title packaging specification packaging of electrostatic discharge

advertisement

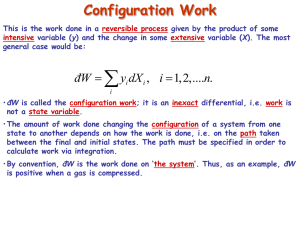

TRW Space & Defense One Space Park Redondo Beach, CA 90278 CAGE CODE NO. 11982 TITLE PACKAGING SPECIFICATION PACKAGING OF ELECTROSTATIC DISCHARGE SENSITIVE ELECTRONIC PARTS AND COMPONENT ASSEMBLIES DATE 18 May 2001 NO. REV. SUPERSEDING: PREPARED BY: PK4-35 G PK4-35F 1 December 1999 R.L. Billett/M. Feeney/E.V. Laguette R.L. Billett 8/30/84 B.B. Evans DATE C.J. Holzbauer 9/5/84 DATE D.J. Bigelow DATE W.B. Hallmark 9/5/84 8/30/84 9/6/84 DATE J.A. Morrow 9/6/84 DATE DATE DATE DATE ORIGINAL PDMO RELEASE: PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 1 APPROVAL SIGNATURES: PD MO SYSTEMS 1391 REV. 7-90 TRW Space & Defense One Space Park Redondo Beach, CA 90278 REVISION/CHANGE RECORD SYMBOL DOCUMENT DATE --- 9/1/84 A1 12/12/84 AUTHORIZATION / DATE FOR DOCUMENT NO. REVISION / CHANGE DESCRIPTION PK4-35G PAGES AFFECTED See Title Page Initial Release All Prep. R.L. Billett Revised upper resistivity limit in 3.1.5.1 (a). Revised 3.4 for clarification. Revised 6.4. Replace pages 2, 5, and 7 2 5 7 Added Table of Contents. Numerous changes to format and requirements in Section 3 effecting lead shorting, carbonloaded materials, Class 1A parts, RF devices and semiconductor wafers. Added Figure 11 and 12. Revised paragraph 4.4 All Appv. B.B. Evans Appv. D. Ayala for C.J. Holzbauer A 2/17/89 Prep. R.L. Billett Appv. B.B. Evans Appv. C.J. Holzbauer B1 10/19/90 Prep. R.L. Billett Appv. R.L. Billett Added 1.2. Revised 3.3 to clarify the use of Table 1. Revised 3.3.9 to provide guideline for the use of Figure 9 package. Revised 6.5. 1, 2, 6, 7, 11 In paragraphs 2. And 6.2 MIL-STD-1676 was DOD-STD-1676. In paragraph 3.1.5.1 upper 12 14 resistivity limit 1 x 10 was 1 x 10 . Paragraph 3.1.5.6 Carbon Loaded Materials, deleted and paragraphs 3.1.5.7 and 3.1.5.8 renumbered as 3.1.5.6 and 3.1.5.7. Paragraph 6.4 Resistivity, deleted and paragraph 6.5 renumbered as 6.4. All Added subparagraph (e) under paragraph 3.1.5.5. Deleted references to Figure 7 in Table I. Deleted paragraph 3.3.7. Figure 7 is not to be used as an approved packaging method. 4 Revised Table I to add references to Figure 7. Added paragraph 3.3.7. Revised Figure 7 to depict the description in paragraph 3.3.7. Incorporated SCN C1. All B 8/12/93 Prep. R.L. Billett Appv. R.L. Billett CADM REL.: Signature in file C1 9/17/93 Prep. R.L. Billett Appv. R.L. Billett CADM REL.: Signature in file C 12/7/94 Prep. R.L. Billett Appv. R.L. Billett CADM REL.: Signature in file 6 7 PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 2 CADM REL.: J. Kroll PD MO SYSTEMS 1391 REV. 7-90 One Space Park Redondo Beach, CA 90278 REVISION/CHANGE RECORD SYMBOL DOCUMENT DATE D 12/22/97 FOR DOCUMENT NO. AUTHORIZATION / DATE Prep. R.L. Billett Appv. R.L. Billett CADM REL.: Signature in file E 7/13/99 Prep: R. L. Billett Materials Technology & Engineering Appv: B. JW. Brooks Materials Technology & Engineering PK4-35G REVISION / CHANGE DESCRIPTION PAGES AFFECTED Revised para. 3.1.5.5 to allow the use of carbon loaded polyethylene foam and to clarify prohibited materials. Added para. 3.1.5.8 to define insulating materials. Revised para. 3.6.4 to add reference to EIA Standard RS-471 for label. Changed references from anti-static materials to static dissipative materials in a number of paragraphs to conform to current industry practice. Minor non-technical editorial changes in a number of paragraphs. All Cover Sheet and RCR Pages are electronic reproductions of the originals. Cover Sheet, RCR Pages Made minor editorial changes. All Broadened document applicability in 1.1 to include parts not susceptible to damage from ESD, but used in areas controlling ESD. 1 Added EIA-625 to 6.2. Added ESD S11.11 to Section 2 and to 3.1.5.1. 3 Changed 3.1.8 from Class 1A Parts to Highly Sensitive Parts. 5 Changed 3.1.8.1 from Static Dissipative Materials to Static Shielded Bags. Removed reference to static dissipative materials and ASTM D257. 5 Added, “as provided in paragraph 3.1.3” to 3.2.1. 5 Deleted “maximum quantity of 20 parts per unit package” from 3.2.1. 5 Removed requirement for placing static dissipative plastic film over cavities before closing carrier in 3.3.4, now optional. 7 Added, “To simplify future handling…” to 3.3.4. 7 Added (f), Lot Number or Date Code to 3.6.2 for intermediate containers. 8 Removed 6.4. 9 PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 3 TRW Space & Defense PD MO SYSTEMS 1392 REV. 7-90 (FILE DIRECTLY AFTER COVER SHEET) One Space Park Redondo Beach, CA 90278 REVISION/CHANGE RECORD SYMBOL DOCUMENT DATE F 12/1/99 FOR DOCUMENT NO. AUTHORIZATION / DATE Prep: R. L. Billett Materials Technology & Engineering Appv: B. JW. Brooks Materials Technology & Engineering G 5/18/01 Prep: R. L. Billett Materials Technology & Engineering Appv: B. JW. Brooks Materials Technology & Engineering REVISION / CHANGE DESCRIPTION PK4-35G PAGES AFFECTED In paragraph 3.1.5.1(b), “static decay time” was “static decay rate”. 4 Added paragraph 3.1.5.5 (g) to prohibit the use of PVC plastics. 5 Added paragraph 6.4. 9 1.1 Added voltage criteria to define ESD sensitivity and deleted reference to TRW drawing M283308. 2. Added TRW Specifications PK4-17, PK420, & PK4-21 and deleted NASA test method MMA-1985-79 and TRW Drawing M283308 in Applicable Documents section. 3.1.5.5 Revised to add description and guidance for prohibited materials. 3.1.5.5 (e) Added materials which contain amines and amides to prohibited items. 3.1.5.5 (g) Deleted prohibition of chloride containing plastics except for polyvinylchloride. Added 3.1.5.5.(h) to prohibit certain types of plastic bags and film. Deleted paragraphs 3.1.8, 3.1.8.1, & 3.1.8.2 which provided additional packaging requirements for highly sensitive parts. Added 3.1.8 to provide for additional requirements imposed by procurement documents. 3.3.4 Revised to delete recommendation for the maximum parts per carrier. Minor editorial changes in a number of locations. 1 2,3 5 5 5 5 5 5 7 PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 4 TRW Space & Defense PD MO SYSTEMS 1392 REV. 7-90 (FILE DIRECTLY AFTER COVER SHEET) PK4-35G 18 May 2001 TABLE OF CONTENTS Page 1. SCOPE ......................................................................................................... 1 1.1 Scope ......................................................................................................... 1 1.2 Purpose ......................................................................................................... 1 3. REQUIREMENTS ......................................................................................................... 4 3.1 General ......................................................................................................... 4 3.1.1 Processes .......................................................................................... 4 3.1.2 Cleaning............................................................................................. 4 3.1.3 Pairs, Sets, and Kits........................................................................... 4 3.1.4 Hardware ........................................................................................... 4 3.1.5 Packaging Materials........................................................................... 4 3.1.5.1 Anti-Static Materials............................................................. 4 3.1.5.2 Shielding Materials .............................................................. 4 3.1.5.3 Lead Shorting ...................................................................... 4 3.1.5.4 Static Shielded Bags............................................................ 4 3.1.5.5 Prohibited Materials ............................................................. 5 3.1.5.6 Corrosivity............................................................................ 5 3.1.5.7 Solderability ......................................................................... 5 3.1.5.8 Insulating Materials.............................................................. 5 3.1.6 Electrostatic Discharge (ESD) Protection ........................................... 5 3.1.7 Connectors......................................................................................... 5 3.1.8 Procurement Documentation.............................................................. 5 3.2 Unit Package Design ........................................................................................ 6 3.2.1 Quantity.............................................................................................. 6 3.2.2 Physical Protection............................................................................. 6 3.2.3 Removal and Replacement Capability................................................ 6 3.2.4 Documentation ................................................................................... 6 3.3 Unit Package Selection..................................................................................... 6 3.3.1 Figure 1.............................................................................................. 6 3.3.2 Figure 2.............................................................................................. 7 3.3.3 Figure 3.............................................................................................. 7 3.3.4 Figure 4.............................................................................................. 7 3.3.5 Figure 5.............................................................................................. 7 3.3.6 Figure 6.............................................................................................. 7 3.3.7 Figure 7.............................................................................................. 7 3.3.8 Figure 8.............................................................................................. 7 3.3.9 Figure 9.............................................................................................. 7 3.3.10 Figure 10.......................................................................................... 7 3.3.11 Figure 11.......................................................................................... 8 3.3.12 Figure 12.......................................................................................... 8 3.4 Intermediate Container ..................................................................................... 8 3.5 Shipping Containers ......................................................................................... 8 PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 5 2. APPLICABLE DOCUMENTS ......................................................................................... 2 PD MO i PK4-35G 18 May 2001 TABLE OF CONTENTS (Continued) Page 3.6 Marking ......................................................................................................... 8 3.6.1 Unit Packages.................................................................................... 8 3.6.2 Intermediate Containers ..................................................................... 8 3.6.3 Shipping Containers ........................................................................... 9 3.6.4 Electrostatic Discharge Sensitive Marking.......................................... 9 3.7 Workmanship ................................................................................................... 9 4. QUALITY ASSURANCE PROVISIONS.........................................................................10 4.1 Inspection Responsibility .................................................................................10 4.2 Acceptance Inspection Procedures..................................................................10 4.3 Visual Examination ..........................................................................................10 4.4 Certification......................................................................................................10 5. PREPARATION FOR DELIVERY..................................................................................10 6. NOTES 6.1 6.2 6.3 6.4 ........................................................................................................................10 Intended Use ...................................................................................................10 ESD Control Programs ....................................................................................10 Topical Antistats ..............................................................................................10 Changes from Previous Issue..........................................................................10 Table TABLE I - UNIT PACKAGE SELECTION GUIDE................................................................ 6 Figure 1 ............................................................................................................................11 Figure 2 ............................................................................................................................11 Figure 3 ............................................................................................................................12 Figure 4 ............................................................................................................................12 Figure 5 ............................................................................................................................13 Figure 6 ............................................................................................................................13 Figure 7 ............................................................................................................................14 Figure 8 ............................................................................................................................14 Figure 9 ............................................................................................................................15 Figure 10............................................................................................................................15 Figure 11............................................................................................................................16 Figure 12............................................................................................................................16 PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 6 Figures PD MO ii PK4-35G 18 May 2001 PACKAGING SPECIFICATION PACKAGING OF ELECTROSTATIC DISCHARGE SENSITIVE ELECTRONIC PARTS AND COMPONENT ASSEMBLIES 1.0 SCOPE 1.1 Scope. This specification establishes requirements for the preservation, packaging, electrostatic discharge protection, packing and container marking for electronic parts and component assemblies which are subject to damage from electrostatic discharge (ESD). These items are referred to herein as parts. The parts applicable to this specification are those susceptible to damage or degradation from ESD voltages of less than 16,000 volts. This specification may also apply to parts which are not susceptible to damage from ESD but which are used in areas requiring control of ESD. G PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 7 1.2 Purpose. The purpose of this specification is to provide requirements and guidance for the application of protective packaging to electronic parts, which will be suitable for the protection of such parts during initial shipment. In addition, it is intended that the packaging will be compatible with subsequent internal handling and transportation operations of receiving, inspection, testing, storage, kitting and issue to manufacturing for assembly. PD MO 1 PK4-35G 18 May 2001 2. APPLICABLE DOCUMENTS The following documents form a part of this specification to the extent specified herein. Unless otherwise specified in the issue in effect on the date of procurement placement shall apply. STANDARDS Federal Federal Test Method Standard 101 Test Procedures for Packaging Materials Military MIL-HDBK-1547 Parts, Materials and Processes for Space & Launch Vehicles, Technical Requirements for MIL-STD-129 Marking for Shipment and Storage Electrostatic Discharge Control Program for Protection of Electrical and Electronic Parts, Assemblies & Equipment American Society for Testing and Materials (ASTM) MIL-STD-1686 ASTM D257 D-C Resistance or Conductance of Insulating Materials ASTM D991 Volume Resistivity of Electrically Conductive and Anti-Static Products EIA-625 Requirements for Handling Electrostatic Discharge Sensitive (ESDS) Devices RS-471 Symbol and Label for Electrostatic Sensitive Items Electrical Overstress/Electrostatic Discharge Association (EOS/ESD) ESD S11.11 Surface Resistance Measurement of Static Dissipative Planar Materials PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 8 Electronics Industries Association PD MO 2 PK4-35G 18 May 2001 SPECIFICATIONS TRW Space & Electronics Group PK4-17 Packaging of Small Electronic Parts in Waffle Packs PK4-20 Packaging of Small Electronic Parts on Tape and Reel Packages for Automated Assembly PK4-21 G PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 9 Packaging of Small Electronic Parts in Matrix Trays PD MO 3 3. REQUIREMENTS 3.1 General. 3.1.1 Processes. All packaging and related activities including cleaning, preservation, packaging and packing shall be conducted in a manner to insure that there is no degradation or physical damage including electrostatic discharge damage to the parts (see 6.2). 3.1.2 Cleaning. Parts shall be clean prior to packaging. When cleaning is required it shall be accomplished by a process or combination of processes, which will remove contaminants without causing degradation or damage including electrostatic discharge damage. 3.1.3 Pairs, Sets, and Kits. Parts furnished in pairs, sets, or kits under one part identification number shall be unit packaged as one pair, one set, or one kit, as applicable. The package design shall prevent part damage from contact with other parts contained in the same package. 3.1.4 Hardware. Hardware accompanying a part (brackets, screws, etc.) shall be protected and enclosed within the unit package in a manner that will not damage the part or package. When practical, the hardware shall be mounted on the part. The package design shall prevent part damage from contact with other parts contained in the same package. 3.1.5 Packaging Materials. All packaging materials shall be clean, dry and chemically inert and shall maintain their required properties including static dissipative properties throughout normal storage, handling and usage. 3.1.5.1 Static Dissipative Materials. Static dissipative materials used for the unit packages and in intimate contact with the part shall conform to the following: (a) Surface resistivity equal to or greater than 1 X 105 but not greater than 1 X 12 10 ohms/square in accordance with ASTM D257 or ESD S11.11. (b) Static decay time of less than 2 seconds in accordance with Federal Test Method Standard 101 Method 4046. (c) The material shall be capable of dissipating static charges when grounded without the production of a spark. 3.1.5.2 Shielding Materials. Conductive materials used for shielding shall have a surface resistivity of less than 1 X 105 ohms/square in accordance with ASTM D991. 3.1.5.3 Lead Shorting. Material, when used for shorting or shunting of part leads to each other, shall be a conductive material having a direct resistance of 200 ohms or less when measured with an ohmmeter with test probes approximately 3/4 inch apart. 3.1.5.4 Static Shielding Bags. Static shielding bags as specified in the unit package descriptions shall consist of three (3) layers or laminations with a static dissipative inner layer and one of the following options: (1) A continuous conductive exterior layer and an insulating intermediate layer or (2) A static dissipative exterior layer and a continuous conductive intermediate layer. Heat sealed bags shall be of a size to permit opening and resealing a minimum of two (2) times. PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 10 PK4-35G 18 May 2001 PD MO 4 PK4-35G 18 May 2001 3.1.5.5 Prohibited Materials. Packaging materials that may contaminate, damage, or degrade parts by chemical degradation, outgassing, particle shedding, or diffusion during long term storage shall not be used in unit packages. Materials prohibited in unit packages include: G (a) Carbon loaded plastic film except as the conductive layer or lamination within a static shielding bag as described in paragraph 3.1.5.4. (b) Carbon loaded polyurethane foam. Cross linked polyethylene foam which contains carbon is acceptable. NOTE: Carbon loaded plastic foams can generally be identified by their dark black color. (c) Materials which will easily shed conductive particles. (d) Materials which have been treated with a topical antistat. (See 6.3) (e) Materials which contain amines, amides, or n-octanoic acid or its precursor. (f) Fiberboard or paperboard products which are in direct or intimate contact with the part contained. (g) Polyvinylchloride (PVC) plastics. (h) Surfactant added plastic bags or film materials commonly known as pink poly. 3.1.5.6 Corrosivity. Materials used for or within unit packages shall be noncorrosive in accordance with Federal Test Method Standard 101 Method 3005. 3.1.5.7 Solderability. Materials used shall not affect part solderability as defined in the applicable part specification. G G 3.1.6 Electrostatic Discharge (ESD) Protection. All parts shall be provided with protection from ESD as described herein. ESD protection shall be provided by the use of a combination of static dissipative packaging materials to prevent the generation of electrostatic charges and conductive materials for shielding which provides a continuous conductive shield enclosing the part. 3.1.7 Connectors. Parts (RF Devices) that have coaxial connectors shall have connector covers made from a static dissipative plastic material installed on all connectors. 3.1.8 Procurement Documentation. In addition to the requirements contained herein, packaging shall conform to specific requirements contained within the procurement documentation (part specifications, purchase order statement of work, etc.) when those requirements are more specific than the requirements contained herein. When packaging specification PK4-17, PK4-20, or PK4-21 is specified in the procurement documentation (to support automated assembly equipment), that specification shall take precedence over the requirements in this specification and conformance to PK4-17, PK4-20, or PK4-21 as applicable, shall be used as criteria for acceptance. G PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 11 3.1.5.8 Insulating Materials. Packaging materials identified herein as insulating shall have a surface resistivity greater than 1 X 1012 ohms/square in accordance with ASTM D257. PD MO 5 PK4-35G 18 May 2001 3.2 Unit Package Design 3.2.1 Quantity. The quantity of parts contained in each unit package shall be one (1) except as provided in paragraph 3.1.3 and chip devices packaged as described in paragraph 3.3.4 (Figure 4). 3.2.2 Physical Protection. The unit package design shall provide physical protection and prevent excessive movement of the part. Leads or terminals shall be maintained in their manufactured configuration without causing undue loads or stresses capable of causing damage to the part. Securing leads by tape or adhesive is not permitted. 3.2.3 Removal and Replacement Capability. The unit package shall be easy to open and reclose for re-use. It shall be constructed in such a manner that the part can be easily removed and replaced without damage to the part or to the integrity of the package. 3.2.4 Documentation. Documentation provided with parts shall be packaged as a separate unit package. When plastic bags or envelopes are used for this purpose they shall be of static dissipative material. 3.3 Unit Package Selection. Table I is provided as a guide to suggest suitable unit packages for a given part configuration. Figures other than those specified in Table I as well as other materials, packages, and containers may also be used. The unit package selected from Table I or any unit package used shall meet the applicable requirements of paragraphs 3.1 and 3.2 of this specification. All required protection from electrostatic discharge shall be provided by the unit package. TABLE I. Unit Package Selection Guide Applicable Figures 1, 2, 4 Axial lead 3, 5, 10 Radial lead 5, 7, 11 Flatpack 5, 6, 7, 11 Dual inline (DIP) 3, 8, 9 TO Can 3, 10 RF Device 3, 5 Semiconductor wafer 12 3.3.1 Figure 1. The unit package shall be a static shielding bag. The bag shall be closed with a zipper type reusable closure. CAUTION: This method shall be used only when the part is rugged enough to be adequately protected in this manner. PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 12 Part Type or Configuration Chip PD MO 6 PK4-35G 18 May 2001 3.3.2 Figure 2. The unit package shall be a static shielding bag. The bag shall be closed by a heat seal or other suitable means. CAUTION: This method shall be used only when the part is rugged enough to be adequately protected in this manner. 3.3.3 Figure 3. The unit package shall be 2-piece molded static dissipative holding device that incorporates a blister cavity or compartment to provide part protection. Closure of the holding device shall be by friction locks or similar means that meet the requirements of paragraph 3.2.3. Each holding device shall be placed in an individual heat-sealed or zipper sealed static shielding bag. 3.3.4 Figure 4. The unit package shall be a two-piece, dustproof carrier made from conductive or static dissipative material formed with individual cavities. No more than one part shall be placed into each cavity. A sheet of static dissipative plastic film or other suitable material may be placed over the cavities before closing the carrier. The closure shall be by friction locks, clips or similar means. Each carrier shall be placed in a static shielding bag. 3.3.5 Figure 5. The unit package shall be a rigid or semi-rigid static dissipative plastic box with preformed 2 or 3-piece static dissipate cushioning inserts. Each box shall be placed in an individual static shielding bag. 3.3.6 Figure 6. The unit package shall be a suitable rigid static dissipative carrier that protects and maintains lead configuration. A clip or other holding device shall secure the part in the carrier. Each carrier shall be placed in an individual static shielding bag. G 3.3.8 Figure 8. The unit package shall be a conductive or static dissipative tube (rail) formed to provide physical protection to the part. The part shall be secured in the tube by plugs, pins, static dissipative foam or other means. Each tube shall be placed in an individual static shielding bag. NOTE: Only one part shall be packaged in each tube and bag combination. 3.3.9 Figure 9. The unit package shall consist of a piece of static dissipative foam into which the part leads are inserted. Each part with foam shall be placed in an individual static-shielding bag. CAUTION: This method shall only be used for parts which have leads rugged enough to withstand insertion and removal from the foam without damage and which have cases rugged enough to be properly protected in this manner. As a guideline, this packaging method should not be used for parts with leads that project more than 0.5 inch from the part body. 3.3.10 Figure 10. The unit package shall be a static dissipative tube or vial into which the part is placed with static dissipative cushioning inserts to secure the part. Each tube or vial shall be placed in an individual static shielding bag. PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 13 3.3.7 Figure 7. The unit package shall consist of a holding device made from a rigid static dissipative plastic material, folded or hinged in half. Cut outs shall be provided in the holding device for the body of the part. The two halves shall be secured in a closed position using static dissipative pressure sensitive tape. The material selected and the design of the holding device shall protect the leads and body of the device from damage. Each holding device shall be placed in a rigid or semi-rigid static dissipative plastic box. Each plastic box shall be placed in an individual static shielding bag. PD MO 7 3.3.11 Figure 11. The unit package shall be a static dissipative plastic box with a rubber permanent magnet secured to the inside bottom of the box that holds the part in place. Each closed plastic box shall be placed into an individual static shielding bag. CAUTION: This method shall be used only with lightweight parts that will be adequately secured by the magnet. A static dissipative foam-cushioning pad may be used to help hold the part in place. 3.3.12 Figure 12. The unit package shall be a static dissipative plastic box that holds the part in a manner to prevent movement and protect critical surfaces. Each closed plastic box shall be placed in an individual static shielding bag. 3.4 Intermediate Container. The use of intermediate containers for parts packaged in unit containers in accordance with paragraph 3.3, is optional except that they are required whenever different part numbers are consolidated for one shipment. Unit packages containing identical parts shall be uniformly loaded into a paperboard or fiberboard folding or setup box. Voids shall be filled using a clean, non-dusting, and chemically neutral cushioning material. Plastic materials in direct contact with the unit packages shall be static dissipative. Gross packed weight for paperboard or fiberboard intermediate containers shall not exceed their design specification. 3.5 Shipping Containers. Only fiberboard boxes bearing the boxmaker’s certificate in accordance with applicable freight classifications shall be used as exterior shipping containers. The gross weight limit indicated in the box certificate shall not be exceeded. 3.6 Marking. All containers shall be legibly and durably labeled, tagged, or marked to show the information specified in the following paragraphs. It is not necessary to duplicate marking on the unit package when it is clearly visible on the part without opening the package. 3.6.1 Unit Packages. Unit packages shall show the following information: (a) TRW Part Identification Number (b) Manufacturer’s Name, Initials, or Trademark (c) Nomenclature (d) Electrostatic-Sensitive Device Label (see paragraph 3.6.4) Special marking, when applicable, shall include: (e) Serial Number (f) Lot Number or Date Code (g) Electrical Rating 3.6.2 Intermediate Containers. Intermediate containers (when used) shall show the following information: (a) TRW Part Identification Number (b) Purchase Order or Contract Number (c) Nomenclature (d) Quantity of parts contained (e) Electrostatic-Sensitive Device Label (see paragraph 3.6.4) (f) Lot Number or Date Code PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 14 PK4-35G 18 May 2001 PD MO 8 PK4-35G 18 May 2001 3.6.3 information: (a) (b) (c) (d) Shipping Containers. Shipping containers shall show the following TRW Purchase Order or Contract Number Manufacturer’s Name and Identifying Code Electrostatic-Sensitive Device Label (see paragraph 3.6.4) Shipping documentation (packing slips) shall indicate the quantity of each part number contained in the shipment if not included in the shipping container marking. 3.6.4 Electrostatic Discharge Sensitive Marking. Marking and labeling shall clearly show the sensitive nature of the parts contained. The applicable label requirements of MIL-STD-129 or EIA Standard RS-471 are preferred; however, other distinctive labels of a similar nature are acceptable. PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 15 3.7 Workmanship. The packaging, packing, electrostatic discharge protection, and marking shall be of uniform good quality and free from defects that will impair service life and appearance. PD MO 9 PK4-35G 18 May 2001 4. QUALITY ASSURANCE PROVISIONS 4.1 Inspection Responsibility. The supplier is responsible for the performance of all inspection requirements as necessary to ensure conformance to this specification. TRW reserves the right to perform any inspection where such inspections are deemed necessary to assure that materials and processes conform to prescribed requirements. 4.2 Acceptance Inspection Procedures. Inspection shall be as specified herein. Shipments that do not conform to the requirements specified herein shall be rejected. 4.3 Visual Examination. Packages shall be examined to verify that the package, packaging materials, orientation of parts, and container markings are in accordance with the requirements specified in Section 3 of this specification. 4.4 Certification. The supplier shall provide certification that the packaging methods and materials used for providing electrostatic discharge protection conform to the requirements of this specification. The supplier’s standard certificate of compliance issued with each product shipment will be interpreted to include compliance to the requirements of this specification. 6. NOTES 6.1 Intended Use. This specification is intended for use by manufacturers and suppliers of electrostatic discharge sensitive electronic parts to TRW as general requirements for packaging. 6.2 ESD Control Programs. Additional information and guidance in establishing and maintaining an ESD control program including processes, handling and packaging can be found in MIL-HDBK-1547 , EIA-625, and MIL-STD-1686. 6.3 Topical Antistats. Topical antistats as referred to herein are those materials applied to the surfaces by brushing, dipping or spraying. They generally consist of a liquid solvent carrier and a primary material that is deposited on the surface to perform a static control function. 6.4 Changes from Previous Issue. A vertical line in the right hand margin is used in this revision to identify changes with respect to the previous issue. PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 16 5. PREPARATION FOR DELIVERY Not applicable PD MO 10 PK4-35G 18 May 2001 Figure 2. Bag (See 3.3.2) PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 17 Figure 1. Reclosable Bag (See 3.3.1) PD MO 11 PK4-35G 18 May 2001 Figure 4. Chip Carrier (See 3.3.4) PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 18 Figure 3. Holding Device in Bag (See 3.3.3) PD MO 12 PK4-35G 18 May 2001 Figure 6. Carrier in Bag (See 3.3.6) PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 19 Figure 5. Cushioned Box in Bag (See 3.3.5) PD MO 13 PK4-35G 18 May 2001 Figure 8. Formed Tube in Bag (See 3.3.8) PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 20 Figure 7. Plastic Holding Device (See 3.3.7) PD MO 14 PK4-35G 18 May 2001 Figure 10. Vial in Bag (See 3.3.10) PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 21 Figure 9. Foam and Bag (See 3.3.9) PD MO 15 PK4-35G 18 May 2001 Figure 12. Wafer Package (See 3.3.12) PK4-35, G. PDMO Released: 2001-05-21 (VERIFY REVISION STATUS). Page: 22 Figure 11. Magnet in Box (See 3.3.11) PD MO 16