FUNdaMENTALS of Design

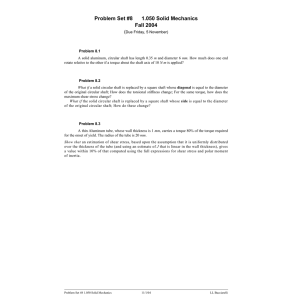

advertisement