report of group i

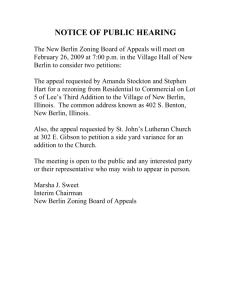

advertisement