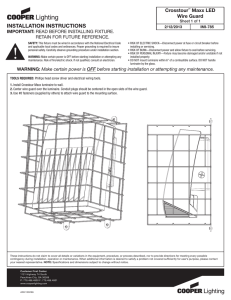

INSTALLATION INSTRUCTIONS

advertisement

WINSCAPE™ INSTALLATION INSTRUCTIONS for HENSLEY SERIES These instructions cover the installation for the following fixtures & options: - Hensley (HE) series - Hensley Brass (HEBR) series. - Any Modified or Custom fixture based on the above listed fixtures. Instruction details on Custom & Modified fixtures may differ slightly as they are custom built to the customer’s specification, please contact Winona Lighting to verify installation on these fixtures. Hensley (HE) series Hensley Brass (HEBR) series Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 BASIC INFORMATION: With each Hensley series fixture you will receive the following: 1. Pre-assembled ingrade fixture. 2. Installation instructions – Please read instructions completely prior to starting installation. Installation instructions may be periodically updated due to corrections, changes in design or changes in procedure. BEFORE INSTALLING, please check our website; www.winonalighting.com , or call Winscape customer service @ 1-800-328-5291, to verify you have the latest and most up to date installation instructions, this can be verified by the revision date in the top right corner of this or any other page. WARNING: This fixture should be installed only by a licensed electrician. WARNING: Hydrel Lighting is not responsible for failures caused by incorrect installation. Incorrect installation voids the warranty of this fixture and ballast enclosure. GENERAL FIXTURE DIAGRAM: FACEPLATE MACHINE SCREWS WIRE COMPARTMENT SEALING PLATE CAPTIVE SCREWS O-RING SOCKET BRACKET ASSEMBLY COMPOSITE HOUSING DISASSEMBLY: Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 2 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 Prior to installation you will have to disassemble the fixture into its main components. 1. Loosen the six (6) captive machine screws that secure the faceplate to the housing with a 3/32” Allen (hex) wrench by turning them counter clockwise (left) while applying very light downward pressure. Please note these screws are captive and should not be removed completely from the faceplate. 2. Remove and place the faceplate to the side in a safe, debris free, dry place. WARNING: Do not place sealing surface (grey gasket) of the faceplate on the ground. It may pick up debris causing the seal between the fixture mount plate and housing to fail, this will void fixture warranty. 3. Remove and place the o-ring to the side in a safe, debris free, dry place. 4. Loosen the two (2) brass thumb screws on socket bracket assembly approximately one turn counter clockwise (left). Do NOT REMOVE these thumb screws from the socket bracket. 5. Grip the socket bracket assembly and pull straight up approximately 6” to 8”. 6. Disconnect the plug between the ballast assembly and wire compartment sealing plate by squeezing the release tab and pulling the plugs apart. WARNING: Grip the plug ONLY by the plug itself; do not pull on the wires. This can cause permanent damage to the plug and will void the warranty. Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 3 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 7. Remove and place the socket bracket assembly to the side in a safe, debris free, dry place. 8. Remove the four (4) machine screws that secure the wire compartment sealing plate to the composite housing with a 3/32” Allen (hex) wrench by turning them counter clockwise (left). Do not lose these four (4) screws; they will be re-used during installation of the housing. 9. Remove and place the wire compartment sealing plate to the side in a safe, debris free, dry place. WARNING: Do not place sealing surface (grey gasket) of the wire compartment sealing plate on the ground. It may pick up debris causing the seal between the compartment sealing plate and housing to fail, this will void fixture warranty. 10. Remove the small bag from inside the wire compartment at the base of the composite housing. This bag contains five (5) screw-in conduit entry plugs and two (2) waterproof wire nuts. Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 4 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 Once disassembled into its main components you will have: 1 – Faceplate W/ six captive screws 1 – O-ring 1 – Socket bracket assembly 1 – Wire compartment sealing plate 4 – Machine screws (FHSCS 8-32 x .500” BZ SS) 1 – Composite housing 2 – Waterproof, direct burial wire nuts 5 – Screw-in conduit entry plugs (1/2” NPS) Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 5 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 HOUSING INSTALLATION: Before starting housing installation, examine ALL components to ensure there is no damage, visible defects or missing parts. If any parts have been damaged, have a visible defect or parts are missing; contact Winscape Customer service immediately @ 1-800-328-5291, before installing housing. Read instructions completely prior to installing fixture. INSTALLATION TIP: If possible, steps 1 thru 4 and 6 thru 7 can be performed PRIOR to installing the housing in the ground. Doing this will allow much greater access to the housing and reduces the chances of debris getting inside the housing. 1. Install conduit entry adaptors (supplied by installer) into the ½” conduit entries on composite housing in orientation that best suits the conditions on the jobsite. Use the correct type of conduit entry adaptors for the conduit system being used on site. Conduit adaptors must be waterproof and rated for direct burial. INSTALLATION TIP: Place a thick bead of high temp RTV silicone on the threads of the conduit entry adaptor(s) prior to installing into the housing. Then place a thick bead of the same RTV silicone around the seam between the conduit entry adaptor and the composite housing. Let the RTV silicone dry completely prior to installing the housing into the ground. 2. Install the screw-in conduit entry plugs in ALL unused conduit entry holes in composite housing. To correctly install, place a thick bead of high temp RTV silicone all the way around the threads on each plug prior to installing them into the housing. Once all plugs are screwed into the housing, smear a thick coat of RTV silicone over the entire plug, covering it and at least ¼” outside the plug in all directions. Let the RTV silicone dry completely prior to installing the housing in the ground. Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 6 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 3. Dig a hole approximately 12” diameter and 10” deep and trench for conduit or burial wire. It is STRONGLY recommended that the bottom 4” to 6” is filled with peat gravel (or other type of drainage rock) to promote proper drainage away from the housing. 4. Place housing into hole and connect conduit entry adaptors to conduit system. Flanged Surface on top of composite housing should be installed approximately ½” above bare dirt ground level or flush with finished grade. 5. Back fill composite housing in 3” to 4” increments making sure fill is properly packed around composite housing (this will reduce the chance of area around the housing sinking), until bare ground level is reached, *if housing is going to be installed in a concrete pour application, see 5a (next page), if not go to step 6. TYPICAL GROUND MOUNT APPLICATION: FIXTURE GROUND COVER FILL COMPOSITE HOUSING DRAINAGE TYPICIAL CONCRETE POUR APPLICATION: POUR COLLAR FIXTURE CONCRETE POUR DRAINAGE COMPOSITE HOUSING Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 7 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 a. If composite housing has been ordered with the optional PC (concrete pour collar). There will be a thin metal collar around the top of the composite housing. The top edge of the pour collar should be set to the same level as the finished concrete pour. BEFORE installing the housing, check to be sure the pour collar has not been bumped or knocked loose or out of position during shipping or handling. With the fixture faceplate installed the top edge of the pour collar should sit flush with the top surface of the fixture faceplate, if it does not, loosen the four (4) screws securing it to the composite housing and adjust the pour collar to the correct position. Before pouring concrete it is strongly recommended that the fixture faceplate is covered with painters’ masking tape & installed to protect it and the composite housing during the concrete pour. DO NOT allow concrete to fill the gap between the pour collar and fixture faceplate. Housing W/ PC option Incorrect adjustment Standard Housing Adjuster screw (4x) Correctly adjusted 6. Pull wire through conduit system and make wire connections with supplied waterproof wire nuts to the wires protruding thru the bottom side of the wire compartment sealing plate. If due to the number of wires needing to be connected, supplied waterproof wire nuts cannot be used, use ONLY under ground, waterproof rated Wire nuts. We recommend Ideal®, UnderGround™ Wire Connectors, model 60 (supplied w/ composite housing) or model 64 (supplied by others). a. Supplied wire nuts are IDEAL®, UnderGround™ Wire Connectors, model 60. For use with the following wire sizes: #20 thru #10 AWG Minimum of two (2) #20 AWG Maximum of three (3) #12 AWG b. Optional wire nuts (supplied by others) are IDEAL®, UnderGround™ Wire Connectors, model 64. For use with the following wire sizes: #18 thru #8 AWG Minimum of two (2) #18 AWG Maximum of three (3) #10 AWG Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 8 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 INSTALLATION TIP: Make wire connections as close to the bottom of the composite housing as possible. This will make installation of the wire compartment sealing plate significantly easier. 7. Install the wire compartment sealing plate to the composite housing using the four (4) supplied screws with a 3/32” Allen (hex) wrench by turning them clockwise (right). When correctly installed, grey gasket will slightly bulge out from underneath the plate, evenly all the way around. Double check that all four (4) screws have been tightened evenly. WARNING: Inside mating surface of housing must be completely free from ALL debris. Any debris trapped between housing and wire compartment sealing plate may cause housing to leak and will void the warranty. WARNING: Use caution NOT to trap any wires between the housing and wire compartment sealing plate this may cause housing to leak and will void the warranty. INSTALLATION TIP: If possible, steps 1 thru 4 and 6 thru 7 can be performed PRIOR to installing the housing in the ground. Doing this will allow much greater access to the housing and reduces the chances of debris getting inside the housing. 8. Install socket bracket assembly by connecting the plug from the wire compartment sealing plate to the plug from the socket bracket assembly, Plug can only be installed one way and will “snap” together. Then lower the socket bracket assembly down into the housing, until the outside ring rests on the upper lip inside of the composite housing. (See “LAMPING, RE-LAMPING & AIMING instructions, page 11, for correct lamp installation & aiming). Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 9 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 INSTALLATION TIP: Place a small amount of dielectric grease (available at local auto parts store) into each of the pin openings on the plugs, this will prevent corrosion from forming between the plugs. 9. All composite housings are shipped with ANTI-SIEZE in the twelve threaded inserts in the top flange of the housing. If the anti-seize has dried out, or there does not visibly appear to be any, place a small amount in ALL twelve (12) threaded inserts. This will prevent the screws used to secure the fixture mount plate to the composite housing from seizing over time. With Anti-Seize Without Anti-Seize 10. Install the o-ring into the half-circle groove on the very top of the composite housing. Please note, changes in temperature and humidity will have an effect on the size of the o-ring. The o-ring has been sized to a slightly smaller diameter than the groove in the housing specifically for this reason. If the o-ring does not lay into the groove just right, it can be stretched slightly by giving it one or two gentle tugs to stretch it out to fit the groove. WARNING: O-ring groove in composite housing and o-ring must be free from ALL debris and dirt. Failure to ensure the sealing surface is completely clean can cause composite housing to leak and will void the warranty. 11. Install fixture faceplate by lowering the faceplate straight down into the composite housing, lining up the screws with the threaded inserts in the composite housing. WARNING: Gasket on bottom side of face plate must be free from all debris and dirt. Failure to ensure the sealing surface is completely clean can cause composite housing to leak and will void the warranty. Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 10 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 12. Tighten down the six (6) machine screws that secure the faceplate to the composite housing with a 3/32” Allen (hex) wrench by turning them clockwise (right) while applying light downward pressure. It is best to start each screw by hand to prevent cross-threading of the screw into the threaded insert in the composite housing. Screws should be tightened down until they stop with light pressure when using a hand driver, do NOT exceed 12 in-lbs of force. Double check that all six (6) screws have been tightened evenly. DO NOT OVER-TIGHTEN THESE SCREWS! WARNING: It is STRONGLY recommended that these screws be HAND tightened only, use of an electric screwdriver or drill can cause permanent damage to the housing such as spinning the threaded insert, cracking the composite housing itself, cause the screws to strip, cross thread, even break, and may round out the hex head. INCORRECT - not tightened down enough Hydrel Lighting CORRECT – gasket will bulge out slightly 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 11 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 LAMPING, RE-LAMPING & AIMING: If any parts have been damaged (or are damaged during lamping, re-lamping or aiming), have a visible defect or parts are missing; contact Winscape Customer service immediately @ 1-800-328-5291, before proceeding. Read instructions completely prior to lamping, re-lamping or aiming the fixture. 1. Loosen the six (6) captive machine screws that secure the faceplate to the housing with a 3/32” Allen (hex) wrench by turning them counter clockwise (left) while applying very light downward pressure. Please note these screws are captive and should not be removed completely from the faceplate. 2. Remove and place the faceplate to the side in a safe, debris free, dry place. WARNING: Do not place sealing surface (grey gasket) of the faceplate on the ground. It may pick up debris causing the seal between the fixture mount plate and housing to fail, this will void fixture warranty. 3. LAMPING / RE-LAMPING: a. (This step is required for RE-LAMPING only, if installing a lamp for the first time, skip to step 3b). Remove the existing lamp from the socket by grasping the lamp around its outside edge and gently wiggling back and forth, while pulling the lamp away from the socket. b. Without touching the bulb portion of the lamp, align the pins and push the new lamp into the socket. If bulb has been touched wipe off with a clean cotton cloth, as the oil from your fingers will significantly shorten the life of the lamp. Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 12 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 4. AIMING: a. To adjust the vertical tilt of the lamp: Insert a 3/32” Allen wrench into the adjuster screw on the top face of the socket bracket assembly. Turn the screw counter clockwise (left) to adjust the vertical aim down (away from vertical). Turn the screw clockwise (right) to adjust the aim up (towards vertical). Note, the bracket is designed to adjust in only one direction from vertical, do not attempt to adjust past vertical; this may cause damage to the socket bracket assembly. b. To adjust the horizontal rotation of the lamp: Loosen the two (2) brass thumb screws on the sides of the socket bracket assembly approximately one turn counter clockwise (left). Rotate the bracket to the desired position. Tighten the two brass thumb screws by hand, with two fingers, until they stop with only light pressure. WARNING: If thumb screws are over-tighten socket bracket assembly could be damaged, or bent. This may cause the faceplate seal to fail and will void fixture warranty. 5. If the o-ring in the top of the housing has been disturbed, removed, or fallen out it must be correctly re-installed. Install the o-ring into the half-circle groove on the very top of the composite housing. Please note, changes in temperature and humidity will have an effect on the size of the o-ring. The o-ring has been sized to a slightly Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 13 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 smaller diameter than the groove in the housing specifically for this reason. If the o-ring does not lay into the groove just right, it can be stretched slightly by giving it one or two gentle tugs to stretch it out to fit the groove. WARNING: O-ring groove in composite housing and o-ring must be free from ALL debris and dirt. Failure to ensure the sealing surface is completely clean can cause composite housing to leak and will void the warranty. 6. Install fixture faceplate by lowering the faceplate straight down into the composite housing, lining up the screws with the threaded inserts in the composite housing. WARNING: Gasket on bottom side of fixture mount plate must be free from all debris and dirt. Failure to ensure the sealing surface is completely clean can cause composite housing to leak and will void the warranty. 7. Tighten down the six (6) machine screws that secure the faceplate to the composite housing with a 3/32” Allen (hex) wrench by turning them clockwise (right) while applying light downward pressure. It is best to start each screw by hand to prevent cross-threading of the screw into the threaded insert in the composite housing. Screws should be tightened down until they stop with light pressure when using a hand driver do NOT exceed 12 inlbs of force. Double check that all six (6) screws have been tightened evenly. DO NOT OVER-TIGHTEN THESE SCREWS! WARNING: It is STRONGLY recommended that these screws be HAND tightened only, use of an electric screwdriver or drill can cause permanent damage to the housing such as spinning the threaded insert, cracking the composite housing itself, cause the screws to strip, cross thread, even break, and may round out the hex head. Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 14 of 16 WINSCAPE™ Installation Instructions Hensley series fixture Revision date: 6/15/15 INSTRUCTIONS PERTAINING TO A RISK OF FIRE OR INJURY TO PERSONS IMPORTANT SAFTEY INSTRUCTIONS CAUTION! Lighted Luminaire is HOT! WARNING: Winona Lighting is not responsible for failures caused by incorrect installation. Incorrect installation voids the warranty of this fixture. If you do not understand or have questions about these installation instructions, please contact Winscape customer service @ 1-800-328-5291 before installing the fixture. WARNING: To reduce the risk of FIRE or INJURY TO PERSONS follow these important safety instructions. WARNING: Fixture gets HOT quickly! Turn off and allow fixture to cool before replacing lamp. Make only contact with switch or plug when turning on or off. WARNING: Do NOT touch Lens or Faceplate when luminaire is on or hot. WARNING: Keep fixture away from combustible materials. WARNING: Do NOT install fixture within 3.0 meters (10 feet) of pools, spas, fountain, or similar locations, except as permitted by NEC (National Electrical Code) Article 680. WARNING: Installation must conform to all national and local building & electrical codes. WARNING: Turn off power before installation, do not make any live wire connections. WARNING: Do NOT operate fixture with missing or damaged parts, doing so will void warranty. WARNING: Fixture voltage must NOT exceed 12.00 volts as measured at the socket. WARNING: Fixture voltage must NOT drop below 10.90 volts as measured at the socket POWER UNIT: This fixture is designed to be used with a remote transformer (landscape lighting type) with electrical ratings not to exceed 15V, 25A. Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 15 of 16 Installation Instructions Hensley series fixture WINSCAPE™ Revision date: 6/15/15 WIRE: Use only cable rated for low voltage. If cable is to be buried, maximum depth is 6” unless direct burial cable is used. The 12-2 & 16-2 direct burial cable is available from Winona Lighting. 10-2 and 8-2 direct burial cable is available by special order. WIRE CONNECTORS: Use silicone filled, waterproof wire nuts to make electrical connections. Wire nuts are available from Winona Lighting. FIXTURE TEST: Test fixture with a digital voltage meter at socket. Voltage at socket must not exceed 12.00 volts or drop below 10.90 volts when measured at the socket. If voltage is outside this range the warranty will be voided CODES: Check all local and national building codes for additional requirements regarding low voltage lighting. WARRANTY: When installed according to the Winscape installation instruction and installation conforms to all local and national building and electrical codes, Winona Lighting warrants all products manufactured by Winscape to be free from defects resulting from the use of inferior materials, equipment or workmanship, normal wear and tear excepted for a period of 60 months (five years) from the date of shipment with the exception of; 1. Clear coat brass finishes; Clear coat finishes on all brass products are warranted for 12 months (one year) only. 2. Lamps; Lamps are covered under lamp manufacturer’s warranty. 3. Ballast; Ballasts are covered under ballast manufacturer’s warranty. 4. Transformers; Transformers are covered under transformer manufacturer’s warranty. In the event of a warranty claim, it is Winona Lighting’s sole decision to either repair or replace the product at no cost to the original purchaser only after Winona Lighting has issued a RGA (Return Goods Authorization) for the defective product. Shipping costs are the sole responsibility of the customer and are not covered under this warranty. Labor costs are the sole responsibility of the customer and are not covered under this warranty. Winona Lighting does not guarantee defects caused by improper handling, modification, tampering, accident (including shipping), poor or incorrect installation, improper maintenance, or misapplication. This warranty is exclusive and in lieu of all other warranties, whether express, implied or statutory including but not limited to any warranty of merchantability or fitness for any particular application. Hydrel Lighting 9144 Deering Ave: 2nd Floor, Chatsworth CA 91311 PH: 866-533-9901 www.hydrel.com SAVE THESE INSTRUCTIONS Page 16 of 16