Design and Development of Wireless Flow Transmitter

advertisement

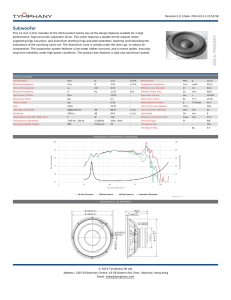

International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT) - 2016 Design and Development of Wireless Flow Transmitter Hemalatha. J, Nikhil P.S, Shaniya Shaji C and Komanapalli Venkata Lakshmi Narayana, Member, IEEE School of Electrical Engineering VIT University Vellore, India Abstract — This paper presents the development of a wireless flow transmitter using rotameter and operational amplifier based signal conditioning circuit. The rotameter is a linear gravity based flow measuring device. It consists of a display unit which directly displays the flow rate. For industrial applications a new circuitry is required to transmit the measured flow rate to the control unit at remote areas. A ferromagnetic wire attached to the float of rotameter acts as a core of an inductance pickup coil constitutes the flow sensor. The self-inductance of the coil changes according to the change in flow rate. An operational amplifier based circuit is used for the measurement of selfinductance. The voltage corresponding to the flow rate is finally converted into 4-20 mA current. A wireless readout is provided using a microcontroller unit and a Bluetooth module. The results show a linear relation between the variation of self-inductance of a pickup coil as well as transmitter output with respect to flow rate. The theoretical equations and the simulation results are added in this paper. Keywords— Rotameter, Self-inductance, Flow transmitter, Maxwell’s bridge, Bluetooth module, Wireless readout E I. INTRODUCTION ffective transmission of measured parameters to the control rooms, which is situated at some distance apart from the field, is inevitable during most of the process control applications. Even though many type of flow meters such as mass flow meter, turbine flow meter, electromagnetic flow meter, orifice meter and venturimeter are available for flow measurement, rotameter has few advantages compared to the other measuring devices .The response of rotameter is linear with respect to the flow rate. It has simple construction and inexpensive too but it does not have a transmission circuitry integrated along with it, which limits its applications where long distance flow transmission and data storage is required. Hence development of a coherent flow transmitter for rotameter seemed to be a good prospect and has been chosen for study in this paper. Many advanced techniques to measure and transmit flow rate is made known from various parts of the world. Bera et al. [1] have implemented a capacitance type level transducer for conducting liquids and it uses a uniform circular cylinder of insulating material as the sensor. The change in level of liquid is indicated by the change in capacitance. It is of low cost and also of non-contact type. Another approach is suggested by T.Moazzeni et al. [2] for high temperature, radioactive and 978-1-4673-9939-5/16/$31.00 ©2016 IEEE corrosive environment. It employs cross correlation method for measuring the flow rate and a thermocouple is used for sensing the thermal flow signals. Beaulieu et al. [3] have used the venturi tube and an advanced version of unsteady Bernoulli equation for the flow meter of unsteady liquid. Bera and Mandal [4] have designed an orifice transducer and validated for conductive liquids. The main advantage of this system is that differential pressure cell is not used; hence the problems caused by the pressure cells are avoided. The conventional flow measurement based on hot wire technique uses Wheatstone bridge circuit has been substituted by an intelligent digital flow rate measurement system which uses pulse width modulation concept by Cao et al. [5]. Another technique has been put forward by Bera and Chakraborty [6] for the flow measurement of conductive liquids. Here the Wheatstone bridge network is constructed using four electrodes kept at a radial distance from the flow tube. Hence the unbalance state of the bridge is indicated as the change of flow. Bera et al. [7] have suggested the use of motor load current as the sensing signal. It is given to thyristor driven pump for the measurement of flow through the pipe line. A precise mass flow measurement method of gas with the measurement of temperature and pressure has been developed by Poveay and Beard [8]. A semi cylindrical structured capacitive sensor with interface circuit has been developed for the flow measurement by Chiang and Huang [9]. It utilises a switched mode charge transfer approach for capacitance measurement. The rotameter is a variable area type flow meter. It consists of a tapered metering tube and a float which is free to move up and down within the tube. The metering tube is mounted vertically with the small end at the bottom. The measuring fluid is entered via bottom of the tube passes upward around the float and out at the top. The movement of the float directly indicates the flow rate with the help of the indicator scale mounted on it. The only limitation of the rotameter is that distant transmission of measured flow rate is not possible. An advanced transmission technique is needed for the transmission of the sensed data to remote areas where flow rate is analysed and controlled. The few works have been carried out by different researchers to add the transmission capability to the rotameter. Li et al. [10] have proposed the replacement of normal float by a magnetized float which behaves the same as that of normal float and the use of a rotatable cam type arrangement made of magnetic material for the sensing element. The position of the float is sensed using the magnetic property of the float. The limitation observed in this approach is frictional losses of the cam arrangement and magnetic losses of the float at higher temperatures. A noncontact inductive approach is proposed by Belforte et al. [11]. In this approach, the inductor coil is placed around the rotameter which act as inductive pickup coil. The change in flow in turn displaces the float, which varies the selfinductance. In this paper, a new method for flow rate transmission is proposed using rotameter as sensor and an operational amplifier based circuit for signal conditioning. Moreover a wireless communication is established between the transducer and the display module using ATmega328 microcontroller unit and a Bluetooth module L(h) = C2 (l1 + h) + L(0) (2) where C2 = ( µ - µ0 ) A1n 2 ; L(0) = µ0 An 2 l where A1 is the cross sectional area of the wire and l is the length of the coil L(h) = L(1) + ΔL (3) where L(1) = C2l1 + L0 and ΔL = K3 h The sensor is designed so that cross sectional area of the coil is very much greater than the cross sectional area of the wire and the total length of the coil is greater than the insertion length of the wire. 2.1. Signal Conditioner II. METHODOLOGY The position of the float in the rotameter changes with the flow rate. In order to detect this change, a thin wire is attached to the top of the float. The self-inductance of the inductor mounted on top of the rotameter changes with float position, as the core position changes with flow rate of the liquid. The variation in self-inductance is sensed by an inductance bridge and corresponding to different float positions, voltage is obtained. The operational amplifier based signal conditioning circuit is used to convert a dc voltage of transducer into a form suitable to convert into a current. The block diagram of the flow transmitter is shown in Fig.1.The linearity of the transducer and the transmitter are verified experimentally and the output is tabulated. Float Position Two operational amplifiers with high impedance and high signal to noise ratio are connected to the arms of the bridge as shown in Fig.2. The points B and D are at ground potential and the effect of stray capacitance is minimised. Using Kirchhoff’s current law in nodes B and D, we get VRG Vout = (4) ( Z3 Z 2 − Z 4 Z1 ) Z1Z 3 Z 4 Considering the balance conditions and substituting the expression for inductance (4) becomes ω jVC2 RG (5) ( l1 + h ) Z3 Z1 From (5) the absolute value of output voltage can be written as Vout = Vout = ( C4 + C6 h ) Transducer Signal Conditioner V to I Converter C3 = ωVC2 RG C5 and from (2) and (3) Fig.1. Block diagram of the flow transmitter Let h be the height of the float for a flow rate of Q. Then height of the float is proportional to the flow rate. Hence h = C1Q where (1) When the float is at the bottom, the inductor will have a base inductance since some length of the wire will be inserted to the coil .The inductor has an initial inductance of 60 mH. With the change in flow rate the inductance changes from the initial value. Let l1 be the insertion length of the wire, when the float is at the bottom and l be the length of the coil. So with change in flow rate the insertion length changes from l1 to l1+h where h is the float position. The inductance change of the coil is given by l1 (6) C6 = ωVC2 RG C5 C5 = Z 3 Z1 Finally, from (1) and (5) Vout = ( C4 + C8Q ) (7) where C8 = C6C1 and 20 − 4 I out = Q + 4 Qm (8) The signal conditioner is designed to obtain an output of 2 to 10 V peak to peak value. The values of R2 and R4 selected as 1 KΩ and the gain resistance Rg is found to be 1 KΩ. The fixed inductance is 50 mH. Rg is found to be 1 KΩ. For the fixed inductance in the bridge, 50 mH inductor is used. OP07 IC’s are used in the circuit because of their high input impedance and signal to noise ratio. Bridge Output Rectifier and Filter Difference Amplifier Voltage Follower V/I Converter Fig.3. Block diagram of signal conditioning circuit 2.2 Experimental Setup In the experimental setup flow varies from 0-100 LPM. The float position changes up to a maximum height of 20 cm. The length of the float is 5 cm. The base inductance of the coil is 50 mH. The core of the coil is fitted to a screw gauge. The core is made to move through the coil. The change in inductance is found to be 50 mH-110 mH. The output is tabulated and the linearity of the sensor and the transducer is analysed. Fig.4. Structural layout of the experimental set up Fig.2. Operational amplifier based signal conditioner The block diagram of the signal conditioning circuit is shown in Fig.3. The bridge output is rectified using a precision full wave rectifier. The output of the rectifier is fed to a filter. The rectified and filtered output is given to a difference amplifier. The resistors of the difference amplifier are chosen to give a 1 to 5 V at the output. The difference amplifier has span adjust and zero adjust resistors. The output of the difference amplifier is given to a voltage follower. The voltage follower increases the input impedance of the V to I converter. The NI Multisim simulation of the transmitter circuit is shown in Fig.5. 2.3 Sensor Specification A ferromagnetic galvanized iron wire of 1.5 mm diameter and 40 cm length is used as a flow sensing element. The wire is brazed exactly at the centre of the steel float of the rotameter. The other end of the wire is guided through a hole to an aluminium casing of diameter 20 mm and length of 30 cm placed at the top of rotameter. At maximum flow rate, the length of the wire movement should not exceed half the length of the coil. The inductance coil is made of 5000 turns and it is mounted on the top of the rotameter. To prevent the flow of water into the casing at high pressure the hole is properly sealed using Teflon and free movement of the wire through the seal is ensured. Fig.5. Simulation diagram of a proposed signal conditioning circuit of flow transmitter 2.4 Wireless Readout The ATmega328 microcontroller along with Bluetooth module is used to read the flow rate wirelessly. The flow rates are displayed in the concerned person’s system. The DC voltage is fed to the analog input pin in Arduino board and it is sent to the microcontroller. The Bluetooth module HC-06 is connected to Arduino using an application. Fig.6 shows the connecting diagram of Bluetooth module with Arduino. conditioning circuit as shown in Fig.8. The current and inductance relationship is also linear as shown in Fig. 9, but the linearity is more prominent in the region between 60 mH and 150 mH. An accuracy of 89% is obtained between the transmitter and calculated output. It has good repeatability. The sensitivity of the transducer can be improved by increasing the turns of the inductance pick up coil. The weight of the ferromagnetic wire plays a major role in determining the accuracy of the transducer. The weight of the former should be at least one tenth the weight of the float for the transducer to be linear and accurate. The wireless communication using Bluetooth provides effective communication within 30 m. Fig.6. Connection diagram of Bluetooth module to Arduino board III. RESULTS AND DISCUSSION The photograph of the developed flow transmitter is shown in Fig.7. The efficiency of the transmitter is studied experimentally and verified through the prototype. The experimental results show that the linear relationship exists between the change in self-inductance of the sensing coil and the output voltage of the operational amplifier based signal Fig.7. Photograph of the developed flow transmitter REFERENCES [1] Fig. 8. Inductance vs. voltage characteristic of a flow sensor Fig. 9. Inductance vs. current characteristic of a flow transmitter IV. CONCLUSION The wireless flow transmitter has been developed based on both operational amplifier based signal conditioning circuit and rotameter. As a result of the experimentation done for the developed transmitter, the possibility for the design of a flow sensor on the basis of a rotameter connected to operational amplifier circuit with inductance pick up coil has been presented. The developed transmitter exhibits excellent linearity and accuracy compared with the methods reported in the literature. The proposed transmitter is particularly suitable for the practical applications requiring remote measurement of flow rate with high accuracy and less pressure drop when compared with commercially available flow measuring systems. The key feature of the proposed transmitter is a lowcost and having the remote readout capability. This opens up for near future studies and applications of developing dynamic, wireless sensor module for physical quantities measurement and automation S. C. Bera, J. K. Ray, and S. Chatterjee, ‘‘A low-cost noncontact capacitance-type level transducer for a conducting liquid,’’ IEEE Trans. Instrum. Meas., vol. 55, no. 3, pp. 778--- 786, Jun. 2006. [2] T. Moazzeni, J. Ma, Y. Jiang, and N. Li, ‘‘Flow rate measurement in a high-temperature, radioactive, and corrosive environment,’’ IEEE Trans. Instrum. Meas., vol. 60, no. 6, pp. 2062---2069, Jun. 2011. [3] A. Beaulieu, E. Foucault, P. Braud, P. Micheau, and P. Szeger,‘‘A flowmeter for unsteady liquid flow measurements,’’ Flow Meas. Instrum., vol. 22, no. 2, pp. 131---137, Apr. 2011. [4] S. C. Bera and H. Mandal, ‘‘A flow measurement technique using a noncontact capacitance-type orifice transducer for a conducting liquid,’’IEEE Trans. Instrum. Meas., vol. 61, no. 9, pp. 2553---2559, Sep. 2012. [5] Y. Cao, Z. Xie, and C. Hou, ‘‘Flow rate measurement system using thermal air flow sensor,’’ in Proc. 9th IEEE ICEMI, Beijing, China, Aug. 2009, pp. 885---889. [6] C. Bera and B. Chakraborty, ‘‘A novel technique of flow measurement for a conducting liquid,’’ IEEE Trans. Instrum. Meas., vol. 58, no. 8 ,pp. 2512---2517, Aug. 2009. [7] S. C. Bera, N. Mandal, and R. Sarkar, ‘‘Study of a thyristor driven pump as a flow indicator,’’ in Proc. ICPS, Kharagpur, India, Dec. 2009,pp. 1--6.[8] S. C. Bera, N. Mandal, and R. Sarkar, ‘‘Study of a thyristor driven pump as a flow indicator,’’ in Proc. ICPS, Kharagpur, India, Dec. 2009,pp. 1---6. [8] T. Poveay and P. F. Beard, ‘‘A novel experiment technique for accurate mass flow rate measurement,’’ Flow Meas. Instrum., vol. 19, no. 5, pp. 251---259, Oct. 2008. [9] C.-T. Chiang and Y.-C. Huang, ‘‘A semi cylindrical capacitive sensor with interface circuit used for flow rate measurement,’’ IEEE Sensor J.,vol. 6, no. 6, pp. 1564---1570, Dec. 2006. [10] X. Li, Y. Liang, L. Fang, Q. He, and Y. Zhang, ‘‘The research on inductive gas rotameter transmission system,’’ in Proc. AASRI, vol. 3. [11] G. Belforte, M. Carello, L. Mazza, and S. Pastorelli, ‘‘Test bench for flow rate measurement: Calibration of variable area meters,’’ Measurement, vol. 20, no. 1, pp. 67---74, Jan. 1997. vol. 20, no. 1, pp. 67---74, Jan. 1997.