SVC

advertisement

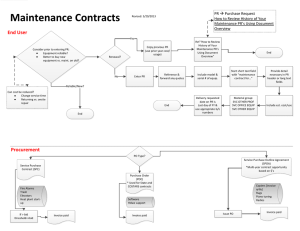

Product manual REVCON SVC 1.0 SAFETY INSTRUCTIONS Before commissioning the power-feedback-unit REVCON• it is important to read this manual carefully. It is intended to give all information for an undisturbed operation together with the exploitation of all advantages of the system. Only authorised specialists are allowed to work at the device in consideration of all relevant regulations of the electrical industry. The guarantee given by us expires if the unit is changed or (even partially) dismantled or if it is used in contradiction to our instructions. The operation of the device is only allowed with a closed cover of the housing and with mounted flanges for the reasons of personnel safety, the observance of the EMC-regulations and for the regular working of the cooling of the device. These safety regulations are not entitled to completeness. In case of questions or problems please contact our technicians. The units, operational data and circuit details described in this manual have to be understood analogously and have to be checked for transferability to each application. The statements of this manual describe the product attributes without guaranteeing them. The constructor of the plant, who has to know the technical guidelines, bears the responsibility for the correct selection and arrangement of the electrical components. Caution Putting into operation is only admissible at VDE conform nets. Non observance can damage the device! In accordance with the corresponding standards and guidelines the operation on even for a short time over-compensated networks (cos••1) respectively on un-choked compensation-units is not admissible. If this is done nevertheless overvoltages (caused by oscillating currents) will occur, which may damage all connected loads, especially electronic units like frequency inverters and power feedback units. To low-powered or unloaded generators and to regulating transformers it is never allowed to feed back power without a previous consultation of our application department. Otherwise you can get unintended voltage rises / excess voltages, which can damage or destroy • REVCON and combined units. The connecting instructions have to be observed absolutely, because an incorrect connection can damage REVCON and combined units. Before operating at nets without neutral ground you must inform our technicians because the devices must be modified in this case. In addition there are separate safety measures necessary which must be agreed with our technicians. With every order you must tell us the form of the net and of the neutral point (grounded or ungrounded)! Version 1.4 12/98 page 1 Product manual REVCON SVC SAFETY INSTRUCTIONS DC-bus terminals After switching off the main circuit voltage the DC-bus terminals of the frequency inverter and of the REVCON still have dangerous high voltage until disconnecting the supply voltage of the frequency inverter. Therefore its necessary to disconnect both supply voltages at the same time! After disconnecting the supply voltage of the frequency inverter the DC-bus terminals of the powerfeedback-unit REVCON still have dangerous high voltage for a few minutes. The exact duration until voltage has decreased to a harmless level depends on the used frequency inverter and has to be observed absolutely (in agreement with the frequency inverter manual). In any case it’s necessary to switch off the main circuit voltage of the frequency inverter and of the REVCON when working at the system. Before opening the cover of the housing it is absolutely necessary to wait a few minutes after switching off the frequency inverter. Warning: Touching active parts – even after switching off the supply voltage – is extremely dangerous. VLT 5001 - 5006: wait min. 4 minutes! VLT 5008 - 5250: wait min. 15 minutes! 1.1 Patent rights The power-feedback-unit REVCON is protected in Germany and Europe by patents: no. DE3938654C1 and no. 90123584.6-2207. Patent infringements become prosecute. page 2 Product manual REVCON SVC Table of Contents Page 1.0 Safety instructions 01 1.1 Patent rights 02 2.0 General information 04 3.0 Technical data 05 4.0 Mounting 07 4.1 Dimension diagram 08 4.2 Space-diagram of the control board 10 5.0 Main circuit connection 11 5.1 Connection of the auxiliary voltage 21 5.2 Connecting diagram of the REVCON• SV 22 5.3 Series fuses 24 5.4 Internal fuses 25 5.5 DC-bus connection 26 5.6 General instructions 29 6.0 Allowed operating data 36 6.1 Thermal limited load graphs 37 7.0 REVCON• control board Version 1.4.x 41 7.1-7.5 Occupation of the control terminal strip 42 8.0 Connecting the external operating and signalling panel 44 8.1 LED messages 45 9.0 Function description of the device 49 10.0 Options 48 10.1 External operating and signalling board 48 10.2 Radio frequency interference filter 48 Appendix page 3 Product manual REVCON SVC 2.0 General information Type description and project-instructions The released energy which results from braking of rotary field motors managed by frequency inverters must no more be converted into heat in resistors. The power-feedback-unit REVCON makes it possible to feed back this power economically into the mains. By using highest modern IGBT-technology in combination with the latest synchronising control module the operator gets a real 4-quadrant inverter with minimal expenditure. The power-feedback-unit REVCON can be used instead of a brake chopper with a brake resistance as braking device for frequency inverters with constant DC-Bus supply and with a main circuit voltage of 400V (3-ph.). The units are no-load constant and they have got the following protective functions and messages: ¦ Protective function: - Short circuit-overcurrent control (UCE-control) - Commutation control ¦ Messages - Operation : LED - False of rotary field or phase failure : LED - Undervoltage control - Short circuit (UCE) : LED - Phase failure control - Overtemperature : LED - Protection of D.C. branches - Control of dissipaters temperature - Collective fault message: LED and potential free contacts The housing has to be connected to ground via PE-terminal or by PE-Screw (from SV50...) respectively. It is recommended to protect the unit separately at mains side 3-ph. with semiconductor fuses. Caution: EMC-measures If the REVCON power-feedback-unit is mounted in plants, which must be build according to EMC-regulations, all connections between the inverter and the power-feedback-unit as well as the synchronise-wires to the mains and the feeding wires to the interference suppression filter must be shielded. page 4 Product manual REVCON SVC 3.0 Technical data General technical data: *1 nom. voltage (V) 3 x 400 ± 10 % 3 x 460 ± 10 % 3 x 500 ± 10 % frequency (Hz) 40 - 60 ± 10 % 40 - 60 ± 10 % 40 - 60 ± 10 % *2 overload capacity ca. 1,2 x Ieff (dynamic) ca. 1,2 x Ieff (dynamic) ca. 1,2 x Ieff (dynamic) efficiency (%) ca. 97 % (3 % therm. losses) ca. 97 % (3 % therm. losses) ca. 97 % (3 % therm. losses) ∼1 ∼1 ∼1 ∼ 0,7- 0,95 ∼ 0,7- 0,95 ∼ 0,7- 0,95 power factor fundamental frequency component Climatic conditions according to Class 3K3 (EN 50178 part 6.1) temperature of environment temperature of cooling air *3 need of airflow *4 altitude above sea level air pressure relative humidity +5 +40°C(+41 +104°F) +5...+35 C (+41...+95°F) a) 200m3/h /b) 350m³/h c) 700m³/h +5 +40°C(+41 +104°F) +5...+35 C (+41...+95°F) a) 200m3/h /b) 350m³/h c) 700m³/h +5 +40°C(+41 +104°F) +5...+35 C (+41...+95°F) a) 200m3/h /b) 350m³/h c) 700m³/h 1000m (3280ft) 1000m (3280ft) 1000m (3280ft) l 86kPa – 106kPa 86kPa – 106kPa 86kPa – 106kPa 5-85% not dewy! 5-85% not dewy! 5-85% not dewy! storage temperature -25...+55°C (-13...+131°F) -25...+55°C (-13...+131°F) -25...+55°C (-13...+131°F) transport temperature -25...+70°C (-13...+158°F) -25...+70°C (-13...+158°F) -25...+70°C (-13...+158°F) Table 3.0 *1 Other voltages on inquiry. *2 Allowed operating duration see "Allowed operating data". *3 Depending on the size of the model (nominal power a) 7-45kW /b) 70-135kW /c) 140-200kW). *4 By mounting on a altitude higher than 1000m (3280ft) above sea level it is necessary to reduce the power rating or rather use the forced cooling (by fan) or reduce the temperature of the cooling air respectively. page 5 Product manual REVCON SVC Current load (400 V, 460 V and 500 V): REVCON ® - Type SVC 11-400-1-230 SVC 18-400-1-230 SVC 28-400-1-230 SVC 38-400-1-230 SVC 50-400-1-230 SVC 70-400-1-230 SVC 100-400-1-230 SVC 135-400-1-230 SVC 160-400-1-230 SVC 200-400-1-230 REVCON ® - Type SVC 15-460-1-115 SVC 24-460-1-115 SVC 33-460-1-115 SVC 42-460-1-115 SVC 64-460-1-115 SVC 83-460-1-115 SVC 105-460-1-115 SVC 138-460-1-115 SVC 160-460-1-115 REVCON ® - Type SVC 17-500-1-230 SVC 27-500-1-230 SVC 37-500-1-230 SVC 45-500-1-230 SVC 70-500-1-230 SVC 90-500-1-230 SVC 115-500-1-230 SVC 150-500-1-230 AC max. current Ieff 16 A 26 A 40 A 55 A 72 A 101 A 144 A 195 A 231 A 289 A DC max. current I 19 A 31 A 48 A 66 A 87 A 122 A 157 A 236 A 279 A 350 A AC max. current Ieff 19 A 30 A 41 A 53 A 81 A 104 A 133 A 173 A 201 A DC max. current I 23 A 36 A 50 A 64 A 98 A 126 A 161 A 209 A 242 A AC max. current Ieff 20 A 31 A 43 A 53 A 81 A 104 A 133 A 173 A DC max. current I 24 A 38 A 52 A 64 A 98 A 126 A 161 A 209 A Table 3.1 Type key SVC 11 - 400 - 1 - 230 V AC (example) auxiliary voltage (V) Number of fans voltage (V) constant power rating (kW)* REVCON• for VLT 5000 page 6 Product manual REVCON SVC 4.0 Mounting The power-feedback-unit REVCON is provided for vertical wall-mounting (+ 15°). Mounting is only allowed on a flat surface without using any kind of spacers. When mounting inside of cabinets it is necessary to mount the device directly on the mounting plate without using any kind of spacers and to drain away the waste heat. This kind of mounting is necessary to guarantee the right way for the cooling air. A power loss of 3% from the max. nominal power rating has to be calculated. Air-temperature may not exceed 40 °C (104 °F) near the unit. Air-in- and air-out-openings at the top and the bottom of the unit may not be concealed by installation materials such as cable ducts or other equipment. Keep a distance of min. 15 cm to the air-in- and air-out-openings and a distance of min. 7 cm to beside mounted parts or cabinet-walls. REVCON• SVC (choke included) REVCON ® type SVC 11-400-1-230 SVC 18-400-1-230 SVC 28-400-1-230 SVC 38-400-1-230 SVC 50-400-1-230 SVC 70-400-1-230 SVC 100-400-1-230 SVC 135-400-1-230 SVC 160-400-1-230 SVC 200-400-1-230 REVCON ® type SVC 15-460-1-115 SVC 24-460-1-115 SVC 33-460-1-115 SVC 42-460-1-115 SVC 64-460-1-115 SVC 83-460-1-115 SVC 105-460-1-115 SVC 138-460-3-115 SVC 160-460-3-115 * Danfoss H+H1 H e f1 H1 B B1 T T1 f2 f3 weight type of protection order-no. (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (kg) 192H3445 192H3446 192H3447 192H3448 192H3449 192H3450 192H3451 192H3452 192H3453 192H3454 530 530 610 610 710 758 758 758 867 867 420 420 500 500 600 600 600 600 804 804 80 80 80 80 80 128 128 128 33 33 245 245 245 245 245 245 245 245 306 306 270 270 270 270 270 270 270 270 380 380 295 295 295 295 295 295 295 295 395 395 85 85 260 260 260 260 260 260 260 260 350 350 80 80 80 80 80 80 80 80 80 80 400 400 680 680 14 15 19 25 26 33 35 41 75 80 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 * H1 B1 T1 f1 Danfoss H+H1 H B T f2 f3 weight type of e protection order-no. (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (kg) 192H3455 192H3456 192H3457 192H3458 192H3459 192H3460 192H3461 192H3462 530 610 610 710 758 758 758 867 867 420 500 500 600 600 600 600 804 804 80 80 80 80 128 128 128 33 33 245 245 245 245 245 245 245 306 306 270 270 270 270 270 270 270 380 380 295 295 295 295 295 295 295 395 395 85 85 260 260 260 260 260 260 260 350 350 80 80 80 80 80 80 80 80 80 400 400 680 680 15 19 25 26 33 35 41 75 80 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 * REVCON ® type Danfoss H+H1 H H1 B B1 T T1 f2 f3 weight type of e f1 order.-no. (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (kg) protection SVC 17-500-1-230 SVC 27-500-1-230 SVC 37-500-1-230 SVC 45-500-1-230 SVC 70-500-1-230 SVC 90-500-1-230 SVC 115-500-1-230 SVC 150-500-3-230 192H3463 192H3464 192H3465 192H3466 192H3467 192H3468 192H3469 192H3470 530 610 610 710 758 758 758 867 420 500 500 600 600 600 600 804 80 80 80 80 128 128 128 33 245 245 245 245 245 245 245 306 270 270 270 270 270 270 270 380 295 295 295 295 295 295 295 395 85 260 260 260 260 260 260 260 350 80 80 80 80 80 80 80 80 400 680 15 19 25 26 33 35 41 70 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 *inclusive metal cable-glands (30mm) page 7 Product manual REVCON SVC All types will be delivered with flange with metal cable glands for shielded cables and fan. page 8 Product manual REVCON SVC 4.1 Dimension diagrams 1. 2. 3. SVC 11-400-1-... to SVC 135-400-1-... SVC 15-460-1-... to SVC 105-460-1-... SVC 17-500-1-... to SVC 115-500-1-... B2 cooling airflow out H2 H1 f f 4'8%10 H 7 f f B e B1 T cooling airflow in All cable inputs from bottom. page 9 Product manual REVCON SVC 1. SVC 160-400-1-... up to SVC 200-400-1-... 2. SVC 138-460-1-... up to SVC 160-460-1-... 3. SVC 150-500-1-... Kühlluftaustritt H1 4'8%10 f3 H f2 8,5 f1 B e B1 T Kühllufteintritt Alle Kabeleinführungen von unten. page 10 Product manual REVCON SVC 4.2 Space diagram of the control board (REV 1.4.X) terminal X3 connection to driver board terminal X5, X8 option X8 J4 X3 X5 TR1 TR2 L4 TR3 TR5 TR4 TR6 J1 LD5 LD3 SW 1 J5 J3 J6 LD4 J7 LD2 LD1 X1 REVCON V. 1.4.3 X2 X4 from version 1.4.2 terminal X1 synchronisation to mains supply terminal X4 connection to signalling board type of control board (example) LED-messages green: operation 1. red: phase failure 2. red: UCE / overcurrent orange: overtemperature yellow: collective error terminal X2 ext. messages and controlling push-button „Quit/Reset“ (only version 1.4.1) Figure 4.2 page 11 Product manual REVCON SVC 5.0 Main circuit connection Power unit : main circuit connection L1, L2, L3, PE DC-bus connection : plus and minus (directly from the DC-bus of the frequency inverter) 530 - 750 V Control unit : supplied by power unit CAUTION: The DC-bus terminals of the frequency inverter must be connected directly to the capacitor unit. The mains connection consists of one connection for the power unit at terminals L1, L2, L3 and PE. For devices from SVC50... the PE-wire must be connected directly to the housing via 8mm earthing screw. The mains connection of the control unit is protected by fuses build in the fuse-terminals or by the control fuses integrated on the control board respectively. The power unit is not protected at the input-side, but it is advisable to protect it according to the power of the device by semiconductor fuses (3-ph.) in addition to the line protection , according to the valid VDE regulations. The input, coming from the DC-bus, is protected internal with semiconductor fuses and will be connected to the DC-bus of the frequency inverter, where each plus- and minus-connection of the frequency inverter and the REVCON• must be coupled. At the standard design the chokes have a switch-on-time of 50% (in 10 min.). Chokes for a higher switch-on-time e.g. 100% on inquiry. page 12 Product manual REVCON SVC F Connection instructions All connections should be made as short and low-inductance as possible. In according to the EMC-regulations it is necessary to use shielded cables. A defined phase sequence (clockwise rotation field) must be observed at the main circuit connection of the power unit. REVCON• is equipped with a phase-sequence control unit. In case of an incorrect rotation field it is not possible to put REVCON• into operation. You get an error message via LED as follows: "rotation field failure" or "phase failure" and "collective error". In this case two phases, connected to the power unit, have to be exchanged. For frequency inverters, whose parameters for running mode and generating mode can be adjusted separately, it is advisable to adjust the generating parameters for the current limit or rather the power limit under the maximum value of the Power-Feedback-Unit. In this connection the possibly existing time ramps for the generating mode must be adjusted, too. To find out the correct value of regenerating power it is necessary to note that the real momentary regenerating power is dependent on the real existing main circuit voltage all the times. To calculate the regenerating power the following formula will be used: P = Ueff · Ieff · v3 · cos• (at regenerating power : cosϕ = 1) The maximum possible regenerating power referred to the momentary voltage value is calculated from the momentary effective main circuit voltage and the maximum root-mean-square current of the respective device. Example: Model SVC 50, maximum root-mean-square current 72A (see technical data), nominal mesh voltage rating e.g. 400V. From it results: P = 400V · 72A · v3 = 49883, that's about 45.0kW. If the momentary effective main circuit voltage is only 395V or even lower for a short time, the maximum possible regenerating power is reduced, too: P = 395V · 72A · v3 = 49259W, that's about 49.2kW. Concerning the parallel connection of Power-Feedback-Units it is to note that the summery of the regenerating power must be reduced by 7% of the whole value. Example: 3 pieces 50kW parallel 3 · 50kW = 150kW - 7% = 139.5kW (at 400V) So the maximum possible regenerating power results in only 139.5kW at the parallel connection of three 50kW devices. page 13 Product manual REVCON SVC Application example: Figure 5.2.1 Within greater plants several power feedback units may be coupled. Figure 5.2.1 shows an example of a crane plant with some possible combinations. The operation of several inverters at one common DC-circuit allows to reduce the amount of power feedback units. On the other hand several power feedback units may be coupled to transmit more power. It’s also possible to drive several motors at one inverter, as they react, seen from the DCcircuit (and that’s, what the REVCON®-unit sees), like one big motor. To proportion such a plant it is important to look at the worst case. The maximum feedback power of the REVCON®-unit has to be higher as or , at a minimum, equal to the total amount of the braking power of the connected motors. page 14 Product manual REVCON SVC Danfoss offers a complete range of power feedback units for VLT frequency converters, types 5001-5051. Example 1 - Conveyor belt Fig. 1 shows the relation between the braking power and the acceleration/braking of a conveyor belt. During braking the motor power is negative, as the torque on the motor shaft is Description of the braking system When the speed reference of a frequency negative, too. The braking power, i.e. the power converter is reduced, the motor acts as a emitted at the REVCON-unit, corresponds generator and brakes. In this case it supplies almost to the negative motor power, reduced by energy to the frequency converter, where it is the losses in the motor and the VLT frequency collected in the intermediate circuit. As soon as converter. the energy respectively the voltage in the VLT- In addition it can be seen that the motor power intermediate circuit rises, the energy will be fed is time-dependent. back into the supplying network by the external REVCON -unit (option). Kinetic energy (E) of conveyor belt + motor Without using a REVCON -unit, the E = ½ ⋅ m ⋅ v 2 + ½ ⋅ j⋅ω 2 [Ws] intermediate circuit voltage would continue to increase, until the converter cuts off for protection. The advantage of using a REVCON m ≅ mass in linear movement [kg] -unit is, that even heavy loads, i.e. with v ≅ speed of the mass in liner movement [m/s] conveyor belts or cranes, could be braked j ≅ inertia factor of motor and gear [kgm²] rapidly to standstill. In addition, the VLT 5000 n ⋅ 2π ω ≅ motor speed = [rad/s] incorporates brake monitoring to ensure, that 60 the maximum current indicated at the REVCON -unit won’t exceed a specific limit. This formula may also be expressed as follows: Danfoss has chosen a solution, where the power [Ws] E = ½ ⋅ m ⋅ v 2 + 0.0055 ⋅ j ⋅ n 2 feedback unit REVCON is no integral part of the frequency converter. However, not all of this energy is released to the power feedback unit REVCON. The To the user this offers the advantage, that the friction of the conveyor belt and the power loss regenerative power respectively the braking current of the REVCON-unit can be selected as of the motor also contribute to the braking function. Consequently the formula for energy required. release (Eb) to the REVCON-unit is as follows: Knowledge of the system 2 2 To select the right size of the REVCON-unit, it E b = (½ ⋅ m ⋅ v ⋅ j ⋅ ω - ½ ⋅ M f ⋅ ω )η Motor [Ws] is necessary to know how often and how powerful the motors brake. [Nm] Mf ≅ Friction torque ηm ≅ Motor efficiency In the following, calculations of the regenerative power are given by the examples n ⋅ 2π , the result is like this: Replacing ω by of a conveyor belt, a crane plant and a 60 centrifuge. E b = (½ ⋅ m ⋅ v 2 ⋅ 0.0055 ⋅ j ⋅ n 2 - 0.052 ⋅ n ⋅ M f ) ⋅ηMotor page 15 Product manual REVCON SVC Fig. 1 The relation between braking power and acceleration/braking of a conveyor belt. Geschwindigkeit Geschwindigkeit Drehmoment Leistung Beschleunigung Tp ≅ Process period time Tb ≅ Braking time page 16 Verzögerung Product manual REVCON SVC Example 2 Crane plant (conveyor belt with ramp) Part 1 Determination of the power when decelerating with constant speed. When decelerating loads with constant speed the energy is calculated according to the following formula: E pot = m ⋅ g ⋅ ∆h Epot m g h ≅ potential energy [Ws] ≅ mass [kg] ≅ acceleration due to gravity [9.81 kg m/s²] ≅ difference in altitude [m] Losses of the motor as well as losses of gear and friction reduce the braking power. EBpot = m ⋅ g ⋅ h ⋅ ηmotor ⋅ η gearing ⋅ η friction Part 2 Determination of the maximum power, which is transmitted from constant decelerating speed till stoppage. If a load is slowed down from constant decelerating speed up to stoppage, so the total energy is the sum of the energy determined in example 2 part 1 and the kinetic energy determined in example 1 (conveyor belt). EBΣ max = Ebkin + EBpot Even in this case the maximum braking power is determined by division of EBΣmax with the time in which the load is slowed down from constant speed to zero. PB = EBΣ max averavge power during = TB the total braking time TB ≅ deceleration time from constant decelerating up to stoppage [s] Consequently the braking power PB is calculated as follows: PB = EBpot TB TB ≅ braking time with constant speed [s] The power feedback unit REVCON must be able to transmit this power according to the temperature-limited-load graphs. page 17 Product manual REVCON SVC Example 3 - Centrifuge Another typical application where braking is required are centrifuges. The weight of the centrifuge content is m. j ≅ inertia factor of the centrifuge = 1 ⋅ m ⋅ (r 2 + r 2 ) [kgm²] 2 1 2 jm ≅ inertia factor of the gearmotor [kgm²] ηm ≅ efficiency of the gearmotor n1 ≅ max. motor speed [rpm] [rpm] n2 ≅ max. centrifuge speed C 2 2 E b = (0.0055 ⋅ jc ⋅ n2 - 0.0055 ⋅ jm ⋅ n1 ) ⋅ηm [Ws] Calculation of braking power When calculating the braking power it has to be ensured that the Feedback-Unit transmits the average power during the braking process and the peak power. The average power results from the temperature-limited load graph. Here the relation between braking time and break has to be kept. The peak power is determined by the braking torque, i.e. during the braking process the Feedback-Unit has to be able to release the delivered energy to the network. Pict. 3 shows the relation between average power and peak power. page 18 Product manual REVCON SVC Calculation of the peak braking power Ppeak,mec is the peak power of the motor when braking at the motor shaft. It can be calculated as follows: Ppeak , mec = Pmotor ⋅ M BR (%) [W] Ppeak is the description of the peak power released to the Feedback-Unit when the motor brakes. Ppeak is lower than Ppeak,mec, as the power is reduced by the efficiency of the motor and the VLT frequency inverter. The peak power can be calculated as follows: Ppeak = Pmotor ⋅ M BR(%) ⋅ ηmotor ⋅ ηvit [W] page 19 Product manual REVCON SVC As with falling frequency the motor-terminal voltage falls proportionally, inversely For braking proceedings with variable frequency proportional the motor current has to rise to keep the power constant. (fmax ⇒ f0) some special features have to be considered. In practice this would be possible, if the frequency output signal is predetermined as Braking with constant torque / current analog value e.g. 0-10 V to the momentAs a rule at the nominal frequency rating fnom the controller input 10-0 V of the frequency inverter. voltage at the motor terminals corresponds to the Another possibility of dynamic braking can be nominal voltage rating Unom and with falling frequency the motor voltage falls proportionally. achieved by the adaptation of the braking ramp, if the ramp with falling frequency is vanished more As a consequence with the given constant back- steeply, hyperbolic steplessly or in several steps. feeding current the transmitted power of the Remark: REVCON-unit falls with the frequency. For applications like motor test stands, wind- and The same is valid for a linear braking ramp-down water-power plants in principle constant power devices with 100% duty-time have to be used. time. In principle, the dimensioning is normally The power results from the division of the energy realised according to the expected constant braking power or the feedback power to the with the braking time TB [s] (see examples of network. use). Dimensioning the Power feedback unit For these cases the power feedback unit has to be designed for the max. generatoring current of motor or frequency inverter with fmax; or the generatoring current of the inverter has to be limited to the max. current of the power feedback unit. Braking with constant power The advantage of dynamic braking is the optimal utilisation of the power feedback unit during the whole braking time so that in this case the REVCON-unit has not to be designed for the max. current or the max. power with fNenn, but only for the average current or the average power of the braking process. To allow the optimal utilisation of the capacity of the power feedback unit, the following settings are possible to realise a braking with constant power. page 20 Product manual REVCON SVC f [Hz] P I/M 50 FI-Frequency f FI-CurrentI FI-Power 0 t Fig. 1: Braking with linear falling frequency at working machines with square load torque f [Hz] P I/M FI-Frequency F FI-Power P 50 FI-Current I 0 t Fig. 2: Braking with constant current / torque at working machines with square load torque f [Hz] P I/M FI-Frequency F 50 FI-Power P FI-Current I 0 t Fig. 3: Braking with constant power at working machines with square load torque page 21 Product manual REVCON SVC distributor. Decelerating of the inertia In the case of braking of high inertia values on the motor shaft, the power feedback units can be based on the inertia moment, ∆ω and ∆t. ω Start ∆ω/∆t ω Ende ∆t Abb. 4 ∆t is determined by the ramp-down time in parameter 208. G ATTENTION! The ramp-down time goes from the rated motor frequency in parameter 104 to 0 Hz. Ppeak can be calculated as: Ppeak = η motor ⋅ηVLT ⋅ ω start ⋅ j ⋅ ∆ω ∆t 2π ∆n Ppeak = η motor ⋅ηVLT ⋅ nstart ⋅ j ⋅ ⋅ 60 ∆t 2 j is the inertia moment at the motor shaft The values of the power feedback unit can be calculated as described under the preceding paragraphs. Continuos braking For continuos braking a power feedback unit has to be selected, in which the constant braking power does not exceed the power defined in the limiting-load graphs. G ATTENTION! For further information contact your Danfoss page 22 Product manual REVCON SVC Optimal braking conditions Dynamic braking is useful from the maximum speed down to about 8% of the nominal speed. Below 8% of the nominal speed DC braking is to be applied as required. The most efficient way to do this is to change from dynamic to DC braking at this point. See fig. 5. f[Hz 50 ] dynamic braking DC-Braking 4 Fig. 5 t[s] G ATTENTION! Only the types REVCON SVC released by Danfoss are to be used. Otherwise the frequency inverter and /or the power feedback unit may be damaged. page 23 Product manual REVCON SVC 5.1 Connection of the auxiliary voltage for fan and temperature supervision At devices with fan and/or temperature supervision two additional terminals [blue one = N, grey fuse-terminal = L11] are present. They are for connecting the auxiliary voltage used by the fan or rather by the temperature supervision. + - to the DCbus of the inverter L1 L2 L3 mains N L11 PE fan and temperature supervision 230 V AC* * Other voltages on inquiry Caution: Non-connection of the 230V auxiliary voltage results in non-working of the temperature supervision and can damage the device by overheat! page 24 Product manual REVCON SVC 5.2 Connecting diagram of the REVCON• SVC L1 L2 L3 N PE 1 L1 N 230V 2 3 4 5 Funkentstörfilter L11 N PE L1 L2 L3 PE L1 L2 L3 Funkentstörfilter 89+ VLT 5000 88- 6 + REVCON SVC...(Typ) - (mit int. Drossel) Steuerelektronik Relaiskontakte Fehlermeldung PE U V W Regler+24 V freigabe ext. AUS X2 2 1 4 3 X2 7 8 ext. EIN ext. EIN RESET RESET 9 10 11 12 + - M 3~ 7 Figure 5.2 page 25 Product manual REVCON SVC Legend for figure 5.2 (REVCON• SVC) 1- Attention! Behind the pre-connected main switch except the frequency inverter and the power feedback unit no additional loads have to be connected. If this is done nevertheless in case of switching off the supplying network during feeding back a dangerous rise of the output voltage would occur. This high voltage within the disconnected network area could damage these additional loads, the frequency inverter and even the power feedback unit itself. Protection according to frequency inverter product manual. 2- In case of different power/sections it is necessary to provide a separate protection according to DIN VDE 0298 or to install short circuit proof wires. In case of equal power/sections (InverterREVCON) line-protection is given by position 1. 3- Line-section according to the valid VDE-regulations. 4- Protection (230 V auxiliary voltage) according to DIN VDE 0298 or short circuit-proofed wiring. 5- If the radio interference filter is mounted inside the frequency inverter’s housing, an additional radio interference filter has to be mounted at the AC-connectors of the REVCON-unit. 6- Line-section according to valid VDE-regulations. The DC-bus connection at the inverter must be made directly at the DC-capacitor-unit of the inverter. 7- Via the terminal pairs 9/10 and 11/12 it is possible to connect an external „ON“ respectively „RESET“. terminal 9 and 10: potential free contact (short time contacting) terminal 11 and 12: positive pulse (12 - 24 VDC); practicable via e.g. PLC-driving (terminal 11 +, terminal 12 -) page 26 Product manual REVCON SVC 5.3 Series fuses The power-feedback-unit is connected to mains supply by the terminals L1, L2, L3 and PE. Mains fuses must be designed according to the current load capacity of allowed connection cables. Semiconductor fuses have to be connected in series of the power-feedback unit as follows: REVCON ® - type SVC 11-400-1-230 SVC 18-400-1-230 SVC 28-400-1-230 SVC 38-400-1-230 SVC 50-400-1-230 SVC 70-400-1-230 SVC 100-400-1-230 SVC 135-400-1-230 SVC 160-400-3-230 SVC 200-400-3-230 REVCON ® - type SVC 15-460-1-115 SVC 24-460-1-115 SVC 33-460-1-115 SVC 42-460-1-115 SVC 64-460-1-115 SVC 83-460-1-115 SVC 105-460-1-115 SVC 138-460-3-115 REVCON ® - type SVC 17-500-1-230 SVC 27-500-1-230 SVC 37-500-1-230 SVC 45-500-1-230 SVC 70-500-1-230 SVC 90-500-1-230 SVC 115-500-1-230 SVC 150-500-3-230 max. fuse AC Ferraz 6,9xx CP gRC 14.51 32A Ferraz 6,9xx CP gRC 14.51 40A Ferraz 6,9xx CP gRC 14.51 63A Ferraz 6,621 CP URQ 27x60 / 80A Ferraz 6,621 CP URQ 27x60 / 100A Ferraz 6,621 CP URQ 27x60 / 160A Ferraz 6,621 CP URQ 27x60 / 200A Ferraz 6,621 CP URQ 27x60 / 315A Ferraz 6,6 URD 31 D11A 0350A Ferraz 6,6 URD 31 D11A 0400A max. fuse AC Ferraz 6,9xxCPgRC 14.51 32A Ferraz 6,9xxCPgRC 14.51 50A Ferraz 6,621CPURQ 27x60 / 63A Ferraz 6,621CPURQ 27x60 / 80A Ferraz 6,621CPURQ 27x60 / 125A Ferraz 6,621CPURQ 27x60 / 160A Ferraz 6,621CPURQ 27x60 / 200A Ferraz 6,621CPURQ 27x60 / 250A max. fuse AC Ferraz 6,9xxCPgRC 14.51 32A Ferraz 6,9xxCPgRC 14.51 50A Ferraz 6,621CPURQ 27x60 / 63A Ferraz 6,621CPURQ 27x60 / 80A Ferraz 6,621CPURQ 27x60 / 125A Ferraz 6,621CPURQ 27x60 / 160A Ferraz 6,621CPURQ 27x60 / 200A Ferraz 6,621CPURQ 27x60 / 250A Connection and max. cross section of the supply line * CS M6 35mm² CS M6 35mm² CS M6 35mm² CS M8 95mm² CS M8 95mm² CS M8 95mm² CS M10 150mm² CS M10 150mm² CS M10 150mm² CS M10 150mm² Connection and max. cross section of the supply line * CS M6 35mm² CS M6 35mm² CS M8 95mm² CS M8 95mm² CS M8 95mm² CS M10 150mm² CS M10 150mm² CS M10 150mm² Connection and max. cross section of the supply line * CS M6 35mm² CS M6 35mm² CS M8 95mm² CS M8 95mm² CS M8 95mm² CS M10 150mm² CS M10 150mm² CS M10 150mm² Table 5.3 CS ≅ cable socket with drill hole for M6 /M8 / M10 * at the copper lug of the commutation choke page 27 Product manual REVCON SVC 5.4 Internal fuses REVCON ® - type SVC 11-400-1-230 SVC 18-400-1-230 SVC 28-400-1-230 SVC 38-400-1-230 SVC 50-400-1-230 SVC 70-400-1-230 SVC 100-400-1-230 SVC 135-400-1-230 SVC 160-400-3-230 SVC 200-400-3-230 Ferraz gRB -16A 660V 10x38mm Ferraz gRC -50A 660V 10x38mm Ferraz gRC -63A 660V 22x58mm Siba 50 160 06 gR-80A 660V 22x58mm Siba 50 160 06 gR-100A 660V 22x58mm Ferraz URQ-160A 660V 27x60mm Ferraz URQ-200A 660V 27x60mm Ferraz URQ-250A 660V 27x60mm Ferraz 6,6 URD 31 D11A 0350A Ferraz 6,6 URD 31 D11A 500A REVCON ® - Type DC-fuses (use fast acting semiconductor fuses only) SVC 15-460-1-115 SVC 24-460-1-115 SVC 33-460-1-115 SVC 42-460-1-115 SVC 64-460-1-115 SVC 83-460-1-115 SVC 105-460-1-115 SVC 138-460-3-115 Ferraz gRB 30A 660V 10x38mm Ferraz gRC 50A 660V 14x51mm Siba 50 160 06 gR-80A 660V 22x58mm Siba 50 160 06 gR-100A 660V 22x58mm Ferraz URQ-160A 660V 27x60mm Ferraz URQ-200A 660V 27x60mm Ferraz URQ-250A 660V 27x60mm Ferraz 6,6 URD 31 D11A 0315A REVCON ® - Type DC-fuses (use fast acting semiconductor fuses only) SVC 17-500-1-230 SVC 27-500-1-230 SVC 37-500-1-230 SVC 45-500-1-230 SVC 70-500-1-230 SVC 90-500-1-230 SVC 115-500-1-230 SVC 150-500-3-230 Table 5.4 Connection and max. cross DC-fuses (use fast acting semiconductor fuses only) Ferraz gRC 50A 660V 14x51mm Ferraz gRC 63A 660V 22x58mm Siba 50 160 06 gR-80A 660V 22x58mm Siba 50 160 06 gR-100A 660V 22x58mm Ferraz URQ-160A 660V 27x60mm Ferraz URQ-200A 660V 27x60mm Ferraz URQ-250A 660V 27x60mm Ferraz 6,6 URD 31 D11A 0350A section of the supply line * ES ES ES ES ES CS CS CS CS CS M8 M8 M8 M10 M10 10mm² 10mm² 35mm² 35mm² 35mm² 95mm² 95mm² 95mm² 185mm² 185mm² Connection and max. cross section of the supply line * ES ES ES ES CS CS CS CS M8 M8 M8 M10 10mm² 10mm² 35mm² 35mm² 95mm² 95mm² 95mm² 185mm² Connection and max. cross section of the supply line * ES ES ES ES CS CS CS CS M8 M8 M8 M10 10mm² 10mm² 35mm² 35mm² 95mm² 95mm² 95mm² 185mm² ES ≅ end sleeve for strands CS ≅ cable socket with drill hole for M6 /M8 / M10 ** at the fuse holder resp. disconnector Please note that replacing an internal fuse is only allowed with original types of fuses (see Table 5.4). page 28 Product manual REVCON SVC Before replacing a fuse you must switch-off all voltages! page 29 Product manual REVCON SVC 5.5 DC-bus connection Power unit : mains connection L1, L2, L3, PE DC-bus connection : plus and minus (from DC-bus of the frequency inverter) 530 - 750 V The installation must be done in accordance with fig. 5.2 between the DC-bus of the frequency inverters and the DC-input of the REVCON•. The input, coming from DC-bus, is internal protected with semiconductor fuses and will be connected to the DC-bus of the frequency inverter, where each plus- and minus-connection must be coupled. CAUTION: An exchange or incorrect connection of + (plus) and - (minus) can damage the frequency inverter! At the frequency inverters VLT 5000-5250 the power-feedback-unit (DC-connection) can be connected directly to the DC-terminals for + (terminal 88) and – (terminal 89) of the inverter. CAUTION: If you get an error message and a switch-off of the power-feedback-unit during a retardation, it is not allowed to reset the error directly. You have to wait until the end of the retardation and until the DC-bus voltage has fallen to normal values. To avoid any kind of problems you can block the impulse-release of the inverter by connecting the collective-error-relay-contact of the power-feedback-unit with the corresponding connection of the frequency inverter. The safety instructions of chapter 1 must absolutely be observed!! page 30 Product manual REVCON SVC Electrical installation, power cables page 31 Product manual REVCON SVC Electrical installation, power cables page 32 Product manual REVCON SVC 5.6 General instructions By these information to erectors and users of a plant hints on properties and directions concerning a REVCON power feedback unit are given. These hints are not entiteld to completeness. Special features in comparison towards a chopper Unlike a braking resistor a power feedback device isn’t a constant sink, but it’s dependent on the momentary characteristics of the supplying net. Commutation brake downs and voltage-flicker in the net have an considerable effect to the backward current of the device. In case of a short time voltage brake down the backward current has to rise correspondingly to feedback the demanded power-amount. Does the level of the supply voltage sink for a longer time, the maximum feedback power is reduced. If only one phase fails, the device is able to work on, but the current in the two remaining conductors will rise up to 150% of the normal level. Length of the DC-connection The maximum conductor inductivity of the DC-connection between the inverter and the power feedback device mustn’t exceed a certain level. The maximum conductor inductivity concerning the power feedback unit Lmax = L+ / − = µ 0l π (ln ar + 0,25) 2 C ⋅ U GL and the couple inductivity between the two DC-conductors i$ 2 give an result in the maximum length of the connection line if the current capacity is fixed by the diameter of the conductors. If the values of the input capacitance C, the during power backfeeding maximum allowed rise of the DC-voltage •UGL=100V, the top level of the AC-current of the device iˆ (=2xIeff), the average distance of the conductors a and the radius of a conductor r are known the maximum longitude of the conductors can be calculated with the following equation: lmax = 2 C ⋅ U GL ⋅π 2 a i$ ⋅ µ 0 ⋅ (ln r + 0,25) page 33 Product manual REVCON SVC Typical capacitance of the DC-connection inside the REVCON : REVCON®-Type SV SVC Power 7-45kW 70-135kW ≤45kW ≤135kW ≤200kW DC-capacitance 4,2µF 7,5µF 100µF 200µF >600µF Table 5.6.1 Example: C=7,5µF, UGL=100V, i=195A, a=20mm, r=2,8mm, µ 0=1,257.10-6 H/m ⇒ lmax=2,2m If there are long distances to span with the DC-conductors supplemental capacities should be installed (If the occasion arises, please contact our application-engineers). Operation on a generator The usage of a power feedback unit within an island network (e.g. with an diesel generator) is possible, but there are restrictive regulations concerning the power limits. G 0,4kV 100kVA REVCON RD R 20kW M 20kW ID FU RD = rectifier device ID = inverter device M Within a network, that is assembled like in figure 5.6.1, there are two additional restrictions: First the power of the motor connected to the inverter must be lower than half of the nominal power of page 34 Product manual REVCON SVC the generator. Second the total amount of the power of the two other loads must be more than double of the backfeed-power. If these conditions aren’t checked up a change from motory to generatory operation may result in load shocks. These shocks are too dynamic for the voltage regulator of the generator. The regulator reacts with an overshoot and as a result of this with an over voltage within the island network. Over voltages may cause serious damages to the connected frequency inverter and /or to the power feedback unit and to the other loads. Operation on a transformer If only a few loads operate within a network section the connected transformer must be able to transport the in this section not used power back to the next voltage level without producing a not allowed voltage increase inside the section. Therefore the nominal power of the transformer has to be one and a half higher than the backfeeded power out of the section, so that also the harmonic and reactive components of the current can be transmitted. In the network section displayed in figure 3.1 these conditions are checked up, even when the other loads are switched off. Is the backfeeded power in the order of the nominal power of the transformer, it’s impedance voltage has to be small enough (max. 6%) to limit the voltage increase in the section. The operation of the REVCON-unit in combination with an adjusting transformer (e.g. in the case of a braked slip-ring induction motor) is only allowed, if the quotient ratio of fed-back-power and nominal power is much smaller than one. page 35 Product manual REVCON SVC 10kV 0,4kV Tr 100kVA REVCON RD R 20kW M 20kW ID FU RD = rectifier device ID = inverter device page 36 M 60kW Product manual REVCON SVC Placing of the commutation choke If the frequency converter is connected to an external commutation choke, the connection of the power feedback unit has to be done at it’s network terminals (figure 5.6.3). Is the connection done at the load terminals of the commutation choke it’s inductivity prevents the synchronising to the supplying net and the induction voltage of the choke when it is switched of under load may result in damages to the power feedback device. Over voltages may cause serious damages to the connected frequency inverter and /or to the power feedback unit and to the other loads. Speisendes Netz REVCON GR WR FU Bild 5.1 M 60kW the same things apply to the also non-admissible pre-connection of further commutation chokes. page 37 Product manual REVCON SVC Line and contact resistances The values of current carrying capacity of conductors refer to the most often used copper conductors. Concerning to it’s higher specific resistance aluminium conductors must have greater dimensions. Regardless of which conducting materials is used, the contact terminals of the conductors have to be low resistive and their number has to be reduced to the minimum. Too much or too high resistive terminals may result in a unsafe voltage magnification during the power feedback operation. ∆U ∆U ∆U ∆U ∆U ∆U ∆U I Supplying network REVCON RD RD = rectifier device ID = inverter device ID FU Figure 6.1 M Proceeding from a stable network with e.g. 400V nominal voltage and a backward current of 80A, at a bad made terminal of 100mΩ a voltage of 8V is dropped (A good made terminal has got a resistance of ca 1 mΩ.). During backfeed operation at seven serial terminals at the net switch there results an voltage of 465V. Over voltages may cause serious damages to the connected frequency inverter and /or to the power feedback unit and to the other loads. page 38 Product manual REVCON SVC Current capacity of copper conductors for frequency inverters and power feedback operation conductor cross section (mm²) per phase 16 25 35 50 70 95 120 185 2x120 2x150 2x185 3x185 3x240 4x240 conductor radius (mm) 2,3 2,8 3,3 4,0 4,7 5,5 6,2 7,7 2x6,2 2x6,9 2x7,7 3x7,7 3x8,7 4x8,7 fuse (A) 63 80 100 125 160 200 250 315 400 500 630 800 1000 1250 max. permanent current (A) 46 59 73 90 106 140 206 250 300 390 485 570 740 920 All values are based on a cable length of 100m and a max. voltage drop of 5V table 5.6.2 Connecting further loads Speisendes Netz The connection of further loads ( e.g. cabinet ventilation or climatisation) parallel to the frequency inverter / REVCON® unit at a common circuit breaker like in figure 5.6.5 is REVCON GR not allowed. If it’s done nevertheless, in case of tripping of the circuit breaker the connection to the network ( energy sink and synchronising WR element for the power feedback unit) misses. FU The IGBT’s now switch the DC-voltage directly to the other loads. The resulting nearly Bild 7.1 M 60kW M rectangular "net"-voltage drives a current through the loads, which level and form depends on their impedance. Is the power consumption of the loads to small, the DC-voltage and also the output voltage of the REVCON-unit rises during the backfeed operation. page 39 Product manual REVCON SVC Over voltages may cause serious damages to the connected frequency inverter and /or to the power feedback unit and to the other loads. Supplying network RD RD RD ID ID ID FU FU Figure 7.2 M M REVCON FU M 60kW Same things apply to the structure like in figure 5.6.6. Even in this case it is necessary to place a circuit breaker in each backfeeding current circuit. UCE-cut-off The power feedback unit cuts off via the UCE-protective-circuitry if the specific maximum current of the device is exceeded. The principle of this protective-circuitry implies that for a short time (less than one millisecond) the IGBT is stressed over its specification for normal operation. For an isolated case this means no problem for the REVCON-unit. However, if the over current cut off arises often or even periodically, the high power semiconductors will age very rapid and fail premature. The cause of periodical UCE cut offs may be over load, under voltage in the network, a defective or oscillating controller, e.g. of the frequency inverter, an oscillating reference input or a wrong dimensionation of the plant. page 40 Product manual REVCON SVC 6.0 Allowed operating data with max. braking power − Devices of product line REVCON® SV 11-400-1 without forced cooling have an allowed operating duration of 100%. − Devices of product line REVCON® SV 18-400-1 without forced cooling have an allowed operating duration of 50% (referring to a cycle time of 10 min.). With forced cooling they have an allowed operating duration of 100%. − Devices of product line REVCON® SV 28-400-1 with forced cooling have an allowed switch on duration time of 50% (referring to a cycle time of 10 min.). − For the devices from product line REVCON® SV 38-400-1 the following thermal limited load graphs are valid. Remark: The specification of the actual mains voltage (between 380V and 500V) serves to the adaptation resp. to the optimal adjustment of the control board. However, the dimensioning of the powercomponents keeps to the nominal voltage of the device ( either 400V or 500V). The power value, named as type-power, ( e.g. 70kW with a SVC70) always refers to the nominal voltage. If the actual voltage is 440V with a 500V-unit, even the power, which can be fed back, is reduced by 12% from 70kW to 61.1kW. On the other hand, if the actual voltage is 415V with a 400V-unit, the power, which can be fed back, is increased by 3.7% from 70kW to 72.6kW. page 41 Product manual REVCON SVC 6.1 Thermal limited load graphs By means of these thermal limited load graphs you can find out the max. switch-on-time depending on the needed braking power. The curves are valid for a max. cooling air temperature of 35°C (95°F). REVCON SV 45-XXX-YY-... 10 33 kW with fan 100 % constant power with fan: 26 kW min 9 braking time 8 7 6 45 kW with fan 5 4 2 33 kW without fan 3 1 2 37 kW without fan 1 2 1 0 0 1 2 3 4 5 6 7 8 9 10 min 11 intermission time Example of an application: Diagram 6.1.1 Example å: Evaluation: Example : Evaluation: Remark: page 42 necessary braking power : 50 kW braking duration : 2 min. time between two brakes : 5 min. In this case the point of intersection of braking time and intermission time is below the thermal limited power graph in the allowed area (with forced cooling). necessary braking power : 50 kW braking duration : 3 min. time between two brakes : 3 min. In this case the point of intersection of braking time and intermission time is above the thermal limited power graph. That means this operation cycle is not allowed. In case of an intermission time of e.g. 4 min. this operation cycle would be allowed again. Product manual REVCON SVC Thermal limited load graphs: REVCON SVC 38-400-1 10 min 9 Bremszeit 8 38 kW mit Lüfter 100 % Dauerleistung mit Lüfter: 30 kW 7 6 5 4 3 2 1 0 0 1 2 3 4 5 6 7 9 10 min 11 Pausenzeit 8 Diagram 6.1.2 REVCON SVC 50-400-1 10 min 40 kW mit Lüfter 100 % Dauerleistung mit Lüfter: 30 kW 9 Bremszeit 8 7 6 50 kW mit Lüfter 5 4 3 2 1 0 0 1 2 3 4 5 6 7 9 10 min 11 Pausenzeit 8 Diagram 6.1.3 REVCON SVC 70-400-1 5 min 4,5 Bremszeit 4 100 % Dauerleistung mit Lüfter: 35 kW 50 kW mit Lüfter 3,5 3 2,5 2 1,5 70 kW mit Lüfter 1 0,5 0 0 1 2 3 4 5 6 7 8 9 10 min11 Pausenzeit Diagram 6.1.4 page 43 Product manual REVCON SVC REVCON SVC 100-400-1 5 min 4,5 Bremszeit 4 100 % Dauerleistung mit Lüfter S3:38 kW 60 kW mit Lüfter S3 3,5 3 2,5 2 1,5 100 kW mit Lüfter S3 1 0,5 0 0 1 2 3 4 5 6 8 9 10 min 11 Pausenzeit 7 Diagram 6.1.5 REVCON SVC 135-400-1 5 min 4,5 Bremszeit 4 100 % Dauerleistung mit Lüfter S3:40 kW 3,5 65 kW mit Lüfter S3 3 2,5 2 1,5 135 kW mit Lüfter S3 1 0,5 0 0 1 2 3 4 5 6 7 8 9 10 min 11 Pausenzeit Diagram 6.1.6 REVCON SV(C) 160-XXX-3-... 5 min 100 % constant power with fan S3: 70 kW 4,5 braking 4 time 3,5 100 kW with fan S3 3 2,5 2 1,5 160 kWwith fan S3 1 0,5 0 0 1 2 3 Diagram 6.1.7 page 44 4 5 6 7 8 9 10 min 11 intermission time Product manual REVCON SVC REVCON SV(C) 200-XXX-3-... 5 min 4,5 braking time 4 100 % constant power with fan S3: 70 kW 3,5 120 kW with fan S3 3 2,5 2 1,5 1 200 kW with fan S3 0,5 0 0 1 2 3 4 5 6 7 8 9 10 min 11 intermission time Diagram 6.1.8 page 45 Product manual REVCON SVC 7.0 REVCON• control board version 1.4.X The control terminal strip is placed on the control board and is indicated with X2. It is also fitted with a plug-in device for easy handling (see figure 4.2). The control board must always be designed for the respective main circuit voltage. Therefore the main circuit voltage (400V) must be declared with every order. This is also necessary for an exchange of the device. From the control terminal strip the operating condition or rather the collective error can be connected to extern. There is also the possibility to execute the external reset or the switchfunctions and to connect them with the frequency inverter. Terminal occupation X2 1 2 3 collective error relay 4 5 6 terminal 5 and 6 intern connected to the temperature supervision 7 external OFF 8 9 external ON/RESET 10 11 12 figure 7.0 page 46 + - ON/RESET Product manual REVCON SVC 7.1 Terminal 1-4 (valid for REV 1.4.X) s. figure 4.2 There are 2 potential-free relay-contacts (one by one make-/brake-contact) with a load-capacity of 250 V ~ / 5 A or 30 V = / 3 A. In figure 7.0 the relay is shown in neutral position. The relay operates when: 1. main circuit voltage is present 2. no collective error exists and after possibly an ON-signal was given. If there is an OFF-signal at the control terminal a collective error will be signalled because in this case the collective error relay falls. 7.2 Terminal 5, 6 (valid for REV 1.4.X) These terminals are used by the internal temperature supervision. 7.3 Terminal 7, 8 (valid for REV 1.4.X) (run the cable shielded) OFF Possibility to connect an external potential-free push button switch (make contact) to switch-off the power-feedback-unit REVCON from external. F Remark Power-feedback will be suddenly interrupted when an OFF-signal is given to the device. When giving the OFF-signal during the retardation it can happen that an error-message of too high DC-bus voltage is displayed at the frequency inverter. page 47 Product manual REVCON SVC 7.4 Terminal 9, 10 (valid for REV 1.4.X) (run the cable shielded and separated from power cables, max. length 2,5m) ( if there are longer distances to span, use terminals 11 and 12) ON / RESET Possibility to connect an external potential-free push button switch (make contact) to switch-on or rather reset the power-feedback-unit REVCON from external. F Remark Power-feedback will be suddenly interrupted when an OFF-signal is given to the device. When giving the OFF-signal during the retardation it can be happen that an error-message of too high DCbus voltage is displayed at the frequency inverter. CAUTION Don’t put an external voltage at terminals 5 - 10. This may cause failures and can damage the device. 7.5 Terminal 11, 12 (valid for REV 1.4.X) Possibility to connect an external voltage 12-24 V DC (e.g. PLC) to switch on or rather reset the power-feedback-unit REVCON. (Plus to terminal 11, Minus to terminal 12) page 48 Product manual REVCON SVC 8.0 Connection of the ext. operating and signalling board (option) When mounting the device inside a cabinet it is possible to mount the operator panel in the door of the cabinet by using the external operating and signalling board. The external board contains the complete display (LED’s) of all running and failure messages and also the ON / RESET push button switch. The connection is realised by means of the ribbon cables at the pin-type-socket X4 (see figure 4.2, page 10) of the control board. The external operating and signalling board is available as option. F Remark The operation of the device with the external operating and signalling board has no influence on signalling the operating and error messages of the LED’s placed on the control board. Both signals are working together. In case of an operation together with the board and an ON-OFF-function by the control terminal X2 the switch-off signal always has priority, independent of the ON-RESET push button switch. CAUTION Don’t put an external voltage to the pin-type-socket X4 or to the external operating and signalling board. This can damage the devices. page 49 Product manual REVCON SVC 8.1 LED messages (control board version 1.4.X) evaluation LED – display LED display operation phase failure UCE overtemp. disturbance green red red orange yellow At first starting During operation Error code: 1 X 2 X 3 X 3a X 4 X 5 X 6 X* 7 X* 8 X X X X ready to operate (after about 1 sec.) system in operation X system is switched off (external OUT) ⇒release necessary system is switched off (external OUT) ⇒release necessary X rotary field incorrect or one phase is missing phase failure has been detected ⇒confirmation necessary in addition from version 1.4.3: overvoltage switch-off X error code 6 heatsink temperature declined to normal and the error is resetable. X X overcurrent has been detected ⇒ confirmation necessary X X X X* X X* X error code 3 and 4 overtemperature of the heat sink ⇒ error-message is not resetable as long as the temperature is too high several errors at the same several errors at the same time time ready for operation, but no power feedback ⇒ check the DC-fuses out of operation, min. 2 phases without voltage 9 10 X 11** X overcurrent has been detected with phase failure, based on a voltage breakdown during commutation X X out of operation, min. 2 phases without voltage overcurrent has been detected ⇒ confirmation is necessary massive voltage breakdown during commutation but without switching off as Jumper 3 and 7 are open (chapter 9e) ⇒ operation possible, mains improvement advisable Table 8.1 *Remark: ** page 50 A separate orange LED in the cover of the housing is not existing. The green LED in the cover is changing the colour from green to orange in the case of failure (only for version 1.4.3 and higher). For control board version 1.4.2 or higher Product manual REVCON SVC 9.0 Function description of the device The coding of the jumpers enables different driving possibilities and different internal functions at special error messages. In the following different definitions are explained which result from specific possibilities of coding. a) "Autostart" Autostart means that the device is starting with a delay-time of about 1 sec. after connecting mains voltage by itself ("automatical switch-on"). Coding via jumper, see figure 4.2: J1 open : no Autostart J1 closed : Autostart b) "Switch off" - "Switch on" Switch-off means that the driving of the semiconductors and the power feedback will be interrupted. A braking operation of the frequency inverter is no longer possible. Switch-on is the activation of driving the semiconductors. c) "Storage" REVCON is equipped with an error storage where special failures can be assigned to. Stored error messages have to be confirmed by RESET or interruption of mains supply. "Storage" always leads to a "switch-off" and to a collective-error-relay drop out. page 51 Product manual REVCON SVC d) "Confirmation" After a storage, when the failure is removed, the error storage must be confirmed by pushing the RESET-button or rather by switching-off the main circuit voltage (3-ph.). CAUTION A confirmation in case of to high DC-bus voltage during the braking operation is not allowed and can damage the device. e) "Phase failure" The phase failure control unit controls the mains supply in all 3 phases. In case of phase failure REVCON stays still in function for internal supplies, e.g. for the error storage. REVCON reacts in different ways on phase failures. One possibility is the "2 phase operation", the other one let the system get out of operation and the collective-error-relay signals the failure. Coding via jumper, see figure 4.2: J3 phase-failure-supervision sensitive 0 Jumper open ___ ___ ___ ___ ___ insensitive Jumper closed ___ 0 X X off, storage “ON” X Jumper random 0 0 X X off, Storage “OFF” Remark: Jumper J7 is mounted on control boards version 1.4.2 or higher. Storage “ON” means, that the “Phase-failure” LED will be active, until the fault is confirmed. “OFF” means, that the LED is active as long as the fault is present. ___ J5 0 J6 0 J7 ___ Disconnecting the Jumper J3 is only allowed, if the pre-connected main switches cut off the pulses of the frequency inverter or the REVCON-unit when the supplying network is switched off. Only with this additional contact it is sure, that in such a case the voltage in the specific network area would not rise up to a dangerous level. The Jumper J7 should only be disconnected, if J3 is page 52 Product manual REVCON SVC disconnected too, because a phase failure would only be displayed as long as it is present and would not be stored. page 53 Product manual REVCON SVC f) Over voltage control With version 1.4.3 or higher an over voltage control for the AC-voltage is mounted inside the unit. It switches off the power feedback unit at an AC-voltage off about 1.15xUN. In this case the error code 3 is displayed (see chapter 8.1). To difference between the error messages “Phase failure” and “Over voltage” it is possible to deactivate the phase failure control by disconnecting Jumper 3 . If then the unit is switched of and the red and the yellow LED are active (error code 3), an over voltage is the cause of the error. Standard setting of the unit Autostart and Switching off in case of phase failure with storage. 10.0 Options 10.1. External operating and signalling board. 10.2 Radio interference filter REVCON ® - type SVC 11-400-1-230 SVC 18-400-1-230 SVC 28-400-1-230 SVC 38-400-1-230 SVC 50-400-1-230 SVC 70-400-1-230 SVC 100-400-1-230 SVC 135-400-1-230 SVC 160-400-1-230 SVC 200-400-1-230 page 54 Order-designation / part-number for filter RF-SVC 11 RF-SVC 18 RF-SVC 28 RF-SVC 38 RF-SVC 50 RF-SVC 70 RF-SVC 100 RF-SVC 135 RF-SVC 160 RF-SVC 200 / / / / / / / / / / 192H3622 192H3622 192H3643 192H3643 192H3644 192H3645 192H3645 192H3646 192H3646 192H3647 Case-type 1 1 1 1 2 2 2 3 3 3 Product manual REVCON SVC The radio interference filter of case-type 1 and 2 are mounted in footprint-housings, which could be placed between cabinet-wall and REVCON-unit. Diagram case-type 1 REVCON PE,L1,L2,L3 Netz PE,L1,L2,L3 Diagram case-type 2 REVCON PE,L1,L2,L3 Netz PE,L1,L2,L3 The radio interference filter of case-type 3 are mounted in housings, which should be placed beside the REVCON-unit. Diagram case-type 3 The power feedback units were fixed with screws M6 , the RFI-filter with screws M8. page 55 Product manual REVCON SVC > Subject to change without notice < Danfoss Antriebs- und Regeltechnik GmbH, Geschäftsbereich Elektrische Antriebe Carl-Legien-Straße 8 63073 Offenbach Tel.: (069) 8902-0 Telefax: (069) 8902-106 www.danfoss-sc.de Danfoss can accept no responsibillity for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. MP.50.R1.32 page 56 Made for Danfoss by ELTROPLAN-REVCON