Facilitating Relationships:

“Cultivating Executive

Engagement”

A Bottom-up Approach

Eileen M. Buzzelli

Director, FE Technologies/Corp. METT

FE Technologies

Key Messages of Presentation

Successful Executive engagement can occur

when collaborative R&D is:

Clearly linked to business GOALS

Delivering measurable results/benefits from

APPLYING technology

COMMUNICATED in ongoing organizational

dialogue

Supported by PROCESSES and TOOLS to

engage executives in understanding VALUE

Not a buy-in, but a BELIEF . . .

2

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

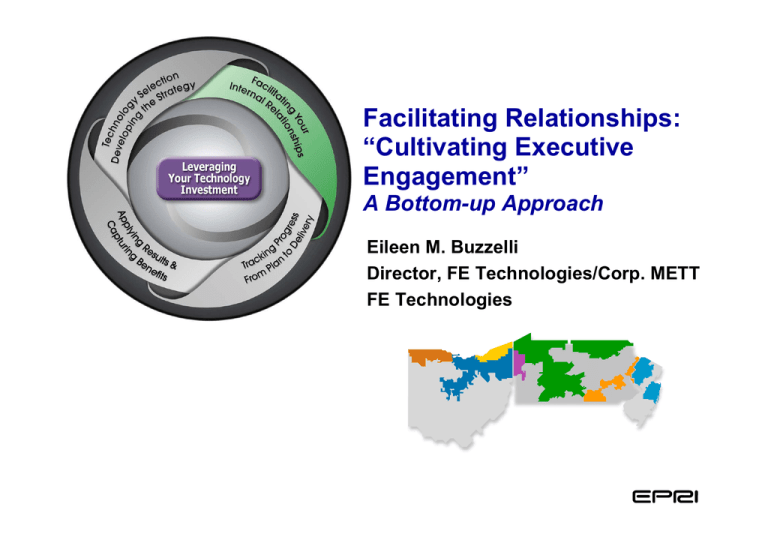

Who is FirstEnergy?

» 5th largest IOU — $12.5B annual revenues, $33B in assets,

4.4 million customers

» 20 generating plants (13,600 MW)

» 135,000 T&D miles within 2 RTOs (MISO, PJM)

» 13,800 employees in electric utility operations and

over 2,100 employees in mechanical contracting operations

Integrated

3

Regional

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

Retail

Corp.

Regulated

T&D

Operations

Ohio Edison

Company

Pennsylvania

Power

Company

Pennsylvania

Electric

Company

The Cleveland

Electric

Illuminating

Company

The Toledo

Edison Company

Metropolitan

Edison

Company

Jersey Central

Power & Light

Company

FirstEnergy

Solutions

Corp.

FirstEnergy

Generation

Corp.

Commodity

Operations

Retail Sales

FirstEnergy

Nuclear Operating

Company

FirstEnergy

Service

Company

Includes the following

Shared-Services Organizations:

• Corp. Finance

• Legal

• IT

• Supply Chain

• Business Development

•

First

Communications,

LLC

FirstEnergy

Ventures

Corp.

American

Transmission

Systems

Incorporated

FirstEnergy

Facilities Services

Group, LLC

MYR Group Inc.

FirstEnergy

Telecom

Services, Inc.

Includes the following Plants:

• Davis-Besse

• Perry

• Beaver Valley

Technology Strategy addresses the DIVERSE needs of

FirstEnergy Operating Companies & Subsidiaries

4

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

FirstEnergy

Technologies

Group

Retail

Technologies

& Tech Transfer

Research Organizations

Technology Sourcing

Knowledge Management

Energy Products

Energy Management

Facilities Services

Commodity Operations

Director

FE Technologies

Energy Delivery

Technologies

Transmission Operations

Distribution Operations

Customer Services

Customer Call Center

Demand

Response

Programs

Energy Supply

Technologies

Fossil Generation

Nuclear Generation

Environmental

Fuel Cell Strategy

PA Demand Response

Programs

PJM/MISO DR

Committees

Interconnections

NJ Clean Energy

Programs

Strategic

Technologies

Venture Capital Funds

Direct Investments

Business Analysis

Long-term Regulatory

Issues

FET

FET Mission

Mission

FE

FE Technologies

Technologies is

is responsible

responsible for

for identifying,

identifying, and

and facilitating

facilitating the

the application

application of

of emerging

emerging

technologies

technologies that

that could

could materially

materially enhance

enhance the

the strategies

strategies of

of our

our businesses

businesses through

through

product

product and

and service

service innovation

innovation opportunities

opportunities and

and operational

operational enhancements

enhancements in

in delivery

delivery

and

and energy

energy supply

supply operations.

operations.

Driven

Driven by

by and

and aligned

aligned with

with the

the business

business unit

unit objectives,

objectives, FE

FE Technologies

Technologies will

will be

be an

an integral

integral

partner

partner to

to provide

provide strategic

strategic technology

technology solutions,

solutions, drawing

drawing from

from our

our existing

existing technology

technology

investments

investments and

and future

future additions

additions to

to the

the portfolio,

portfolio, to

to meet

meet both

both near-term

near-term business

business unit

unit

priorities

priorities and

and long-term

long-term corporate

corporate objectives.

objectives.

5

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

FirstEnergy Technologies Group

Key Roles in assisting Business Units

Business Unit

Focus

Tool Kit

Technology

Watch / Screen

Due Diligence

Experience

Development

Education /

Communication

Technology

Access

6

DISCOVER Business Unit needs in order to provide

appropriate solutions

Enhance Business Unit’s “tool kit” as a resource to

DISCOVER technology to address business needs

DECIDE what new technologies help to fulfill

Business Unit needs

DECIDE which technologies to pursue based on

technical criteria & detailed evaluations

DEVELOP focused pilot projects associated with

promising technologies

DEPLOY learnings, serving as technical resource for

what's on the horizon, and who the major players are

DEPLOY knowledge management database that

Business Units can access in the future

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

Six

Six Key

Key Elements

Elements of

of technology

management

management to

to produce

produce results:

results:

Technology Management Process

Apply Results through Discipline

1.

1.

2.

2.

3.

3.

4.

4.

5.

5.

6.

6.

Technology

Technology Strategy

Strategy

Executive

Executive Commitment

Commitment

Resource

Resource Commitment

Commitment

Process

Process Management

Management

Relationship

Relationship Management

Management

Communications

Communications

Technology Strategy

Align technology strategies with business objectives

Make technology an integral part of business planning

Executive Commitment

Establish top-bottom senior-management leadership and participation

Make technology acquisition planning & delivery process integral to

business unit and corporate management process

Establish cross-functional teams to implement technology initiatives

Communicate technology development process to all stakeholders

Resource Commitment

7

Implement highly visible technology acquisition organization

Ensure accountability of technology strategies to deliver business results

Fund technology acquisition endeavors sufficiently and continuously

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

Technology Management Process

Key Elements (continued)

Process Management

Use disciplined, business-managed process for technology integration

Develop clear and actionable performance measures

Execute an effective and efficient stage-gate process

Relationship Management

Establish disciplined, yet creative, relationship management process,

internally with business units and externally with technology sources

Leverage venture capital opportunities

Communications

8

Continuously communicate the corporate role and value of technology

acquisition in a clear, thorough and timely fashion

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

PROCESS and TOOLS

To Engage Executives

PROCESS AND TOOLS

for Executive Engagement

• Identify Executive Champion(s)

• Establish Common Technology Framework

Late

Early

Majority

• New Executive EPRI Orientation

Majority

Early

• Continuing Executive Briefings

Laggards

Adopters

Innovators

– Palo Alto, CA; Charlotte, NC

– On-site EPRI Executive Visits

• EPRI Topical Issue Briefings

– Advanced Coal Fleet for Tomorrow

– Climate Challenge

• Technical Advisory Group (TAG) Quarterly Meetings

10

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

PROCESS AND TOOLS

for Executive Engagement (Cont.)

• Executive Approval of Advisors

• Advisor Engagement & Accountability

– Active Program Management & Participation

– Transfer Deliverables & Knowledge into Organization

• Executive Recognition of Advisor Contributions

– Presentations to Management

– EPRI Awards

• Executive Participation on Business Sector Councils

• Access to Best Practices in Technology Application

– Peer-to-peer Learnings

– Co-Development with Key Suppliers & EPRI

11

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

PROCESS AND TOOLS

for Executive Engagement (Cont.)

• Partnership Plan Development & Discussion

• Alignment with Business Unit Objectives

• EPRI Program Membership Evaluations

• Membership Selection/Portfolio Review

• Specific Project Applications

– Emphasis on On-Site TC Projects at home

• EPRI Value Report

• Communications at ALL LEVELS

12

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

TOOLS for Executive Engagement

Partnership

Plans

Identify FE business direction/needs, set

goals, & align with EPRI R&D Programs

DISCOVERY PROCESS:

Engage with business units at all levels

Compile understanding of business unit

needs and objectives

Establish technology strategy based on

need assessment

Develop & implement Partnership Plans

Fossil, Nuclear, Energy Delivery, Retail,

Commodity Operations, Environmental, Corp.

13

Map appropriate EPRI R&D Programs

to FE direction, needs, and goals

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

TOOLS for Executive Engagement

BU

Alignment

Apply, link and communicate technology

SELECTIONS and EXPECTATIONS

DECISION PROCESS

EPRI Program

Membership

ALIGNMENT OF FE BU OBJECTIVES WITH EPRI 2005 SELECTIONS

PROGRAM DESCRIPTION

LINKED TO FE BU OBJECTIVES

NUCLEAR (FENOC)

Nuclear Base Program (41)

Jim Powers

Safe Plant Operations

People Development & Effectiveness

Improved Outage Performance

Nuclear Supplemental Programs

– Link to business unit

objectives

ENVIRONMENTAL

Air Toxics Health and Risk

Assessment (42)

Excellent Material Condition

– Advisor confirmation

for input to EPRI

14

BWR VIP: reduced P/M savings; SGMP: savings though

improved inspection methodology and operability evaluations;

MRP: improved inspections/regulatory compliance; FRP:

reduced fuel costs; NEI 03-08: Compliance w ith NEI 03-08

related to all of these Program

Numerous

Advisors for all

FENOC

Programs

Dan Steen

Ensure future emission reduction legislation Low er cost of Phase II mercury emissions reduction,

and regulations allow cost-effective

estimated at $300M-$1B, w ith changed mercury rule

compliance.

requirements. ($650M) Provides policy makers w ith sound

health-impact assessments for input on future regulations.

Protect environment and meet customer

Minimize cost of meeting hazardous w aste regulations for ash

needs for reliable and competitively priced and other combustion by-products. ($24M-$100M) Facilitates

electricity.

opportunities for community w aste management partnerships.

Fred Starheim

Hydropower Environmental Issues

(58)

Optimize diverse generating portfolio to

achieve cost-effective environmental

compliance.

Chuck

Mow bray/

Anthony Skicki

Mercury Package - Mercury Flue Gas

Characterization & PICES DB (PS59A)

Protect environment and meet customer

needs for reliable & competitively priced

electricity.

Ensure future emission reduction legislation

and regulations allow cost-effective

compliance.

Produce reliable electricity in a costcompetitive manner.

Ensure future emission reduction legislation

and regulations allow cost-effective

compliance.

Groundwater Protection/Coal

Combustion Management (49)

Integrated Environmental Control

Evaluations (PS75A)

Particulate and Opacity Control (76)

– Expected value

documented

FE SPONSOR

/FE Advisor

Fleet Efficiency/Effectiveness

– Corporate program

selection is

documented

EXPECTED VALUE

(Program, Project Set, Project No.)

Assessment Tools for Ozone,

Particulate Matter, and Haze (91)

Assessment of Air Quality Impacts

on Health & the Environment (92)

Global Climate Change Policy

Costs/Benefits (102)

Greenhouse Gas Reduction Options

(103)

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

Reduce cost of re-licensing hydro projects, natural resource

studies, & asset alternatives analysis (CAP EX);

Collaborative for innovative fish management approaches.

Reduce cost of developing mercury measurement & control

technologies. Access to extensive industry-w ide database

recognized as credible information source by regulators.

Influence future regulatory development & minimize future env.

compliance costs; Tech Assessments of integrated

environmental controls & costs for future business planning.

Reduce particulate & opacity, increase regulatory compliance,

restore plant capacity, reduce environmental control costs.

Develop air-quality management tools & transport models,

including mobile sources, to achieve cost-effective

environmental performance & compliance plans for emission

control requirements. (>$100M)

Ensure future emission reduction legislation Key data on ecological & health impacts of air pollution to

and regulations allow cost-effective

obtain cost-effective air quality policies and standards.

compliance.

($1.25B)

Ensure future emission reduction legislation Key data to influence policy makers & ensure environmentally

and regulations allow cost-effective

effective & efficient global climate policy decisions and energy

compliance.

regulatory programs to maintain coal in portfolio mix. Provides

economic impact assessments of various proposals on global,

nati

Protect environment and meet customer

Manage risks & reduce costs associated w ith global climate

needs for reliable & competitively priced

change policies. Assess compliance options & effectiveness

electricity.

of measures to mitigate risk.

Mike Horvath

Ray Evans/Fred

Starheim

Dale Kanary

Dale Kanary/

Morgan Jones

Fred Starheim

Fred Starheim

Mike G. Williams

Mike G. Williams

TOOLS for Executive Engagement

Program

Membership

Evaluation

Document membership selections, goals

and expected value

EPRI Program Membership

Evaluations

– Basis for program selection is

documented

– Advisor evaluation/input on EPRI

Programs

– Bottom-up process for R&D expected

value.

15

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

R&D

Portfolio

Summary

2004 FirstEnergy-EPRI Partnership Highlights

Working Together to Make a Difference

FE

FE Business

Business Plan

Plan &

& Management

Management Focus

Focus

Nuclear Fleet

Strategy for top industry performance

FE-EPRI

FE-EPRI Strategy,

Strategy, Technology,

Technology, Objectives

Objectives

Fossil Generation

Optimize portfolio, reduce wear and tear

from cycling, improve reliability, and

improve cost competitiveness

Environmental

Manage future environmental issues

including NSR, NOx, SO2, Hg, and CO2

16

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

Industry Collaborative – Resolve industry issues associated

with fuel failure, burn-up rates, and corrosion

Best Practices – Ensure the safe & reliable plant operation

through best practice maintenance and repair

Material Science – Ensure materials integrity for improved

reliability at FE and other nuclear plants worldwide

Availability –- Increase plant availability by reducing boiler

tube failures and improving plant chemistry

Outage Management – Reduce the cost and duration of

turbine-generator outages and extend the time between them

Compliance – Reduce costs of NOx controls (SCR, SNCR)

Burner Diagnostics – Demonstrate plant burner diagnostic

system to optimize performance and reduce emissions without

having to install costly commercial equipment

Particulate Control – Assess several low-cost particulate

control systems to regain load at opacity-limited plants

Air Quality – Manage air quality regulation risks (environmental & cost compliance - fine particulate, mercury emissions)

PowerSpan ECO – Evaluation/cost-sharing for novel multipollutant control technology

Climate Change – Assess strategic options associated with

climate change policies

Clean Water Act 316b – Identify cost-effective fish protection

compliance options

(continued)

2004 FirstEnergy-EPRI Partnership Highlights

Working Together to Make a Difference

FE

FE Business

Business Plan

Plan &

& Management

Management Focus

Focus

FE-EPRI

FE-EPRI Strategy,

Strategy, Technology,

Technology, Objectives

Objectives

Improve reliability by upgrading control

room computer systems, strengthening

operator training & procedures, and

aggressively managing transmission

vegetation

T&D Tools – Provide tools to improve reliability through:

Enhanced T&D system operator capabilities & training

Improved prediction capability for T-line line sag clearances

Enhanced outage management systems to more quickly

pinpoint outage events & locations

Development of uniform industry transmission reliability metrics

Analysis & support for system & customer power quality issues

Risk Reduction

Energy Delivery

Reduce commodity market exposure risk

Risk Management – Provide tools to help FE manage

commodity risk with an increased understanding of power

market directions and volatility

In addition, EPRI:

17

Helps FE identify emerging technology opportunities

Serves as an extension of FE’s in-house expertise

Provides insights on opportunities and trends in the electric power industry

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

PROCESS AND TOOLS

for Executive Engagement

TC

Projects

Realize value through applying

technology at home

DEPLOYMENT PROCESS:

18

Leveraged technology learnings at home

Actively participate in technology

solutions

Maximize co-funding opportunities

Communicate results across other

company facilities

Learn “What to do” and “What NOT to

do”, based on these projects

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

TOOLS for Executive Engagement

EPRI

Benefit

Report

Apply and communicate technology

strategy, goals, & RESULTS at all levels

Annual Benefit Report – highlights

benefits received based on:

– Corporate/Business Unit value as measured

in “eyes of beholder”

– Qualitative and quantitative basis

• Avoided costs, O&M or capital reduction,

strategic options, regulatory compliance

– Short- & long-term perspective

– Captures delivered value for executive

discussions

19

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

PROCESS AND TOOLS

for Executive Engagement

Communicate

COMMUNICATE technology strategy,

goals, & results frequently & at all levels

Communications Plan –

– Plan integrated with Corporate

Communications

– Meetings with business units on

technologies

– Employee newsletters

– Awards

• Seven EPRI Technology Transfer

Award winners in 2005 representing

multiple parts of FirstEnergy

– Technology Assessment Group

(TAG) Quarterly Updates

20

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

ADDITIONAL AREAS

for Executive Engagement

• Technology Strategy/Roadmapping

• Technology Showcase/Fair

• R&D Program Performance Metrics

• Financial implications of technology alternatives:

– Regulatory cost recovery

– Capital vs. O&M Expense

– R&D Tax Credits

– Collaboration vs. “Going it alone”

21

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

CONCLUSION

Executives engaged in collaborative R&D demonstrate:

LEADERSHIP, A VISION OF THE FUTURE, AND A

CLEAR RECOGNITION OF THE VALUE OF

TECHNOLOGY TO ADDRESS KEY BUSINESS

CHALLENGES

NOT A “BUY-IN” TO CHANGE, BUT COMMITMENT TO

A PROCESS THAT DELIVERS VALUE

22

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

TDC PARTICIPATION

VALUE SHARED

QUESTIONS?

23

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

APPENDIX

Additional Information

24

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

Our Business Focus

Integrated

–

–

–

–

Seven regulated distribution companies

75% of revenues derived from regulated businesses

13,387 MW of fuel-diverse owned generation capacity

Competitive energy businesses related to core competencies

Regional

– Focused primarily in our three state region

– Serve 30% of distribution customers in OH, PA and NJ

Retail

– Focused on end-use customers who can be served by FE

generation

– Over 90% of generation output committed to retail customers

at fixed prices

25

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

FirstEnergy

System

FE operates a portfolio of diversified, centrally-located generation

assets used to manage risk and meet retail pricing expectations.

Ohio

Eastlake

1,262 MW

Sumpter (Michigan)

340 MW

Bay Shore

Stryker

18 MW

648 MW

Toledo

Pennsylvania

Ashtabula

Perry

244 MW

Seneca

1,266 MW

435 MW

New Jersey

Erie

Lake Shore

249 MW

Towanda

Yards Creek

200 MW

Cleveland

Richland

432 MW

Edgewater

48 MW Akron

Davis-Besse

883 MW

West Lorain

545 MW

New Castle

Morristown

Johnstown

Reading

Harrisburg

Newark

Allenhurst

Trenton

W. H. Sammis

2,233 MW

Columbus

Mad River

60 MW

R. E. Burger

413 MW

Beaver Valley

1,630 MW

Operating Companies

Customers

Ohio Edison

26

York Haven

19 MW

Bruce Mansfield

2,360 MW

Square Miles

1,019,000

7,000

Illuminating Company

753,000

1,600

Toledo Edison

308,000

2,300

FirstEnergy Power Plants:

Met-Ed

516,000

3,300

C

H

N

G

O

Penelec

585,000

17,600

Pennsylvania Power

156,000

1,100

1,050,000

3,200

4,387,000

36,100

Coal – 7,339 MW (55%)

Hydro – 654 MW (5%)

Nuclear – 3,795 MW (28%)

Gas – 1,269 MW (10%)

Oil – 330 MW (2%)

Jersey Central Power & Light

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

Total

Forked River

86 MW

FE/EPRI Success Stories

Program/Project Engagement Identification of key

FirstEnergy needs has translated into successful

program engagement and site-specific project activities

PROGRAMS:

• NMAC

Successful plant maintenance strategies

• Forward Price Forecasting

• Global Climate Change

FastForward Software

Strategy/Tech Support

PROJECTS:

• Powerspan Multi-Pollutant Control Technology

• FENOC Switchyard Preventive/Predictive Maintenance

• NEV Harmonics Study

27

Advanced PQ Modeling

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.

FE/EPRI Success Stories

Program/Project Engagement Identification of key

FirstEnergy needs has translated into successful

program engagement and site-specific project activities

PROJECTS: (continued)

• Gorge Ballpark “Ashes to Diamonds”

• Ohio River Ecological Research CWA Section 316(b)

• Richland CT Low Frequency Noise Abatement

• Mansfield SCR/SBS Opacity Control Technology

• Resin Tester Resin

28

Field Diagnostic Tool

Copyright © 2005 Electric Power Research Institute, Inc. All rights reserved.