READ, UNDERSTAND and FOLLOW the Safety and Opera

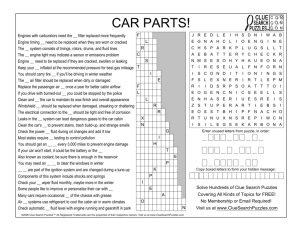

advertisement