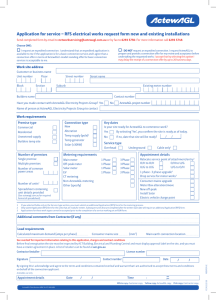

Guidelines for embedded generator connection to ActewAGL`s low

advertisement