Basics of Hazardous Locations

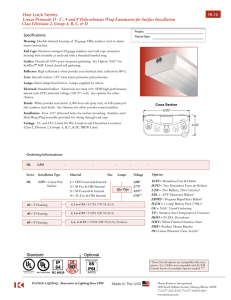

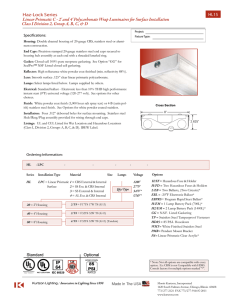

advertisement