WM_Spring07_Cover.qxd

26/3/07

8:16 pm

Page 1

WIRING

MATTERS

Spring 07 Issue 22

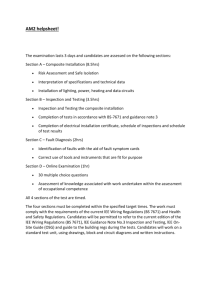

NEW 17TH EDITION TO

BE LAUNCHED IN 2008

Extract fans in dwellings

Competency for persons involved

in electrical installation work

Equipotential bonding

Installing downlighters safely

Uninterruptible power supplies

WM_Spring07_Cover.qxd

9/3/07

3:02 pm

Page 3

8/3/07

10:03 pm

Page 1

17th EDITON

WM_Spring07.qxd

1

NEW 17TH EDITION TO

BE LAUNCHED IN 2008

A BRIEF OVERVIEW

by Geoff Cronshaw

Introduction

BS 7671: 2008 Requirements for

Electrical Installations, IEE Wiring

Regulations 17th Edition is scheduled

to be issued on January 1st 2008 and is

intended to come into effect 6 months

later. The 17th Edition will be

completely restructured compared to

the present 16th Edition and includes

changes necessary to maintain

technical alignment with CENELEC

harmonisation documents. The new

edition will adopt the IEC numbering

system. In addition, the layout and

parts will be completely revised; for

example, many of the chapters will be

completely rewritten. The current

Part 6 (special locations) will become

Part 7 to align with IEC. The next

edition of BS 7671 will include

additional sections on special

locations not currently included in

BS 7671 and the existing special

locations will be revised to align with

changes in CENELEC harmonisation

documents. This article is based on the

draft for public comment and therefore

the actual requirements of the 17th

Edition may change.

against indirect contact becomes fault

protection. Socket- outlets up to 20A for

use by ordinary persons require 30mA

RCD protection and socket-outlets up

to 32A for mobile equipment for use

outdoors require 30mA RCD

protection. Note that certain

exceptions are permitted – refer to

Regulation 411.3.3.

There are new additional

requirements for the connection of

low voltage generating sets including

SSEGs in Chapter 55.

Section 559 Luminaires and Lighting

Installations is a new series of

Regulations concerning lighting

installations and also includes

highway power supplies and street

furniture previously in Part 6.

Chapter 56 has been expanded and

includes requirements for emergency

escape lighting and fire protection

applications.

There are also changes to inspection

and testing. Changes have been made to

the requirements for insulation

resistance; when testing SELV and

PELV circuits at 250 V, the minimum

insulation resistance is raised to 0.5 M;

for systems up to and including 500 V,

(including FELV), the minimum

insulation resistance is raised to 1.0 M.

What’s new?

Part 1 adds requirements to protect

against voltage disturbances and

implement measures against

electromagnetic influences.

Part 3 adds requirements for safety

services, e.g. emergency escape lighting,

and fire protection applications. Also,

Chapter 36 requires that an assessment

shall be made for each circuit of any

need for continuity of service

considered necessary during the

intended life of the installation.

In the new Chapter 41, the terms

protection against direct contact

becomes basic protection and protection

IEE Wiring Matters | Spring 07 | www.theiet.org

8/3/07

5:18 pm

Page 2

17th EDITON

WM_Spring07.qxd

2

Special installations or locations

The next edition of BS 7671 will include

additional sections on special locations

not currently included as follows:

Marinas (Section 709)

Exhibitions, shows and stands

(Section 711)

Floor and ceiling heating systems

(Section 753)

Mobile or transportable units

(Section 717)

Fairgrounds, amusement parks and

circuses (Section 740)

Photovoltaic power systems

(Section 712).

Special locations are areas of

increased shock risk, for example:

Marinas. There are particular risks

associated with electrical installations

in marinas. The environment of a

marina or yachting harbour is harsh for

electrical equipment. The water, salt

and movement of structures accelerate

deterioration of the installation. The

presence of salt water, dissimilar metals

and a potential for leakage currents

increases the rate of corrosion. There

are also increased electric shock risks

associated with a wet environment by

reduction in body resistance and contact

with earth potential.

Exhibitions. There are particular

risks associated with exhibitions,

shows and stands. These arise from:

1. The temporary nature of the

installation

2. Lack of permanent structures

3. Severe mechanical stresses

4. Access to the general public.

Changes to the Existing Requirements

for Special Locations

The current special locations contained

in the IEE Wiring Regulations will be

revised to align with the latest IEC and

CENELEC standards.

For example, the requirements for

locations containing a bath or a shower

unit will require 30mA RCD protection

on all circuits in a bathroom/shower

room. Zone 3 is no longer defined. Socket

outlets other than SELV and shaver

units are allowed 3 metres horizontally

beyond the boundary of zone 1.

Supplementary equipotential bonding is

no longer required providing main

equipotential bonding is installed in

accordance with Chapter 41.

The requirements for swimming

pools now include fountains and the

zones have changed from A, B, and C

to 0, 1, and 2.

In agricultural and horticultural

premises and construction sites the

reduced disconnection times and 25

volt equation no longer appear. The

UK has retained the use of reduced

low voltage supplies for construction

sites which will continue to be a

requirement in the 17th Edition.

In caravan/camping parks each

socket outlet must now be

individually protected with

overcurrent and RCD protection.

Changes to Appendices

Appropriate changes have been made

to the existing Appendices 1 to 7. In

addition the following new Appendices

are now included:

Appendix 8 Current-carrying capacity

and voltage drop for busbar trunking

and powertrack systems

Appendix 9 Definitions – multiple

source, d.c. and other systems

Appendix 10 Protection of conductors

in parallel against overcurrent

Appendix 11 Effect of harmonic

currents on balanced three-phase

systems

Appendix 12 Voltage drop in

consumers’ installations

Appendix 13 Methods for measuring

the insulation resistance/impedance

of floors and walls to Earth or to the

protective conductor system

Appendix 14 Measurement of fault

loop impedance, consideration of the

increase of the resistance of conductors

with increase of temperature.

Further information

Important: This article is only

intended as a brief overview and only

gives a small number of the changes.

For further information on the 17th

Edition please refer to the IET

website: www.theiet.org/DPC Published by IET Publishing & Information Services Michael Faraday House, Six Hills Way, Stevenage, Herts, SG1 2AY, United Kingdom

Tel: +44 (0)1438 313311 Fax: +44 (0)1438 313465

Sales and Project Coordinator L Hall +44 (0)1438 767351 lhall@theiet.org | Editor G D Cronshaw +44 (0)1438 767384

gcronshaw@theiet.org | Contributing Editors J Ware, M Coles, J Elliott | Design Sable Media Solutions

IEE Wiring Matters is a quarterly publication from the Institution of Engineering and Technology (IET). The IET is not as a body responsible for

the opinions expressed.

©2007: The Institution of Engineering and Technology. All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted in any form or by any means without the permission in writing of the publisher. Copying of articles is not permitted

except for personal and internal use. Multiple copying of the content of this publication without permission is always illegal. Web-offset

printing by Wyndeham Heron, The Bentall Complex, Colchester Road, Heybridge, Maldon, Essex, UK

Co-operating Organisations The Institution of Engineering & Technology acknowledges the contribution made by the following

organisations in the preparation of this publication: British Electrotechnical & Allied Manufacturers Association Ltd – R Lewington,

P D Galbraith, M H Mullins | Department for Communities and Local Government – I Drummond | Electrical Contractors Association – D Locke,

S Burchell | City & Guilds of London Institute – H R Lovegrove | Energy Networks Association – D J Start | Electrical Contractors Association

of Scotland SELECT – D Millar, N McGuiness | Health & Safety Executive – K Morton | Electrical Safety Council | ERA Technology Limited –

M Coates | British Cables Association – C Reed | Scottish Building Standards Agency | DTI – D Tee | CORGI – P Collins | GAMBICA –

K Morris.

ISSN 1749-978-X

IEE Wiring Matters | Spring 07 | www.theiet.org

8/3/07

5:18 pm

Page 4

EXTRACT FANS

WM_Spring07.qxd

4

EXTRACT FANS IN DWELLINGS

by John Ware

Kitchens and bathrooms now are often fitted with

extract fans either to meet the requirements of the

Building Regulations or at the owner’s request. Such

fans will need to be replaced or repaired during the

lifetime of the installation. The IET Helpline often

receives enquiries relating to two aspects of these

fans; the isolation and switching requirements of

BS 7671 and the ventilation requirements of the

Building Regulations.

In this article we will explain briefly the concepts of

isolation and switching and then discuss these

functions in relation to extract fans and in an

upcoming article we will cover the ventilation

requirements placed by Part F of the Building

Regulations.

Isolation and switching.

The term isolation and switching, as used in BS 7671:

2001 Requirements for Electrical Installations (The

IEE Wiring Regulations) refers to four distinct

functions:

Isolation,

Switching off for mechanical maintenance,

Emergency switching, and

Functional switching.

Isolation and switching: The four functions

Isolation:

Purpose:

For:

Switching off for mechanical maintenance:

Purpose:

To enable non-electrical work to be carried out safely on the switched

circuit or equipment

For:

Non electrically-skilled persons

Functional switching:

Purpose:

To enable proper functioning and control of electrical equipment

For:

The user of the installation

Emergency switching:

Purpose:

To cut off rapidly electrical energy to remove an unexpected hazard

For:

Anyone

Table 1: Summary of the four functions of Isolation and Switching

Summary of requirement

The concepts of isolation and switching are

summarized in Table 1.

Isolation

The definition of isolation, in BS 7671 (The IEE

Wiring Regulations) is: ‘A function intended to cut off

for reasons of safety the supply from all, or a discrete

section, of the installation by separating the

installation or section from every source of electrical

energy’. Isolation is provided to permit an electricallycompetent person to work safely on all or part of an

electrical installation. Once electrical equipment has

been securely isolated from the source of energy and

any electrical energy has been discharged, a skilled or

instructed person should be able to safely access parts

that are normally live, or may become live, without

the risk of danger from electric shock, electric arcing

or explosion or from electrically-powered equipment

and machines.

The corresponding definition in the Electricity at

Work Regulations (EWR) adds the specific

requirement that the isolation is to be secure. This

IEE Wiring Matters | Spring 07 | www.theiet.org

To enable electrical work to be carried out safely on the isolated circuit or

equipment

An electrically-skilled or supervised person.

Regulation(s) in BS 7671

and the EWR which refer

Every circuit to be capable of being isolated

461-01-01

Neutral conductor to be capable of being isolated

(with certain permitted exceptions1)

461-01-01

460-01-04

Group of circuits may be isolated by a common means

461-01-01

A means of isolation to be provided as close to the

origin of an installation as possible

460-01-02

476-01-01

Means of isolation to be non-automatic

460-01-01

Means of isolation to be suitably positioned or durably marked

461-01-05

Means of isolation not to be inadvertently or unintentionally energized

461-01-02

Means of isolation may need to be secured in the open position

476-02-02

Requirements where there is more than one device to be operated

461-01-03

514-11-01

Circuits containing stored energy may need to be discharged2

461-01-04

Means of isolation to be secure

EWR (Regulation 12)

Table 2: Principal requirements in BS 7671 and the EWR applicable

to isolation in dwellings

1

A neutral conductor falls within the definition of a live conductor. With permitted exceptions for TN-S and

TN-C-S systems, the neutral conductor is required to be able to be isolated from the corresponding

supply conductor. A means of isolation of the neutral conductor in a TN-S or TN-C-S system is not

generally required where that conductor can reliably be regarded as being at Earth potential. The neutral

conductor (PEN or N) for supplies provided in accordance with the ESQCR 2002 is considered to be

connected with Earth by a suitably low resistance. For a TT system, the neutral conductor as well as the

phase conductor are required to be provided with a means of isolation.

2

Note that motor circuits may include a capacitor such as a start capacitor which would store energy. The

stored energy has to be discharged before work can be undertaken on the circuit.

means the isolated equipment cannot be re-energised accidentally

or inadvertently.

The procedure of ‘Isolation’ includes (a) correct identification

of the equipment and circuit to be worked on, (b) disconnection,

(c) securing the means of disconnection, (d) posting notices and

8/3/07

10:13 pm

Page 5

EXTRACT FANS

WM_Spring07.qxd

5

8

9

*

>Ãi

}

Ì

ÃÜÌV

>

/iÀ

ÕÌ

}

Ì

>Ê>ÃÃiLÞ

iÕÌÀ>

8

9

"/\Ê

ÀVÕÌÊ«ÀÌiVÌÛiÊV`ÕVÌÀÃÊÌÊÃ

Ü

Figure 1: Insertion of a local isolator in the lighting and extract fan circuit for a windowless

bathroom in dwellings

Figure 2: Three-pole isolator which can be

locked off. Courtesy of MK Limited

(e) proving dead. In some cases

additional precautions will also be

needed. Please refer to the HSE

publication: Electricity at Work: Safe

Working Practices.

Requirements applicable to isolation

are given in BS 7671: 2001

Requirements for Electrical

Installations and Regulation 12 of the

EWR and these requirements are

summarized in Table 2.

Isolation of an extract fan

Let us take the case of an extract fan in

a dwelling and assume the installation

is part of a single-phase TT system. The

issue of isolation will arise during the

lifetime of the installation when an

electrician is called in to repair or

replace the extract fan. The electrician

will need to isolate the fan from the

source of energy in order to work safely

on it. As the installation is part of a TT

system, both the phase and neutral

conductors will need to be isolated.

The main switch in the consumer unit

In many dwellings the main switch of

the consumer unit can form a perfectly

adequate means of isolation. In such a

case, the electrician will switch off the

main switch, take precautions that it

will not be inadvertently or

unintentionally switched back on, and

then having verified all the conductors

Local isolator

Often a local isolator, such as a pull

cord switch, a switched fused

connection unit or a switched device

installed outside the bathroom but

next to the door leading in to the

bathroom is provided. Providing the

switch meets the requirements of

isolation, the advantages of using such

a switch are:

of the fan circuit are dead, be able to

work in safety on the fan. The

difficulty that can arise when using

the main switch as the means of

isolation is that it is often remote from

the extract fan and there is a very real

risk of someone inadvertently

switching the supply back on. The

electrician is therefore required to

take adequate precautions against this

happening by means such as securing

the main switch with a padlock or

locking the cupboard or door where

the consumer unit is located and

putting notices.

A circuit-breaker in the consumer unit

In the case of an installation forming

part of a TN system where the

neutral conductor can be regarded as

being reliably connected with Earth,

it may not be necessary to disconnect

both conductors and safe isolation

may be able to be achieved by

isolating the phase conductor by

means such as switching off and

locking off the appropriate circuitbreaker providing the device is

suitable for such use. Note that

putting a bit of insulation tape over a

switched-off circuit-breaker is not

sufficient. Once again, part of the

isolation procedure is to verify that

all conductors are indeed ‘dead’.

1. The electrician may decide it is safe

to isolate the extract fan at this switch

leaving the main switch at the

consumer unit on thereby permitting

operation of other electrical

equipment in the dwelling, for

example, the lighting circuits and the

socket-outlet circuits.

2. Providing the isolator is local to the

extract fan the electrician may decide

there is minimal risk of it being

inadvertently or unintentionally

switched back on while he is working

on the extract fan because he is next to

it and can stop anyone interfering with

it. Securing the means of isolation is

thereby simplified.

Once again, the conductors that are

to be worked on have to be proved

to be dead.

IEE Wiring Matters | Spring 07 | www.theiet.org

8/3/07

10:05 pm

Page 6

EXTRACT FANS

WM_Spring07.qxd

6

Mechanical maintenance

An extract fan should be maintained

periodically and such maintenance

normally includes cleaning as the fan

will almost certainly get dirty. In

order for such maintenance to be

performed safely, a means of

switching off for mechanical

maintenance is to be provided

(Regulation 462-01-01 refers). The

means of switching off is not

necessarily intended to provide

protection against electric shock but

has to reliably stop the fan turning

(Regulation 462-01-03 refers).

Switching off for mechanical

maintenance, in this case, is to enable

non-electrical maintenance to be

performed safely without the risk of

injury from mechanical movement.

The demands of safety are such that

the same means of preventing

unintentional or inadvertent reclosure

of the switch must be provided as for

the function of isolation. The means

provided for the function of isolation

will, in almost all cases, be sufficient

to meet the requirements for

switching off for mechanical

maintenance.

Functional switching

Functional switching is an operation

intended to switch ‘on’ or ‘off’ or vary the

supply of electrical energy to all or part

of an installation for normal operating

purposes. The purpose of functional

switching is to enable current-using

equipment, such as an extract fan, to be

controlled for normal operating

purposes. The control may be manual,

such as a simple fan on/off switch or

automatic such as a timer circuit or

variable such as a speed control.

Emergency switching

The provision of emergency switching

requires the identification and

assessment of reasonably foreseeable

dangers. Regulation 463-01-01 refers. An

extract fan in a bathroom or kitchen is

unlikely to cause danger such that an

emergency switch will be required.

IEE Wiring Matters | Spring 07 | www.theiet.org

A mains voltage extract fan may be installed in zone 1, 2 or 3 providing

the additional requirements listed below are met:

Requirement

Zone 11

IP rating

At least IPX4 (Regulation 601-06-01)

RCD protection

30 mA RCD

protection is

required2.

(Regulation

601-09-02)

Zone 2

Zone 3

The fan has to be suitable for the

conditions (Regulation 512-06-01)

Note that Manufacturer’s

instructions for mains voltage fans

may include the recommendation

that 30 mA protection be provided.

Such instructions should be followed.

A SELV extract fan may be installed in zone 1, 2 or 3 providing the requirements

listed below are met:

Source

The safety source, such as the transformer, may have to be installed outside of the zones

(Regulation 601-08)

IP rating

At least IPX4 (Regulation 601-06-01)

The fan has to be suitable for the

conditions (Regulation 512-06-01)

Table 3: Requirements applicable to a fixed extract fan installed in a location containing a bath tub or

shower basin

1

Fixed current-using equipment such as an extract fan may be installed in zone 1 if (i) it is suitable for the conditions of that zone,

(ii) can reasonably only be located in that zone and (iii) RCD protection is provided (See Regulation 601-09-02(iii)).

2

The Residual Current Device used is required to have a rated residual operating current not exceeding 30 mA in accordance with

Regulation 412-06.

Requirement

Zone 1

Zone 2

Zone 3

Outside the

Zones

Outside the

bathroom

Local isolator

permitted?

Isolator operating at mains

voltage not permitted. Only SELV

switches are permitted

(Regulation 601-08-01)

A local isolator may be installed but it

has to be suitable for the conditions

(Regulation 512-06-01)

IP rating

At least IPX4

(Regulation 601-06-01)

Isolator has to be suitable for the

conditions (Regulation 512-06-01)

Table 4: Requirements applicable to a local isolator1 for an extract fan installed in or adjacent to a

location containing a bath tub or shower basin

1

Note that plate-type switches are unlikely to have a suitable IP rating and will need to be installed in zone 3 or outside the zones.

Often such switches are installed on the outside of the bathroom but next to the door leading into the bathroom. Pull cord switches are

unlikely to have a suitable IP rating and while the pull cord itself may enter zone 1 or 2, providing it is an insulating pull cord, the body of

the switch will have to be installed in zone 3 or outside the zones. Hence, in a bathroom with a ceiling height greater than 2.25 m or 3 m

the body of the pull cord switch may be installed in zone 3 or outside the zones (But see Regulation 512-06-01) and the insulating pull

cord allowed to enter zone 1 or zone 2 (See Regulation 601-02-01 and Figures 601A and 601B in BS 7671).

Windowless bathrooms.

Windowless bathrooms and toilets have

to be fitted with a fan that often includes

a timer circuit to ensure the fan

continues to run for a period after the

light has been switched off. Figure 1

illustrates a typical configuration for a

circuit. The timer unit is often part of

the fan assembly. A two pole isolator

inserted at X-X in the circuit would

effectively isolate the fan and timer unit

but would also isolate the bathroom light

which would result in inconvenience

for the electrician who would then need

to provide a light source.

A three-pole isolator inserted at Y-Y in

the circuit would be preferable as it

would permit the light to be left

energized whilst the fan or timer unit

was being worked on.

The electrican called upon to work on

the timer unit or extract fan has to verify

that the correct circuit has been isolated

and all the conductors are indeed dead

before he starts work as there is a real

risk of incorrect wiring in such a circuit.

WM_Spring07.qxd

8/3/07

5:21 pm

Page 7

THING E

Y

R

E

EV

TRAD ™

e

h

t

for T DAY !

– NEX

iÊiÝÌÀ>VÌÊv>

ÕVÌ}

>Ì

À

Figure 3: Inline extract fan and ducting

Additional requirements applicable to an extract fan

installed in a location containing a bath tub or shower

basin in a dwelling

A fixed extract fan can be installed in a location containing a

bath tub or shower basin providing the additional

requirements listed in Table 3 are met.

The requirements given in Table 4 are required to be met for

a local isolator installed in or adjacent to a location containing

a bath tub or shower basin.

Supplementary bonding

Where a mains voltage fan or its local isolator, if any, is

installed in zones 1, 2 or 3, local supplementary bonding has to

be provided connecting together the protective conductor of

the fan circuit and extraneous-conductive-parts in these zones

(Regulations 601-04-01 and 601-04-02 refer).

Inline extract fans

Inline extract fans providing air extraction through ducting

are often installed in the loft above a bathroom to provide

bathroom ventilation as illustrated in Figure 3. An extract fan

mounted in the loft above the bathroom is not ‘in the

bathroom’ and hence is not subject to the supplementary

requirements placed by Section 601 of BS 7671. Note that the

fan is, of course, subject to the general requirements contained

in the other Parts of BS 7671. S

W

E

R

SC INGS

FIX OLS

O

T

&

ders,

l

i

u

b

r

ge fo ans

n

a

r

ssive electrici ices.

a

m

r

A

,

nters at trade p

e

p

r

a

c

s

mber for your

u

l

p

&

e NOW

Phon atalogue.

c

FREE

S

PRICE

E

D

A

S

TR

DUCT

O

R

P

0+

14,00

IVEReYtails

L

E

D

AY ewfix.com for d

D

T

X

NE ns. See scr

ptio

ery o

deliv

y

a

d

Next

OVER

950

PAGES

our

y

t

e

G

Ee

E

R

F talogu

a

c

W!!

OW

N

NO

1

4

1

0

6

9

0

m

o

0

c

0

08 ewfix. nters

scr rade Cou

T

ons

locati

rs for

te

n

u

co

307

/trade

IRING

.com

te: W

ewfix

e quo

r

s

c

a

s

le

P

Go to

IEE Wiring Matters | Spring 07 | www.theiet.org

8/3/07

11:12 pm

Page 8

COMPETENCY

WM_Spring07.qxd

8

COMPETENCY FOR

PERSONS INVOLVED

IN ELECTRICAL

INSTALLATION WORK

by Jon Elliott

Introduction

The IET technical advice line often

receives calls relating to the

competency of persons carrying out

electrical installation, maintenance,

inspection & testing and similar

activities and what qualifications are

required to be classed as an

“electrician”. The helpline often takes

enquiries from persons currently

working as electricians who have no

formal qualifications who now wish to

find an appropriate qualification, and

from those who wish to enter the

electrical industry from a wide range

of backgrounds.

A number of typical questions

relating to competency, qualifications

and training for electricians are given

below with appropriate answers.

What is an electrician?

The term electrician is generic, has no

legal status and is in no way protected.

Anyone may refer to themselves as

IEE Wiring Matters | Spring 07 | www.theiet.org

being an electrician. As such, the term

is no indicator of a person’s level of

training, technical qualifications

achieved, or the extent of relevant work

experience accumulated - all factors

which will affect a person’s ability to do

electrical work properly. The ability to

perform a particular task properly is

defined as competency. Generally

speaking, a suitably qualified and

competent electrician should be able to

perform a wide range of installation

activities in domestic, industrial and

commercial installations. Persons

wishing to employ an electrician

should ask for some evidence of their

competency. This might include

production of certificates obtained

from successful completion of

recognised training at a technical or

further education college, a Joint

Industry Board Electrotechnical

Certification Scheme card, or proof of

membership/affiliation with a

recognised industry body.

What are the legal requirements?

The Electricity at Work Regulations

1989 imposes duties on persons

involved in electrical work

commercially whether employers, the

self employed or employees, including

most trainees.

Regulation 16 (Persons to be

competent to prevent danger and

injury) states:

“No person shall be engaged in any

work activity where technical

knowledge or experience is necessary to

prevent danger or, where appropriate,

injury, unless he possesses such

knowledge or experience, or is under

such degree of supervision as may be

appropriate having regard to the

nature of the work.”

It is stated in the Memorandum of

guidance on the Electricity at Work

Regulations 1989 (HSE: 1989) that “the

object of the regulation is to ensure

that persons are not placed at risk due

to a lack of skills on the part of

themselves or others in dealing with

electrical equipment”.

It continues: “the scope of ‘technical

knowledge or experience’ may include:

(a) adequate knowledge of electricity;

(b) adequate experience of electrical

work;

(c) adequate understanding of the

system to be worked on and practical

experience of that class of system;

(d) understanding of the hazards

which may arise during the work and

the precautions which need to be

taken;

(e) ability to recognise at all times

whether it is safe for work to

continue.”

What qualifications are needed to

become an electrician?

People have come into the electrical

installation industry from a number of

routes and may have a number of

different electrically-biased

qualifications.

8/3/07

11:14 pm

Page 9

COMPETENCY

WM_Spring07.qxd

9

Concentrating on electrical

installation work, typically persons

wanting to become electricians

complete a City & Guilds qualification.

Over the years, City & Guilds has

offered a number of qualifications

which provided the knowledge

evidence requirements for electrical

trainees:

- 236 part “A” and “B” certificates (not

available since the late seventies)

- 2360 part 1 (not available since

October 2006) and part 2 (no longer

available from October 2008)

- 2330 part 1 and 2 certificates (both

available from September 2004)

All of the above could, and in the

case of the 2330 can, be studied by

persons not directly employed in the

electrical installation industry.

What subject updating and

further development qualifications

are available?

For persons who have been employed

in the electrical industry for some

time and who have no electrical

qualifications, or who qualified prior

to the advent of the 16th Edition, the

most appropriate subject updating or

“refresher” course is probably the City

& Guilds 2381 “16th Edition”

certificate. Those wishing to refresh

and/or improve their skills in relation

to the inspection, testing and

certification of an installation may

choose to take the City & Guilds 2391

Inspection & testing certificate, which

may also be beneficial to those

wanting to be graded as an Approved

Electrician on the Joint Industry

Board (JIB) Electrotechnical

Certification Scheme, or who wish to

become a Qualified Supervisor for an

NICEIC Approved Contractor or ECA

registered company.

What about persons wishing to

become electricians having

qualifications that are not electrical

installation work specific?

Many persons have entered the

industry having successfully

completed electrically biased BTEC

(and later Edexcel) National Certificate

or diploma courses or other

electrically related qualifications. In

the case of qualifications other than

those provided by City & Guilds listed

above an assessment will have to be

made of their suitability in terms of

providing the necessary knowledge

base for someone involved in electrical

contracting if they wish to obtain a

JIB grading or become affiliated with

other electrical organisations.

However, qualifications primarily

relating to electronics and/or

computing even if at a notionally

higher level in the National

Qualifications Framework may not be

suitable without the addition of some

electrical installation specific

training/experience.

What is the National Qualifications

Framework?

The National Qualifications

Framework categorises all accredited

qualifications on a scale ranging from

entry level through to level 8. In the

field of electrical installation work

levels 2, 3 and 4 are of relevance.

Broadly speaking, level 2 is “first

certificate” level, will cover a narrow

range of work activities and in many

cases may be awarded as an interim

stage on the way to becoming fully

qualified in a particular occupation.

Completion of part 1 of the City &

Guilds 2360 or 2330 qualifications will

result in the award of a level 2

certificate. Level 3 is “craft” level, or

the level required to be competent in a

particular occupation. Completion of

part 2 of the City & Guilds 2360 or 2330

qualifications will result in the award

of a level 3 certificate. Level 4 would

equate to technician level and as such

falls beyond the remit of this article.

Companies or persons carrying out

electrical work in domestic premises

were required to either notify the

relevant Building Control department

for the area where notifiable work was

being carried out prior to starting

work or to become registered as

domestic installers. A qualified

electrician generally met the

requirements to become a registered

domestic installer. However, many

persons carrying out work activities in

domestic premises requiring a degree

of work on the electrical installation,

such as central heating installers and

kitchen fitters did not. As such there

was a need for a recognised

qualification to be developed that

would provide “non electricians” with

the necessary knowledge and skills to

be considered competent for such

work. The examination board EMTA

Awards Ltd (EAL) developed a level 2

qualification for domestic electrical

installers in conjunction with a

What is a domestic installer?

In 2005 the Building Regulations as

applied to England and Wales were

modified to include requirements for

domestic electrical installations.

IET Wiring Matters | Spring 07 | www.theiet.org

8/3/07

9:17 pm

Page 10

COMPETENCY

WM_Spring07.qxd

10

number of interested parties from the

electrical industry. It should be

remembered that due to the limited

course content of this qualification,

successful completion does not meet

the requirements of any electrical

organisation for grading as an

electrician.

What is an Electrical Apprenticeship?

When school leavers wish to become

electricians the best route into the

industry is via an apprenticeship. This

will normally take 3 to 4 years to

complete. The apprentice will receive

practical “on the job” work experience

and training throughout this time and

will be given opportunities to be more

involved in work as time progresses

and their skills and abilities develop.

During the first three years, they

attend a further education college on a

day-release basis (that is, attending

one day per week during college term

time) where the knowledge obtained in

the workplace is reinforced by

instruction and training. They will

also receive key skills training for

communication, application of

number, information technology,

working with others, improving

learning and performance and

problem solving. On completion of

their studies at college they receive a

technical certificate and take the

Achievement Measurement 2 (AM2)

timed practical assessment and with

the assistance of their employer

compile a site based logbook in order

to obtain their level 3 National

Vocational Qualification (NVQ) or

Scottish Vocational Qualification

(SVQ) as appropriate.

What are the JIB Grading requirements?

Electrician

In order to be registered as an

electrician with the Joint Industry

Board for the Electrical Contracting

Industry (JIB) a person must:

have been a registered apprentice or

undergone some equivalent method of

training and have had practical

IET Wiring Matters | Spring 07 | www.theiet.org

training in electrical installation

work, and

have obtained an NVQ / SVQ Level 3

in electrical installation work (or

approved equivalent such as successful

completion of the City & Guilds 2360

part 2 certificate and have passed the

Achievement Measurement 2 (AM 2),

or be able, with the application for

Grading and any other relevant

supporting evidence (i.e. the City &

Guilds Electricians' Certificate) which

may be required, to satisfy the

Grading Committee of his experience

and suitability), and

be 21 years of age (this requirement

may be waived if the applicant has

obtained a pass in the City & Guilds

2360 Electrical Installation Theory

Part 2 Course or approved equivalent),

in addition to the above

Electricians are expected to be able

to carry out electrical installation

work efficiently in accordance with

the National Working Rules for the

Electrical Contracting Industry, the

current IEE Regulations for Electrical

Installations, and the Construction

Industry Safety Regulations.

Approved Electrician

In order to be registered as an

Approved Electrician with the JIB a

person must have met the

requirements to be graded as an

electrician above and must

additionally:

have had two years experience as an

electrician subsequent to the

satisfactory completion of training

and immediately prior to the

application for the Approved

Electrician grade, or be 22 years of

age, whichever is the sooner, and

have demonstrated competence and

obtained a suitable qualification (such

as the City & Guilds 2391 qualification)

in the inspection, testing and

commissioning of installations.

Approved Electricians are expected:

to possess the practical, productive

and electrical engineering skills with

adequate technical supervisory

knowledge so as to be able to work on

their own proficiently and carry out

electrical installation work without

immediate supervision in the most

efficient and economical manner

be able to set out jobs from

drawings and specifications and

requisition the necessary installation

materials

be able to accept responsibility for

the proper completion of jobs and,

if required, supervise other

operatives.

References

Electricity at Work Regulations 1989

(HMSO: 1989)

Memorandum of guidance on the

Electricity at Work Regulations 1989

(HSE: 1989)

Requirements for Grading of Electrical

Operatives. (Joint Industry Board:

2006-2007)

Further Information

Qualifications

In general

- Qualifications and Curriculum

Authority: www.qca.org.uk

Electrical installation work

- City and Guilds: www.city-andguilds.co.uk

Domestic electrical installer

- EMTA Awards Ltd: www.eal.org.uk

Apprenticeships

In England and Wales

- JTL: www.jtlimited.co.uk

- Modern Apprenticeships:

www.apprenticeships.org.uk

In Northern Ireland

- The Electrical Training Trust:

www.ett-ni.org

In Scotland

- The Scottish Electrical Charitable

Training Trust: www.sectt.org.uk

- The Scottish Enterprise:

www.scottish-enterprise.com/

modernapprenticeships

Electrotechnical Certification Scheme

- Joint Industry Board: www.jib.org.uk 8/3/07

11:28 pm

Page 12

BONDING

WM_Spring07.qxd

12

equipment exposed-conductive-part

and the simultaneously accessible

extraneous-conductive-part is:

Uf = If R2

Where:

If is the fault current

R2 is the resistance of the circuit

protective conductor.

(Ignoring any reactance of the circuit

protective conductor, and any small

effect of current flowing in the main

equipotential bonding conductor)

The effect of connecting the main

equipotential bonding conductor to the

extraneous-conductive-part is to

minimise Uf . Without this conductor,

the potential difference would

approximate to the voltage drop

produced by If along the full length of

the earth return path, and this could

be significantly greater than (If R2).

Therefore, failure to install all

necessary main equipotential bonding

conductors within an installation will

certainly increase the shock risk

associated with indirect contact.

Equipotential Bonding

by Geoff Cronshaw

Introduction

BS 7671: 2001 (incorporating

Amendments No 1: 2002 and No 2: 2004)

has requirements for protection

against electric shock, and lists a

choice of five basic measures which

shall be used to protect against

indirect contact. Protection by earthed

equipotential bonding and automatic

disconnection of supply is the most

common measure. Its purpose is that

under earth fault conditions, voltages

between simultaneously accessible

parts are not of such magnitude and

duration as to be dangerous.

IET Wiring Matters | Spring 07 | www.theiet.org

Main equipotential bonding

Regulation 413-02-02 requires main

equipotential bonding to be carried

out. Its importance is often

underestimated (see Figure 1). An

earth fault in the current-using

equipment produces a fault current

(If) which flows along the circuit

protective conductor and back to the

source. A small proportion of the

current may flow through the main

equipotential bonding conductor

directly to earth, and then back to

the source.

The potential difference between the

Installation of main equipotential

bonding conductors

IEE Guidance Note 5 recommends

that main equipotential bonding

conductors should be kept as short as

practicable and be routed to minimise

the likelihood of damage or

disturbance to them. The connections

to gas, water and other services

entering the premises must be made

as near as practicable to the point of

entry of each service, on the

consumer’s side of any insulating

section or insert at that point or any

meter. Any substantial extraneousconductive-part which enters the

premises at a point remote from

the main earthing terminal or bar

must also be bonded to this terminal

or bar.

Extraneous-conductive-parts should

preferably be bonded using individual

main equipotential bonding

8/3/07

9:31 pm

Page 13

BONDING

WM_Spring07.qxd

13

conductors. Alternatively, two or more

such parts may share a main

equipotential bonding conductor, but

where this arrangement is employed

the conductor should be continuous,

i.e. disconnection of the conductor

from one extraneous-conductive-part

must not interfere with or endanger

the security of the bonding of the

other part(s).

Regulation 547-02-01 and Table 54H of

BS 7671 gives sizing requirements for

main equipotential bonding

conductors. However, it is

recommended that the electricity

distributor or supplier should be asked

to confirm their agreement to the

proposed size(s) it is intended to

install.

Regulation 514-13-01(ii) requires a

permanent label to be fixed at or near

the point of connection of every main

equipotential bonding conductor to an

extraneous-conductive-part.

Supplementary equipotential bonding

BS 7671 also has requirements for

supplementary equipotential bonding,

which includes installations and

locations of increased shock risk such

as rooms containing a bath or shower,

as shown in Figure 3.

Where supplementary equipotential

bonding is applied in a particular

location within an installation, e.g. a

bathroom, it has the effect of reestablishing the equipotential

reference at that location for all the

exposed-conductive-parts and

extraneous-conductive-parts which

are bonded together locally. This

further reduces any potential

differences that may arise between

any of these parts during an earth

fault.

current-using

equipment

origin

of

installation

L

<2 m

Uf

N

main earthing

terminal

~

– If

R2

If

circuit

protective

conductor (cpc)

E

extraneous-conductive-part

main equipotential

bonding conductor

earth

Figure 1: Illustration of main equipotential bonding

Figure 2: PME supply (TN-C-S system) Schematic of earthing and main equipotential

bonding arrangements. Based on 25 mm2 tails and selection from Table 54G.

Note: An isolator is not always installed by the electricity distributor.

Ceiling

metal

pipe

luminaire

Pull cord switch

Outside Zones

Zone 2

Zone 3

shower

Switch

for fire

Radiant fire

Cord

3.0 m

Zone 1

Zone 2

Shaver

unit

Zone 3

2.25 m

Zone 0

Outside Zones

metal pipes

*

metal waste

Further information.

For more information on earthing

and bonding refer to IEE Guidance

Note 5. Also a new IEE Guidance Note

8 specifically on earthing and

bonding is due to be published shortly

by the IET. exposed-conductive-part

0. 6 m

2. 4 m

* Zone 1 if the space is accessible without the use of a tool.

Spaces under the bath, accessible only with the use of a tool, are outside the zones.

Figure 3: Supplementary bonding in a bathroom - metal pipe installation with soldered joints

providing reliable electrical continuity

IET Wiring Matters | Spring 07 | www.theiet.org

9/3/07

12:31 am

Page 14

DOWNLIGHTERS

WM_Spring07.qxd

14

Installing Downlighters Safely

Following these steps should ensure a

downlighter will not pose a risk of fire

due to overheating

1. Only use downlighters that conform

to BS EN 60598, the British Standard

for Luminaires and ensure the

requirements of BS 7671 are met

2. Follow the Manufacturer’s

instructions

3. Ensure the requirements of the

Building Regulations (England and

Wales) are met

4. Provide space around the

downlighter

5. Fit the correct lamp

1. EN 60598. International Standard

EN 60598 specifies general

requirements for luminaires

incorporating electric light sources for

operation from supply voltages up to

1 000 V. The requirements and related

tests of this standard cover all aspects

of safety including electrical, thermal

and mechanical in the areas of

classification, marking, mechanical

IET Wiring Matters | Spring 07 | www.theiet.org

construction and electrical

construction.

BS 7671 Requirements for Electrical

Installations requires, in Regulation 511,

that electrical equipment, which includes

luminaires, conforms to an applicable

Standard. Section 422 of

BS 7671 gives requirements for protection

against fire and harmful thermal effects

and Regulation 422-01-02 applies to fixed

electrical equipment such as a

downlighter that, in normal operation,

has a surface temperature sufficient to

cause a risk of fire or harmful effects to

adjacent materials. The Regulation gives

three methods of preventing danger

which are (i) mounting within a suitable

enclosure, (ii) screening or (iii) provision

of sufficient distance from adjacent

material. Refer to the Regulation for full

details.

2. Manufacturer’s instructions. The

manufacturer’s instructions supplied

with the downlighter must be followed.

The Manufacturer may require a

by John Ware

certain amount of space be left around

the back of the downlighter or that the

downlighter must not be covered with

loft insulation, or only lamps of a

particular type and maximum wattage

be fitted or that a fire hood or

intumescent hood be installed.

3. Building Regulations (England and

Wales). The installer must be aware of

the requirements of the Building

Regulations in England and Wales

before installing a downlighter. For

example, before cutting a hole in the

fabric of the building the installer

must ensure that the structural

integrity, fire resistance or other

aspects of the structure are not

compromised. Approved Document B

gives guidance on the precautions to

be taken to inhibit the spread of fire

within a building. Approved Document

A deals with structure and the basic

requirement is that persons installing

electrical equipment must not cut,

drill, chase, penetrate or in any way

interfere with the structure so as to

8/3/07

5:26 pm

Page 15

DOWNLIGHTERS

WM_Spring07.qxd

15

vÀ

LÝÊvÌÌi`ÊvÊÃÕ>Ì

ÃÌ>i`ÊÊÛ`

Vi}

Õ>Ài

Figure 1: Installing a downlighter

F

in the void between a ceiling and an upstairs floor

L>À`Ê>``i`ÊLiÌÜii

Vi}ÊÃÌÃ

vÌÊÃÕ>Ì

Vi}

Õ>Ài

Figure 2: Installing a downlighter

F

in a ceiling with a loft space above

cause significant reduction in its load

bearing capacity.

Regulation 4(2) states that, on

completion of electrical installation

work, the building (and parts of the

electrical installations in the building

that were not the subject of work)

should be no worse in terms of the

level of compliance with the other

applicable Parts of Schedule 1 to the

Building Regulations than before the

work was undertaken.

For example, one or more

perforations of a ceiling lining

beneath a floor – made to

accommodate recessed lighting or

similar fittings – may have an adverse

effect on that floor’s performance in

terms of its resistance to fire and

sound penetration. Due regard should

therefore be paid to the guidance in

Approved Documents B and E on

the performance of compartment

floors.

Regulation 4(2) also means that,

when extending or altering an

installation, only the new work must

meet current requirements and there

is no obligation to upgrade the

existing installation unless the new

work would adversely affect the safety

of the existing installation, or the state

of the existing installation was such

that the new work could not be

operated safely, or where there is a

requirement to upgrade imposed by

the energy efficiency requirements of

the Building Regulations.

4. Provide space around the

downlighter. A downlighter can

develop significant heat and sufficient

space must be provided around it.

When installing the downlighter in

the void between the ground floor

ceiling and the upstairs floor, there

should be sufficient space around the

downlighter as illustrated in Figure 1.

The downlighter used must be marked

with symbol: F . Building debris and

other flammable material must be

removed from the void. Cables must be

IET Wiring Matters | Spring 07 | www.theiet.org

8/3/07

5:27 pm

Page 16

DOWNLIGHTERS

WM_Spring07.qxd

16

Dichroic:

Light away from luminaire

Heat back to luminaire

GZ10 holder

Aluminised:

Light and heat away

from luminaire

GU10 holder

GZ10 holder:

Accepts GZ10 & GU10 lamps

GU10 holder:

Only accepts GU10 lamps

V

cool

Li>

beam

Figure 4: Cool beam or dichroic lamps forbidden

dichroic

`

reflector

aluminium

reflector

Figure 3: GU10 and GZ10 bases

secured such that they do not come

into contact with the hot surfaces of

the downlighter.

When installing a downlighter in a

ceiling with a loft space above,

precautions must be taken to ensure

that loft insulation or other material

does not surround or come into

contact with the downlighter.

Installing a board between two joists

as shown in Figure 2 will, and running

the loft insulation over the top of the

board will, in most cases, ensure

sufficient air space around the

downlighter. Once again the

downlighter used must be marked

with the symbol: F .

5. Fit the right lamp. Many

downlighters are designed either for

use with 230 V dichroic lamps fitted

with GZ10 caps or aluminised lamps

fitted with GU10 caps. (See above).

As can be seen in Figure 3 a GZ10

holder will accept lamps having a GZ10

cap and lamps having GU10 cap. A

GU10 holder will only accept lamps

with a GU10 cap due to the chamfer.

A luminaire employing a dichroic

lamp will run hotter than an

equivalent luminaire fitted with an

aluminized lamp.

However, lamps that can be purchased

are GZ10 - dichroic and aluminised and

GU10 - dichroic and aluminised. Use of

dichroic lamps in a luminaire designed

for use with aluminised lamps could

create excessive heat within the

luminaire leading to an unsafe situation

and risk of fire.

The European standard EN 60598

presently caters for this situation by

application, on the luminaire, of a

symbol warning against the use of cool

beam lamps (dichroic) (see Figure 4).

It is recognized that many people

will not know what the above symbol

means nor will they know the

difference between dichroic lamps and

aluminised lamps. To avoid the

occurrence of unsafe situations the

Lighting Association advises its

members to supply only luminaires

suitable for both applications i.e. even

if fitted with a GU10 holder the

luminaire design should accommodate

the additional heat produced by the

possible use of a dichroic lamp. A serious fire occurred in a listed building when a new lamp was fitted in a

downlighter that had not been working for years.

In the attic above, an old oily coat had been thrown down and was partially

covering the non-working downlighter. The heat generated by the new lamp set fire

to the coat and destroyed the upstairs and roof of the property.

IET Wiring Matters | Spring 07 | www.theiet.org

8/3/07

5:28 pm

Page 21

UPS

WM_Spring07.qxd

21

UNINTERRUPTIBLE

POWER SUPPLIES

by Mark Coles

The aim of this article is to give an overview of uninterruptible

power supplies and how to meet the requirements of BS 7671.

What is an uninterruptible power

supply (UPS)?

Fundamentally, an uninterruptible

power supply, or UPS, is a unit which

maintains the electrical supply to a

piece of equipment, or load, following

the failure of the primary source of

supply. The UPS is, therefore, installed

between the source of the electrical

supply and the load.

BS EN 62040-1-1:2003 defines a UPS

as a combination of converters,

switches and energy storage devices

(for example, batteries), constituting a

power system for maintaining

continuity of load power in case of

input power failure.

Static Static UPS systems deliver the

output voltage derived from a stored

source, e.g. a series of batteries

through an inverter.

With a static UPS there will be “no

visible” loss of supply to the load

when the mains supply is lost; the

following, figure 1, shows an example

of the layout of a static UPS system

Rotary Rotary UPS systems consist of

one, or more, electrical rotating

machines to provide the output

voltage, e.g. a generator or multiplesynchronised generators.

Bypass

switch

Electrical

mains supply

UPS

unit

AC output

(Load)

Inverter

Rectifier

Are there different types of UPS?

Fundamentally, there are two

categories of UPS – rotary systems

and static systems.

Under normal circumstances, the

electrical supply can be routed directly

through to the load whilst the rectifier

“rectifies” the a.c. supply to d.c. to

charge the storage batteries.

In the event of loss of the electrical

supply, d.c. from the batteries is

inverted back to a.c. and will supply

the load; the bypass switch opens and

stops the inverted UPS supply from

being routed back to the origin of the

installation. This is known as a passive

standby system.

The bypass switch can be used for

another function. Should the electrical

supply to the installation, or load, be

non-sinusoidal, e.g. the harmonic

content is such that the supply

waveform is no longer considered to be

sinusoidal, the UPS unit may be used as

a “smoothing” device and clean up the

supply for use on sensitive or vulnerable

equipment and critical loads. In reality,

the batteries will be charging whilst

supplying the load. This is known as an

active standby system. Operation in this

mode will also compensate for dips or

surges in the supply.

Static UPS systems are available in

many different sizes, ranging from very

small and simple to very large and

complex. Small and autonomous

systems are available providing circa

1kVA; large UPS units can be paralleled

to provide, in excess of, 1MVA.

Storage

Batteries

Figure 1: Example of a static UPS system

IET Wiring Matters | Spring 07 | www.theiet.org

8/3/07

5:29 pm

Page 22

UPS

WM_Spring07.qxd

22

Bypass

switch

Electrical

mains supply

Diesel

engine

Point of isolation for both supplies

(see Regulation 460-01-02)

AC output

(Load)

Generator

Figure 2: Example of a rotary UPS system

The rotary UPS system generally

sits dormant until it is required.

Control equipment will sense the loss

of mains supply and switch the

installation over to be supplied by the

generator. Usually, there will be a

period of time when the load is

without a supply; this could be a

period of seconds, even minutes,

whilst the prime-mover starts and the

generator attains full speed. This

known as the automatic load transfer

time. Figure 2, shows the layout of an

installation with a back-up generator

or rotary UPS.

The requirements of BS 7671

Isolation and switching

A UPS is a source of energy and, to

comply with Regulation 460-01-01, a

non-automatic means of isolation and

switching should be installed to

disconnect the source from the load.

BS 7671 lists four types of switching –

Isolation, Switching off for

mechanical maintenance, Emergency

switching and Functional switching.

The concepts of isolation & switching

are examined here:

The definition of isolation is:

Isolation

A function intended to cut off for

reasons of safety the supply from all,

or a discrete section, of the

installation by separating the

installation or section from every

source of electrical energy.

The definition of a switch is:

IET Wiring Matters | Spring 07 | www.theiet.org

Switch

A mechanical device capable of

making, carrying and breaking

current under normal circuit

conditions, which may include

specified operating overload

conditions, and also of carrying for a

specified time currents under specified

abnormal circuit conditions such as

those of short-circuit. It may also be

capable of making, but not breaking,

short-circuit currents.

Regulation 460-01-02 requires that where

an installation is supplied from more

than one source, a main switch shall be

provided for each source of supply and

a durable warning notice shall be

permanently fixed in such a position

that any person seeking to operate any

of these main switches will be warned

of the need to operate all such switches

to achieve isolation of the installation.

Alternatively, a suitable interlock

system shall be provided.

Characteristics of supply

As with any installation, it is a

requirement of BS 7671 that the nature

of the supply parameters are assessed,

e.g. Ze (Ω) and Ipf (A); UPS systems,

which are a source of supply, are no

exception.

Further, Regulation 551-02-02

requires that the prospective shortcircuit current and prospective earth

fault current shall be assessed for each

source of supply or combination of

sources which can operate

independently of other sources or

combinations.

Protection against electric shock

An important aspect of providing

protection against indirect contact

which can be readily overlooked by the

designer is the need to ensure

satisfactory operation of the relevant

protective device(s) when the

installation, or part thereof, is

energised from a UPS. To be certain

that the requirements of BS 7671 for

protection against electric shock (and

short-circuit) will still be satisfied, the

designer must obtain full information

for the alternative supply and make

the necessary checks of the design,

which will have been based upon the

characteristics of the normal supply

source.

Regulation 551-04-04 requires that

where the conditions for automatic

disconnection of Regulation 413-02

cannot be achieved for parts of the

installation on the load side of the

static inverter, supplementary

equipotential bonding shall be

provided on that side in accordance

with Regulations 413-02-27 and 413-0228. The resistance (R) of the

supplementary equipotential bonding

conductor between simultaneously

accessible exposed-conductive-parts

and extraneous-conductive-parts shall

fulfil the following condition:

R≤

50

I

where: I is the maximum fault current

which can be supplied by the static

inverter alone for a period of up to 5 s.

Further, Regulation 551-04-05 states

that precautions shall be taken or

8/3/07

5:30 pm

Page 23

UPS

WM_Spring07.qxd

23

equipment shall be selected so that the

correct operation of protective devices

is not impaired by direct current

generated by a static inverter or by the

presence of filters.

Protection against overcurrent

Regulation 551-05-01 requires that

where means of detecting overcurrent

of the generating set is provided, this

shall be located as near as practicable

to the generator terminals. A

generator control panel or UPS

equipment may include selfprotection, a feature of which is the

rapid collapse of output voltage to the

load. This will inhibit the operation of

any fault protective device situated

beyond the equipment terminals and

the feature cannot be assumed to

provide a fail-safe operational

arrangement for the user. Safety of

the system as a whole must be

ensured by, if necessary, involving the

equipment supplier.

Earth electrode

Regulation 551-04-03 requires that

protection by automatic disconnection

of supply shall not rely upon the

connection to the earthed point of the

distributor’s network when the

generator is operating as a switched

alternative to a TN system. A suitable

earth electrode shall be provided.

Clause 18.2.1 of BS 7430 states

generator earthing calls for the

provision of an independent earth

electrode. It is necessary that the earth

loop impedance at any point of the

installation is low enough to ensure

operation of the earth fault protection,

and this should be taken into account

when the earth electrode forms part of

the earth fault loop. For independent

earth electrodes associated with the

local earthing of the star point of

generating plant, it is recommended

that the earth resistance should not

exceed 20 Ω.

Supplies for safety services

Safety services, such as fire alarm

systems, sprinkler systems, etc., are

often supplied by UPS systems as loss

of supply to such equipment could

result in loss of life. BS 7671 defines a

safety service as an electrical system

for electrical equipment provided to

protect or warn persons in the

event of a hazard, or essential to their

evacuation from a location.

BS 7671 recognises that UPS

systems may operate in a parallel

configuration. Regulation 566-01-01

requires that protection against shortcircuit and against electric shock

shall be provided whether the

installation is supplied by either of

the two sources or by both in parallel.

Further, Regulation 566-01-02 requires

that precautions are taken to limit

circulation currents, particularly that

of third harmonics or multiples

thereof, in the connection

between the neutral points of

sources.

Harmonic distortion

Static UPS systems may create

harmonics on the sinusoidal

waveform. Other than selecting the

use of low harmonic-producing

equipment, there are two recognised

methods of reducing harmonic

content; install harmonic filters

which are suited to the load of the

UPS or increase the size of the

neutral conductor. Regulation 524-0202 requires that the neutral conductor

is adequately sized to carry the

maximum current likely to flow in it

under normal operating conditions.

IET Wiring Matters | Spring 07 | www.theiet.org

8/3/07

10:19 pm

Page 24

UPS

WM_Spring07.qxd

24

Small systems

Some small UPS systems, circa 1kVA,

can be unearthed and effectively

operate as an electrically separated

system. Note that certain items of

equipment require a reliable

connection to the means of earthing to

operate, i.e. filters within the switchmode power-supplies of personal

computers. Prior to connecting

equipment to a UPS, it must be

ensured that the equipment is suitable

for operation in such circumstances.

Regulation 413-06-03 requires that

where only a single item of equipment

is supplied in this manner, there

should be no connection between the

separated circuit and any other

circuit, or to Earth. The flexible

cable/cord supplying the load, which

is liable to mechanical damage, should

be visible throughout its length. It is

preferred that a separate wiring

system should be used for the

separated circuit (although multicore

cables without magnetic sheath or

insulated conductors in an insulated

enclosure are permitted if the rated

voltage of the cables is not less than

the highest voltage likely to occur and

each circuit is protected against

overcurrent). Every live part of each

separate circuit shall be electrically

separated from all other circuits to a

standard not less than that provided

between input and output windings of

an isolating transformer to BS 3535.

Regulation 413-06-04 requires that no

exposed-conductive-part of the

separated circuit shall be connected to

either the protective conductor of the

source circuit, or to any exposedconductive-parts of any other circuit.

Other considerations

Prolonged loss of supply

In the UK, some areas are more

susceptible to power cuts than others,

particularly rural areas. Should

inclement weather bring down

overhead power lines, for example, the

mains supply could be interrupted for

IET Wiring Matters | Spring 07 | www.theiet.org

quite some time, perhaps days. A static

UPS would not have the capacity to

supply the load for a period of days

but it would, however, provide enough

time to allow back-up of information

and data during the enforced power

outage. This is known as the autonomy

time. If the installation is located in

such an area, a static UPS system

could be used for short term power

loss with a rotary UPS installed to

provide an alternative long-term backup source.

Storage batteries

Static UPS systems are usually

equipped with storage batteries to

meet the power requirements of the

connected load; large loads require

large battery banks. Small UPS

systems may have maintenance free

batteries but large banks will consist

of one of two types of rechargeable

battery, namely, lead-acid or alkaline.

Lead-acid batteries are the most

commonly used rechargeable battery,

they are found in such applications as

cars, motorcycles and electric vehicles.

Note that the correct battery must be

chosen for the particular application.

Alkaline rechargeable batteries,

such as nickel-cadmium, nickel-metal

hydride and lithium ion, are widely

used in small items such as laptop

computers. Large capacity versions of

these cells are now used in transport

and UPS applications.

There are two different types of

lead/acid and alkaline rechargeable

batteries: valve-regulated

(‘maintenance-free’) and vented. In

valve-regulated batteries, any

hydrogen and oxygen produced during

charging does not escape but is

converted back into water. Water

cannot be added to these batteries as

they do not need topping up. In

contrast, vented batteries allow any

hydrogen and oxygen produced to

escape into the surrounding

atmosphere and they require regular

topping up with water. However,

installation, commissioning and

maintenance should only be carried

out by a competent person trained in

this line of work and experienced with

the particular equipment. Sources of further information

1) BS 7671: 2001 (2004) Requirements

for electrical installations

2) BS 7430: 1998 Code of practice for

earthing.

3) The Selection and operation of

uninterruptible power supplies, HES

107/1996. http://www.hse.gov.uk/

research/crr_pdf/1996/CRR96107.pdf

4) Using electric storage batteries safely.

http://www.hse.gov.uk/pubns/

indg139.pdf

5) BS EN 88528-11:2004 Reciprocating

internal combustion engine driven

alternating current generating sets Part 11: Rotary uninterruptible

power systems - Performance

requirements and test methods

6) BS EN 62040-3:2001 Uninterruptible

power systems (UPS) - Part 3:

Method of specifying the

performance and test requirements

Thanks to Uninterruptible Power

Supplies Ltd. for the images used

http://www.upspower.co.uk