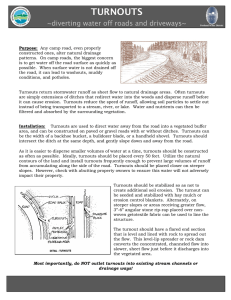

Turnouts and Expansion Switches

advertisement