DESIGN GUIDE

advertisement

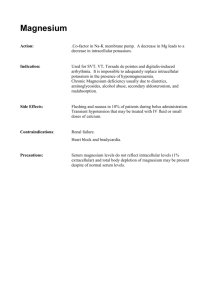

MAG Magnesium Injection Molding DESIGN GUIDE PHILLIPS PLASTICS CORPORATION ® Phillips Plastics Corporation ® Serving original equipment manufacturers in virtually every market since 1964, Phillips Plastics Corporation® has established itself as one of the premiere sources for the design and manufacture of custom plastic and metal injection molded components. Today, Phillips Plastics employs over 1,600 people in 15 locations throughout the United States. phillipsmetals.com What is Magnesium Injection Molding? Magnesium injection molding (MAG) produces components with attributes that include superb quality, high repeatability, dimensional precision, and design flexibility. The magnesium injection molding process is similar to plastic injection molding, with mechanical properties equivalent to or better than die-cast components. Phillips Plastics’ acquisition of the oldest magnesium injection molding operation in North America, combined with its extensive knowledge of the injection molding process, ensures customers receive the expertise necessary for the design and development of the most complex magnesium injection molding programs. Magnesium Market Trends The use of magnesium is beginning to expand rapidly in an array of markets, including the medical, automotive, and recreational fields. Products made with this metal are light-weight, strong, environmentally friendly, recyclable, and beneficial in conserving energy and helping meet CAFÉ requirements. The Magnesium Molding Process Magnesium injection molding is a single step, semi-solid molding process that combines the best of plastic injection molding and die-casting. Chips of magnesium alloy are fed into a heated screw and barrel where the alloy is thermally and mechanically processed into a semi-fluid state and is injected directly into the tool cavity. In contrast to the higher temperatures necessary for die-casting, magnesium injection molded components are processed at temperatures more than 100 degrees Fahrenheit cooler. The resulting semi-solid properties allow the metal alloys to flow like a thermoplastic with a more controlled, laminar flow. The magnesium injection molding process delivers net shaped components with many inherent benefits which include: superior strength to weight ratios, EMI/RFI shielding, better straightness and flatness, heat dissipation, low porosity, and tighter tolerances, which may reduce or eliminate some secondary machining operations. Thixotropic Structure Conventional dendrite formation in semi-solid alloy Thixotropic structure of semi-solid alloy resulting from stirring Conventional Die-Casting Cold Chamber Magnesium Injection Molding Hot Chamber Prototype Capabilities Phillips offers several prototyping capabilities, which provide solutions to questions and concerns regarding product design and performance. For customers that want to test prototype parts, Phillips offers in-house stereolithography (SLA), and can supply many other rapid prototyping technologies, including machining. Should actual injection molded prototypes be required, P20 prototype tools or a pull-ahead cavity production tool option is available. EMI/RFI Phillips offers six shielding methods for products requiring immunity from EMI/RFI generators – electroless plating, conductive paint, vacuum metalizing, imbedded mesh, conductive foil, and magnesium. Magnesium injection molding is a single step, semi-solid molding process in which chips of magnesium alloy are fed into a heated screw and barrel where the alloy is thermally and mechanically processed into a semi-solid state and injected directly into a tool cavity. Secondary Operations Phillips Plastics can provide secondary operations, many in-house, to meet a wide range of specified requirements. Some of the most common secondary operations include: trimming, vibratory or tumble deburring, drilling/tapping, CNC machining, electroplating, assembly, and painting/decorating. Machining Magnesium is the easiest metal to machine and is used as a benchmark for all other metals. However, there are still machining guidelines that must be adhered to. Magnesium can be machined at high speeds and feeds and tooling should be sharpened or ground to specific criteria. Magnesium can be machined in a dry or wet system. Generally, a wet machining process is used for higher volumes and a dry machining process is used for lower volumes. Various surface finishes can also be achieved while machining magnesium, which includes profiling parting lines that result in an improved aesthetic appearance. Punching or piercing holes with the trim die can eliminate some machining operations. Also, thread-forming screws, specifically designed for use with magnesium, can eliminate tapping operations. Capability Options Phillips’ magnesium injection molding capabilities include: conventional single shot, overmolding with plastic, and insert molding. Insert molding metals into magnesium alloys can be accomplished with almost any type of insert, including dissimilar metals, as long as the insert does not have a lesser melting point than the alloy. Complexity and part design are considerations with regards to part cost. Hinges and tongue and groove features (popular when considering a plastic part with a magnesium part for rigidity characteristics) are all items that can be incorporated into the product design and easily molded into the parts. Additionally, these designs can help eliminate visible parting lines on critical surfaces. Environmental Considerations Magnesium injection molding is an environmentally friendly, 100% recyclable process that uses no ozone layer depleting gases. A closed operating system, running at lower than melting temperatures, eliminates molten metal hazards and prevents the generation of oxides. Magnesium, weighing 1/4 the weight of steel and 1/3 lighter than aluminum, is the eighth most abundant element in the earth’s surface and can be safely manufactured in a low hazard environment. Assembly Considerations Phillips’ in-depth knowledge of the entire manufacturing process, combined with its assembly services, provides customers with true turnkey capabilities. Phillips provides customers an unparalleled range of assembly services, which includes: component design, design for manufacture, and quotes for assembly and finishing operations. Metallurgical Lab Phillips’ in-house metallurgical lab is an integral part of the Thixomolding® process with people exclusively trained to perform microstructure studies on materials. This lab gives Phillips the capability to fully monitor and analyze materials, and aids in the development of the magnesium injection process. Design Considerations Walls and Wall Thickness The walls should be kept as uniform in thickness as possible. Thick sections will be more likely to have porous centers than thin ones. The magnesium injection molding process has the ability to produce a higher percent of solids than conventional die-casting thus reducing porosity issues. Magnesium injection molding can produce walls as thin as 0.015 inch. A general rule is that the flow distance of the metal will be 100 times the thickness of the wall. However, Phillips has experience with walls as thin as 0.050 inches with flow distances as much as 6 inches (120 times the thickness). The ability to place a gate close to the thin sections to be filled, greatly enhances successful filling of thin walls. Wall thickness should be as uniform as possible to avoid local hot spots during solidification. Design Considerations (continued…) Ribs Ribs should be used to obtain maximum strength of a wall as well as brace or strengthen a sidewall or surface. The thickening of walls does not add strength as well as a properly designed part incorporating ribs. Deep, thin ribs, or ribs that are spaced close together, should be avoided unless sufficient ejection can be designed into the tool. Thicker sections such as bosses and ribs generally will not cause sinks on walls as in the plastic injection molding process. The ability to now place a screw boss tangent to an outside wall of an assembly without concern of sink, allows the designer more freedom for other components. Avoid Sharp Corners Sharp corners should be avoided and a progressive change in shape is recommended to help the metal flow during die filling to avoid turbulence. Fillets and blend radii should be used to strengthen the components and enhance die life. Draft All molded surfaces, normally perpendicular to the parting line of the injection molding die, require draft (taper) for proper ejection of the mold from the die. A draft of 1 degree is recommended. Less draft can be used on longer draws while short draws require more draft. Zero draft is possible but the design must allow for sufficient ejection to keep the part from distorting. Precision tolerances for draft call for a draft on inside walls at 1 degree per side, with outside walls requiring half this amount of draft. Inserts Inserts are pieces of material, usually metal, that become an integral part of the component. Inserts are usually set in the die and magnesium is molded around that portion of the insert that is left exposed in the die cavity. However, before designing an insert as part of a component, consider that inserts slow machine cycles and increase the cost of recycling scrap. Often times, inserts can be installed by a secondary operation, such as pressing or screwing, as economically as molding them into the component. Undercuts An undercut is a recess in the sidewall or core hole of a mold. Undercuts can be formed using slides and lifters. Slides are used to form undercuts on the outside of the component and can be either mechanically or hydraulically actuated. Lifters are used to form undercuts on interior wall surfaces and are designed similar to lifters in a plastic injection mold. Hinges Hinges can be incorporated into the design and are easily molded. With plastics, the flexural/fatigue characteristics permit an integral molded-in hinge that connects the container and the lid, commonly referred to as a living hinge. However, even though the properties of magnesium do not permit a living hinge, the flow characteristics of magnesium will allow for a wide variety of hinges and hinge designs. Tongue and Groove Tongue and groove can be incorporated into the product design and easily molded into the parts. This type of joint is highly recommended when joining a plastic part to a magnesium part. Creep Creep is plastic deformation of metals that are held for long periods under stresses less than the normal yield strength. Creep is a design consideration only when components are operated at temperatures above 250 degrees Fahrenheit for extended periods. Magnesium alloys are known for poor creep behavior at elevated temperatures when compared to aluminum or ferrous alloys, although they do perform better than most plastics. However, creep is generally a design concern only if the magnesium component will operate at elevated temperatures on a sustained basis. If the component is designed for tensile or compressed loads at elevated temperatures, creep needs to be addressed early in the design phase. Snap Fits Because magnesium’s mechanical properties include excellent stiffness and poor elasticity, snap fit designs between two magnesium parts are not encouraged. Snap members would need to be long enough to allow proper deflection without stressing or fracturing the magnesium. Many designs may not allow for this amount of length. Successful snap fit designs between magnesium and plastic can be achieved as long as the plastic becomes the flexible member and you use good plastic design principles. Flammability The issue that magnesium burns when subjected to high temperature is a design consideration that is not generally a great concern. For more information and to see a video on how magnesium really burns, visit the magnesium molding capabilities on Phillips’ Web site at www.phillipsplastics.com. Phillips Plastics can provide secondary operations, many in-house, to meet a wide range of specified requirements. Dimensional Considerations Dimensional Considerations Magnesium injection molded components may be designed to a tighter tolerance than conventional die-castings. Phillips has found that magnesium injection molded components can be designed using North American Die Cast Association (NADCA) – Precision Standards. The superior dimensional stability of the magnesium injection molding process allows the designer greater flexibility in design, while holding tighter tolerances. Moving Die Moving die components (also called moving die parts) are most commonly core slides (or pulls) used to form inset holes or features in die-casting. Precision Tolerance Added to Linear Dimension (Projected Area) Up to 21 to 50 inches2 + 0.004 51 to 100 inches2 + 0.006 101 to 200 inches2 + 0.008 201 to 300 inches + 0.011 2 Tolerances shown are plus (+) values only Source: NADCA Product Specification Standards for Die Casting/Sec. 4A/9-2006 Linear Dimension Any dimension to features of the die molding that is formed in the same die component (half). Any straight-line dimension on a part of die print. Precision Tolerance Basic Tolerance Up to 1 inch (25.4 mm) ± 0.002 (± 0.05 mm) Additional Tolerance For each additional inch ± 0.001 Over 1 inch (25.4 mm) (± 0.025 mm) Source: NADCA Product Specification Standards for Die Casting/Sec. 4A/9-2006 Machining Stock Allowance Precision Tolerance The best mechanical properties are achieved on the skin of the component. Removing the skin completely will adversely affect the strength of the design. Generally, the minimum machining stock allowance is 0.010 inch. The maximum amount is a combination of the minimum stock allowance and the machining and casting tolerances. Source: NADCA Product Specification Standards for Die Casting/Sec. 4A/2000 Linear Tolerances 0.05 0.045 Tolerance in ± Inches 0.04 0.035 0.03 0.025 0.02 0.015 0.01 0.005 0 1 2 3 4 5 6 7 8 9 10 11 12 (25.4) (50.8) (76.2) (101.6) (127.0) (152.4) (177.8) (203.2) (228.6) (254.0) (279.4) (304.8) Tolerance Zone in Inches (mm) Al, Mg, Zn Standard Tolerance Cu Standard Tolerance Al, Mg, Zn Precision Tolerance Cu Precision Tolerance Flatness Precision Tolerance Maximum Dimension of Die-Cast Surface Up to 3.00 inches 0.005 (76.20 mm) (0.13 mm) Additional Tolerance For each additional inch 0.002 (25.4 mm) (0.05 mm) The maximum dimension is the diameter of a circular surface or the diagonal of a rectangular surface Source: NADCA Product Specification Standards for Die Casting/Sec. 4A/9-2006 Flatness Tolerance 0.05 0.045 Tolerance in ± Inches 0.04 0.035 0.03 0.025 0.02 0.015 0.01 0.005 0 1 2 3 4 5 6 7 8 9 10 11 12 (25.4) (50.8) (76.2) (101.6) (127.0) (152.4) (177.8) (203.2) (228.6) (254.0) (279.4) (304.8) Tolerance Zone in Inches (mm) Standard Tolerance Zone Precision Tolerance Zone Parting Line A witness line that is cast on the part formed where the two halves of the die or mold meet in closing. Precision Tolerance Added Linear Tolerance (Projected Area) Up to 10 inches2 + 0.0035 11 to 20 inches2 + 0.004 + 0.005 21 to 50 inches2 51 to 100 inches + 0.008 2 2 + 0.012 201 to 300 inches2 + 0.016 101 to 200 inches Tolerances shown are plus (+) values only Source: NADCA Product Specification Standards for Die Casting/Sec. 4A/-2006 Parting Line Tolerances 0.03 Tolerance in ± Inches 0.025 0.02 0.015 0.01 0.005 0 10 20 50 100 200 300 (64.50) (129.0) (322.6) (645.2) (1290) (1935) Projected Area in Inches Square (cm sq) Al, Mg Standard Tolerance Cu Standard Tolerance Zn Standard Tolerance Al, Mg Precision Tolerance Cu Precision Tolerance Zn Precision Tolerance Draft The taper given to cores and other parts of the die cavity to permit easy ejection of the casting. Precision Tolerance Minimum precision draft for inside walls is generally recommended at 0.75 degrees per side, with outside walls requiring half as much draft. Draft should be calculated based on the formula shown in the Draft Requirements Section of the NADCA standard. Source: NADCA Product Specification Standards for Die Casting/Sec. 4A/2000 Cored Holes or Cut, Formed and Pipe Treads Dimensions for depth, diameter, and draft are provided in the NADCA standard. Source: NADCA Product Specification Standards for Die Casting/Sec. 4A/2000 Equipment List Molding Equipment · 2 – 220 metric ton or 245 U.S. ton Thixomolder® · 2 – 500 metric ton or 550 U.S. ton Thixomolder® · 2 – 650 metric ton or 715 U.S. ton Thixomolder® · 1 – 850 metric ton or 935 U.S. ton Thixomolder® Deburring Equipment · 4 cu. ft. to 18 cu. ft. vibratory deburring machines · 1 tumble/blast deburring machine Tooling Machining Equipment · Assortment of CNC and special purpose machining equipment Tool Construction Tooling for the magnesium injection molding process is designed like a die-casting tool. However, some of the more intricate plastic tooling components can be incorporated such as small lifters and cams. Slides, both mechanical and hydraulic, are easily incorporated into tool designs. Zero draft conditions can be designed into the tool as long as adequate ejection can be provided. Traditional tool steels are recommended. Cavity inserts for production tooling can be made from H-13 and holder blocks made from 4140. Low volume market-entry and prototype tools can be made using P-20 tool steel. Lab · Metallographical sample preparation equipment · Olympus 1x70 metallurgical microscope · Archimedes density measurement device Machine Specifications Locking Tonnage 245 to 935 U.S. Ton (220 to 850 Metric Ton) Mold Size Range Tool Life 12"x 12" x 9.5" to 61" x 61" x 41.5" Probable tool life for Magnesium Injection Molding Functional parts Aesthetic parts 500,000 shots 150,000 shots Tools used to make magnesium components will last 3-5 times longer than those used to produce aluminum parts. Aluminum has a high affinity for iron and will actually dissolve mold components with each shot. Magnesium, on the other hand, cannot dissolve iron components, thus a longer tool life. LxWxT (305 mm x 305 mm x 240 mm to 1550 mm x 1550 mm x 1050 mm) Injection Volumes 0.1 lb to 12 lb (45 grams to 5445 grams) Projected Area 3.5 to 200 inches2 (22.5 cm2 to 1290 cm2) Coatings Electrodeposition (e-coat) Process The e-coat process applies paint to the part in a tank of water-based solution. The paint is “grown” on the surface using electricity and covers the entire part with a uniform coating. These paint tanks are dedicated to one paint only and are not changed. Various colors or gloss levels of paint are available, but only one is dedicated to the tank due to the high cost of change-over. For full coverage of paint on the part, this efficient system could be the least expensive coating process. Standard Coatings for Magnesium Conversion Coatings Chromate Non-Chromate Iron Phosphates Alodine Anodizing Tagnite Keronite Anomag Powder Coating Phillips Plastics’ magnesium injection molding produces components with attributes that include repeatability, dimensional precision, superb quality, and design flexibility. Types of Plating Electroless plating – a chemical process used to deposit layers of copper and nickel Powder coating is a method of applying a coating to the part in the form of powder (ground resin) using special paint guns. The powder and part are charged to attract each other and provide a method of adhesion in the dry state until the resin is melted and bonded to the substrate. Because no solvents are used, there is no discharge into the atmosphere. Disadvantages of this process are that masking the part for selective painting can be more difficult and expensive than liquid. Powder coating also needs to be cured at higher temperatures than liquid (350 - 400°F), which can lead to outgassing of the magnesium. Many types of resins can be applied (like liquid) such as polyurethane and epoxy, and in the right application, can be less expensive than liquid paints. Leveling or flow of the paint can also be a problem (polyester polyurethane is the best). Single coat multi-colors like hammertones can be applied, and powder coating can achieve very attractive textures. Liquid Paints Liquid paints require low temperature curing, good leveling, and detailed masking. Liquids are easier to shade or color match in-house. The types of paint, Phillips recommends, are epoxy or polyurethane. onto molded parts. This can be done on one or two sides of a part, with two sides being the lowest cost because there are no masking or selective plating requirements. Electroless plating provides excellent surface conductivity for in-process testing and interconnection to other parts. At this time, Phillips Plastics offers electroless nickel as a functional coating. Metal plating – most metals can be plated onto magnesium including chrome. Bright nickel is used to plate magnesium in the place of chromium. Precious metals can also be used to plate magnesium. The precious metals are: pure (99.9%) or bright (99.7%) gold, silver, or platinum. Hydrographics A process used to apply a pattern finish to threedimensional parts, adding cosmetic appeal and surface protection to the product. Corrosion As with many active metals, corrosion is an issue that should be addressed early in the design of the component. Today’s high purity magnesium alloys exhibit excellent corrosion resistance and can be used with confidence in many applications. The two types of corrosions that are addressed are atmospheric and galvanic. Atmospheric Corrosion Unprotected magnesium alloys exposed to atmospheres that do not contain salt spray will develop a gray film. This film will provide some corrosion protection; however, if the surface comes in contact with materials that hold moisture or chlorides and sulfates, the unprotected surface will corrode. This type of corrosion is easily overcome by the proper application of a suitable surface coating. The following table depicts magnesium alloy corrosion rates (using a standard ASTM test) compared to aluminum and steel. The most popular magnesium alloy, AZ-91-D, corrodes significantly less than either carbon steel or 380 aluminum. Salt Spray Corrosion Performance* Magnesium vs. Iron and Aluminum Material Corrosion Rate (mils/yr) Carbon Steel 30 Aluminum 380 (die-cast alloy) 13 AZ-91-D Magnesium Alloy 4 AM-50-B Magnesium Alloy 13 AM-60-B Magnesium Alloy 13 AS-41-B Magnesium Alloy 4 AE-42-A Magnesium Alloy 6 *10-day ASTM B-117 Salt Fog Source: ASTM Standard for Galvanic Corrosion Galvanic Corrosion When designing a magnesium component, galvanic corrosion must be addressed. Galvanic corrosion occurs when the magnesium component is brought into intimate contact with a dissimilar metal in the presence of an electrolyte. An electric current can be generated when such conditions exist, with magnesium being the sacrificial component. Designing contact points to incorporate insulating components can easily prevent galvanic corrosion. If the electric circuit is broken, galvanic corrosion is stopped. Also, design connection points in such a manner that water is not likely to collect near the joint. Remember to choose metals more compatible with magnesium, and insulate against electrical contact. Magnesium provides many inherent benefits for programs in all markets including, medical, lawn and garden, appliance, consumer, telecommunications, defense, recreational, and automotive. Relative Effects of Various Metals on Galvanic Corrosion of Magnesium Alloys Group #1 Group #2 Group #3 Group #4 (Least effect) Group #5 (Greatest effect) Aluminum Alloys Aluminum Alloys Alclad 2024 Zinc-plated Steel Low-carbon Steel 5052 6063 Aluminum Alloys Cadmium-plated Steel Stainless Steel 5056 7075 2017 Monel 6061 3003 2024 Titanium Alclad 7075 Zinc Lead Copper Brass Phillips Plastics Corporation At A Glance · Established in 1964, Phillips Plastics is a privately held custom injection molder of plastic and metal · Phillips Plastics is a technology driven Company, providing contract manufacturing services to original equipment manufacturers in the automotive, appliance, telecommunications, consumer electronics, industrial, medical, defense, and recreational markets · Fiscal year 2006 sales were approximately $260 million · Phillips Plastics employs more than 1,600 people; supported by a network of 814 production people, 31 quality assurance people, 20 designers, 166 engineers (includes design, process, and manufacturing), and 115 toolmakers (includes tool managers, coordinators, team leaders, mold makers, mold polishers, machinists, jig and fixture, EDM specialists, and apprentices) · Total number of presses is 254, ranging in tonnage from 0.44 to 935 · Phillips Plastics consists of 15 locations throughout the United States, occupying over 718,737 square feet, with total manufacturing square footage equaling 333,658 square feet · Facilities are certified to TS16949:2002, ISO 14001, and ISO 9001:2000. Our medical facilities are registered with the FDA for medical device manufacturing. Facility certificates will be supplied upon request PHILLIPS PLASTICS CORPORATION® Opportunity Development 877.508.0260 info@phillipsplastics.com phillipsmetals.com © 2007 Phillips Plastics Corporation®