Product Information Bulletin

advertisement

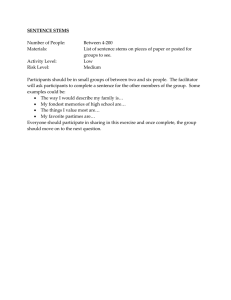

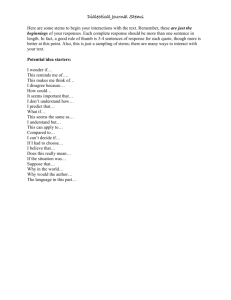

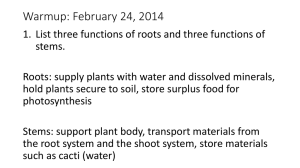

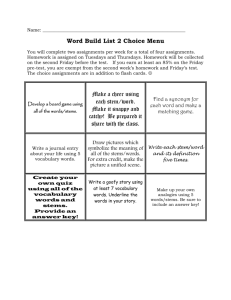

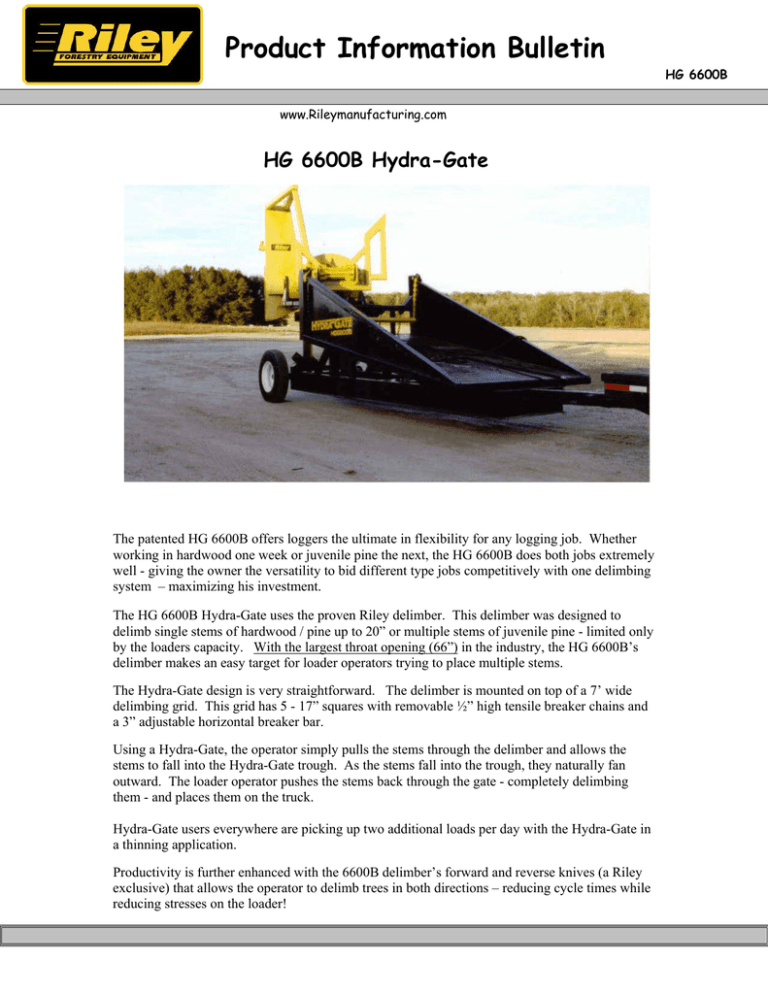

Product Information Bulletin HG 6600B www.Rileymanufacturing.com HG 6600B Hydra-Gate The patented HG 6600B offers loggers the ultimate in flexibility for any logging job. Whether working in hardwood one week or juvenile pine the next, the HG 6600B does both jobs extremely well - giving the owner the versatility to bid different type jobs competitively with one delimbing system – maximizing his investment. The HG 6600B Hydra-Gate uses the proven Riley delimber. This delimber was designed to delimb single stems of hardwood / pine up to 20” or multiple stems of juvenile pine - limited only by the loaders capacity. With the largest throat opening (66”) in the industry, the HG 6600B’s delimber makes an easy target for loader operators trying to place multiple stems. The Hydra-Gate design is very straightforward. The delimber is mounted on top of a 7’ wide delimbing grid. This grid has 5 - 17” squares with removable ½” high tensile breaker chains and a 3” adjustable horizontal breaker bar. Using a Hydra-Gate, the operator simply pulls the stems through the delimber and allows the stems to fall into the Hydra-Gate trough. As the stems fall into the trough, they naturally fan outward. The loader operator pushes the stems back through the gate - completely delimbing them - and places them on the truck. Hydra-Gate users everywhere are picking up two additional loads per day with the Hydra-Gate in a thinning application. Productivity is further enhanced with the 6600B delimber’s forward and reverse knives (a Riley exclusive) that allows the operator to delimb trees in both directions – reducing cycle times while reducing stresses on the loader! Product Information Bulletin www.Rileymanufacturing.com Sales Features include: • High-strength alloy forward and reverse cutting blades • 58" reversible bar • Automatic chain lubricator with 4-gallon capacity • Direct-drive saw motor • Large feed roller for faster pull-through • No exposed hydraulic hoses, all lines completely enclosed • Easy access to all service area, with an internally mounted accumulator Specifications for 6600B Delimber Throat Opening: 66” Max Log Diameter: 32” Min Throat Opening: 3” ----------------------------------------------------------------------------------------------------------Knives: Three 8”forward and two 8” reverse Knives (Riley exclusive) Made from high strength alloy steel; quenched and tempered Knife Holder: Low profile 1.5” high-tensile knife arms with 3.5” knife arm boss and 2” pins. Knife Cylinders: (2) 2 ½” bore, 8” stroke Nose Roller and Knife Arm Mounts: Sleeve-mounted bearings ----------------------------------------------------------------------------------------------------------Saw Bar: 58” Bar Chain: 11 ¾” pitch, 96 links Bar Cylinder: 2” bore, 10” stroke Chain Oiler: Automatic drip with 4-gallon reservoir Saw Drive: Direct Drive Sprocket: 4” – 9 Tooth Rotating Bearing: 20.5” diameter Cradle Mount: 2” King Pins ----------------------------------------------------------------------------------------------------------Delimber Frame Dimensions: 107” long, 82” wide, 85” high, Delimber Weight: 6,750 lbs Feed Roller: 12” diameter Required Flow from Loader: 40 GPM @ 2250 PSI Trough Specifications as follows: Width – 8’ Height - 3’8” Length –14’ Delimbing Grid: (5) 17” x 17” Squares with removable ½“ High-Tensile Breaker Chains. Floating Horizontal Breaker Bar – 3” Square / Adjustable. Total Machine Dimension - Length – 26’1” lbs. Width - 8’ Tires – 22.5 Bias, Uni-mount wheel Axle 22,500 lb. Capacity Connector – Pintle Height – 13’2” Weight – 14,375 The information contained in this bulletin is for the employees of Riley Manufacturing and Riley Dealers only. Every effort has been made to obtain the latest and most accurate information, however, these specs are subject to change without notice. Any duplication of this bulletin is prohibited without this information. For Dealer Sales Personnel September 2002