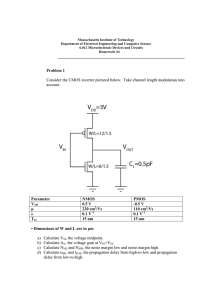

optimization and characterization of 130 nm cmos

advertisement