(HVD-ROM) – Capacity: 100 Gbytes per disk

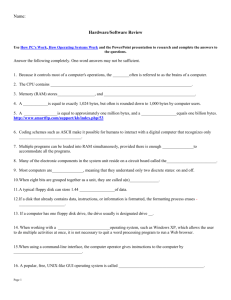

advertisement