Dimming LED Lamps White Paper

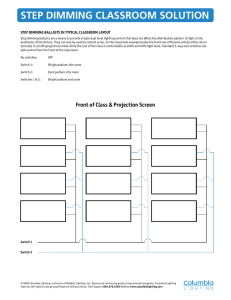

advertisement

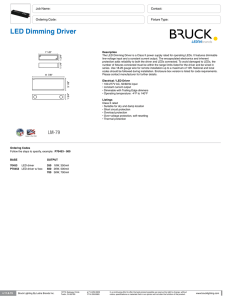

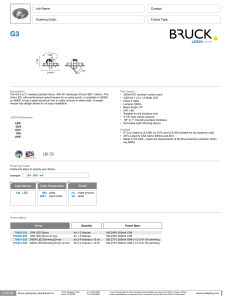

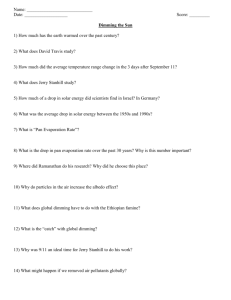

CEDIA WHITE PAPER Dimming LED Lamps White Paper © 2014 CEDIA TABLE OF CONTENTS 01 Why LED Lighting? Comparison of Different Lighting Sources and Types Advantages and Limitations of LEDs IESNA Lighting Source Comparison chart 4 4 5 02 Which LED Light? Important Aspects of Selecting Fixtures Certifications Performance Parameters Environmental Impact Warranty 6 6 6 6 6 03 LED Lighting Fixture Control Architecture LED based lighting fixture 6 7 04 Why Dim LEDs? Questions to Ask When Dimming an LED Lamp Types of LED Products Dimming Range Dimming Performance Control Technologies Forward Phase Control Reverse Phase Control 0-10V Control DALI (Digital Addressable Lighting Interface) DMX (Digital Multiplex Interface) Number of Lamps on a Dimmer 8 9 9 11 11 11 11 12 12 12 12 13 05 Types of Controls and installation Central Control System Local Control Installation of LED Lamps Installation of LED Fixtures 14 14 14 14 14 06Conclusion 14 07 Appendix A 14 DIMMING LED LAMPS WHITE PAPER ACKNOWLEDGMENTS DEFINITIONS Amanda Beebe – Lutron Efficacy (LPW): The overall system efficiency of a luminaire, which is the total usable light output (given in lumens) divided by the real electrical power input (given in watts). Commonly referred to as “Lumens Per Watt,” or LPW. Aussie Kizirian - Interior Technologies Ken Byrd – Cree ACRONYMS CBCP Center Beam Candlepower CCT Correlated Color Temperature CFL Compact Fluorescent Lamp CRI Color Rendering Index DALI Digital Addressable Lighting Interface DMX-512 Digital Multiplex Interface ELV Electric Low Voltage LED Light Emitting Diode LPW Lumens Per Watt MLV Magnetic Low Voltage UL Underwriters Laboratories INFORMATIVE REFERENCES National Electrical Manufacturers Association LSD-49 Solid State Lighting for Incandescent Replacement Best Practices for Dimming Illuminating Engineering Society of North America Lighting Handbook, 9th Edition Correlated Color Temperature (CCT): The temperature of the black body, or Planckian radiator, whose perceived color most closely resembles that of a given light source at the same brightness and under specified viewing conditions. Given in Kelvin (K). Color Rendering Index (CRI): The ability of a light source to reproduce the color of various objects faithfully in comparison with an ideal or natural light source. LED Lifetime: The number of operating hours that the LED can maintain >70% of its original light output for a given set of temperature and light flux conditions. Lifetime is given as L70. (LEDs do not catastrophically fail like incandescent or fluorescent lights. Instead, they get progressively dimmer over a long period of time as they are operated.) Spectral Power Distribution (SPD): The light power per unit area per unit wavelength of an illuminating source. Given as a two dimensional graph, with the x-axis being wavelength and the y-axis being relative light power per unit area. Power Factor (PF): The ratio of real power to apparent power. Commonly given as a percentage (%) or a two decimal number (0.00). Dimming Range: Ratio of minimum to maximum measured light, usually expressed as a percentage (%). Driver: Auxiliary device(s) needed to operate and vary the intensity of light output from LED lamp source(s) by regulating the voltage and current powering the source. Measured Light: Stated light level defined by a manufacturer. © 2014 CEDIA 3 DIMMING LED LAMPS WHITE PAPER INTRODUCTION: DOCUMENT SCOPE The objective of this document is to educate the reader regarding benefits, performances, correct usage and limitations of Light Emitting Diode (LED) lighting. The paper discusses available lamp types and their characteristics (i.e., dimming range), are their different power sources: external or internal drivers, performance and LED dimmers. Dimming LED lighting addresses the residential lighting applications and technical requirements needed to properly prepare wiring for LED fixtures. The paper also compares LED lighting to other technologies that are currently available in the market, with respect to compatibility with control systems, photometry, light quality, spectro-power distribution, expected life-span, special installation requirements, source impedances and line noise. LED lighting for most applications meets all the residential requirements in a satisfactory to superior manner. This paper discusses the return on investment (ROI), including greater efficiency, fewer hazards than CFLs, cost effectiveness and increased visual appeal. Additionally, this document contains a list of potential questions the electronic system contactor (ESC) should discuss with a client prior to system design. The applications and information contained in this document only refer to white LED lights and not their RGB counterparts. Government rebates on LED products are not covered, but may be discussed in a future white paper. Differences between manufacturers aren’t discussed either, although guidance is provided on how to which identify manufacturers meet the criteria of a job or an application. A list of standards that govern the efficiency requirements and performance of products is provided in the informative references section. The information provided in this document is for educational purposes only and is not a CEDIA endorsement of any manufacturer or product. 4 © 2014 CEDIA 01 WHY LED LIGHTING? A Light Emitting Diode (LED) is an electronic device that produces light when an electrical current is passed through it. The color of light that is emitted is dependent on materials from which the LED is made. LEDs are available in red, blue, amber, green and near-UV colors, with lumen outputs ranging from 10 200 lumens. The LEDs used predominantly in general illumination applications are “phosphor converted blue” LEDs, which are blue LEDs that have a layer of yellow phosphor placed over the chip. The phosphor absorbs some of the blue light and emits yellow light. When the unabsorbed blue light mixes with the yellow light, it creates “white” light. There are several advantages as well as limitations in LEDs for general illumination purposes as seen in the IESNA table below. LED-based lighting fixtures can achieve efficacies ranging from 25 LPW to over 80 LPW, compared to an incandescent efficacy of 5-10 LPW. LEDs convert electrical energy to light at an efficiency of ~30%, compared to <5% for an incandescent, resulting in dramatically lower heat produced. LEDs can also achieve useful lifetimes ranging from 25,000 hours to >100,000 hours, compared to ~1000 hours for an incandescent. In addition, LEDs do not contain hazardous materials such as mercury vapor found in siCFLs. One of the limitation of LEDs are higher costs as high brightness LEDs, necessary for general illumination, are expensive. They also require electronic drivers to convert conventional AC voltage to discrete DC voltages for the LED arrays. These factors, combined with special thermal design considerations, make LED-based fixtures considerably more expensive. Another is limited applications due to the constraints of operating temperature environments, relative young technology and a slower uptake. LED-based lighting fixtures are not always available for every application or aesthetic requirement. Lastly, the wide range of LED-based lighting product types available means not all LED lamps are dimmable, and the ones that are can be limited in dimming performance and system compatibility. DIMMING LED LAMPS WHITE PAPER Table 1: IESNA lighting source comparison chart Some of the parameters of interest when comparing lighting sources are efficacy, quality and lifetime as shown in Table 1 above. Efficacy is expressed in LPW, which denotes lumens out per electrical watt in, light quality is expressed by color rendering index (CRI), which is the ability of a light source to render every visible color in the spectrum and lifetime measures useful life of lamp in hours. CRI Starting and Warmup time (minutes) Dimming Range (Percent Light Output) Initial Lumens 750 100 0 100-0 1690 20 2000 100 0 100-0 6000 90 14 2500 100 0 100-0 1280 High Output Fluorescent (3000 K – 4000 K) 54 93 20,000 85 0 100-1 2900 Fluorescent ( 3000 K – 4100 K) 32 88 20,000 75 0 100-1 2800 Compact Fluorescent, long twin (3000 K-4100 K) 38 87 20,000 82 1 100-5 3300 Compact Fluorescent, double (2700 K -4100 K) 26 70 10,000 82 1 100-5 1800 Mercury Vapor (6800 K) 175 45 24,000 20 < 10 1000-10 7900 Metal Halide, low wattage (3200 K) 100 81 10,000 70 <5 100-50 8075 Metal Halide, high wattage (4000 K) 400 90 20,000 65 < 10 100-50 36,000 HPS, low wattage (2100 K) 70 90 24,000 21 <5 100-50 6,300 HPS, high Wattage (diffuse) 250 104 24,000 21 <5 100-50 26,000 Source and Correlated Color Temperature Lamp (Watts) Efficacy (LPW) Life (Hours) Standard Incandescent Filament (2700 K) 100 17 Tungsten – Halogen (2950 K) 300 Tungsten – Halogen (2850 K) © 2014 CEDIA 5 DIMMING LED LAMPS WHITE PAPER 02 WHICH LED LIGHT? IMPORTANT ASPECTS FOR SELECTING FIXTURES Some important aspects such as certifications, performance parameters and warranty, when selecting LED lighting fixtures are discussed in this section. Certifications one should be aware of are: Underwriters Laboratories (UL) listed and compliant, California Title 24 Compliant, Department of Energy’s EnergyStar Program Certification, and Illuminating Engineering Society of North America (IESNA). California title 24 is a high efficiency lighting program in effect in California and Washington State. IESNA is the generally accepted industry guidelines for measuring parameters of Solid State Lighting (SSL) fixtures. Any LED-based lighting fixture should be tested using IESNA guidelines to ensure accurate data as described in Appendix A. Performance parameters to look for when procuring LED lighting fixtures are light quality, efficacy, power factor and lifetime. Different white light sources have different attributes and care should be taken in the selection process to ensure the right source is used for the right application. The most common measurements of light quality are: correlated color temperature (CCT) and color rendering index (CRI). The CRI of LED based fixtures can vary from ~80 to ~95. For typical phosphor-converted blue LEDs, CRI is generally inversely proportional to efficacy, meaning that high CRI translates into low LPW, and vice versa. Efficacy becomes very important when there are limitations on total power that can be consumed by lighting. To make sure there is enough light for the given power restrictions requires choosing a light source with high LPW. Power factor (PF) is the ratio between real power and apparent power. Apparent power, which is what the power source sees, must be supplied to a load. If the real power is substantially lower, this results in power loss. This is particularly important for commercial applications where the local power company bills for apparent power. Lifetime is another characteristic to closely examine when selecting LED lighting. L70 is the industry standard for stating lifetime and IESNA 6 © 2014 CEDIA has testing requirements on how it is to be measured and calculated. The two main factors that affect it are operating temperature and operating current. The luminaire manufacturer should be able to provide results from an independent third party testing laboratory. Environmental impact is another aspect to consider when selecting a lighting fixture. It is important to be aware if the lighting fixture is RoHS compliant meaning it contains no toxins or toxic substances such as mercury and/or lead, if the luminaire is made from recycled or recyclable materials and if the fixture can withstand the temperature and humid conditions of the application. Lastly, warranty is a critical aspect that should be examined before procurement. The typical industry standard is a three-year limited warranty on manufacturing defects, although there are some companies offering five-year warranties. The buyer or specifier should ensure that the manufacturer has the ability to back their warranty. The buyer should also ensure that the fixture is compatible with existing hardware and able to shed heat appropriately in retrofit applications, is compatible with different types of control and if the new fixture has a system of “replaceable parts” for future upgrades. 03 LED LIGHTING FIXTURE CONTROL ARCHITECTURE The fixture usually consists of the following parts: LED Array, Heatsink, Light Diffuser (optional) and Housing. LED Array is the array or grouping of LED(s). In some fixtures, it consists of one LED of a certain color, and in others, several independent strings of different colored LEDs. Heatsink is the primary heat dissipation mechanism for the LED array. In certain fixtures, it might be necessary that the heatsink be exposed to convective airflow. Housing is the mechanical structure that holds the other pieces together and typically provides mounting brackets/supports. In addition, some fixtures use direct emission of LEDs with no diffuser, while others use a diffuser to mix different colors of LEDs and/or create a “single point” light source. DIMMING LED LAMPS WHITE PAPER Figure 1: Sub-components of an LED Light Fixture LED-based lighting fixtures consist of several sub-components. Different manufacturers will incorporate some or all of these sub-components into a single unit. This means that some fixtures require an external LED driver and/or power supply, while others are completely integrated. The main sub-components are demonstrated below in Figure 1. Input Voltage (120/277vac) Power Supply Dimming Interface LED Fixture LED Driver • • • • LED Array Heatsink Diffuser Housing Dimming Input LEDs are discreet DC devices and, depending on the array configuration, can require either one or several discreet DC voltages to drive the particular LED array. The LED Driver typically receives 12vdc, 24vdc, 32vdc or custom DC levels from the power supply. The LED driver usually receives the dimming signal from the dimming interface. Power Supply converts the source power to the discreet DC level(s) required by the LED driver. Depending on the fixture type, the source of power can be 120, 230 or 277 VAC from a line voltage source or 12vdc or 24vdc from a battery or photovoltaic array controller. Dimming Interface converts the dimming signal to the proper signal required by the LED driver for dimming operations. There are generally two types of dimming inputs are Line Voltage or “Phase Cut” and Low Voltage. In Line Voltage, the dimming interface examines the alternating current waveform and determines the level of dimming to be applied. The most common dimmer types are Incandescent, Magnetic Low Voltage (MLV), and Electronic Low Voltage (ELV). Incandescent is called a “leading edge” or “forward phase” dimmer and is typically a SCR-based triac device that cut the AC waveform on the leading edge. Magnetic Low Voltage (MLV) is also a leading edge dimmer. They are designed for inductive loads, like magnetic dimming ballasts. Electronic Low Voltage (ELV) are called “trailing edge” or “reverse phase” dimmers and these are typically FET (field effect transistor)-based devices that cut the AC waveform on the trailing edge. They are designed for capacitive loads, for example electronic dimming ballasts. Low Voltage will be discussed in greater detail in the Control Technologies section (page 14), but consist of: 0-10v, DMX, Digitally Addressable Lighting Interface (DALI) and EcoSystem. © 2014 CEDIA 7 DIMMING LED LAMPS WHITE PAPER Figure 2: LED Power Usage The why dim story for LEDs is the same for fluorescent, incandescent and other conventional light sources. Dimming LEDs saves energy linearly. This means that if you dim LEDs down to 50% of their light output you will save nearly 50% of your energy usage as seen in Figure 2. By dimming LEDs, not only do you save with a more efficient source, you save even more energy. LED Driver: Power vs. Measured Light 100% 90% 80% 70% Power 60% 50% 40% 30% 20% 10% 0% 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% Measured Light 04 WHY DIM LEDS? Dimming LEDs also makes them run cooler. Cooler temperatures should extend the life of the electronic components of the driver, as well as the phosphor, by allowing them to run at a lower temperature. This will extend their life, doubling or tripling the LEDs usable hours. Dimming any lamp – incandescent, CFL or LED enhances ambiance. Whether you are in a restaurant, theater or presentation space, you can get the feeling that the lighting designer intended. The home and the workplace should be designed to address/adjust to client needs. As client needs change throughout the day, the lighting should adapt as well: bright to read a book, but dim for computer use, for example. Lighting control can create a comfortable atmosphere to support activities throughout the day. 8 © 2014 CEDIA Lighting controls can enhance the safety and security of a customer’s home as well. The customer can control both interior and exterior lights from the car as they approach the driveway to ensure optimal visibility—and no more fumbling for the light switch when unlocking the door. Lighting controls can even connect to security systems to turn on lights in case of an emergency. Dimmers installed by the stairs and in hallways can illuminate a path of light in key areas of the house making it easier to navigate from one room to the other during the night. Lighting control also increases productivity allowing the user to select the level they need to reduce eye strain and fatigue so that they can work at peak performance DIMMING LED LAMPS WHITE PAPER A. QUESTIONS TO ASK WHEN DIMMING AN LED LAMP Before you commit yourself or your customer to investing in LED technology you need to understand its limitations, especially when it comes to dimming control compatibility. Many LED luminaire manufacturers are new to the lighting industry and are not familiar with the multitude of control types and the corresponding product design requirements that accompany them. This has resulted in “dimmable” products that do not work as claimed, flicker or never completely turn off. These are major problems that need to be addressed so that consumers do not associate all LEDs with poor performance and become averse to using them. High-performing LED products do exist, but you need to ask the right questions to make sure you have chosen one of those products appropriately. By using the five questions below as a guide, ESCs can confidently purchase and install an LED fixture or lamp and ensure all customer expectations are met. 1. What type of LED product am I using: LED lamp or LED fixture? 2. What is the dimming range of the fixture? 3. What is the dimming performance of the product? 4. On what type of control does the LED product operate? 5. What is the minimum or maximum number of fixtures/lamps that can be connected to one dimmer? B. TYPES OF LED PRODUCTS LEDs are inherently low-voltage devices. Therefore, additional electronic components are required to convert the line voltage power to low voltage for the LEDs. These electronics may also interpret control signals, and dim the LEDs accordingly. These electronics are referred to as a driver. LED luminaires come in two distinct types: LED bulbs (also called LED is or retrofit lamps) and LED fixtures. LED bulbs have Edison base sockets and are meant to replace standard incandescent or screw-in CFL bulbs. LED bulbs have integral drivers that determine if they are dimmable, and if so, to what performance level. LED fixtures can vary from cove lights to downlights and usually have an external driver. Some fixture manufacturers offer different driver options on the same fixture to support different control technologies or applications (such as dimmable vs. non-dimmable.) There are two different types of LED drivers: constant voltage types (usually 10V, 12V and 24V) or constant current types (350mA, 700mA and 1A). Just as their names would suggest, a constant current driver provides a constant current, such as 700mA, to a permade LED array that is designed to operate at or below that current level. A constant voltage driver provides a constant voltage to one or more LED arrays connected in parallel. These two types of drivers are NOT interchangeable, and it is the design of the LED array that determines which driver is appropriate. Often this is based on application, but it is still the configuration of the LED that determines if a constant current or a constant voltage driver is needed. A constant current LED driver allows for simpler LED array design because multiple LEDs in a single array are merely wired in series. However, it can only be used with an LED array designed for the same or higher current level. A 700mA light engine will work with a 700mA driver, but you cannot connect additional 700mA loads to the same driver. This is great for a downlight, sconce or other LED fixtures that use only one light source per driver (much like a fluorescent lamp with its associated ballast). Note that some drivers support multiple currents, making them more flexible when designing a fixture. A voltage driver is used in areas where you may have a variable amount of fixtures, such as a cove or undercabinet light. Here you can keep adding LED arrays to the driver up to the driver’s maximum power limit. These are similar and sometimes identical to electronic or magnetic low voltage power supplies and often have 12V and 24V outputs. Some drivers are manufactured to operate specific LED devices or arrays, while others can operate most commonly available LEDs. LED drivers are usually compact enough to fit inside or on a junction box, include isolated Class 2 output for safe handling of the load, operate at high system efficiency, and offer remote operation of the power supply. However, not all drivers meet these criteria. © 2014 CEDIA 9 DIMMING LED LAMPS WHITE PAPER Drivers with dimming capability can dim the LED light output over the full range from 100% to 1% or less. Dimming drivers can dim LEDs by reduction in the forward current or pulse width modulation (PWM) via digital control. Most dimming drivers operate using the PWM method as seen in figure 3. With this method, the frequency could range from a hundred modulations per second to as high as hundreds of thousands of modulations per second, so that the LED appears to be continuously lit without flicker. The application will determine whether a very high PWM frequency or continuous current reduction (CCR) is needed as seen in figure 4. Compatibility is essential between the LED driver and the control, whether the driver is built into the lamp or is external to a fixture. For example, a 0-10V driver must follow the same standards as the 0-10V control in order for them to function together properly. When using a control system, you may run into 0-10V control devices and systems such as occupancy sensors, photocells, wall box dimmers, remote controls, architectural and theatrical controls, and building and lighting automation systems. LEDs can also work with devices governed by the DMX and digital addressable lighting interface (DALI) protocols. In the future, they may include wireless (RF) as a control option. The driver has a wider range of possible control types that are discussed in the Control Technologies section (page 14). One of the most important LED driver features to examine is the quality of the DC output voltage of the driver. To maximize the light output from the LEDs without overstressing them requires a constant DC current to be maintained. Additionally, the instantaneous response of LEDs to changing current makes them highly susceptible to flicker, especially compared to incandescent sources. Finally, be cautioned that remote mounting of the driver results in potential voltage drops and power losses on the DC wiring that must be properly accounted for. 10 © 2014 CEDIA PWM Dimming Rated LED Current (or Voltage) Driver Output Current (or Voltage) Time Figure 3: PWM Dimming CCR Dimming Rated LED Current (or Voltage) Driver Output Current (or Voltage) Time Figure 4: CCR Dimming DIMMING LED LAMPS WHITE PAPER C. DIMMING RANGE Incandescent lamps dim to below 1% perceived light, which appears as the filament glow you are familiar with. The dimming range of an LED lamp or fixture could vary from one device to another. Some may dim to a minimum level of only 50%, while a different product may dim to 1%. Additionally, manufacturers will quote measured light numbers, but consumers are familiar with perceived light. What is the difference? Measured light output is the quantifiable value of light measured by a light meter or similar device. This is the dimming percentage indicated on LED product specification sheets. Perceived light is the amount of light that your eye interprets due to pupil dilation. The eye’s pupil dilates at lower light levels, causing the amount of light to be perceived higher than measured (i.e., 20% measured light equals 45% perceived light). The equation for determining perceived light is to take the square root of the measured light percentage (e.g. √0.2 = 0.45). You need to select the dimming range of your fixture or lamp that will meet your expectations. A product that dims to 20 percent measured light (45 percent perceived) wouldn’t make sense in a media room, but may be the energy-saving solution necessary for an office. D. DIMMING PERFORMANCE Each manufacturer defines dimming in a different way; what you need to know is if the dimming will be distracting or will have noticeable unexpected drops in light. The publics experience with incandescent dimming is that it is smooth and continuous. Specifically, a change in the control (dimmer) position should be reflected by an equal change in light level. There should be no abrupt change in light level as the light source is being dimmed. Even more important than smooth and continuous dimming is ensuring that there are no points of flicker in the dimming range. Flicker is the unexpected modulation of light level that is visible to the human eye. Flicker can come from many sources, including line noise, control noise, component tolerance and LED driver circuit design. Flicker can be continuous (happening all of the time), or intermittent (only happening some of the time or at certain light levels). A good lamp should account for all of these factors and still provide flicker-free, smooth and continuous dimming. In addition, it is important to be aware of ambient temperatures at the application. While LEDs have the ability to start at temperatures as low as -40°C, operating them at cold ambient temperatures can cause operating problems. LEDs draw higher power at cold ambient temperatures – the opposite of what happens with fluorescent lamps – and can lead to system malfunction. For outdoor applications where the power supply is mounted remotely, the maximum LED load on the driver should be de-rated by 10-20% to avoid system conflicts during cold temperatures. Another consideration is that customers don’t want “pop on” in their lighting. The level the light is at when it is turned off is the level the light should return to when it is turned back on. There should be no dropout, so the light should only turn off when the switch is turned off. This can be achieved by utilizing the low end trim settings available on many wall box and system level dimmers to ensure that the lights remain on at their lowest light level at the bottom of the dimmer’s travel. The light levels should change any time the control is adjusted. Adjusting the control without a corresponding change in light level is undesirable and is referred to as “dead travel.” E. CONTROL TECHNOLOGIES The following control technologies refer to the signal and wiring between the control on the wall and the fixture or lamp. LED retrofit lamps generally use one of two control technologies: forward or reverse phase control methods. LED fixtures may use any method, and are independent of the driver type (constant current or constant voltage). These control technologies are used in stand-alone applications and control systems as well as in wired and wireless lighting control systems. Controls that use forward phase control to control a lamp may also use a wireless technology to communicate among fixtures or within an entire home lighting control system. i. Forward Phase Control. Typically used for incandescent and MLV light sources, forward phase control is the most common method of dimming control. NEMA estimates that there are approximately 150 million forward phase control dimmers installed residentially (NEMA LSD-49), and many of these are bound to control LED replacement lamps. © 2014 CEDIA 11 DIMMING LED LAMPS WHITE PAPER Working well with forward phase control is critical to the success of LED bulbs because there are hundreds of millions of forward phase dimmers already installed for use with incandescent and halogen lamps. Unfortunately, the controls were never designed for LED lights and are not UL listed to operate LED lights, so the performance is hit or miss and in many cases will cause LEDs to flicker, drop out, pop on or not dim very low. These dimming controls may also require multiple lamps per control in order to meet the minimum load requirements of the control. standard. This leads to drivers and lamps that claim to be 0-10V compatible, but instead drop out, pop on or dim backwards with the lowest light at the top of the control and the brightest light at the bottom. Some 0-10V products do not work at all with controls designed for 0-10V ballasts, which are the majority of installed 0-10V commercial controls. Since the control signal is a small analog voltage, long wire runs can produce a significant drop in the signal level resulting in varying light levels from different drivers controlled by the same control device. Please note that new forward phase control dimmers have recently entered the market that have been specially designed to reduce or eliminate the problems seen with controlling LED loads on existing incandescent dimmers. iv. DALI. This digital standard originated in Europe for control of fluorescent ballasts, but is now commonplace in commercial buildings in the United States. It is also defined in IEC standard 60929 Annex E and allows for digital control of individual fixtures, maximizing the user’s control and productivity. ii. Reverse Phase Control. Typically used to control ELV light sources, reverse phase control is best for capacitive loads such as LED drivers. While it does not have the installed base that incandescent dimmers possess, this control type is more successful at high performance LED dimming without flicker. Reverse phase dimmers were designed for the lower power “electronic loads” of electronic low voltage transformers, so they tend to work better with the drivers required for LED loads. Unfortunately, these controls require a neutral wire to power the internal electronics, and not every electrical back box has a neutral present. Installing reverse phase dimmers in older buildings may require that a neutral wire is pulled to the box. Furthermore, these types of controls are not as widely available in the marketplace. iii. 0-10V Control. This analog control standard has been used in energy management controls such as occupancy and daylight sensors and is now becoming popular with many LED products. This control type is isolated and considered low voltage class 2, enabling it to be safe to the touch and allowing for simplified wiring. One of the benefits of 0-10V controls is that it is defined in the IEC (International Electrotechnical Consortium) standard number 60929 Annex E. Unfortunately, some manufacturers don’t follow the 12 © 2014 CEDIA DALI provides addressing of individual fixtures and status feedback from the drivers. This makes it easy to digitally assign occupancy sensors, daylight sensors, time clocks, manual controls and other controls to one or many fixtures without complicated wiring. It opens up an entire suite of energy-saving and systemmonitoring control schemes where the design and setup is all done within software, making designing with them simple. Some derivatives of DALI, such as EcoSystem, further simplify the programming process by allowing you to use a handheld device in the space and not have to know details of the system, such as fixture addresses. v. DMX-512. Typically used in theatrical applications, DMX remains popular with RGB LED applications where multiple channels are necessary for individual color control. Some manufacturers are using DMX as the control type for white light in general illumination applications, which can often be complicated in terms of wiring, addressing and interacting with other controls in the space. Contact the manufacturer for more information about how DMX controls can be integrated with control systems. Integrating between general lighting control systems and DMX fixtures can often be complicated. A fixture and the desired control may use the same control technology (ex: 0-10V) but it does not mean DIMMING LED LAMPS WHITE PAPER they will perform well together. This is especially true with forward and reverse phase control, due to the lack of a formal standard. Even control technologies that have a standard only pertain to compatibility and do not indicate anything about performance. The only way to know for sure if an LED lamp or fixture will work with a particular dimmer is to test them before installation in the client’s home. Whether that testing is a mock-up or testing by the manufacturer, it is necessary to determine if flicker, pop-on, dead travel, etc will occur. Keep in mind that you will not be able to visually determine the inrush of an LED product. Therefore, find out from the manufacturer or limit the number lamps to avoid overloading the dimmer. This transient electrical stress, among many other reasons, may limit the maximum number of lamps you can install on one dimmer. A minimum number of fixtures may be required to operate a dimmer because of the 25-watt to 60-watt minimum load that most incandescent dimmers require to operate correctly under all conditions. When using incandescent bulbs, the minimum load requirement was easily met with usually only a single bulb. However, with LEDs, four or more loads may be needed on a dimmer in order to meet the required minimum load. Keep in mind this inrush stress only occurs on phase control products (forward or reverse). The inrush current is shown in Figure 5. Many manufacturers (both LED luminaire manufacturers and control manufacturers) conduct compatibility testing of their products. It is up to you to determine if a manufacturer’s assessment of “good dimming” will meet client needs. Inrush Current F. NUMBER OF LAMPS ON A DIMMER A common problem associated with LED system operation is overloading the driver. LED drivers are rated for a maximum load which must be given proper attention. Connecting too many LEDs in series may result in too low a voltage being available to the last LED(s) in the chain. Similarly, some LED drivers may not perform well if too little load is put on them. Using a wrong voltage driver will cause the LEDs to either not light up or operate at higher currents than intended. A prudent practice is to check the voltage rating of the LED load being used against the rated output voltage of the driver. For example, using a 12V driver on a 10V LED load could result in a significantly shorter life of the module. Turn on Current Voltage Time Figure 5: Inrush Current The number of lamps to be installed on a single dimmer may seem like an easy question to answer, but it is not as simple as looking at a 600-watt dimmer and dividing 600 by the 10-watt LED lamp selected. This calculation yields that 60 lamps can be used on a circuit and while the LED lamp may only draw 10 watts continuously, there is a possibility of an inrush current spike during every half-cycle. Neglecting this inrush performance can put significant stress on the dimmer and can cause premature product failure. © 2014 CEDIA 13 DIMMING LED LAMPS WHITE PAPER 05 TYPES OF CONTROL AND INSTALLATION Forms of lighting control include occupancy sensors, daylight sensors, timeclock switches, a variety of manual and automatic dimming devices, and centralized controls. Some controls operate on line voltage power, while others are low-voltage (DC) powered. a. Central Control System. Centralized lighting control systems can be used to automatically turn on, turn off, and/or dim lighting at specific times or under certain conditions. This type of control system can be used in an individual room or an entire house. Centralized lighting control systems can also be integrated with other home automation systems, such as audio/visual systems, fire alarms and security systems. Centralized lighting control systems can be programmed to use a variety of inputs from occupancy sensors, daylight sensors, timeclocks, keypads, remotes, touch screens or other devices and systems to trigger lighting events. A lighting control system can simultaneously adjust groups of lights to predefined levels to create the desired mood and ambiance. b. Local Control. Local control is typically achieved by having individual dimmers or lighting control devices directly controlling the attached lamps or fixtures. Local controls can be integrated with sensors or other inputs on a smaller scale than a central control system or, in some cases, can be integrated into the central control system. c. Installation of LED lamps. When installing a screw-in LED lamp, you may unscrew the existing lamp and replace it with an LED lamp. Be sure to check with your fixture’s manufacturer about heat shedding compatibility. However, you may need to replace the dimmer in order to have acceptable dimming performance of the lamp. You can reference the manufacturer’s packaging or website (for example http://www.lutron.com/LEDtool) for information on what dimmers are compatible with specific lamps. If you are replacing a stand-alone wall box dimmer you can often do this without an electrician. If the lamp is on a system device, contact a dealer to determine what product is best and how to install it. 14 © 2014 CEDIA d. Installation of LED fixtures. LED fixtures need to be installed by a licensed electrician and require that they are installed with the appropriate control device. Some of these fixtures easily retrofit into existing wiring, while others require more extensive renovations, depending on the compatible controls. Keep in mind that interfaces may be available to eliminate the need for wiring changes. 06 CONCLUSION LEDs are a promising new light source for most applications and dimming saves energy by reducing the light level and electric power consumption. The use of LEDs can lead to even greater savings compared to incandescent bulbs because of its longer life-time, greater efficacy and construction. It is necessary to examine the LED luminaire’s specification sheet to determine if the lighting is compatible with the control system and the driver desired. In addition to energy savings, dimming LEDs contributes to a soothing ambiance in the home, which the customer is willing to pay a premium for. 07 APPENDIX A The following two procedures outline measurements of SSL fixtures, components and modules using IESNA guidelines: 1. LM-79-08. This approved method describes the procedures and precautions for performing reproducible measurements of total luminous flux, electrical power, luminous intensity distribution and chromaticity of solidstate lighting (SSL) products for illumination purposes under standard conditions. 2. LM-80-08. This method allows a reliable comparison of test results among laboratories by establishing uniform test methods. It addresses the measurement of lumen maintenance testing for LED light sources, including LED packages, arrays and modules. It does not provide guidance or recommendations regarding prediction estimations or extrapolations for lumen maintenance beyond the limits of the lumen maintenances determined from actual measurements.