mechanical case outline

advertisement

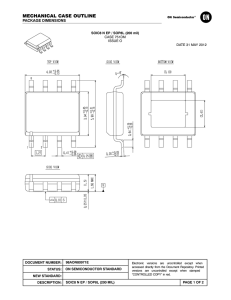

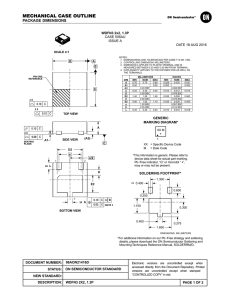

MECHANICAL CASE OUTLINE PACKAGE DIMENSIONS LQFP256 EP 28x28, 0.4P CASE 561BB ISSUE A DATE 04 FEB 2013 SCALE 0.5:1 SIDE AND DETAIL VIEWS ON PAGE 2 DIMENSIONS, NOTES, SOLDER FOOTPRINT & MARKING DIAGRAM ON PAGE 3 DOCUMENT NUMBER: STATUS: NEW STANDARD: 98AON83217E ON SEMICONDUCTOR STANDARD 1 http://onsemi.com LQFP256 EP 28X28, 0.4P 1 © Semiconductor Components Industries, LLC, 2002 October, DESCRIPTION: 2002 − Rev. 0 Electronic versions are uncontrolled except when accessed directly from the Document Repository. Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red. Case Outline Number: PAGE 1 OFXXX 4 LQFP256 EP 28x28, 0.4P CASE 561BB ISSUE A DATE 04 FEB 2013 DIMENSIONS, NOTES, SOLDER FOOTPRINT & MARKING DIAGRAM ON PAGE 3 DOCUMENT NUMBER: STATUS: NEW STANDARD: 98AON83217E ON SEMICONDUCTOR STANDARD http://onsemi.com LQFP256 EP 28X28, 0.4P 2 © Semiconductor Components Industries, LLC, 2002 October, DESCRIPTION: 2002 − Rev. 0 Electronic versions are uncontrolled except when accessed directly from the Document Repository. Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red. Case Outline Number: PAGE 2 OFXXX 4 LQFP256 EP 28x28, 0.4P CASE 561BB ISSUE A NOTES: 1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994. 2. CONTROLLING DIMENSION: MILLIMETERS. 3. DIMENSION b DOES NOT INCLUDE DAMBAR PROTRUSION. ALLOWABLE PROTRUSION SHALL BE 0.08 TOTAL IN EXCESS OF b AT MMC. 4. DIMENSION b APPLIES TO THE PLATED LEAD AND IS MEASURED BETWEEN 0.10 AND 0.25 FROM THE LEAD TIP. 5. DIMENSIONS D1 AND E1 ARE DETERMINED AT DATUM PLANE H. DIMENSIONS D1 AND E1 DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS. MOLD FLASH SHALL NOT EXCEED 0.25 PER SIDE. DIMENSIONS D1 AND E1 ARE MAXIMUM PLASTIC BODY SIZE INCLUDING MOLD MISMATCH. 6. DATUM PLANE H IS LOCATED AT THE BOTTOM OF THE LEAD AND IS COINCIDENT WITH WHERE THE LEADS EXIT THE PLASTIC BODY AT THE BOTTOM OF THE PARTING LINE. DATUMS A, B, AND D ARE TO BE DETERMINED AT DATUM PLANE H. 7. DIMENSIONS D AND E ARE DETERMINED AT SEATING PLANE DATUM C. 8. EXACT SHAPE OF THE CORNER IS OPTIONAL. 9. A1 IS DEFINED AS THE VERTICAL DISTANCE FROM THE SEATING PLANE TO THE LOWEST POINT ON THE PACKAGE BODY. DIM A A1 A2 A3 b D D1 D2 E E1 E2 e L L2 M MILLIMETERS MIN MAX 1.60 --0.05 0.15 1.35 1.45 0.20 0.09 0.13 0.23 30.00 BSC 28.00 BSC 9.75 9.85 30.00 BSC 28.00 BSC 9.75 9.85 0.40 BSC 0.45 0.75 0.25 BSC 0_ 7_ DATE 04 FEB 2013 RECOMMENDED SOLDERING FOOTPRINT GENERIC MARKING DIAGRAM* XXXXXXXXXXXX XX AWLYYWWG XXXXX A WL YY WW G = Specific Device Code = Assembly Location = Wafer Lot = Year = Work Week = Pb−Free Package *This information is generic. Please refer to device data sheet for actual part marking. Pb−Free indicator, “G”, may or not be present. DOCUMENT NUMBER: STATUS: NEW STANDARD: 98AON83217E ON SEMICONDUCTOR STANDARD http://onsemi.com LQFP256 EP 28X28, 0.4P 3 © Semiconductor Components Industries, LLC, 2002 October, DESCRIPTION: 2002 − Rev. 0 Electronic versions are uncontrolled except when accessed directly from the Document Repository. Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red. Case Outline Number: PAGE 3 OFXXX 4 DOCUMENT NUMBER: 98AON83217E PAGE 4 OF 4 ISSUE REVISION DATE O RELEASED FOR PRODUCTION. REQ. BY D. GASTELUM. 07 JAN 2013 A CORRECTED DIMENSIONS D2 AND E2 MIN & MAX VALUES IN TABLE TO 9.75 & 9.85. REQ. BY D. GASTELUM. 04 FEB 2013 ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner. © Semiconductor Components Industries, LLC, 2013 February, 2013 − Rev. A Case Outline Number: 561BB