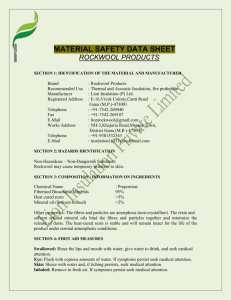

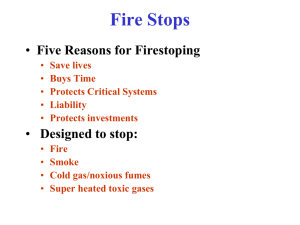

Comprehensive range of fire resistance products

advertisement