Guidelines to the Safety,Health and Welfare at Work

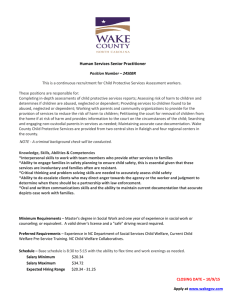

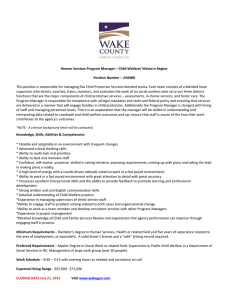

advertisement