Surge Protective Devices

Current Regulatory

and Industry Updates

for Surge Protective

Devices (SPD)

A summary of the new NEC guidelines

for emergency facilities and

renewable energy applications.

The 2008 and 2014 National Electric Code (NEC ) guidelines

have expanded the requirements for where surge protection

devices (SPD) must be used to include emergency facilities

and renewable energy applications.

®

®

Since their proper function can be critical in an emergency or for the proper operation of the electrical grid,

it is important that the correct type of SPD be specified for these applications, so the methods used to test

their operation are important.

Anatomy of a Surge

Electrical surges can cause disruptions in computer signals

and microprocessors, degradation of component junctions

that cause random, delayed failure, or instant damage to

electrical components.

A power surge, or transient voltage, is an increase in voltage

significantly higher than the designated level in a flow of

electricity. In the United States, standard voltage for

residential and commercial structures is 120 volts. When the

voltage rises above this level, damage can occur to sensitive

electronic equipment.

While lightning might be thought to be the major cause of

electrical surges, it actually is one of the least common. Fully

80 percent of surges are caused by internal disturbances,

such as load switching, variable frequency drives, lighting

and HVAC systems. Even though surges from internal

disturbances are usually relatively low in intensity, they can

add up over time, weakening the sensitive circuitry in today’s

electronic devices.

External disturbances, like surges from utility line switching

or lightning, occur far less frequently than internal surges, but

their strength can be devastating. When lightning strikes

close to power lines, the electrical energy can boost electrical

pressure by millions of volts.

2

SPDs are designed to act like pressure-sensitive valves,

diverting this extra current to ground.

Microvaristor

Zinc oxide

Intergrandular

boundary

10 - 50 µm

At the heart of many SPDs are metal oxide varistors (MOV)

that have a crystalline structure inside, containing zinc oxide.

When exposed to over voltage, or a transient surge, the

varistors switch from a nearly open state to a clamping state.

This is enough to bridge the gaps within the crystalline

structure and the MOV becomes an active part of the circuit,

providing an attractive path to ground, protecting the

equipment downstream.

Turn-on Voltage: This is the level at which the MOV begins

to activate.

Both the NEC (in the 2008 and 2014 NEC ) and National

Electrical Manufacturers

Clamping Voltage (also referred to as “let-through

voltage”): This specifies the voltage that will be seen by the

downstream (connected) equipment. Clamping voltages vary

and are directly dependent upon the magnitude of the surge

seen by the SPD. Using the UL 1449 3rd Edition VPR (Voltage

Protective Rating) surge value of 6kV/3kA, a good clamping

voltage for a 120V system would be 700, or 800 volts. A

lower clamping voltage indicates better protection.

Association (NEMA ) specify that SPDs must be used for each

voltage level of the facility’s service entrance and distribution

panels:

®

®

®

• NEC Article 708.20 (D): “Surge protection devices shall be

provided at all facility distribution voltage levels.”

®

• 2014 NEC Article 700.8: “ A listed SPD shall be installed in

or on all emergency switchboards and panel boards.”

®

• NEC Article 240.21 (B) (1): “Where listed equipment, such

as a SPD, is provided with specific instructions on

minimum conductor sizing, the ampacity of the tap

conductors supplying that equipment shall be permitted to

be determined base on the manufacturer’s instructions.”

®

Eliminated Voltage

1,500v

........................................................

150v

........................................................

SPD

Clamped Voltage

Turn on Voltage

Wind Electrical System Protection

The 2014 NEC also specifies that SPDs must be

incorporated into wind-powered electrical supply systems to

prevent damage from surges.

®

Source

Load

Emergency Systems Surge Protection

• NEC Article 694.10 (D) states: “ A SPD shall be installed

between a wind electric system and any loads served by

the premises electrical system.”

®

New NEC guidelines have been established to identify critical

operations power systems (COPS) and to increase protection

and reliability of the power infrastructure for critical facilities.

Critical facilities include any entity that, if damaged, might

disrupt national security, the economy, public health or safety.

Obvious critical facilities would include:

• Law enforcement

• Fire departments

• Military installations

• Hospitals, doctors’ offices

• Financial institutions

• Water and wastewater

• Airports and air traffic control

• Traffic light systems

• All government agencies

3

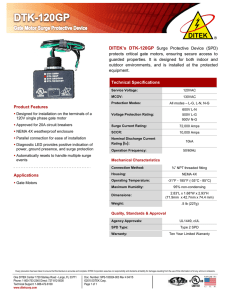

Types of Surge Protection Devices

Type 1 SPD – Line Side

A Type 1 SPD is a permanently connected, hard-wired SPD

that can be installed on the line side of the main service

disconnect. This type of SPD is safe by itself and does not

require external over-current protection.

SPDs for mounting at

Service Entrance

SPDs for mounting on

Panelboards

Type 2 SPD – Load Side

A Type 2 SPD is a permanently connected, hard-wired SPD

intended for installation on the LOAD side of the service

disconnect over-current device, including SPDs located at the

branch panel. They are not safe by themselves, and require

an external fuse or breaker to trip to safely remove them from

the circuit.

SPDs for protection of downstream equipment

Type 3 SPD

Type 3 are point of utilization SPDs, installed a minimum of 10 meters (30 feet) from the electrical service panel, for example

cord connected, direct plug-in (DPI), receptacle type and SPDs installed at the utilization equipment being protected.

Type 4 SPD

Type 4 are component SPDs, including discrete components as

well as component assemblies. They consist of one or more Type

5 components assembled together with a disconnect (integral or

external) as a means of complying with the limited current tests.

Component SPDs

Type 5 SPD

Type 5 SPDs are discrete component surge suppressors (such as MOVs) that may be mounted on a printed circuit board,

connected by its leads or provided within an enclosure with mounting means and wiring terminations.

4

Ensuring Proper Function

Additional Resources

Surge Protection Devices are available in a range of ratings,

depending on the level of protection needed. They are used

to insure that electrical surges do not cause damage to

sensitive electronics. Higher surge ratings provide a higher

level of protection and greater redundancy for ensuring a

longer useful life. However, like any insurance policy, the

higher the level of protection specified, the higher the cost.

Here are some additional resources about the new NEC

guidelines for surge protection in emergency facilities and

renewable energy applications:

The ratings used to classify SPDs can be determined in two

ways:

• Calculated: The surge rating is the sum of all the MOVs in

a given mode or phase; three 50kA MOVs A-N would be

150 kA per mode. However, this does not take into account

design elements that may reduce the surge protection in

real world conditions, such as printed circuit board traces

used as surge current carrying paths in the design of the

SPD.

http://www.nemasurge.org/

The NEMA Surge Protection Institute (NSPI) is an

educational outreach effort initiated by the Low Voltage

Surge Protective Devices Section of the National Electrical

Manufacturers Association (NEMA).

http://www.mikeholt.com/necadoptionlist.php

A listing of each state and the status of NEC adoption.

• Independently verified: An independent testing labora tory

tests the SPD under real-world conditions to measure the

true protection capacity. This ensures the SPD will deliver

the level of protection it claims.

Considering the importance of the COPS facilities being

protected, a third-party laboratory should independently test

any SPD used in these applications.

5

AC Voltage SPD Applications and Location Guide

IEEE C62.41.2-2002 Category C

IEEE: Category C – Service Entrance Exposure

NEC 285 & NRTL: SPD Type 1, 2, or equivalent

Type 4

Type 1

SPD

Line Side

Service Entrance

N&G Bonded (i.e., L-N and L-G are same)

Higher available fault currents require

appropriate SCCR ratings

Historical kA ratings:

Per Phase: 400kA to 200kA per phase

Per Mode: 200kA to 100kA per mode

(Per Phase generally considered Sum of

L-N plus L-G)

Load Side

Type 1 or 2

SPD

Surge Current kA ratings for all

Categories are subjective. Consult

SPD mfg for specific

recommendations

IEEE: Category B – External remnant or

Internally Induced

IEEE C62.41.2-2002 Category B

Line side requires

Type 1 SPD per

NEC 285 & UL 1449

Distribution

NEC 285 & NRTL: SPD Type 1, 2, or equivalent

Type 4

L-N and L-G are different – need L-N, L-G,

and N-G

Require appropriate SCCR ratings

Historical kA Ratings:

Per Phase: 300kA to 100kA per phase

Per Mode: 150kA to 50kA per mode

(Per Phase generally considered Sum of

L-N plus L-G)

UL 96A Lightning

Protection System

SPDs at Service

Entrances require

20kA I-n and UL Mark

Indoor

HVAC (VFD)

Type 1 or

2 SPD

Indoor

Outdoor

Equipment installed outside of the building

could increase exposure level to Category C.

Consider effects of Ground Potential Rises

from direct lightning strikes to earth.

Wind or PV

Generation

Outdoor

Lighting

Type 1 or 2

SPD

Type 1 or

2 SPD

IEEE C62.41.2-2002 Category A

IEEE: Category A, maybe B, maybe C if outdoor

loads are connected

L-N and L-G are different – need L-N, L-G,

and N-G

Require appropriate SCCR ratings

Historical kA Ratings;

Per Phase: 160kA to 100kA per phase

Per Mode: 80kA to 50kA per mode

(Per Phase generally considered Sum of L-N

plus L-G)

Revision Date: April 14, 2014

6

Branch

NEC 285 & NRTL: SPD Type 1, 2, or equivalent

Type 4. Could be Type3.

Branch

“Pre” SPD

(Type 1)

Indoor

Lighting

UPS

(or PDU, PDM)

“Post” SPD

Computers or

Servers

Type 1 or 2

SPD

Outdoor

Lighting

Images depected herein are for demonstration purposes. Each facility is different and user

needs may vary. Adjust accordingly, based on equipment value and/or downtime expenses.

Provided by NEMA

Relevant SPD Standards (1000V and Less):

• ANSI/UL 1449 – Surge Protective Devices

• UL 1283 – EMI/RFI Filtering

• ANSI/IEEE C62.41.1-2002 – Guide on Surge Environment

• ANSI/IEEE C62.41.2-2002 – Characterization of Surges

• ANSI/IEEE C62.45-2002 – Testing

• IEEE C62.62-2010 – Testing

• IEEE C62.72-2007 – Application Guide

Gen Set

ATS / STS

Type 1 or 2

SPD

Load side of the Switch protects

Service and Gen Set

Distribution

Type 1 or 2

SPD

Type 1 or 2

SPD

MCC

Type 1 or 2

SPD

Outdoor

HVAC (VFD)

Busway

Type 1 or 2

SPD

Type 1 or 2

SPD

Type 1 or 2

SPD

Protect both ends of the busway against reflections

Establishes a new reference to ground, like a service entrance.

L-N only may be sufficient

Type 3

SPD

Type 1 or 2

SPD

Separately Derived System

Small or Office

Equipment

Type 1 or 2

SPD

Branch

Type 1 or 2

SPD

Indoor

Branch

Outdoor

Type 1 or 2

SPD

Outdoor

Equipment

Type 1 or 2

SPD

Equipment

Type 1 or

2 SPD

Series

SPD

Equipment installed outside of the building could increase exposure level to Category C.

Consider effects of Ground Potential Rises from direct lightning strikes to earth

Equipment

Series or two-port SPDs may disconnect downstream

loads at end of life

7

Visit the T&B world of

electrical product solutions

Visit our web site for more information about Thomas & Betts

solutions and our newest products. For a user-friendly

catalog and competitive part number search, application

and technical support and other useful information,

go to: www.tnb.com

Industry codes and specifications

Thomas and Betts surge protection devices meet or exceed

applicable industry specifications or codes which are detailed in

the appropriate T&B product literature.

Online CAD library

Thomas & Betts offers free download of two- and threedimensional CAD models of many of its products in more

than 90 native CAD formats at: www.tnb.com/cadlibrary

American Recovery and Reinvestment Act (ARRA)

United States

Europe/Africa

Thomas & Betts Corporation

Electrical Division Headquarters

8155 T&B Boulevard

Memphis, TN 38125

Phone: 901.252.8000

Fax: 901.252.1354

Technical Services:

888.862.3289

Customer Service:

1.800.816.7809

Email: elec_custserv@tnb.com

T&B European Centre

200 Chaussée de Waterloo

B-1640 Rhode-St-Genèse

Belgium

Phone: +32.235.98200

Email: europe_inquiry@tnb.com

Thomas & Betts Power Solutions

5900 Eastport Blvd., Bldg. V

Richmond, VA 23231

Phone: 800.238.5000

Fax: 804.236.4040

Thomas & Betts Ltd

PO Box 54567

Office 107 5EA East Wing

Dubai Airport Free Zone

Dubai

United Arab Emirates

Phone: +9714.609.1635

Fax: +9714.609.1636

Email: me_ex_enquiry@tnb.com

Canada

Asia Pacific

Thomas & Betts Ltd

700 Avenue Thomas

St.-Jean-sur-Richelieu

Quebec J2X 2M9

Phone: 450.347.5318

Fax: 450.347.1976

Thomas & Betts Asia Pte Ltd

10 Ang Mo Kio Street 65

#06-07 Techpoint

Singapore 569059

Phone: +65.6720.8828

Fax: +65.6720.8780

Email: asia_inquiry@tnb.com

Latin America

Mexico: 01-800-TNB-HELP

Central America & Caribbean:

+52.81.8329.7707

South America:

+52.81.8329.7643

Email: servicioalcliente@tnb.com

Get certification letters for

compliant products online at:

www.tnb.com/ARRA

© 2015 Thomas & Betts Corporation. All rights reserved. Printed in the U.S.A.

02/18/15

Middle East

Thomas & Betts Corporation

5900 Eastport Blvd., Bldg. V

Richmond, VA 23231

Phone: 800.238.5000

www.tnbpowersolutions.com