1/8/US/4

Floor Diffusers

TROX USA, Inc.

4305 Settingdown Circle

Cumming, Georgia 30028

USA

Telephone770-569-1433

Facsimile770-569-1435

www.troxusa.com

e-mail: sales@troxusa.com

Contents • Description

Contents • Description

Product Features

Dimensional Information

Installation Procedure

2

3

4

6

Performance Data

Product Specification

Order Details

TROX type FB diffusers supply air from the floor in a swirling

fashion. The discharge air is mixed with the surrounding room air

quickly to dissipate any temperature differences and velocities.

This provides a comfortable environment for the occupants and

allows the diffusers to be placed within a few feet of a seated

occupant.

Special features

FB diffusers can be used in an open office space where one

diffuser can be placed in each cubical. This would allow each

occupant to have control over their own environment by twisting

the face of the diffuser allowing more or less conditioned air into

the space.

• All metal construction available

Large enclosed offices or conference rooms can utilize the VAV

feature of the diffusers allowing several diffusers to be tied into

one thermostat.

7

9

11

• Diffusers available in aluminum and plastic construction

• All plastic diffusers are NFPA 90A compliant

• Aluminum diffusers can support up to 5000 lbs

• Quick installation in any raised access floor using spring clips

• Standard dirt trap can hold up to 20oz of liquid

• VAV diffusers can be installed in the same location as other FB diffusers

Design changes reserved. All rights reserved © TROX USA (02/10/15)

2

Product Features

DESIGN

APPLICATION

Type FB floor diffusers with the occupant adjustable (OA) feature

incorporate a unique airflow control damper whose position can

be manually adjusted by rotating the face of the diffuser core

assembly, affording the occupants of the space individual airflow

control. The retention basin is designed to catch and retain up to

20 fluid ounces of debris or liquid that might fall through the face

of the diffuser. The diffuser core assembly is removable to allow

periodic removal and cleaning of the debris basin.

Type FB floor diffusers can be used anywhere air is required and

pressurized floor plenum is available.

Diffusers with the concealed (SM) airflow adjustment allow

the installer to set the airflow by adusting the height of the dirt

basket. This allows the designer to specify the correct airflow

required for the space.

Alternative to a manual airflow adjustment would be using a VAV

actuator. These units can be ordered with either a 3 wire (floating point) actuator or a proportional control. These actuators are

24V and have plug and play connections.

If the diffusers are to be installed in a concrete floor, the concealed airflow adjustment is available for a floor up to 8” thick.

Once the slab thickness exceeds that depth typically the diffuser is selected without the dirt basket. This is due to the overall

length of the diffuser being 3” longer than the slab thickness.

Commercial office spaces have many areas where floor diffusers can be applied. The occupant adjustable visions are ideal for

large open office spaces. The occupant adjustable version gives

the workers control over their own environment. By twisting the

face open or closed they are able to increase or decrease the

airflow to the space. Larger private offices or small conference

rooms can be best controlled by using the VAV version. A thermostat controls when the diffusers open or close.

Theaters or places of worship are good applications for the

concealed adjustment diffusers. The diffusers can be sized to

be very quiet and be placed under the seats of the occupants.

Typically you will see one diffuser placed under every other seat

in a large audiitorium area.

Metal floor diffusers in particular are a good solution for casinos

due to their sturdy construction. Additionally supplying cool air at

the floor will allow smoke and odors to rise out of the occupied

zone

3

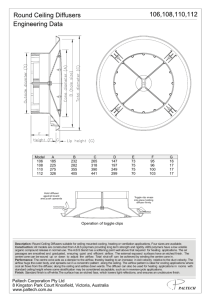

Dimensional Information

FBK-VF-K-SM

FBK-VF-K-OA

Damper Position

Indicators

Overall = 9 ⅞″

Overall = 9 ⅞″

Hole Size = 8¾″

Hole Size = 8 ¾″

Carpet

Attachment Spring

6″

Damper

Attachment Spring

Carpet

6″

Dirt Basket

Dirt Basket

NOTE: Airflow Adjustment Requires Removal of the Diffuser Face

FBK-VF-K-SM (installed in slab)

FBK-VAV-VF-K

Overall = 9 ⅞”

Hole Size = 8 ¾”

Slab

Thickness

(x”)

Carpet

Spring Clips

Overall = 9 ⅞”

Hole Size = 8 ¾”

Carpet

Attachment

Spring

X + 3”

Dirt Basket

Actuator

RJ12 (Female) Connectors

NOTE: Overall depth MUST be specified (x+3″)

NOTE: Airflow adjustment requires removal of the diffuser face

4

Carpet

8 1/4”

Dimensional Information

FBK/FBA/FBM 200 with Carpet Flange

FBK/FBA/FBM 200 without Carpet Flange

¾″

9 93/4”

7 ⅞″

Mounting Hole

83∕4”

Upper

8″

Upperhole

hole diameter

diameter ==8″

Carpet

Carpet

6 6″

3/2”

Bore

hole

= =⅞″

Bore

hole

⅞″

Lower

hole

7⅝″

Lower

holediameter

diameter =

= 7⅝″

Mounting Hole Size

8 ¾″

8¼″

FBK-VAV/200

5

Installation Procedure

Installation with Carpet Flange

(in a raised floor tile or concrete slab)

Mounting Hole Size

8 ¾″

STEP 1: Locate and install the access floor panel and carpet

tiles. Assure that the opening in the floor tile is within the

dimensional tolerance shown above.

STEP 2: Align the springs such that the long ends (with

metal caps) are inserted within the hole in the raised floor

tile.

STEP 3: Push firmly (applying equal pressure to each side

of the carpet flange) until the carpet flange snaps in to the

floor tile. Install the core assembly (and VAV chassis, where

applicable) into the carpet flange making sure the damper

movement arms are placed into the notched openings of the

damper sleeve and the core rotation stop is within the milled

slot on the bottom of the core.

6

Performance Data

Horizontal Discharge

Vertical Discharge

Performance Data for VF Element (Fixed Vertical Discharge)

Airflow Rate

(CFM)

Pressure Loss

(in.w.g.)

Outlet NC*

T50

Local Temperature Differential (°F) at T50 and R50

R50

(in.)

(in.)

8

9

10

TROOM - TSUPPLY (°F)

11

12

13

14

20

0.003

<10

10

7

-1.77

-1.99

-2.21

-2.44

-2.66

-2.88

-3.10

30

0.007

<10

14

9

-1.18

-1.33

-1.48

-1.62

-1.77

-1.92

-2.07

40

0.013

<10

19

10

-0.89

-1.00

-1.11

-1.22

-1.33

-1.44

-1.55

50

0.020

<10

24

11

-0.71

-0.80

-0.89

-0.97

-1.06

-1.15

-1.24

60

0.029

<10

29

12

-0.59

-0.66

-0.74

-0.81

-0.89

-0.96

-1.03

70

0.040

<10

33

13

-0.51

-0.57

-0.63

-0.70

-0.76

-0.82

-0.89

80

0.052

12

38

14

-0.44

-0.50

-0.55

-0.61

-0.66

-0.72

-0.78

90

0.066

15

43

15

-0.39

-0.44

-0.49

-0.54

-0.59

-0.64

-0.69

100

0.082

18

48

16

-0.35

-0.40

-0.44

-0.49

-0.53

-0.58

-0.62

110

0.099

21

52

17

-0.32

-0.36

-0.40

-0.44

-0.48

-0.52

-0.56

120

0.118

24

55

19

-0.30

-0.33

-0.37

-0.41

-0.44

-0.48

-0.52

130

0.138

27

58

21

-0.27

-0.31

-0.34

-0.37

-0.41

-0.44

-0.48

140

0.160

30

60

23

-0.25

-0.28

-0.32

-0.35

-0.38

-0.41

-0.44

150

0.184

33

62

24

-0.24

-0.27

-0.30

-0.32

-0.35

-0.38

-0.41

PERFORMANCE NOTES:

1.Pressure loss and noise data is for basic assembly with carpet flange, dirt basket, and airflow control damper in wide open position.

2.NC levels shown assume 10 dB room absorption.

3.Local temperature differentials shown are those predicted at a height coincident with T50 and a horizontal distance R50 from the diffuser centerline

(see diagram above). For example, temperature differentials exceeding -0.66°F(shown above for an airflow rate of 80 CFM and Troom - Tsupply of

12°F) and velocities greater than 50 FPM should be confined to the area within 38 inches of the floor and 14 inches (measured horizontally) from

the centerline of the diffuser.

4.Value shown in shaded cells represent airflow rates which can generally be achieved only when the diffusers are ducted and/or directly connected

to fan powered terminal units and are not recommended for pressurized floor plenum applications.

7

Performance Data

Adjustable EU Element

Performance Data for EURO (EU) Element, Set for Vertical Discharge Position

Airflow Rate

Pressure Loss

20

0.004

30

40

(CFM)

(in.w.g.)

Outlet NC*

T50

Local Temperature Differential (°F) at T50 and R50

R50

TROOM - TSUPPLY (°F)

(in.)

(in.)

8

9

10

11

12

13

14

<10

11

8

-1.77

-1.99

-2.21

-2.44

-2.66

-2.88

-3.10

0.008

<10

16

10

-1.18

-1.33

-1.48

-1.62

-1.77

-1.92

-2.07

0.014

<10

21

11

-0.89

-1.00

-1.11

-1.22

-1.33

-1.44

-1.55

50

0.022

<10

26

12

-0.71

-0.80

-0.89

-0.97

-1.06

-1.15

-1.24

60

0.032

<10

32

14

-0.59

-0.66

-0.74

-0.81

-0.89

-0.96

-1.03

70

0.044

<10

37

15

-0.51

-0.57

-0.63

-0.70

-0.76

-0.82

-0.89

80

0.057

<10

42

16

-0.44

-0.50

-0.55

-0.61

-0.66

-0.72

-0.78

90

0.072

<10

47

17

-0.39

-0.44

-0.49

-0.54

-0.59

-0.64

-0.69

100

0.089

<10

53

18

-0.35

-0.40

-0.44

-0.49

-0.53

-0.58

-0.62

110

0.108

<10

58

19

-0.32

-0.36

-0.40

-0.44

-0.48

-0.52

-0.56

120

0.128

10

63

20

-0.30

-0.33

-0.37

-0.41

-0.44

-0.48

-0.52

130

0.151

12

66

21

-0.27

-0.31

-0.34

-0.37

-0.41

-0.44

-0.48

140

0.175

14

69

22

-0.25

-0.28

-0.32

-0.35

-0.38

-0.41

-0.44

150

0.200

16

72

23

-0.24

-0.27

-0.30

-0.32

-0.35

-0.38

-0.41

PERFORMANCE NOTES:

1.Pressure loss and noise data is for basic assembly with carpet flange, dirt basket, and airflow control damper in wide open position.

2.NC levels shown assume 10 dB room absorption.

3.Local temperature differentials shown are those predicted at a height coincident with T50 and a horizontal distance R50 from the diffuser centerline

(see diagram on page 7). For example, temperature differentials exceeding -0.89°F(shown above for an airflow rate of 60 CFM and Troom - Tsupply of 12°F) and velocities greater than 50 FPM should be confined to the area within 32 inches from the floor and 14 inches (measured horizontally)

from the centerline of the diffuser.

4.Value shown in shaded cells represent airflow rates which can generally be achieved only when the diffusers are ducted and/or

directly connected to fan powered terminal units and are not recommended for pressurized floor plenum applications.

Performance Data for EURO (EU) Element, Set in Horizontal Discharge Position

Airflow Rate

(CFM)

Pressure Loss

(in.w.g.)

Outlet NC*

Local Temperature Differential (°F) at R50 (4” above floor)

R50

(in.)

9

10

TROOM - TSUPPLY (°F)

11

12

13

14

20

0.011

<10

<12

N/A

N/A

N/A

N/A

N/A

N/A

N/A

30

0.025

<10

<12

N/A

N/A

N/A

N/A

N/A

N/A

N/A

40

0.044

<10

<12

N/A

N/A

N/A

N/A

N/A

N/A

N/A

50

0.069

<10

14

-2.66

-2.99

-2.99

-2.99

-2.99

-2.99

-2.99

60

0.100

17

20

-2.22

-2.49

-2.49

-2.49

-2.49

-2.49

-2.49

70

0.136

22

27

-1.90

-2.14

-2.14

-2.14

-2.14

-2.14

-2.14

80

0.177

28

35

-1.66

-1.87

-1.87

-1.87

-1.87

-1.87

-1.87

90

0.224

33

44

-1.48

-1.66

-1.66

-1.66

-1.66

-1.66

-1.66

PERFORMANCE NOTES:

8

1.Pressure loss and noise data is for basic assembly with carpet flange, dirt basket, and airflow control damper in wide open position.

2.NC levels shown assume 10 dB room absorption.

3.Local temperature differentials shown are those predicted at a height coincident with 4” and a horizontal distance R50 from the diffuser centerline

(see diagram on page 7). For example, temperature differentials exceeding -2.49°F (shown above for an airflow rate of 60 CFM and Troom - Tsupply

of 12°F) and velocities greater than 50 FPM should be confined to the area within 20 inches (measured horizontally) from the centerline of the

diffuser.

4.Value shown in shaded cells represent airflow rates which can generally be achieved only when the diffusers are ducted and/or directly connected

to fan powered terminal units and are not recommended for pressurized floor plenum applications.

8

Product Specification

PART 1 – GENERAL

1.1

RELATED DOCUMENTS

Drawings and general provision of the Contract, including

General and Supplementary Conditions and other

Division 1 Specification Sections, apply to this Section.

PART 2 – PRODUCTS

2.1.

UNDERFLOOR AIR DISTRIBUTION DIFFUSERS

A. Acceptable Manufacturers:

1. TROX Floor Diffuser Series FB (Basis of Design)

2. Approved Equal

B. Furnish and install TROX Series FB floor diffusers

of capacities indicated on plans. Diffusers shall

incorporate a removable (single piece) core section which

consists of a series of visible concentric rings supported

by radially aligned air deflection vanes which distribute

the supplied air in a 360 degree cyclonic “swirl” discharge

pattern.

C. Materials:

Type FBA:

Diffuser Core and Trim Ring: Aluminum. Dirt

Basket/ Damper Assembly: Plastic (NFPA90A

Compliant)

Type FBK:

Diffuser Core and Trim Ring: Plastic (NFPA90A

Compliant)

Dirt Basket/ Damper Assebmly: Plastic

(NFPA90A Compliant)

Type FBM:

Diffuser Core and Trim Ring: Aluminum

Dirt Basket/ Damper Assembly: Steel

D. Finish:

Type FBA diffusers core and trim ring surfaces shall be

brushed aluminum. All other visible internal parts shall be

flat black.

Type FBK diffusers core and trim ring surfaces shall be

(grey or black). All other visible internal parts shall be flat

black.

Type FBM diffusers core and trim ringsurfaces shall be

brushed aluminum. All other visible internal parts shall be

flat black.

E. Diffuser Features and Performance:

1. Occupant Airflow Adjustment:

The assembly shall provide for occupant adjustment

of the outlet airflow without necessitating removal of the diffuser face or other components. Adjustment of the outlet airflow shall be accomplished by rotation of the diffuser core.Full adjustment shall require no less than a 30 degree rotation of the core. This rotation

must be accomplished by hand and not require the

use of tools or any other devices. An indicator scale shall be inscribed on the outlet face and provide visual evidence of the damper at all times.

2.

Balancing Provisions:

The outlet shall incorporate provision for the field

adjustment of a maximum airflow setting. Adjustment

of this setting shall not affect the individual occupant’s

ability to adjust the outlet airflow, except to limit the

maximum airflow available to that occupant.

3.

Liquid and Solid Retention Capacity:

A dirt and liquid catch basin shall be furnished to

facilitate removal of any dust, spills, or other objects that may have penetrated the outlet face. This basin must be capable of capturing and retaining at least 20 fluid ounces of liquid spillage through the diffuser face.

4. Air Diffuser Performance:

Outlet airflow rates shall be limited to that which results in a terminal velocity no greater than 50 fpm at any point four (4) feet above the diffuser face. This is based on a temperature differential of 12˚F between room and supply air. Maximum airflow rate so determined shall be clearly identified and substantiated by manufacturer’s data upon submission. Airflow rates resulting in terminal velocities exceeding that specifically stated herein shall not be allowed.

9

Product Specification

PART 3 – EXECUTION

3.1

INSTALLATION:

Installation requires that a mounting hole (8.75 inches

diameter) in the access floor panel be provided by the

raised floor contractor. A separate trim ring shall be

supplied to support the diffuser core while preventing

fraying of the carpet edges along the hole in which the

diffuser is installed. This trim ring shall allow a minimum of

½” overlap of the carpet surface when installed in the

recommended size floor opening. Floor diffuser carpet

flange shall be rigidly mounted to the access flooring

system by snap fastening clips that contact the lower

surface of the access floor tile at a minimum of four points.

Diffusers mounting shall be performed after completion

of the installation of the raised floor platform and shall not

necessitate the removal of any carpet or floor tiles.

3.2

STRUCTURAL CAPACITY:

The diffusers shall be capable of supporting a load of

1,350 pounds (FBK) or 5,000 pounds (FBA or FBM)

applied evenly across a minimum 1 inch diameter area

located at the center of the diffuser face.

3.3

COMPLIANCE WITH SPECIFICATION

The diffuser specifications and requirements contained

herein supercede and transcend any other mention or

description of floor supply diffusers offered in other

sections of the building plans and/or specification.

10

Order details

Order code

FBA

-

4

-

VF

-

K

/

200

-

SM

/

8

/ 0

Type

FBA =Core and trim ring: aluminum;

Damper: plastic

FBK =Core and trim ring: plastic;

Damper: plastic

FBM =Core and trim ring: aluminum; Damper: steel

Finish

1

2

3

4

=

=

=

=

Gray (FBK)

Black (FBK)

Black with brushed aluminum rings (FBA/FBM)

Brushed aluminum (FBA/FBM)

Overall Height of Diffuser (Type SM only)

Enter the overall height of diffuser when

installed in slab greater than 3″ thick

(slab thickness + 3″). See page 4.

Operator

OA

SM

VAV-PC

VAV-FP

0

=

=

=

=

=

Occupant adjustable

Concealed adjustment

Proportional control actuator

3 wire, floating point actuator

No dirt basket

Element

VF

EU

= Vertical (Fixed)

= Adjustable (Horizontal/Vertical)

Trim ring

K

O

= With carpet flange

= No carpet flange (stepped bore)

Order example

FBA-4-VF-K/200-SM/8/0

11