ECOBAY: Closed loop water cooled server cabinet for data centers

ECOBAY: Closed loop water cooled server cabinet for data centers

ELECTRONICS

MANUFACTURING

SERVICES

Communications • Computing • Multimedia & Consumer • Industrial & Semiconductor • Defense & Aerospace • Medical • Automotive

Mirko Stevanovic, M.A.Sc. Mech. Eng.

New Product Design

Sanmina-SCI Enclosure Systems

Toronto, Canada

IBM Power and Cooling Technology Symposium, September 2008

Preamble: Clear Market Trends

“We are currently in the biggest data center construction boom in history. At the same time, this boom is dramatically weakening the future flexibility and financial performance of

Information Technology. How can this be?

It's the old domino effect at work again.” The new “must know” topic for senior executives responsible for the energy consumption and costs of today’s increasingly high-density computing environments is the true economic and environmental costs of enterprise computing and what steps must be taken, beginning now , to control them”.

Source: Ken Brill, Director of “The Uptime Institute” Sept 2008

Sanmina-SCI Confidential

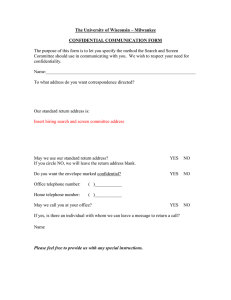

Market Need

Current Requirement:

• Integrated enclosures with 30kW thermal management systems that provide optimum environment for high density “clustered computing”.

• Scalable systems deployable in large or small quantities in new or existing sites.

• Simple, efficient & highly reliable thermal management technology that enables cost savings in infrastructure, real estate and power.

• “Green” products with low acoustic output, built in ‘fail safe’ devices and appropriate redundancy of critical systems.

• Optional power distribution, environmental monitoring, smoke detection & fire suppression.

Sanmina-SCI Confidential

What is The Problem?

High Density Blade Servers introduce new considerations:

Heat Loads continue to Rise

Heat Densities continue to Increase

Conventional Cooling can not cope (see next slide)

Efficiency and reliability of traditional Data Center declines and

“De-population” of room occurs when input power exceeds values >3.5kW per enclosure

Data Centers with raised floor (Plenum) cooling systems cannot support input power values of >7kW per enclosure without overheating problems

New generation processors in high density configurations can require as much as 25kW+ input power per enclosure

Sanmina-SCI Confidential

What is The Problem?

Sanmina-SCI Confidential

What is The Problem?

Sanmina-SCI Confidential

Sanmina’s ECOBAY Solution

Our Solution:

An integrated enclosure using chilled water in a closed loop system to provide cooling & facilitate heat removal at a rate

3630 times greater than the same volume of air.

History

Sanmina was the first to develop & market a product of this type.

Update

In December 2007 the last of 5 ECOBAY Patents was granted by the USPTO providing Sanmina with greatly increased protection against Infringement of key elements of it’s design.

Sanmina-SCI Confidential

ECOBAY Thermal Management System

What is ECOBAY?

High Performance, Closed Loop

Water Cooled Cabinet.

Heat generated inside the cabinet is removed by chilled water.

Minimal stress on room cooling system.

42RU of useable space.

Cooling Air

Constant air temperature in front of servers.

Uniform air distribution in front of servers.

Chilled Water ► from Chiller

Sanmina-SCI Confidential

Heated Air

Thermal Core

◄ Warmed Water to Chiller

What Ecobay Offers

Solution for Customer Needs:

Improved Cooling

Sealed system

Noise Reduction

Dense packing/heat density per area

Lower energy cost

Smoke Detection/Fire suppression

Monitoring

Improved work area

RELIABILITY

PERFORMANCE

COST

SECURITY

Sanmina-SCI Confidential

ECOBAY Solution

For Blade Servers

Low Density Solution

1 kW 7 kW

Current Generation

High Density Blades

NGR Blade’s & Multi

Processor Enterprise

24 kW 35 kW

Sanmina-SCI Confidential

ECOBAY Thermal Management System

Sanmina-SCI Confidential

ECOBAY Thermal Management System

Sanmina-SCI Confidential

ECOBAY Thermal Management System

Five Blade Chassis operating at full power ~ 18 kW

0.76 l/s (12 gpm) Water at 14°C

(57°F)

Blades operated within manufacturers specs.

RH 40% - 60% inside cabinet

Acoustic performance – “very good”

Sanmina-SCI Confidential

ECOBAY Thermal Management System

Performance Table (in US units)

Inputs Heat Load

Water Temp

Water Flow

24 kW

55 °F

12 USgpm

Results

Background

Cold Air Supply

Hot Air Disch

Air ∆ T

Water Rise

Water Disch

Water ∆ P

Server Fans

Fan Power

73.0

°F

115.5

°F

42.1

°F

12.8

°F

67.8

°F

7.0

psi

1680 CFM

700 W

SI units

24.0

kW

12.8

degC

0.76

l/sec

22.8

°C

49.8

°C

23.4

°C

7.1

°C

19.9

°C

48.3

kPa

Varies by manufacturer

Sanmina-SCI Confidential

Typical Mechanical Layout

Sanmina-SCI Confidential

ECOBAY For Smaller Projects

- 324 KW LOAD

Traditional Air-Cooled Cabinets

TOTAL ROOM FT

ELECTRICAL

2 2170 FT 2

324.0 kW

# of Cabinets @ 5kW each

4 Power Distribution Units

65

225 kVA/pdu

Sanmina-SCI Confidential

ECOBAY 1-18 High Density Enclosures

TOTAL ROOM FT 2 910 FT 2

ELECTRICAL 324.0 kW

# of Cabinets @ 18kW each

4 Power Distribution Units

18

225 kVA/pdu

Cabinet Monitoring

Temperature in front and back of servers

Fans/Power Supply Status

Humidity

Actual water leakage

Door security

Incipient Smoke Detection

Fire Suppression Activation

Sanmina-SCI Confidential

To Central Monitor or Building BMS

CABLE/POWER MANAGEMENT

Sanmina-SCI Confidential

Rack Mounted Smoke/Fire Suppression with

Optional VESDA

Sanmina-SCI Confidential

Fire Suppression

Fully monitored smoke detection and fire suppression

Sanmina-SCI Confidential

Closed-Loop Water-Cooled System

RESILIENCY

How do we make the Cabinet Cooling System Reliable ?

Redundant Pumps, Heat Exchangers, and Chillers

Matrix piping system

Redundant Fans

Redundant power supplies

Preemptive Monitoring & Alarm System

Fall Back Strategy

If the cooling in a cabinet fails for any reason:

Automatic door release.

Room air temporarily removes heat.

Door release has dual power & dual thermostats

Sanmina-SCI Confidential

Thank You

ELECTRONICS

MANUFACTURING

SERVICES

Communications • Computing • Multimedia & Consumer • Industrial & Semiconductor • Defense & Aerospace • Medical • Automotive