Application of Multilevel Inverter Using Modulation

advertisement

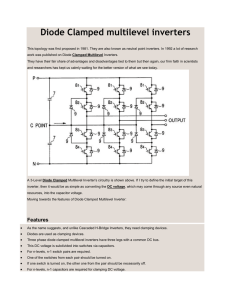

"Sharpening Skills..... Serving Nation" International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459 (Online), Volume 4, Special Issue 1, February 2014) International Conference on Advanced Developments in Engineering and Technology (ICADET-14), INDIA. Application of Multilevel Inverter Using Modulation Technique For Running Induction Motor Smoothly Sandeep Kumar1, Ishtiyaque Ahmed2 1 Student, M.Tech, 2Assistant Professor, Dehradun Institute of Technology, Dehradun Abstract - The Multilevel Inverter topology is advantageous in high-power and power-quality demanding application without use of transformer with reduced harmonic distortion. This paper explain the basic type of Multilevel Inverter such as diode clamped multilevel inverter (neutral point clamped), flywheel capacitor multilevel inverter (capacitor clamped), cascade multilevel inverter also the modulation and control technique like Pulse Width Modulation, Space Vector Modulation, Selective Harmonic Elimination are applied on MLI and the gate signal through modulation technique is given to MLI in such a way to reduce Harmonic Distortion with the fact that when Induction Motor are fed through MLI, motor run smother. Induction motor has advantage like reduced total harmonic distortion and higher torque. The effectiveness of the system is verified through simulation using MATLAB / SIMULINK package Keywords--Induction Modulation technique Motor, Multi-Level 3- Reduce the stress in motor bearing by generating smaller common mode voltage 4- Produce voltage with reduce harmonic content and near sinusoidal waveform The term Multilevel was first introduced by Nable el al;[5] as number of levels increase in inverter the output voltage has more steps generating a staircase waveform with a reduced harmonic distortion but a higher number increase the control complexity. PWM, SVM, SHE, DTC etc are the modulation and control strategies [6] developed for multilevel inverter. Inverter, I. INTRODUCTION In two inverter technology output waveform is of two values (level) include increase harmonic distortion, ripple factor, higher voltage derivative, torque pulsation in induction motor. Multilevel inverter [1]-[4] is considered as a state of art power conversion from DC to AC for high power and power quality demanding applications. Multilevel inverter is useful in some application as transport, mining, manufacturing and others. Recently they have been proposed to enable new possibility for other important applications like electronic and hybrid vehicle, wind energy conversion, UPS, photovoltaic energy conversion and others. Multilevel is suitable for high power and power quality demanding application. Some of the other feather of Multilevel Inverter is as follows 1- The output generated voltage is of extremely low distortion and lower voltage derivative 2- The switching frequency on which they are operated are of lower order Fig 1. (a) two levels, (b) three levels, (c) n levels This paper emphasizes on the fact that when induction motor are fed with Multilevel Inverter [7]-[9] it torque pulsation are reduced and motor run smoothly. In this manner efficiency of induction motor are also increase and losses are reduced. II. MULTILEVEL INVERTER Voltage source inverter produces an output voltage or current with two levels. Two levels inverter have some limitation in operating due to harmonic content and switching losses. Lord Krishna College of Engineering (An ISO 9001:2008 Certified Institute) Ghaziabad, Uttar Pradesh, INDIA. Page 416 "Sharpening Skills..... Serving Nation" International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459 (Online), Volume 4, Special Issue 1, February 2014) International Conference on Advanced Developments in Engineering and Technology (ICADET-14), INDIA. Now it is easy to produce a high power, high voltage inverter with multilevel structure increasing the number of voltage or current level at output terminals. Various PWM strategies are to be applied on multilevel inverter to obtain quality output voltage or current. The general purpose of multilevel inverter is to synthesize a near sinusoidal voltage and to reduce harmonic content and ripple factor. The number of level of inverter can be defined as the number of steps or constant voltage that is generated by inverter at output terminal. Minimum three different voltage levels have to be generated at output terminal to be called as multilevel inverter. This is the basic difference between two level inverter and multilevel inverter. Multilevel inverter has an array of power semiconductor and capacitor voltage sources thus generate output with stepped waveform when proper switching is performed. It eliminates the use of step up transformer. With this phenomenon kv rating can be extended and it is suitable for high voltage high current application. Diode Clamped Multilevel Inverter In fig 3 three level and five level Multilevel Inverter are shown. N is the neutral point [5]. Vdc is the input and C1 and C2 are the two capacitor voltage connected to this input. For three level the output voltage Van has three states: Vdc/2 , 0, and –Vdc/2 . For voltage level Vdc/2 , switches S1 and S2 need to be turned on; for –Vdc/2 , switches S1’ and S need to be turned on; and for the 0 level,S2 and S1’ need to be turned on. Diode clamped inverter[5] have some advantage over other type of multilevel inverter such as when number of level are high enough harmonic content are low enough. Inverter efficiency are high and control method are low. It has some major drawback also like excessive clamping diode are required when the number of level are high also it’s difficult to control real power flow of the individual converter in multi converter system. Fig 3. Diode clamped multilevel inverter circuit (a) three level (b) five level Capacitor Clamped Multilevel Inverter Fig 4 show the capacitor clamped multilevel inverter [10]-[11]. It is also called flywheel capacitor inverter. The basic difference between capacitor clamped multilevel inverter and diode clamped multilevel inverter is that in capacitor clamped multilevel inverter diode is replaced by capacitor. In capacitor clamped multilevel inverter also Van has three output voltage level that is Vdc/2 , 0, and – Vdc/2. For voltage level Vdc/2, switches S1 and S2 need to be turned on; for – Vdc/2, switches S1’ and S2’ need to be turned on; and for the 0 level, either pair (S1,S1’ ) or (S2,S2’) needs to be turned on. Lord Krishna College of Engineering (An ISO 9001:2008 Certified Institute) Ghaziabad, Uttar Pradesh, INDIA. Page 417 "Sharpening Skills..... Serving Nation" International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459 (Online), Volume 4, Special Issue 1, February 2014) International Conference on Advanced Developments in Engineering and Technology (ICADET-14), INDIA. Clamping capacitor C1 is charged when S1 and S1’ are turned on, and is discharged when S2 and S2’ are turned on. Its advantage is large amount of capacitor can provide capability during power outage and it provide switch combination redundancy for balancing different voltage level. The major disadvantage is large number of capacitor is required when level is high also inverter control is very complicated. Fig 6. Cascade multilevel inverter with its waveform Modulation and control strategies Fig 4. Capacitor clamped multilevel inverter (a) three level (b) five level Cascade Multilevel Inverter Cascade H-Bridge multilevel inverter [12]-[14] are formed by series connection of two or more single phase H-Bridge inverter. Fig 5 shows the basic diagram of cascade multilevel inverter. Each single phase full bridge inverter generates three voltage at the output +Vdc, 0, and – Vdc. The H-Bridge inverter that are connected in series do not necessarily need to have the same dc input voltage in such manner we can generate different combination of voltage levels and eliminate redundancies. Some advantages of cascade multilevel inverter are that compared to other it require least number of component to achieve same number of voltage level also no extra clamping diode and voltage balancing capacitor is required and it has less switching loss, device stress. It drawback is that it need separate DC sources for real power conversion. Fig 6. Modulation technique for multilevel inverter Switching state of a converter is a set of signal used to control each switching device of power circuit. The above control technique [15]-[21] are use to reduce harmonic content by giving proper pulses to multilevel inverter. There is inherent additional complexity of having more power electronic device but it create possibility to take advantage of the extra degree of freedom with the help of these modulation and control technique. A very popular method is the classic carrier based sinusoidal PWM which use phase shifting technique to reduce the harmonic. Another alternative is SVM, SHE, DTC etc. Lord Krishna College of Engineering (An ISO 9001:2008 Certified Institute) Ghaziabad, Uttar Pradesh, INDIA. Page 418 "Sharpening Skills..... Serving Nation" International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459 (Online), Volume 4, Special Issue 1, February 2014) International Conference on Advanced Developments in Engineering and Technology (ICADET-14), INDIA. III. S IMULATION MODAL AND R ESULTS For the validation of previously discussed approach, simulation on three level diode clamped multilevel inverter fed induction motor is carried out using Matlab Simulink. Induction motor parameter are given below Motor typesquirrel-cage, 10 hp, 7.5 kw, 400 V, 50 Hz, 1440 RPM REFRENCES [1] [2] [3] [4] [5] [6] [7] Below figure shows simulation result. [8] [9] [10] [11] [12] Fig 7. (a) motor current, (b) motor speed, and (c) electromagnetic torque [13] IV. CONCLUSION Multilevel inverter are very useful in high power and power quality application. Modulation method are getting trend on multilevel inverter for better performance. When these topology are applied on induction motor its performance get increase compared to conventional inverter. Torque pulsation get reduced and motor run smoothly. [14] [15] [16] J. S. Lai and F. Z. Peng, ―Multilevel converters–A new breed of power converters,‖ IEEE Trans. Ind. Applicat., vol. 32, pp. 509–517, May/June 1996. L. Tolbert, F.-Z. Peng, and T. Habetler, ―Multilevel converters for large electric drives,‖ IEEE Trans. Ind. Applicat., vol. 35, pp. 36–44, Jan./Feb. 1999. R. Teodorescu, F. Beaabjerg, J. k. Pedersen, E. Cengelci, S. Sulistijo, B. Woo, and P. Enjeti, ―Multilevel converters — A survey,‖ in Proc. European Power Electronics Conf. (EPE’99), Lausanne, Switzerland, 1999, CD-ROM. jose Rodriguez, Samir Kouro, Ramon C. Portillo and Marcelo A. Perez ―Multilevel converter: enabling technology for High-Power Application‖ 2009 IEEE A. Nabae, I. Takahashi, and H. Akagi, ―A new neutral-point clamped PWM inverter,‖ IEEE Trans. Ind. Applicat., vol. IA-17, pp. 518– 523, Sept./Oct. 1981. J Rodriguez, J.S. Lai and F.Z. Peng, ―Multilevel Inverter: A survey of topologies, controls and applications,‖ IEEE Trans. Ind. Electron., vol 49, pp. 724-738, aug. 2002 Dr.Rama Reddy and G.Pandian, ―Implementation of Multilevel inverter fed Induction motor Drive,‖ Journal of Industrial Technology, vol 24, no. 1, April 2008. Nikolaus P. Schibli, T. Nguyen, and Alfred C. Rufer, ―A ThreePhase Multilevel Converter for High - Power Induction Motors,‖ IEEE Trans on Power Electronics, vol.13, no.5, Sept 1998. N.Celanovic and D.Boroyevich, ― A Comprehensive study of neutral-pointvoltage balancing problem in three-level neutral –point clamped voltage source PWM inverters,‖ IEEE Trans on Power Electronics, vol.15, no. 2, pp. 242 – 249, March 2000 T. A. Meynard and H. Foch, ―Multi-level choppers for high voltage applications,‖ Eur. Power Electron. Drives J., vol. 2, no. 1, p. 41, Mar. 1992. C. Hochgraf, R. Lasseter, D. Divan, and T. A. Lipo, ―Comparison of multilevel inverters for static var compensation,‖ in Conf. Rec. IEEE-IAS Annu. Meeting, Oct. 1994, pp. 921–928. P. Hammond, ―A new approach to enhance power quality for medium voltage ac drives,‖ IEEE Trans. Ind. Applicat., vol. 33, pp. 202–208, Jan./Feb. 1997. E. Cengelci, S. U. Sulistijo, B. O. Woom, P. Enjeti, R. Teodorescu, and F. Blaabjerge, ―A new medium voltage PWM inverter topology for adjustable speed drives,‖ in Conf. Rec. IEEE-IAS Annu. Meeting, St. Louis, MO, Oct. 1998, pp. 1416–1423. R. H. Baker and L. H. Bannister, ―Electric power converter,‖ U.S. Patent 3 867 643, Feb. 1975. J. Rodríguez, P. Correa, and L. Morán, ―A vector control technique for medium voltage multilevel inverters,‖ in Proc. IEEE APEC, Anaheim, CA, Mar. 2001, pp. 173–178. L. Tolbert and T. G. Habetler, ―Novel multilevel inverter carrierbased PWM method,‖ IEEE Trans. Ind. Applicat., vol. 35, pp. 1098– 1107, Sept./Oct. 1999. Lord Krishna College of Engineering (An ISO 9001:2008 Certified Institute) Ghaziabad, Uttar Pradesh, INDIA. Page 419 "Sharpening Skills..... Serving Nation" International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459 (Online), Volume 4, Special Issue 1, February 2014) International Conference on Advanced Developments in Engineering and Technology (ICADET-14), INDIA. [17] Y. Liang and C. O. Nwankpa, ―A new type of STATCOM Based on cascading voltage-source inverters with phase-shifted unipolar SPWM,‖ IEEE Trans. Ind. Applicat., vol. 35, pp. 1118–1123, Sept./Oct. 1999. [18] L. Li, D. Czarkowski, Y. Liu, and P. Pillay, ―Multilevel selective harmonic elimination PWM technique in series-connected voltage inverters,‖ in Conf. Rec. IEEE-IAS Annu. Meeting, Oct. 1998, pp. 1454–1461. [19] S. Sirisukprasert, J. S. Lai, and T. H. Liu, ―Optimum harmonic reduction with a wide range of modulation indexes for multilevel converters,‖ in Conf. Rec. IEEE-IAS Annu. Meeting, Rome, Italy, Oct. 2000, pp. [20] D. G. Holmes and B. P. McGrath, ―Opportunities for harmonic cancellation with carrier-based PWM for two-level and multilevel cascaded inverters,‖ IEEE Trans. Ind. Applicat., vol. 37, pp. 574– 582, Mar./Apr. 2001. 2094–2099. [21] A. Campagna et al., ―A new generalized multilevel three-phase structure controlled by PWM,‖ in Proc. Fourth European Conf. Power Electronics and Applications, 1991, pp. 235–240 Lord Krishna College of Engineering (An ISO 9001:2008 Certified Institute) Ghaziabad, Uttar Pradesh, INDIA. Page 420