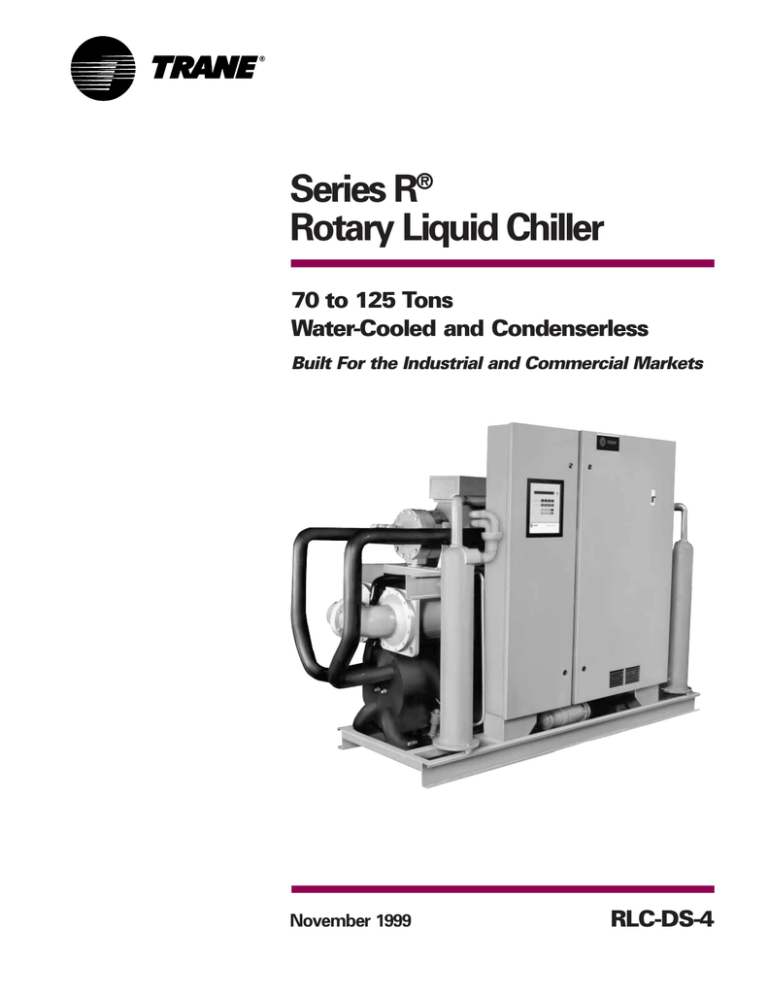

Series R ® Rotary Liquid Chiller Water

advertisement