Switch Mode Power supply Design and testing using Labview

advertisement

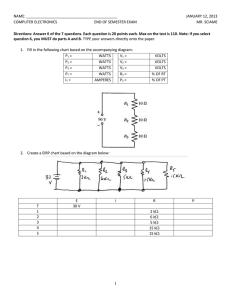

Electronic Manufacturing Design ENB6071 Push-Pull Switch Mode Power Supply, design & testing using LabVIEW By John Leek 1 PBL Teaching Objective • Component testing using Elvis II prototype board – FGEN , Scope, Inductance meter Impedance Analyzer • LabVIEW for Final testing & plotting results 2 • • • • • • Product specification Input voltage 10 to 15 Volts D.C. Output voltage 25 Volts D.C. Output Power 30 Watts SMPS configuration – Push-Pull Switching frequency 100KHz Minimum efficiency > 75% at > 5 Watts load 3 • Switch mode power supply design Component Testing as lab experiments • Capacitors • Transformer design and testing • Fast switching diode • Switching MOSFET • Switching regulator IC (SG2526) 4 5 Component selection - Capacitor Testing 6 7 8 9 10 Diode Reverse recovery time 11 Component selection – Switching Regulator • Measurement of switching regulator SG2526 • Using manufactures test circuit • Build on Elvis II prototype board and Measurement of pulse width change with control voltage 12 13 Final Product testing Automatic testing of power supply • Measurement of input Volts & Current • Measurement of output Volts & Current • Plotting of converter efficiency from min load to maximum load (30 Watts) • Logging data to file for investigation of converter losses 14 Student Built Final Product 15 Student Built Final Product 16 Measure Output Current Measure input Current Power Supply Unit under Test UUT Measure input Volts Unit Measure output Volts Active load Control Load Current 17 Final Product Testing 18 • • • • Using NI cDAQ9174 Analog Input module NI-9215 Input Volts (10 to 15V) Current 0 to 3 Amps) Output Volts & Current (25 V) Current 0 to 1.20 Amps • Analog Output Module cDAQ NI-9263 – Control of Active load 19 Labview ATE testing 20 • ATE system used to test • Student build vero-board power supply • Results saved to file and plotted using Matlab – to investigate losses – constant and variable 21 Many thanks for your time Any Questions ? 22 Demonstration of ATE system 23