Operations Leadership Program (OLP)

advertisement

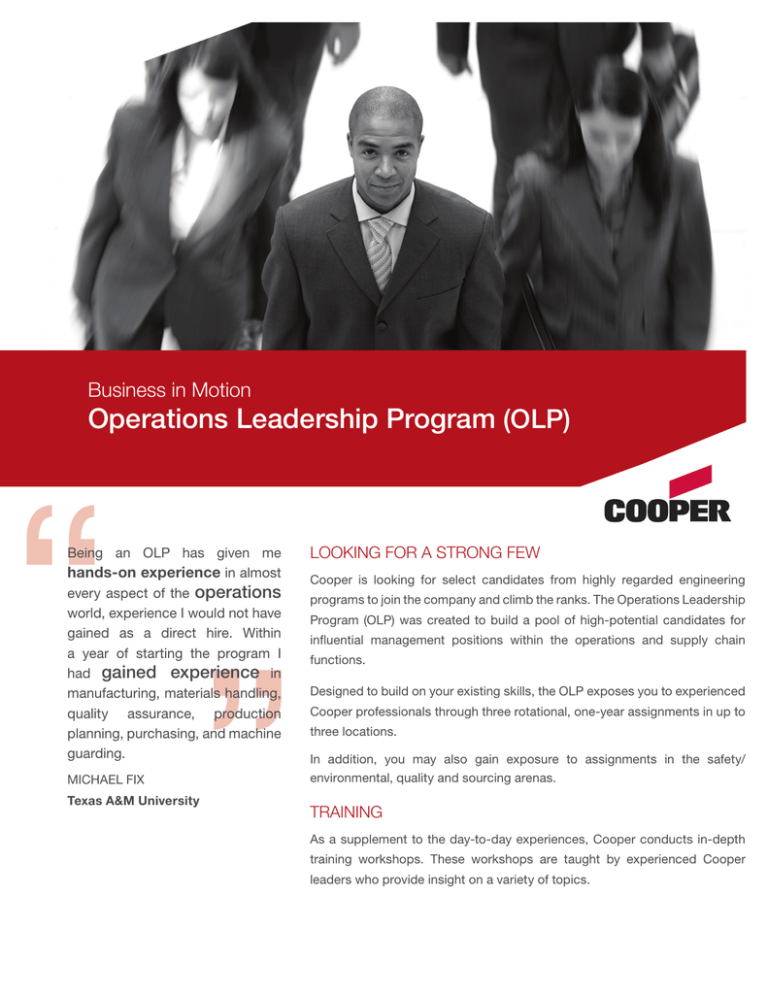

Business in Motion Operations Leadership Program (OLP) Being an OLP has given me hands-on experience in almost every aspect of the operations world, experience I would not have gained as a direct hire. Within a year of starting the program I had gained experience in manufacturing, materials handling, quality assurance, production planning, purchasing, and machine guarding. MICHAEL FIX Texas A&M University looking for a strong few Cooper is looking for select candidates from highly regarded engineering programs to join the company and climb the ranks. The Operations Leadership Program (OLP) was created to build a pool of high-potential candidates for influential management positions within the operations and supply chain functions. Designed to build on your existing skills, the OLP exposes you to experienced Cooper professionals through three rotational, one-year assignments in up to three locations. In addition, you may also gain exposure to assignments in the safety/ environmental, quality and sourcing arenas. training As a supplement to the day-to-day experiences, Cooper conducts in-depth training workshops. These workshops are taught by experienced Cooper leaders who provide insight on a variety of topics. Operations Leadership Program (OLP) ASSIGNMENT OVERVIEW Manufacturing Engineering • Participate on new product development teams • Develop automation processes • Design and procure equipment and tooling • Improve the manufacturability of products • Resolve capacity and productivity issues • Improve plant layouts and material flows • Assess new/existing manufacturing processes • Develop and implement engineering controls • Participate in noise control or ventilation projects Supply Chain • Develop material flow and control plans • Design material optimization systems • Integrate marketing requirements into manufacturing plans • Develop production schedules • Procure and certify vendors for goods and services • Implement or supervise inventory management systems Manufacturing Variance Program (MVP) • Provide continuous improvement program support and project leadership • Drive performance improvements in manufacturing and/or business processes • Lead Kaizen activities • Map value streams • Develop visual pull or Kanban systems • Implement 5S and cellular manufacturing • Conduct TPM (Total Productive Maintenance) • Manage product line transfers/relocations Plant Supervision • • • • • Supervise and train employees Improve manufacturing practices Execute production schedules Develop and implement quality improvement plans Liaison between functional areas and line employees are you qualified? • • • • • Undergraduate or graduate degrees in mechanical, industrial or electrical engineering fields Relevant manufacturing experience Proven leadership experience Strong interpersonal skills Must be willing to relocate The trade names and brand names contained herein are valuable trademarks of Cooper Industries in the U.S. and other countries. You are not permitted to use the Cooper Trademarks without the prior written consent of Cooper Industries. Cooper Industries plc 600 Travis, Ste. 5600 Houston, TX 77002-1001 P: 713-209-8400 www.cooperindustries.com/careers UniversityRelations@cooperindustries.com ACF101117 Printed in USA 25%