ABB Drives ELEC-C8001 Sähköenergiatekniikka Anssi

advertisement

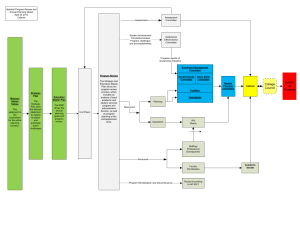

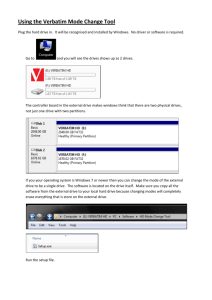

25.4.2016 ABB Drives ELEC-C8001 Sähköenergiatekniikka Anssi Sinervo Introduction Who is Anssi Sinervo Master’s degree from TKK 2003–2008 Automation and Control Engineering, Electromechanics Ph.D. Electrical engineering, Aalto University 2009–6/2013 Electromechanics, Control Engineering Senior Engineer, ABB Drives 6/2013– R&D, Control Software ABB in Finland € 2,2 billion 5 100 Revenue (2015) employees Founded 1889 1/5 Of employees in R&D © ABB Group April 25, 2016 | Slide 3 Factories in Helsinki, Vaasa, Porvoo, and Hamina Helsinki E-factory Pitäjänmäki Number of employees 1200 Low voltage AC drives and drives modules Power range 0,18 – 5600 kW Functions Finland 400 Focus In R&D Sales and marketing Engineering and assembly R&D Sourcing Service Hub Training Contents of presentation What is a drive Where are the drives used What is ABB drives selling Why would you need one What kind of knowledge is needed to build drives What courses should you take What is a drive What is ABB drives selling What is ABB drives selling Drive = frequency converter? Power conversion and control Process control Surface level sensor Frequency converter Electric grid Frequency converter + motor = drive • Frequency converter control the motor speed … • … and allows the control of the water level © ABB Group 25 April 2016 | Slide 7 Frequency converter basics Re-organizes electrical energy AC voltage is first rectified to a constant voltage (energy reserve) Voltage is then chopped into small pieces that produce the desired wave-form when filtered Motor is controlled by changing the frequency BU Drives and Controls Products LV Low Power Drives LV High Power Drives Medium Voltage Drives PLC and Automation Drives and Controls Service PG 4120 PG 4114 PG4117 PG 4113 PG 4159 High power AC drives Cabinet drives Servo drives and 100 - 5600 kW motion control offering Multidrives Wall-mounted AC 1.5 - 5600 kW drives Modules 1.1 - 4000 kW Drives designed for DC drives machine building Modules 9 – 6 MW HVAC bypasses and Cabinet drives drives 9 - 36 MW Micro drives Product Groups General 250 kW – 7 MW Special purpose drives purpose drives Scalable PLCs HMI control panels Wireless Input/Output devices 2 – 100 MW Common configuration software for PLC, Drives Networks and HMIs Global services for the complete life cycle Spare parts Technical support Service contracts Training Market shares according to ARC in 2014 Total drives market Source: Low Power AC Drives Worldwide Outlook – 2015 Edition, ARC High Power AC Drives Worldwide Outlook – 2015 Edition, ARC Note: Danfoss acquired Vacon and is not reported separately any longer. Clear increase on Danfoss market share follows aminly from this. Please note: For companies with less than 2% market share on any ARC product class this arithmetic total underestimates the total market share respectively. April 2016 Customers do not buy devices They buy performance Our main product to our end-users is shaft motion which user can define Our drives include (or we deliver separately) line controllers that take care of grid voltage quality We offer tools to control and monitor entire factories and plants Where are the drives used Why would you need one Why would you need one BU Drives and Controls Global presence Finland, Helsinki Estonia, Jüri Poland Lodz USA, Wisconsin New Berlin China, Beijing Korea, Seoul Switzerland, Turgi MV Drives Malaysia, Kuala Lumpur Sorocaba, Brazil Singapore, Central stock Asia India, Bangalore Production and R&D Worldwide R&D Centrum and Production Central stocks Sales April 2016 Germany, Menden Central stock Europe BU Drives and Controls Markets served April 2016 HVAC Food industry Cement Mining and minerals Chemicals Oil upstream Water and waste water Wind Metals industry Marine Power generation Pulp & Paper Material handling Textile Beverage industry Energy efficiency with ABB drives Helping customers do more using less About 40% of the generated electricity is consumed by industries, and two-thirds of that energy is used by electric motors. Variable speed drives (VSD's) regulate the speed of a motor and can reduce energy consumption by 30% to 50% in many applications. Yet, less than 10% of motors are equipped with VSD's. Alternative is often to let motor run at full speed and “throttle” output (which is like controlling a car’s speed by braking while other foot is still on accelerator) Energy efficiency in the chain From power station to a pump application Throttling © ABB Group April 25, 2016 | Slide 17 Drive controlled Ecological payback – in one day! Carbon footprint for manufacturing ACS350 (7.5 kW) 54 kg CO2 ACS800 (250 kW) 910 kg CO2 Ecological payback time ACS350 (7.5 kW) 1,1 (day) ACS800 (250 kW) 0,5 (day) Definition April 2016 Manufacturing and disposal of a product consume natural resources and load the environment. The ecological payback time is calculated as the time needed to use a product until the one-time environmental burden caused by the product manufacturing has been compensated, thereby reducing the environmental load. The time quoted is an estimate based on average usage of drives. Control is required Drive is a must Power to the grid ISU (Inverter Supply Unit) applications Water and wastewater treatment Hundreds of motors and drives What kind of knowledge is needed What courses should you take Tunnuslukuja Suomen henkilöstöstä • 5070 henkilöä, joista toimihenkilöitä 70 % ja työntekijöitä 30 % • Miehiä 80 %, naisia 20 % • Tekninen koulutustausta 66 %:lla toimihenkilöistä • Kesäharjoittelijoita noin 890 henkilöä • Työssäoppijoita ja työharjoittelijoita noin 100 henkilöä • Valmistuneet opinnäytetyöt 167 • Ulkomaankomennuksella vuoden aikana 148 henkilöä • Suomen ABB:llä ulkomaankomennuksella vuoden aikana 51 henkilöä • Ulkomaalaistaustaisia henkilöitä 176 41 maasta ABB tänään - Kohti kestävää April 25, 2016 maailmaa 23 Tekn.tri, tekn.lis 1.0 % Dipl.ins. 17.0 % Muu 32.0 % Insinööri 20.0 % Muu korkeak.tutk. 1,7 % Merkonomi 3.0 % Teknikko 6.0 % KTM, ekon., traden. 6.0 % Ammattikoulu 12.0 % R&D jobs at ABB Drives Main groups in departments Electrical design Software development Main circuit Control Control cards Operating system Electrical development (e.g. cabinets) Mechanical development Structural Thermal design and cooling Air and water flow 1000-2000 parameters Applications Product development Project management System design Documentation Verifications Testing What should you learn while in university Some guidelines • Not everyone in R&D (not to mention Sales) needs very deep understanding in technology • You need to know what others are talking about (and not just during breaks!) No one has time to teach you the basics after you graduate • You need to be able to convert data given in various formats to the format your company is using • Computer skills, programming, and computing Operation point speed torque power terminal voltage sync. gen. voltage current frequency phase resistance phase-ind. Ld phase-ind. Lq 1 500 820 43 33 2 5000 820 430 310 3 8200 500 430 460 4 10000 400 430 460 24 1062 25 1.4 0.06 0.069 240 1056 250 2 0.06 0.069 410 610 420 2.5 0.061 0.072 520 560 525 3 0.061 0.073 Specialize in an area that interests you! Control software engineer requirements Digital control (+ classic control theory) Computer modeling (+ parameters estimation) C/C++, python, real-time programming Electric machine types and modeling Power electronics (components, losses,…) Power grid modeling Computer (Control card) architecture, FPGA logics Mechanical modeling basics Thermal modeling basics Understanding various customer applications (general knowledge from different fields)