain [alumina oxide] -Titanium SAMPLES -ON REQUEST AVAILABLE Phone: 1-800-327-2742 METAL FINISHING Three University Plaza Hackensack, NJ 07601 201 I487-3700 425